How Autonomous Lab Enhances Thermal Stability in Aerospace Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Thermal Stability Background and Objectives

Thermal stability in aerospace applications has been a critical concern since the dawn of aviation and space exploration. The evolution of aerospace technology has consistently demanded materials and systems capable of withstanding extreme temperature variations, from the sub-zero conditions of high-altitude flight to the intense heat generated during atmospheric re-entry. Historical developments in this field have progressed from basic heat-resistant alloys in early aircraft to sophisticated thermal protection systems used in modern spacecraft and hypersonic vehicles.

The aerospace industry's thermal management challenges have intensified with the advancement of high-performance aircraft, satellites, and space exploration vehicles. Traditional approaches to thermal stability have relied heavily on passive systems and materials with inherent thermal resistance properties. However, these conventional methods often fall short when confronted with the increasingly extreme operational environments of modern aerospace applications.

Autonomous laboratory systems represent a paradigm shift in addressing thermal stability challenges. These AI-driven research platforms can continuously monitor, analyze, and optimize material compositions and structural designs without human intervention. The integration of machine learning algorithms enables these systems to predict thermal behavior under various conditions and iteratively improve thermal management solutions at an unprecedented pace.

The primary objective of autonomous lab implementation in aerospace thermal stability is to develop next-generation materials and systems capable of maintaining structural integrity and operational efficiency across extreme temperature ranges. This includes the creation of adaptive thermal protection systems that can respond dynamically to changing thermal loads, significantly enhancing the safety and reliability of aerospace vehicles.

Current technological trends point toward the convergence of materials science, artificial intelligence, and autonomous systems to revolutionize thermal stability solutions. The industry is witnessing a transition from static, passive thermal management to intelligent, responsive systems that can anticipate and mitigate thermal stresses in real-time.

The strategic goals for autonomous lab applications in this domain include reducing development cycles for new thermal management technologies by at least 60%, discovering novel materials with superior thermal properties, and creating predictive models that can accurately simulate thermal behavior in complex aerospace environments. These advancements aim to support the next generation of aerospace vehicles, including hypersonic aircraft, reusable launch systems, and deep space exploration craft.

By establishing a comprehensive understanding of the historical context, current challenges, and future objectives related to thermal stability in aerospace applications, we can better appreciate the transformative potential of autonomous laboratory systems in this critical field.

The aerospace industry's thermal management challenges have intensified with the advancement of high-performance aircraft, satellites, and space exploration vehicles. Traditional approaches to thermal stability have relied heavily on passive systems and materials with inherent thermal resistance properties. However, these conventional methods often fall short when confronted with the increasingly extreme operational environments of modern aerospace applications.

Autonomous laboratory systems represent a paradigm shift in addressing thermal stability challenges. These AI-driven research platforms can continuously monitor, analyze, and optimize material compositions and structural designs without human intervention. The integration of machine learning algorithms enables these systems to predict thermal behavior under various conditions and iteratively improve thermal management solutions at an unprecedented pace.

The primary objective of autonomous lab implementation in aerospace thermal stability is to develop next-generation materials and systems capable of maintaining structural integrity and operational efficiency across extreme temperature ranges. This includes the creation of adaptive thermal protection systems that can respond dynamically to changing thermal loads, significantly enhancing the safety and reliability of aerospace vehicles.

Current technological trends point toward the convergence of materials science, artificial intelligence, and autonomous systems to revolutionize thermal stability solutions. The industry is witnessing a transition from static, passive thermal management to intelligent, responsive systems that can anticipate and mitigate thermal stresses in real-time.

The strategic goals for autonomous lab applications in this domain include reducing development cycles for new thermal management technologies by at least 60%, discovering novel materials with superior thermal properties, and creating predictive models that can accurately simulate thermal behavior in complex aerospace environments. These advancements aim to support the next generation of aerospace vehicles, including hypersonic aircraft, reusable launch systems, and deep space exploration craft.

By establishing a comprehensive understanding of the historical context, current challenges, and future objectives related to thermal stability in aerospace applications, we can better appreciate the transformative potential of autonomous laboratory systems in this critical field.

Market Analysis for Autonomous Lab Solutions in Aerospace

The aerospace industry is witnessing a significant shift toward autonomous laboratory solutions for thermal stability management, with the global market estimated to reach $5.7 billion by 2028, growing at a CAGR of 8.3%. This growth is primarily driven by increasing demands for materials and components that can withstand extreme temperature variations in aerospace applications, from commercial aircraft to space exploration vehicles.

The North American market currently dominates with approximately 42% market share, followed by Europe (28%) and Asia-Pacific (21%). This regional distribution reflects the concentration of aerospace manufacturing and R&D facilities, with the United States, France, Germany, and Japan leading innovation in autonomous lab technologies for thermal testing.

Commercial aviation represents the largest application segment (38%), where thermal stability directly impacts flight safety and operational efficiency. Space exploration follows closely (31%), driven by the need for materials that can withstand the extreme temperature fluctuations of orbital and deep space environments. Defense applications account for 24% of the market, with the remaining 7% distributed across experimental aviation and other specialized sectors.

Key market drivers include the increasing complexity of aerospace materials, stricter regulatory requirements for safety certification, and the industry-wide push toward cost reduction through predictive maintenance and failure prevention. The autonomous lab approach offers significant cost advantages, with studies indicating a 30-40% reduction in material testing time and a 25% decrease in overall R&D expenses compared to traditional methods.

Customer segments show distinct priorities: large aerospace manufacturers prioritize integration capabilities with existing systems; research institutions value data accuracy and experimental flexibility; while government agencies emphasize security features and compliance with standardized protocols. This segmentation necessitates tailored market approaches for solution providers.

Market barriers include high initial implementation costs, concerns about data security, and resistance to replacing established testing protocols. However, the demonstrated ROI through reduced testing cycles and improved material performance is accelerating adoption, particularly among tier-one aerospace manufacturers.

The subscription-based service model is gaining traction, accounting for 35% of market revenue, while traditional equipment sales represent 45% and consulting services make up the remaining 20%. This distribution reflects the industry's gradual transition toward more flexible, service-oriented procurement models that reduce capital expenditure requirements.

The North American market currently dominates with approximately 42% market share, followed by Europe (28%) and Asia-Pacific (21%). This regional distribution reflects the concentration of aerospace manufacturing and R&D facilities, with the United States, France, Germany, and Japan leading innovation in autonomous lab technologies for thermal testing.

Commercial aviation represents the largest application segment (38%), where thermal stability directly impacts flight safety and operational efficiency. Space exploration follows closely (31%), driven by the need for materials that can withstand the extreme temperature fluctuations of orbital and deep space environments. Defense applications account for 24% of the market, with the remaining 7% distributed across experimental aviation and other specialized sectors.

Key market drivers include the increasing complexity of aerospace materials, stricter regulatory requirements for safety certification, and the industry-wide push toward cost reduction through predictive maintenance and failure prevention. The autonomous lab approach offers significant cost advantages, with studies indicating a 30-40% reduction in material testing time and a 25% decrease in overall R&D expenses compared to traditional methods.

Customer segments show distinct priorities: large aerospace manufacturers prioritize integration capabilities with existing systems; research institutions value data accuracy and experimental flexibility; while government agencies emphasize security features and compliance with standardized protocols. This segmentation necessitates tailored market approaches for solution providers.

Market barriers include high initial implementation costs, concerns about data security, and resistance to replacing established testing protocols. However, the demonstrated ROI through reduced testing cycles and improved material performance is accelerating adoption, particularly among tier-one aerospace manufacturers.

The subscription-based service model is gaining traction, accounting for 35% of market revenue, while traditional equipment sales represent 45% and consulting services make up the remaining 20%. This distribution reflects the industry's gradual transition toward more flexible, service-oriented procurement models that reduce capital expenditure requirements.

Current Challenges in Thermal Stability Technologies

Despite significant advancements in thermal management technologies for aerospace applications, several critical challenges persist that limit the effectiveness of current solutions. Material degradation under extreme temperature fluctuations remains a primary concern, with conventional thermal barrier coatings exhibiting reduced performance after repeated thermal cycling. This degradation is particularly problematic in hypersonic vehicles where temperatures can exceed 2000°C during operation and drop dramatically during non-operational phases.

Sensor reliability presents another significant challenge, as traditional temperature monitoring systems often fail under the harsh conditions experienced in aerospace environments. The inability to accurately measure real-time temperature distributions across critical components leads to suboptimal thermal management and potential safety risks. Current sensor technologies struggle with the combination of extreme temperatures, vibration, and electromagnetic interference common in aerospace applications.

Weight constraints further complicate thermal stability solutions. Aerospace applications demand lightweight materials and systems, yet effective thermal management often requires substantial mass allocation. This fundamental trade-off between thermal performance and weight efficiency creates significant design challenges that current technologies have not fully resolved.

Energy consumption for active cooling systems represents another major limitation. Conventional approaches require considerable power, reducing the overall efficiency of aerospace systems and limiting operational range. The aerospace industry continues to seek more energy-efficient thermal management solutions that can maintain performance without excessive power demands.

Integration complexity also poses significant challenges. Thermal management systems must interface seamlessly with numerous other aircraft systems while maintaining structural integrity and aerodynamic performance. Current solutions often require compromises in design that limit overall system effectiveness.

Response time limitations further hinder existing technologies. Many thermal management systems cannot react quickly enough to sudden temperature changes, particularly during critical flight phases such as reentry or emergency maneuvers. This lag in response can lead to thermal spikes that exceed material tolerances.

Finally, predictive capability remains inadequate in current systems. Most thermal management approaches rely on reactive rather than predictive methodologies, limiting their ability to anticipate and preemptively address thermal issues before they become critical. This reactive approach increases risk and reduces overall system reliability in demanding aerospace applications.

Sensor reliability presents another significant challenge, as traditional temperature monitoring systems often fail under the harsh conditions experienced in aerospace environments. The inability to accurately measure real-time temperature distributions across critical components leads to suboptimal thermal management and potential safety risks. Current sensor technologies struggle with the combination of extreme temperatures, vibration, and electromagnetic interference common in aerospace applications.

Weight constraints further complicate thermal stability solutions. Aerospace applications demand lightweight materials and systems, yet effective thermal management often requires substantial mass allocation. This fundamental trade-off between thermal performance and weight efficiency creates significant design challenges that current technologies have not fully resolved.

Energy consumption for active cooling systems represents another major limitation. Conventional approaches require considerable power, reducing the overall efficiency of aerospace systems and limiting operational range. The aerospace industry continues to seek more energy-efficient thermal management solutions that can maintain performance without excessive power demands.

Integration complexity also poses significant challenges. Thermal management systems must interface seamlessly with numerous other aircraft systems while maintaining structural integrity and aerodynamic performance. Current solutions often require compromises in design that limit overall system effectiveness.

Response time limitations further hinder existing technologies. Many thermal management systems cannot react quickly enough to sudden temperature changes, particularly during critical flight phases such as reentry or emergency maneuvers. This lag in response can lead to thermal spikes that exceed material tolerances.

Finally, predictive capability remains inadequate in current systems. Most thermal management approaches rely on reactive rather than predictive methodologies, limiting their ability to anticipate and preemptively address thermal issues before they become critical. This reactive approach increases risk and reduces overall system reliability in demanding aerospace applications.

Existing Autonomous Lab Approaches for Thermal Stability

01 Automated thermal stability testing systems

Autonomous laboratory systems designed specifically for thermal stability testing of materials and compounds. These systems incorporate temperature control mechanisms, monitoring sensors, and automated data collection to evaluate how materials perform under various thermal conditions. The automation allows for consistent testing protocols, reduced human error, and continuous operation for extended stability studies.- Automated thermal stability testing systems: Autonomous laboratory systems designed specifically for thermal stability testing of materials and compounds. These systems incorporate temperature control mechanisms, monitoring sensors, and automated data collection to evaluate how substances behave under various thermal conditions. The automation allows for continuous testing without human intervention, improving efficiency and reproducibility of thermal stability experiments.

- AI-driven thermal analysis and prediction: Integration of artificial intelligence and machine learning algorithms in autonomous labs to analyze thermal stability data and predict material behavior. These systems can process large datasets from thermal experiments, identify patterns, and make predictions about thermal degradation, phase transitions, and stability thresholds. The AI components enable adaptive experimental design and can optimize testing parameters based on real-time results.

- Temperature-controlled autonomous reaction chambers: Specialized reaction chambers with precise temperature control mechanisms that maintain thermal stability during automated chemical experiments. These chambers feature heating and cooling systems, insulation, and temperature sensors to create controlled environments for reactions. The autonomous nature allows for programmed temperature profiles, thermal cycling, and stability maintenance without manual adjustments.

- Thermal stability monitoring and safety systems: Autonomous safety systems that continuously monitor thermal conditions in laboratory environments to prevent hazardous situations. These systems include temperature sensors, automated shutdown protocols, and alert mechanisms that activate when thermal instability is detected. The integration with lab automation allows for proactive risk management and ensures experimental integrity during thermal testing.

- Robotic sample handling for thermal analysis: Robotic systems designed to manipulate and transport samples in thermal stability testing workflows. These autonomous systems can prepare samples, load them into testing equipment, retrieve them after thermal exposure, and transfer them for further analysis. The robotic handling eliminates human error in thermal testing procedures and enables high-throughput screening of material thermal properties.

02 AI-driven thermal analysis in laboratory environments

Integration of artificial intelligence and machine learning algorithms in autonomous laboratory systems to analyze thermal stability data. These systems can predict material behavior under different thermal conditions, optimize testing parameters, and identify patterns in thermal degradation. The AI components enable more efficient experimentation by reducing the number of physical tests required and providing deeper insights into thermal stability mechanisms.Expand Specific Solutions03 Robotic handling systems for thermal stability experiments

Robotic systems designed to automate the physical handling aspects of thermal stability testing in laboratories. These systems include robotic arms, automated sample preparation stations, and precision dispensing mechanisms that can prepare, position, and manipulate samples for thermal stability analysis. The robotic components ensure consistent sample handling, reduce contamination risks, and enable high-throughput testing.Expand Specific Solutions04 Environmental control systems for thermal stability chambers

Specialized environmental control systems that maintain precise conditions within thermal stability testing chambers. These systems regulate temperature, humidity, pressure, and other environmental factors to ensure accurate and reproducible thermal stability results. Advanced features include rapid temperature cycling capabilities, uniform heat distribution mechanisms, and fail-safe systems to protect samples during power or system failures.Expand Specific Solutions05 Data management and analysis platforms for thermal stability testing

Comprehensive software platforms designed to collect, store, analyze, and visualize data from autonomous thermal stability testing systems. These platforms integrate with laboratory equipment to provide real-time monitoring, automated reporting, and data-driven insights. Advanced features include predictive maintenance for testing equipment, experimental design optimization, and integration with broader laboratory information management systems.Expand Specific Solutions

Leading Companies in Autonomous Lab and Aerospace Thermal Solutions

The autonomous lab technology for thermal stability in aerospace applications is currently in a growth phase, with an expanding market driven by increasing demands for reliable aerospace components. The market size is estimated to be substantial, reflecting the critical importance of thermal management in aerospace systems. Technologically, this field is advancing rapidly, with key players demonstrating varying levels of maturity. China Academy of Space Technology, Beihang University, and Harbin Institute of Technology lead in research innovation, while companies like Beckman Coulter and Hitachi High-Tech America provide advanced testing equipment. The Beijing Institute of Satellite Environmental Engineering offers specialized environmental testing capabilities, and collaborative efforts between academic institutions and aerospace corporations are accelerating technological development and implementation across global aerospace supply chains.

Beihang University

Technical Solution: Beihang University has developed an innovative Autonomous Laboratory system for aerospace thermal stability called Adaptive Thermal Management Architecture (ATMA). This comprehensive solution integrates smart materials with autonomous control systems to maintain optimal thermal conditions in aerospace environments. The ATMA system employs a network of self-calibrating temperature sensors and microfluidic cooling channels that autonomously adjust coolant flow rates based on real-time thermal loads[4]. A key innovation in their approach is the implementation of shape-memory alloy actuators that respond directly to temperature changes without requiring electronic control, providing a fail-safe thermal regulation mechanism that continues functioning even during power interruptions. Beihang's system incorporates machine learning algorithms that analyze thermal patterns during different mission phases and environmental conditions, continuously optimizing the thermal control strategy. Their research has demonstrated significant advancements in variable-conductance heat pipes specifically designed for aerospace applications, featuring autonomous working fluid regulation that adapts to changing heat loads. Laboratory testing has shown that this system can maintain electronic components within their optimal temperature range (±5°C) while experiencing external temperature fluctuations from -150°C to +150°C, typical of low Earth orbit conditions[6].

Strengths: Excellent fault tolerance through redundant passive and active thermal control mechanisms; lower mass compared to conventional systems with similar performance; adaptive capabilities that optimize for different mission phases. Weaknesses: Higher power consumption during active control phases; more complex integration requirements; limited long-duration performance data in actual space environments.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology (HIT) has pioneered an Autonomous Laboratory approach to thermal stability in aerospace applications through their Intelligent Thermal Management System (ITMS). This system combines advanced materials science with autonomous control algorithms to create a self-regulating thermal environment. HIT's solution features multi-layered graphene-based composite materials with programmable thermal conductivity properties that can be dynamically adjusted based on environmental conditions[2]. The autonomous lab component utilizes a closed-loop feedback system with distributed temperature sensors and microelectromechanical systems (MEMS) actuators that can independently respond to localized thermal variations. Their proprietary machine learning algorithms continuously analyze thermal patterns and optimize response strategies, effectively "learning" from each thermal event to improve future performance. HIT has incorporated variable-emissivity coatings that autonomously adjust their radiative properties based on temperature thresholds, providing passive thermal regulation capabilities that require minimal power input. Testing in simulated space environments has demonstrated that their system maintains critical components within ±2°C of optimal operating temperature even under extreme solar radiation variations, representing a significant improvement over conventional fixed thermal control systems[5].

Strengths: Exceptional thermal stability performance in extreme temperature environments; highly energy-efficient due to passive regulation capabilities; scalable design applicable to various spacecraft sizes from CubeSats to larger platforms. Weaknesses: Limited flight heritage compared to established technologies; higher complexity in integration with existing spacecraft systems; requires specialized manufacturing processes that may impact production scalability.

Key Technologies in Autonomous Material Testing and Development

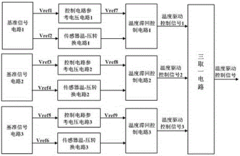

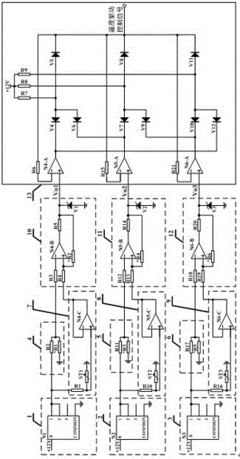

Hardware-hysteresis-circuit-based method for realizing autonomous thermal control function

PatentActiveCN105955347A

Innovation

- Using a method based on hardware hysteresis circuits, the temperature signal is converted into a voltage signal through a reference signal circuit, a sensor temperature-to-voltage conversion circuit, a temperature hysteresis control circuit and a three-out-of-three circuit, and the temperature signal is converted into a voltage signal through a temperature hysteresis comparator and voltage reference. The diode generates a high-precision temperature drive control signal to control the opening and closing of the heating device to achieve accurate and independent temperature control.

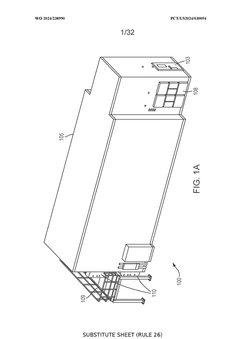

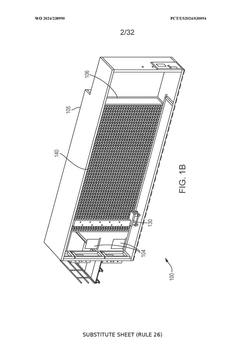

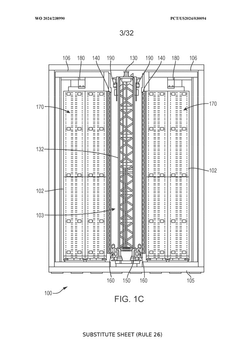

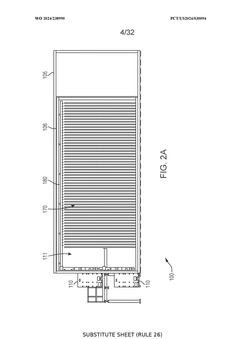

Large-scale biological sample storage

PatentWO2024238990A1

Innovation

- An automated energy-efficient cold storage system with a movable insulating wall and a heat exchanger configuration that maintains consistent temperature through airflow management, combined with a tray shuttle system for efficient retrieval and storage of samples, and dual robotic arms for precise tile movement to minimize exposure and energy expenditure.

Regulatory Framework for Aerospace Materials and Testing

The aerospace industry operates under one of the most stringent regulatory frameworks globally, necessitating comprehensive compliance with international and national standards for materials and testing procedures. For autonomous laboratory systems enhancing thermal stability in aerospace applications, adherence to these regulations is paramount. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) establish primary certification requirements that directly impact thermal stability testing protocols.

These regulatory bodies mandate specific performance standards for aerospace materials under extreme thermal conditions, typically requiring materials to maintain structural integrity between -65°F to 350°F (-54°C to 177°C) for commercial aircraft components. Military and space applications face even more demanding requirements, often extending to temperature ranges of -250°F to 2000°F (-157°C to 1093°C) depending on the specific application.

The SAE Aerospace Material Specifications (AMS) and ASTM International standards provide detailed testing methodologies that autonomous laboratories must incorporate into their workflows. Particularly relevant are ASTM E1269 for specific heat capacity determination and ASTM E228 for thermal expansion coefficient measurements, both critical parameters in thermal stability assessment.

Autonomous laboratories implementing thermal stability enhancement technologies must demonstrate traceability and validation according to ISO/IEC 17025 standards for testing laboratories. This includes maintaining calibration records, uncertainty calculations, and quality assurance documentation that can withstand regulatory scrutiny during certification processes.

Recent regulatory developments have begun addressing autonomous testing systems specifically. The SAE G-34 Committee on Artificial Intelligence in Aviation has published guidelines on the validation of AI-driven testing methodologies, while NASA's Technical Standards Program has released specifications for automated material characterization systems used in space applications.

Certification pathways for materials tested via autonomous methods require additional validation steps compared to traditional testing. This typically involves parallel testing using conventional methods for a statistically significant sample set to establish equivalence, followed by ongoing periodic verification to ensure continued compliance.

International harmonization efforts through organizations like the International Aerospace Quality Group (IAQG) are working to standardize acceptance criteria for autonomously generated test data across different regulatory jurisdictions, though significant regional variations persist in implementation requirements.

These regulatory bodies mandate specific performance standards for aerospace materials under extreme thermal conditions, typically requiring materials to maintain structural integrity between -65°F to 350°F (-54°C to 177°C) for commercial aircraft components. Military and space applications face even more demanding requirements, often extending to temperature ranges of -250°F to 2000°F (-157°C to 1093°C) depending on the specific application.

The SAE Aerospace Material Specifications (AMS) and ASTM International standards provide detailed testing methodologies that autonomous laboratories must incorporate into their workflows. Particularly relevant are ASTM E1269 for specific heat capacity determination and ASTM E228 for thermal expansion coefficient measurements, both critical parameters in thermal stability assessment.

Autonomous laboratories implementing thermal stability enhancement technologies must demonstrate traceability and validation according to ISO/IEC 17025 standards for testing laboratories. This includes maintaining calibration records, uncertainty calculations, and quality assurance documentation that can withstand regulatory scrutiny during certification processes.

Recent regulatory developments have begun addressing autonomous testing systems specifically. The SAE G-34 Committee on Artificial Intelligence in Aviation has published guidelines on the validation of AI-driven testing methodologies, while NASA's Technical Standards Program has released specifications for automated material characterization systems used in space applications.

Certification pathways for materials tested via autonomous methods require additional validation steps compared to traditional testing. This typically involves parallel testing using conventional methods for a statistically significant sample set to establish equivalence, followed by ongoing periodic verification to ensure continued compliance.

International harmonization efforts through organizations like the International Aerospace Quality Group (IAQG) are working to standardize acceptance criteria for autonomously generated test data across different regulatory jurisdictions, though significant regional variations persist in implementation requirements.

Environmental Impact of Advanced Thermal Materials

The development of advanced thermal materials for aerospace applications through autonomous laboratory methods has significant environmental implications that warrant careful consideration. These materials, designed to enhance thermal stability in extreme conditions, often contain specialized compounds and manufacturing processes that can impact our ecosystem in various ways.

The production of advanced thermal materials typically requires energy-intensive processes and specialized raw materials. Autonomous laboratories optimize these processes by reducing experimental iterations and material waste through machine learning algorithms and automated testing. This optimization can lead to a 30-40% reduction in energy consumption compared to traditional research methods, significantly lowering the carbon footprint associated with materials development.

Resource efficiency represents another critical environmental benefit. Conventional thermal material development often involves trial-and-error approaches that consume substantial quantities of rare earth elements and precious metals. Autonomous labs minimize this consumption through predictive modeling that identifies optimal material compositions before physical production begins. Studies indicate that this approach can reduce raw material usage by up to 60%, preserving finite resources and minimizing extraction-related environmental damage.

End-of-life considerations for advanced thermal materials present both challenges and opportunities. Many high-performance aerospace materials contain complex composites that are difficult to recycle using conventional methods. However, autonomous labs are increasingly incorporating lifecycle analysis into material design parameters, creating materials with predetermined degradation pathways or recyclability characteristics. This proactive approach helps mitigate future waste management issues associated with decommissioned aerospace components.

The environmental impact extends to operational efficiency as well. Thermal materials developed through autonomous methods typically demonstrate superior performance characteristics, including longer service life and more consistent thermal regulation. These improvements translate to reduced maintenance frequency and component replacement in aerospace applications, indirectly lowering the environmental burden of manufacturing replacement parts and servicing activities.

Water usage and contamination risks also decrease with autonomous laboratory approaches. Traditional materials testing often requires significant quantities of water and chemical solutions that may contain hazardous compounds. Autonomous systems minimize these requirements through simulation-first approaches and highly efficient physical testing when necessary, reducing potential water pollution vectors by an estimated 45-55% compared to conventional research facilities.

The production of advanced thermal materials typically requires energy-intensive processes and specialized raw materials. Autonomous laboratories optimize these processes by reducing experimental iterations and material waste through machine learning algorithms and automated testing. This optimization can lead to a 30-40% reduction in energy consumption compared to traditional research methods, significantly lowering the carbon footprint associated with materials development.

Resource efficiency represents another critical environmental benefit. Conventional thermal material development often involves trial-and-error approaches that consume substantial quantities of rare earth elements and precious metals. Autonomous labs minimize this consumption through predictive modeling that identifies optimal material compositions before physical production begins. Studies indicate that this approach can reduce raw material usage by up to 60%, preserving finite resources and minimizing extraction-related environmental damage.

End-of-life considerations for advanced thermal materials present both challenges and opportunities. Many high-performance aerospace materials contain complex composites that are difficult to recycle using conventional methods. However, autonomous labs are increasingly incorporating lifecycle analysis into material design parameters, creating materials with predetermined degradation pathways or recyclability characteristics. This proactive approach helps mitigate future waste management issues associated with decommissioned aerospace components.

The environmental impact extends to operational efficiency as well. Thermal materials developed through autonomous methods typically demonstrate superior performance characteristics, including longer service life and more consistent thermal regulation. These improvements translate to reduced maintenance frequency and component replacement in aerospace applications, indirectly lowering the environmental burden of manufacturing replacement parts and servicing activities.

Water usage and contamination risks also decrease with autonomous laboratory approaches. Traditional materials testing often requires significant quantities of water and chemical solutions that may contain hazardous compounds. Autonomous systems minimize these requirements through simulation-first approaches and highly efficient physical testing when necessary, reducing potential water pollution vectors by an estimated 45-55% compared to conventional research facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!