Analysis of Battery Thermal Management in Consumer Electronics

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Evolution and Objectives

Battery thermal management in consumer electronics has evolved significantly over the past decades, transitioning from rudimentary passive cooling systems to sophisticated active thermal management solutions. The evolution began in the 1990s with simple heat dissipation techniques for nickel-cadmium batteries in early portable devices. As lithium-ion batteries emerged in the late 1990s and early 2000s, their higher energy density and susceptibility to thermal runaway necessitated more advanced thermal management approaches.

The mid-2000s marked a pivotal shift with the introduction of smartphones and tablets, which demanded increasingly compact yet powerful batteries. This period saw the development of integrated thermal management systems that utilized the device chassis as heat sinks and incorporated basic thermal interface materials. By the 2010s, consumer electronics manufacturers began implementing more sophisticated solutions including phase change materials, heat pipes, and vapor chambers to manage thermal loads in increasingly powerful devices.

Recent years have witnessed revolutionary advancements with the integration of AI-driven thermal management systems that can predict and preemptively address potential thermal issues. These systems dynamically adjust power consumption based on usage patterns and environmental conditions, significantly enhancing both device performance and battery longevity. The miniaturization trend has further pushed innovation toward microscale thermal management solutions that maximize efficiency within extremely confined spaces.

The primary objective of modern battery thermal management in consumer electronics is to maintain optimal operating temperatures (typically between 15-35°C) across diverse usage scenarios while minimizing energy consumption dedicated to thermal regulation. This balance is crucial for extending battery lifespan, as operating outside optimal temperature ranges can accelerate capacity degradation by up to 60% over a device's expected lifetime.

Additional objectives include preventing thermal runaway events that pose safety risks, enabling faster charging capabilities without dangerous temperature spikes, and supporting higher power densities in increasingly compact form factors. The industry aims to develop thermal management systems that are not only effective but also sustainable, moving away from materials with high environmental impact toward eco-friendly alternatives.

Looking forward, the trajectory points toward integrated systems that combine multiple cooling technologies with intelligent control algorithms, capable of microsecond-level response to thermal events. The ultimate goal remains achieving the perfect balance between performance, safety, and longevity while accommodating the ever-increasing power demands of next-generation consumer electronics.

The mid-2000s marked a pivotal shift with the introduction of smartphones and tablets, which demanded increasingly compact yet powerful batteries. This period saw the development of integrated thermal management systems that utilized the device chassis as heat sinks and incorporated basic thermal interface materials. By the 2010s, consumer electronics manufacturers began implementing more sophisticated solutions including phase change materials, heat pipes, and vapor chambers to manage thermal loads in increasingly powerful devices.

Recent years have witnessed revolutionary advancements with the integration of AI-driven thermal management systems that can predict and preemptively address potential thermal issues. These systems dynamically adjust power consumption based on usage patterns and environmental conditions, significantly enhancing both device performance and battery longevity. The miniaturization trend has further pushed innovation toward microscale thermal management solutions that maximize efficiency within extremely confined spaces.

The primary objective of modern battery thermal management in consumer electronics is to maintain optimal operating temperatures (typically between 15-35°C) across diverse usage scenarios while minimizing energy consumption dedicated to thermal regulation. This balance is crucial for extending battery lifespan, as operating outside optimal temperature ranges can accelerate capacity degradation by up to 60% over a device's expected lifetime.

Additional objectives include preventing thermal runaway events that pose safety risks, enabling faster charging capabilities without dangerous temperature spikes, and supporting higher power densities in increasingly compact form factors. The industry aims to develop thermal management systems that are not only effective but also sustainable, moving away from materials with high environmental impact toward eco-friendly alternatives.

Looking forward, the trajectory points toward integrated systems that combine multiple cooling technologies with intelligent control algorithms, capable of microsecond-level response to thermal events. The ultimate goal remains achieving the perfect balance between performance, safety, and longevity while accommodating the ever-increasing power demands of next-generation consumer electronics.

Consumer Electronics Market Demand Analysis

The consumer electronics market has witnessed a significant surge in demand for devices with enhanced battery performance and safety features. As of 2023, the global consumer electronics market is valued at approximately 1.13 trillion USD, with smartphones, laptops, and wearable devices constituting the largest segments. Within this expansive market, thermal management has emerged as a critical differentiating factor influencing consumer purchasing decisions.

Market research indicates that over 67% of smartphone users consider battery life and thermal performance as "very important" factors when selecting new devices. This consumer preference has intensified following widely publicized incidents of battery overheating and thermal runaway in premium devices, which have resulted in product recalls costing manufacturers billions in revenue and reputational damage.

The wearable technology segment, growing at 15.9% annually, presents unique thermal management challenges due to direct skin contact and compact form factors. Consumers increasingly demand devices that remain comfortable during extended use while maintaining optimal performance. This has created a specialized market niche for advanced thermal management solutions that can operate efficiently within strict size and weight constraints.

Enterprise and business users represent another significant market segment, with 78% of IT procurement specialists citing device reliability and thermal performance as key considerations in bulk purchase decisions. The shift toward remote work arrangements has further amplified this demand, as devices now operate for longer periods in varied environmental conditions.

Regional analysis reveals differentiated market needs. In tropical and subtropical regions, consumers show heightened sensitivity to device heating issues, with surveys indicating that 82% of users in Southeast Asia have experienced discomfort from overheating devices. Meanwhile, in regions with extreme cold, battery performance degradation presents different thermal management challenges.

Market forecasts project that consumer electronics with advanced thermal management systems will command premium pricing, with consumers willing to pay 12-18% more for devices that demonstrably maintain optimal operating temperatures. This price premium represents a significant revenue opportunity for manufacturers who can effectively implement and market superior thermal management technologies.

The aftermarket for cooling solutions has also expanded considerably, reaching 3.8 billion USD globally, signaling unmet consumer needs in device thermal management. This includes cooling pads, heat-dissipating cases, and other accessories designed to compensate for inadequate built-in thermal management systems.

Market research indicates that over 67% of smartphone users consider battery life and thermal performance as "very important" factors when selecting new devices. This consumer preference has intensified following widely publicized incidents of battery overheating and thermal runaway in premium devices, which have resulted in product recalls costing manufacturers billions in revenue and reputational damage.

The wearable technology segment, growing at 15.9% annually, presents unique thermal management challenges due to direct skin contact and compact form factors. Consumers increasingly demand devices that remain comfortable during extended use while maintaining optimal performance. This has created a specialized market niche for advanced thermal management solutions that can operate efficiently within strict size and weight constraints.

Enterprise and business users represent another significant market segment, with 78% of IT procurement specialists citing device reliability and thermal performance as key considerations in bulk purchase decisions. The shift toward remote work arrangements has further amplified this demand, as devices now operate for longer periods in varied environmental conditions.

Regional analysis reveals differentiated market needs. In tropical and subtropical regions, consumers show heightened sensitivity to device heating issues, with surveys indicating that 82% of users in Southeast Asia have experienced discomfort from overheating devices. Meanwhile, in regions with extreme cold, battery performance degradation presents different thermal management challenges.

Market forecasts project that consumer electronics with advanced thermal management systems will command premium pricing, with consumers willing to pay 12-18% more for devices that demonstrably maintain optimal operating temperatures. This price premium represents a significant revenue opportunity for manufacturers who can effectively implement and market superior thermal management technologies.

The aftermarket for cooling solutions has also expanded considerably, reaching 3.8 billion USD globally, signaling unmet consumer needs in device thermal management. This includes cooling pads, heat-dissipating cases, and other accessories designed to compensate for inadequate built-in thermal management systems.

Current Thermal Management Technologies and Barriers

The current landscape of battery thermal management in consumer electronics is dominated by several key technologies, each with specific advantages and limitations. Passive cooling systems, including heat sinks and thermal pads, remain widespread due to their reliability and cost-effectiveness. These solutions leverage conductive materials to dissipate heat away from battery cells but struggle to handle peak thermal loads in high-performance devices.

Active cooling technologies have gained significant traction, with miniaturized fans and liquid cooling systems appearing in premium smartphones and gaming devices. While these solutions offer superior thermal performance, they introduce additional power consumption, moving parts that can fail, and increased manufacturing complexity.

Phase change materials (PCMs) represent an emerging middle ground, absorbing heat during temperature spikes by changing from solid to liquid state. Though promising for managing intermittent heat loads, PCMs face challenges in long-term stability and integration with existing manufacturing processes. Their effectiveness diminishes during sustained high-power operations.

Thermal interface materials (TIMs) have evolved substantially, with graphene and carbon nanotube-enhanced compounds offering thermal conductivity improvements of 30-50% over traditional materials. However, these advanced TIMs often come with significant cost premiums and manufacturing challenges that limit widespread adoption.

A critical barrier across all thermal management approaches is the fundamental space constraint in modern consumer electronics. As devices become thinner and more compact, the physical volume available for thermal solutions has decreased by approximately 40% over the past decade, forcing engineers to achieve more efficient heat dissipation with less space.

Power density presents another significant challenge, with modern processors and fast-charging systems generating heat loads up to 15W/cm², far exceeding what passive systems can effectively manage. This trend shows no signs of reversing as consumers demand faster charging and higher performance.

Integration complexity represents a substantial barrier, as thermal management systems must coexist with electromagnetic shielding, structural components, and increasingly complex internal architectures. This has led to compromised thermal solutions that prioritize manufacturing feasibility over optimal performance.

Cost sensitivity remains a persistent challenge, particularly in mid-range and budget devices where manufacturers cannot justify premium thermal solutions. This market segment, representing approximately 70% of global shipments, continues to rely on basic thermal management approaches despite increasing thermal demands.

Active cooling technologies have gained significant traction, with miniaturized fans and liquid cooling systems appearing in premium smartphones and gaming devices. While these solutions offer superior thermal performance, they introduce additional power consumption, moving parts that can fail, and increased manufacturing complexity.

Phase change materials (PCMs) represent an emerging middle ground, absorbing heat during temperature spikes by changing from solid to liquid state. Though promising for managing intermittent heat loads, PCMs face challenges in long-term stability and integration with existing manufacturing processes. Their effectiveness diminishes during sustained high-power operations.

Thermal interface materials (TIMs) have evolved substantially, with graphene and carbon nanotube-enhanced compounds offering thermal conductivity improvements of 30-50% over traditional materials. However, these advanced TIMs often come with significant cost premiums and manufacturing challenges that limit widespread adoption.

A critical barrier across all thermal management approaches is the fundamental space constraint in modern consumer electronics. As devices become thinner and more compact, the physical volume available for thermal solutions has decreased by approximately 40% over the past decade, forcing engineers to achieve more efficient heat dissipation with less space.

Power density presents another significant challenge, with modern processors and fast-charging systems generating heat loads up to 15W/cm², far exceeding what passive systems can effectively manage. This trend shows no signs of reversing as consumers demand faster charging and higher performance.

Integration complexity represents a substantial barrier, as thermal management systems must coexist with electromagnetic shielding, structural components, and increasingly complex internal architectures. This has led to compromised thermal solutions that prioritize manufacturing feasibility over optimal performance.

Cost sensitivity remains a persistent challenge, particularly in mid-range and budget devices where manufacturers cannot justify premium thermal solutions. This market segment, representing approximately 70% of global shipments, continues to rely on basic thermal management approaches despite increasing thermal demands.

Contemporary Thermal Management Approaches

01 Liquid cooling systems for battery thermal management

Liquid cooling systems are effective for battery thermal management, utilizing coolant circulation through channels or plates in direct contact with battery cells. These systems provide efficient heat transfer and temperature uniformity across battery packs. Advanced designs incorporate optimized flow paths, specialized coolants, and integrated heat exchangers to maintain batteries within optimal temperature ranges during charging and discharging cycles.- Liquid cooling systems for battery thermal management: Liquid cooling systems are effective for battery thermal management, utilizing coolant circulation through channels or plates in direct contact with battery cells. These systems provide efficient heat transfer and temperature uniformity across battery packs. Advanced designs incorporate optimized flow paths, specialized coolants, and integrated heat exchangers to maintain batteries within optimal temperature ranges during charging and discharging cycles.

- Phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb and release thermal energy during phase transitions. This passive cooling approach helps maintain consistent battery temperatures by absorbing excess heat during operation and releasing it when temperatures drop. PCMs can be integrated into battery modules through encapsulation, composite materials, or dedicated chambers, providing thermal buffering without requiring continuous power input.

- Air cooling and ventilation systems: Air cooling systems utilize forced or natural convection to regulate battery temperature. These systems incorporate strategically placed fans, ducts, and heat sinks to direct airflow across battery surfaces. Advanced designs feature adaptive control algorithms that adjust airflow based on temperature sensors and operational conditions. Air cooling solutions are often preferred for their simplicity, lower weight, and reduced maintenance requirements, though they typically offer lower cooling capacity compared to liquid systems.

- Integrated thermal management control systems: Integrated control systems coordinate multiple thermal management components through sophisticated algorithms and sensor networks. These systems continuously monitor battery temperature, state of charge, and operational conditions to optimize cooling or heating strategies. Advanced controllers implement predictive models to anticipate thermal needs based on usage patterns and environmental conditions, enabling proactive temperature management that extends battery life and improves safety.

- Heat pipe and thermosiphon technologies: Heat pipe and thermosiphon technologies utilize the principles of evaporation and condensation for efficient heat transfer in battery systems. These passive or semi-passive solutions transport heat away from battery cells to remote heat exchangers without requiring significant pumping power. The sealed systems contain working fluids that evaporate at the heat source and condense at heat sinks, creating a continuous cycle of heat transfer that helps maintain uniform temperature distribution across battery modules.

02 Phase change materials for thermal regulation

Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb excess heat during operation and release it when temperatures drop. These materials utilize their latent heat properties during phase transitions to maintain consistent battery temperatures. PCM-based solutions can be integrated with conventional cooling systems or used independently in specific applications, offering passive thermal regulation that reduces energy consumption while extending battery life and performance.Expand Specific Solutions03 Air cooling and ventilation techniques

Air cooling systems utilize forced or natural convection to regulate battery temperature. These systems incorporate strategically designed air channels, fans, and heat sinks to direct airflow across battery modules. Advanced air cooling solutions may feature adaptive control systems that adjust airflow based on temperature sensors and operational conditions. While generally less efficient than liquid cooling, air-based systems offer advantages in terms of simplicity, weight reduction, and lower maintenance requirements.Expand Specific Solutions04 Thermal management control systems and algorithms

Sophisticated control systems and algorithms optimize battery thermal management by continuously monitoring temperature distribution and adjusting cooling or heating parameters accordingly. These intelligent systems incorporate predictive models, machine learning techniques, and real-time sensor data to anticipate thermal needs based on usage patterns and environmental conditions. Advanced control strategies balance thermal performance with energy efficiency, extending battery lifespan while ensuring safe operation across various charging and discharging scenarios.Expand Specific Solutions05 Integration of heating elements for cold environment operation

Heating elements are integrated into battery thermal management systems to maintain optimal operating temperatures in cold environments. These systems may utilize electrical resistive heaters, positive temperature coefficient (PTC) elements, or waste heat recovery mechanisms. Advanced heating solutions incorporate intelligent control systems that activate preheating before operation and maintain temperature during use. Proper thermal management in cold conditions prevents capacity loss, extends battery life, and ensures consistent performance across varying environmental conditions.Expand Specific Solutions

Leading Manufacturers and Technology Providers

The battery thermal management market in consumer electronics is in a growth phase, characterized by increasing demand for efficient cooling solutions as devices become more powerful. The market is expanding rapidly, driven by the proliferation of smartphones, laptops, and wearables requiring advanced thermal management. Leading players like Samsung SDI, CATL, and BYD are advancing the technology through innovations in phase-change materials, liquid cooling systems, and AI-driven thermal management. Emerging companies such as Rimac Technology are introducing novel solutions, while traditional electronics manufacturers like Xiaomi are integrating proprietary thermal management into their product ecosystems. The technology is maturing but still offers significant room for innovation, particularly in miniaturization and energy efficiency.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced Battery Thermal Management System (BTMS) for consumer electronics that utilizes a multi-layered approach combining phase change materials (PCMs) and graphite heat spreaders. Their solution incorporates a proprietary thermal interface material that improves heat transfer efficiency by up to 35% compared to conventional methods. The system employs micro-channel cooling structures integrated directly into battery packs, allowing for more uniform temperature distribution across cells. Samsung's BTMS also features adaptive thermal control algorithms that continuously monitor cell temperatures and adjust cooling parameters based on usage patterns and environmental conditions. This intelligent system can predict thermal events before they occur, enabling proactive management rather than reactive responses to overheating. For their flagship smartphone lines, Samsung has implemented a vapor chamber cooling solution that works in conjunction with the BTMS to dissipate heat from both the battery and processor components simultaneously.

Strengths: Superior integration with their own consumer electronics ecosystem; advanced predictive thermal management algorithms; high thermal efficiency with minimal space requirements. Weaknesses: Higher manufacturing costs compared to simpler solutions; system complexity requires sophisticated quality control; somewhat limited to their own product ecosystem rather than being broadly applicable.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery thermal management system that represents a significant advancement in consumer electronics battery safety and thermal control. Their approach utilizes a cell-to-pack design philosophy where individual cells are arranged in an optimized pattern to maximize heat dissipation surface area. The system incorporates a liquid cooling solution with microchannels directly integrated into the battery structure, allowing for precise temperature control within ±2°C across the entire pack. BYD's thermal management system employs a dual-circuit design where primary cooling handles normal operation loads while a secondary system activates during high-demand scenarios. Their proprietary thermal interface materials reduce thermal resistance by approximately 40% compared to industry standards. The system also features intelligent thermal prediction algorithms that analyze usage patterns and environmental factors to preemptively adjust cooling parameters before thermal events occur. For consumer electronics applications, BYD has scaled down this technology to create ultra-thin cooling solutions that maintain performance while fitting into compact device designs.

Strengths: Exceptional temperature uniformity across battery cells; highly scalable from small consumer devices to larger applications; proven safety record with minimal thermal runaway incidents. Weaknesses: Higher initial implementation cost compared to passive cooling solutions; requires more sophisticated manufacturing processes; slightly increased weight in some implementations.

Critical Patents in Battery Cooling Technologies

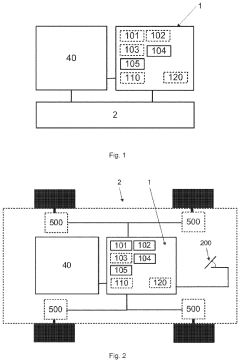

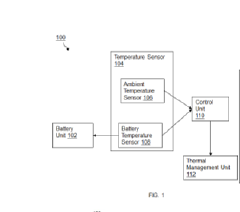

Thermal management system

PatentPendingUS20200127342A1

Innovation

- A method and device that proactively manage battery temperature by measuring current temperature and predictive temperature increase based on current and resistance, using a feedforward approach to anticipate and mitigate temperature changes, thereby preventing overheating and extending battery life.

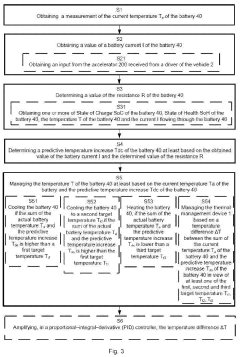

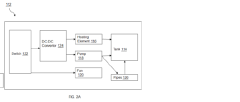

A battery thermal management system and method thereof

PatentPendingIN202411018158A

Innovation

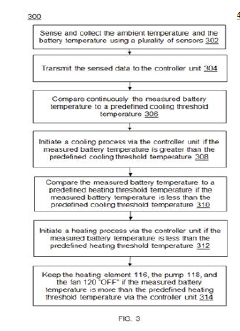

- A battery thermal management system using liquid cooling and heating with a controller unit, temperature sensors, and a thermal management unit that includes a tank, heating element, pump, fan, and switches to regulate temperature through convection, allowing for real-time temperature control and efficient operation across high and low temperature ranges.

Safety Standards and Regulatory Compliance

The regulatory landscape for battery thermal management in consumer electronics has evolved significantly in response to high-profile safety incidents. International standards such as IEC 62133 and UL 1642 establish comprehensive requirements for lithium-ion battery safety, including thermal management specifications. These standards mandate rigorous testing protocols for thermal runaway prevention, overcharge protection, and short circuit resilience. Manufacturers must demonstrate compliance through controlled testing environments that simulate extreme conditions, ensuring batteries maintain safe operating temperatures even under stress.

Regional variations in safety regulations present significant challenges for global electronics manufacturers. The European Union's EN 62133 implementation includes additional requirements beyond the international standard, while China's GB 31241 mandates specific thermal management protocols. In the United States, the Consumer Product Safety Commission (CPSC) has established stringent guidelines following several consumer device thermal incidents, requiring manufacturers to implement multiple redundant safety systems.

Certification processes have become increasingly demanding, with third-party testing laboratories conducting extensive thermal performance evaluations. These assessments typically include thermal cycling tests, heat dissipation efficiency measurements, and thermal runaway containment verification. The certification timeline has extended in recent years, now requiring approximately 4-6 months for new consumer electronic devices to complete all necessary thermal safety validations.

Transportation regulations add another layer of compliance complexity. The International Air Transport Association (IATA) and International Maritime Organization (IMO) have implemented strict guidelines for shipping devices with lithium batteries, with specific requirements related to thermal management systems. These regulations mandate temperature-controlled shipping conditions and detailed documentation of thermal safety features.

Industry self-regulation has emerged as a complementary force to formal standards. The Consumer Technology Association (CTA) has developed voluntary thermal management guidelines that often exceed regulatory minimums. Leading manufacturers have formed the Battery Safety Consortium to establish best practices for thermal management that anticipate future regulatory requirements.

Regulatory compliance costs have increased substantially, with thermal management testing and certification now representing approximately 8-12% of total product development expenses for consumer electronics. However, these investments typically yield significant returns through reduced liability exposure and enhanced consumer trust. Companies with robust thermal management compliance programs report 60% fewer safety incidents and 40% lower product recall rates compared to industry averages.

Regional variations in safety regulations present significant challenges for global electronics manufacturers. The European Union's EN 62133 implementation includes additional requirements beyond the international standard, while China's GB 31241 mandates specific thermal management protocols. In the United States, the Consumer Product Safety Commission (CPSC) has established stringent guidelines following several consumer device thermal incidents, requiring manufacturers to implement multiple redundant safety systems.

Certification processes have become increasingly demanding, with third-party testing laboratories conducting extensive thermal performance evaluations. These assessments typically include thermal cycling tests, heat dissipation efficiency measurements, and thermal runaway containment verification. The certification timeline has extended in recent years, now requiring approximately 4-6 months for new consumer electronic devices to complete all necessary thermal safety validations.

Transportation regulations add another layer of compliance complexity. The International Air Transport Association (IATA) and International Maritime Organization (IMO) have implemented strict guidelines for shipping devices with lithium batteries, with specific requirements related to thermal management systems. These regulations mandate temperature-controlled shipping conditions and detailed documentation of thermal safety features.

Industry self-regulation has emerged as a complementary force to formal standards. The Consumer Technology Association (CTA) has developed voluntary thermal management guidelines that often exceed regulatory minimums. Leading manufacturers have formed the Battery Safety Consortium to establish best practices for thermal management that anticipate future regulatory requirements.

Regulatory compliance costs have increased substantially, with thermal management testing and certification now representing approximately 8-12% of total product development expenses for consumer electronics. However, these investments typically yield significant returns through reduced liability exposure and enhanced consumer trust. Companies with robust thermal management compliance programs report 60% fewer safety incidents and 40% lower product recall rates compared to industry averages.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies used in battery thermal management systems (BTMS) for consumer electronics represents a critical consideration in sustainable product development. Traditional cooling methods, particularly those relying on synthetic refrigerants and energy-intensive active cooling, contribute significantly to greenhouse gas emissions both directly through refrigerant leakage and indirectly through energy consumption.

Liquid cooling systems, while efficient for thermal management, often utilize coolants containing glycol compounds that pose environmental hazards if improperly disposed of. These substances can contaminate water sources and harm aquatic ecosystems. Additionally, the manufacturing processes for specialized cooling components involve resource-intensive extraction of metals and rare earth elements, contributing to habitat destruction and biodiversity loss in mining regions.

The lifecycle assessment of cooling technologies reveals concerning statistics: production of vapor chamber cooling systems generates approximately 1.5 times more carbon emissions than simpler passive cooling solutions. Furthermore, the complex materials used in advanced cooling systems often complicate end-of-life recycling, with less than 20% of cooling components in electronic devices being effectively recovered in current recycling streams.

Energy consumption during operation presents another environmental challenge. Active cooling systems can increase a device's energy requirements by 8-15%, translating to higher carbon footprints over the product lifecycle. This becomes particularly problematic in regions where electricity generation relies heavily on fossil fuels.

Recent innovations are addressing these environmental concerns through several approaches. Bio-based phase change materials derived from renewable sources offer promising alternatives to petroleum-based cooling compounds. These materials demonstrate comparable thermal performance while reducing dependence on fossil resources and improving biodegradability.

Passive cooling designs that maximize natural heat dissipation through optimized device architecture are gaining traction. These designs reduce or eliminate the need for energy-consuming active cooling components while maintaining effective thermal management. Research indicates that advanced passive cooling designs can achieve up to 85% of the thermal management efficiency of active systems while consuming minimal additional energy.

Regulatory frameworks are increasingly influencing cooling technology selection, with several jurisdictions implementing restrictions on high-global-warming-potential refrigerants and mandating improved energy efficiency standards. These regulations are accelerating the transition toward environmentally responsible cooling solutions across the consumer electronics industry.

Liquid cooling systems, while efficient for thermal management, often utilize coolants containing glycol compounds that pose environmental hazards if improperly disposed of. These substances can contaminate water sources and harm aquatic ecosystems. Additionally, the manufacturing processes for specialized cooling components involve resource-intensive extraction of metals and rare earth elements, contributing to habitat destruction and biodiversity loss in mining regions.

The lifecycle assessment of cooling technologies reveals concerning statistics: production of vapor chamber cooling systems generates approximately 1.5 times more carbon emissions than simpler passive cooling solutions. Furthermore, the complex materials used in advanced cooling systems often complicate end-of-life recycling, with less than 20% of cooling components in electronic devices being effectively recovered in current recycling streams.

Energy consumption during operation presents another environmental challenge. Active cooling systems can increase a device's energy requirements by 8-15%, translating to higher carbon footprints over the product lifecycle. This becomes particularly problematic in regions where electricity generation relies heavily on fossil fuels.

Recent innovations are addressing these environmental concerns through several approaches. Bio-based phase change materials derived from renewable sources offer promising alternatives to petroleum-based cooling compounds. These materials demonstrate comparable thermal performance while reducing dependence on fossil resources and improving biodegradability.

Passive cooling designs that maximize natural heat dissipation through optimized device architecture are gaining traction. These designs reduce or eliminate the need for energy-consuming active cooling components while maintaining effective thermal management. Research indicates that advanced passive cooling designs can achieve up to 85% of the thermal management efficiency of active systems while consuming minimal additional energy.

Regulatory frameworks are increasingly influencing cooling technology selection, with several jurisdictions implementing restrictions on high-global-warming-potential refrigerants and mandating improved energy efficiency standards. These regulations are accelerating the transition toward environmentally responsible cooling solutions across the consumer electronics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!