Evaluation of Battery Thermal Management in Renewable Energy Systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Background and Objectives

Battery thermal management systems (BTMS) have emerged as a critical component in the evolution of renewable energy technologies over the past two decades. The fundamental purpose of these systems is to maintain optimal operating temperatures for battery cells, thereby ensuring safety, extending lifespan, and maximizing performance efficiency. As renewable energy adoption accelerates globally, the importance of effective thermal management has become increasingly apparent, particularly in large-scale energy storage applications where thermal runaway presents significant safety risks.

The historical development of BTMS technology has progressed from simple passive cooling methods to sophisticated active management systems incorporating liquid cooling, phase change materials, and intelligent thermal control algorithms. This evolution has been driven by the increasing energy density of modern battery technologies and the more demanding operational environments encountered in renewable energy applications.

Current BTMS technologies face significant challenges in balancing thermal performance with system complexity, weight, cost, and energy consumption. The technical objectives for next-generation systems focus on achieving uniform temperature distribution across battery packs, minimizing parasitic energy losses, and developing adaptive systems capable of responding to varying environmental conditions and load profiles characteristic of renewable energy applications.

In the context of renewable energy systems, BTMS must address unique operational patterns including deep discharge cycles, intermittent charging from variable energy sources, and potential exposure to extreme environmental conditions. These factors differentiate renewable energy BTMS requirements from those in electric vehicles or consumer electronics applications.

The primary technical goals for BTMS in renewable energy applications include: reducing temperature gradients within battery packs to below 3°C; extending battery cycle life by at least 20% through improved thermal management; developing systems capable of operating efficiently across temperature ranges from -20°C to 60°C; and integrating predictive thermal management capabilities that anticipate thermal behavior based on renewable energy generation forecasts.

Additionally, there is growing emphasis on developing sustainable BTMS solutions that minimize environmental impact through reduced material usage, lower energy consumption, and integration with waste heat recovery systems. This aligns with the broader sustainability objectives of renewable energy deployment and represents an emerging frontier in BTMS research and development.

The technological trajectory suggests that future BTMS will increasingly incorporate artificial intelligence for predictive thermal management, advanced materials for enhanced thermal conductivity, and holistic system designs that integrate thermal management with other battery management functions to optimize overall energy storage performance in renewable energy applications.

The historical development of BTMS technology has progressed from simple passive cooling methods to sophisticated active management systems incorporating liquid cooling, phase change materials, and intelligent thermal control algorithms. This evolution has been driven by the increasing energy density of modern battery technologies and the more demanding operational environments encountered in renewable energy applications.

Current BTMS technologies face significant challenges in balancing thermal performance with system complexity, weight, cost, and energy consumption. The technical objectives for next-generation systems focus on achieving uniform temperature distribution across battery packs, minimizing parasitic energy losses, and developing adaptive systems capable of responding to varying environmental conditions and load profiles characteristic of renewable energy applications.

In the context of renewable energy systems, BTMS must address unique operational patterns including deep discharge cycles, intermittent charging from variable energy sources, and potential exposure to extreme environmental conditions. These factors differentiate renewable energy BTMS requirements from those in electric vehicles or consumer electronics applications.

The primary technical goals for BTMS in renewable energy applications include: reducing temperature gradients within battery packs to below 3°C; extending battery cycle life by at least 20% through improved thermal management; developing systems capable of operating efficiently across temperature ranges from -20°C to 60°C; and integrating predictive thermal management capabilities that anticipate thermal behavior based on renewable energy generation forecasts.

Additionally, there is growing emphasis on developing sustainable BTMS solutions that minimize environmental impact through reduced material usage, lower energy consumption, and integration with waste heat recovery systems. This aligns with the broader sustainability objectives of renewable energy deployment and represents an emerging frontier in BTMS research and development.

The technological trajectory suggests that future BTMS will increasingly incorporate artificial intelligence for predictive thermal management, advanced materials for enhanced thermal conductivity, and holistic system designs that integrate thermal management with other battery management functions to optimize overall energy storage performance in renewable energy applications.

Market Analysis for Thermal Management in Renewable Energy Storage

The global market for battery thermal management systems in renewable energy storage is experiencing robust growth, driven by the increasing deployment of renewable energy sources and the critical need for efficient energy storage solutions. Current market valuations indicate that the thermal management segment within energy storage reached approximately 2.8 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 22.3% through 2030. This accelerated growth reflects the essential role thermal management plays in optimizing battery performance and longevity in renewable energy applications.

Market demand is particularly strong in regions with aggressive renewable energy targets, including Europe, North America, and parts of Asia-Pacific. The European market shows the highest growth rate, influenced by stringent environmental regulations and substantial investments in renewable infrastructure. China remains the largest single market by volume, accounting for nearly 35% of global demand, followed by the United States at 21%.

Consumer segments driving market expansion include utility-scale energy storage projects, commercial and industrial applications, and residential energy storage systems. Utility-scale projects represent the largest market share at approximately 42%, though residential applications are showing the fastest growth rate at 27% annually as distributed energy resources gain popularity.

Key market drivers include the declining costs of renewable energy generation, increasing grid instability concerns, and the push for energy independence. The integration of thermal management solutions has become a critical differentiator for energy storage providers, with customers increasingly recognizing the value proposition of enhanced battery life and improved safety profiles.

Market challenges persist, including cost sensitivity among end-users, technical integration complexities with existing systems, and varying regulatory frameworks across regions. The price premium for advanced thermal management solutions remains a significant barrier, particularly in price-sensitive emerging markets where cost considerations often outweigh performance benefits.

Industry analysts identify several emerging market opportunities, including the integration of artificial intelligence for predictive thermal management, specialized solutions for extreme climate conditions, and thermal management systems optimized for next-generation battery chemistries. The vehicle-to-grid (V2G) segment also presents substantial growth potential as electric vehicle adoption accelerates and integration with renewable energy systems becomes more commonplace.

Market consolidation is occurring through strategic acquisitions and partnerships, with major energy storage providers increasingly bringing thermal management capabilities in-house rather than relying on third-party solutions. This vertical integration trend is reshaping competitive dynamics and creating entry barriers for smaller specialized providers.

Market demand is particularly strong in regions with aggressive renewable energy targets, including Europe, North America, and parts of Asia-Pacific. The European market shows the highest growth rate, influenced by stringent environmental regulations and substantial investments in renewable infrastructure. China remains the largest single market by volume, accounting for nearly 35% of global demand, followed by the United States at 21%.

Consumer segments driving market expansion include utility-scale energy storage projects, commercial and industrial applications, and residential energy storage systems. Utility-scale projects represent the largest market share at approximately 42%, though residential applications are showing the fastest growth rate at 27% annually as distributed energy resources gain popularity.

Key market drivers include the declining costs of renewable energy generation, increasing grid instability concerns, and the push for energy independence. The integration of thermal management solutions has become a critical differentiator for energy storage providers, with customers increasingly recognizing the value proposition of enhanced battery life and improved safety profiles.

Market challenges persist, including cost sensitivity among end-users, technical integration complexities with existing systems, and varying regulatory frameworks across regions. The price premium for advanced thermal management solutions remains a significant barrier, particularly in price-sensitive emerging markets where cost considerations often outweigh performance benefits.

Industry analysts identify several emerging market opportunities, including the integration of artificial intelligence for predictive thermal management, specialized solutions for extreme climate conditions, and thermal management systems optimized for next-generation battery chemistries. The vehicle-to-grid (V2G) segment also presents substantial growth potential as electric vehicle adoption accelerates and integration with renewable energy systems becomes more commonplace.

Market consolidation is occurring through strategic acquisitions and partnerships, with major energy storage providers increasingly bringing thermal management capabilities in-house rather than relying on third-party solutions. This vertical integration trend is reshaping competitive dynamics and creating entry barriers for smaller specialized providers.

Current Challenges in Battery Thermal Management Technologies

Despite significant advancements in battery technology, thermal management remains one of the most critical challenges in renewable energy storage systems. Current battery thermal management systems (BTMS) face several persistent issues that limit their efficiency and reliability. Temperature non-uniformity within battery packs represents a fundamental challenge, with temperature gradients often exceeding 5-10°C across large-scale systems. This non-uniformity accelerates degradation in hotter regions while underutilizing cooler sections, resulting in reduced overall system lifespan and performance.

Cooling system efficiency presents another significant hurdle, particularly in high-power applications like grid-scale storage and electric vehicle fast-charging. Conventional air cooling systems struggle to dissipate heat effectively during rapid charge/discharge cycles, while liquid cooling systems, though more efficient, introduce complexity, weight, and potential leakage risks. The trade-off between cooling performance and system simplicity remains unresolved in many applications.

Energy consumption of thermal management systems themselves constitutes a parasitic load that can consume 5-15% of stored energy in extreme conditions. This self-consumption significantly reduces the net efficiency of renewable energy storage systems, particularly in off-grid applications where energy conservation is paramount. Current passive cooling technologies lack sufficient capacity for high-power applications, while active systems demand excessive energy.

Material limitations further constrain BTMS development. Thermal interface materials with both high conductivity and long-term stability remain elusive. Phase change materials show promise but face challenges in cycle stability and containment. Additionally, thermally conductive polymers that could replace metal components while maintaining structural integrity are still in early development stages.

Integration challenges with renewable energy sources add another layer of complexity. Solar and wind energy's intermittent nature creates unpredictable thermal loads on battery systems. Current BTMS designs struggle to adapt dynamically to these fluctuating conditions, often resulting in either insufficient cooling during peak generation or wasteful overcooling during low-activity periods.

Extreme environment operation presents perhaps the most demanding challenge. Renewable energy systems deployed in desert regions face ambient temperatures exceeding 45°C, while those in cold climates must function below -30°C. Current thermal management solutions rarely perform optimally across this entire range, with most systems designed around moderate temperature conditions and struggling at the extremes.

Cost and sustainability concerns round out the major challenges. Advanced thermal management solutions often incorporate expensive materials and complex manufacturing processes, increasing overall system costs by 15-25%. Additionally, many current solutions utilize materials with significant environmental footprints, contradicting the sustainability goals of renewable energy systems.

Cooling system efficiency presents another significant hurdle, particularly in high-power applications like grid-scale storage and electric vehicle fast-charging. Conventional air cooling systems struggle to dissipate heat effectively during rapid charge/discharge cycles, while liquid cooling systems, though more efficient, introduce complexity, weight, and potential leakage risks. The trade-off between cooling performance and system simplicity remains unresolved in many applications.

Energy consumption of thermal management systems themselves constitutes a parasitic load that can consume 5-15% of stored energy in extreme conditions. This self-consumption significantly reduces the net efficiency of renewable energy storage systems, particularly in off-grid applications where energy conservation is paramount. Current passive cooling technologies lack sufficient capacity for high-power applications, while active systems demand excessive energy.

Material limitations further constrain BTMS development. Thermal interface materials with both high conductivity and long-term stability remain elusive. Phase change materials show promise but face challenges in cycle stability and containment. Additionally, thermally conductive polymers that could replace metal components while maintaining structural integrity are still in early development stages.

Integration challenges with renewable energy sources add another layer of complexity. Solar and wind energy's intermittent nature creates unpredictable thermal loads on battery systems. Current BTMS designs struggle to adapt dynamically to these fluctuating conditions, often resulting in either insufficient cooling during peak generation or wasteful overcooling during low-activity periods.

Extreme environment operation presents perhaps the most demanding challenge. Renewable energy systems deployed in desert regions face ambient temperatures exceeding 45°C, while those in cold climates must function below -30°C. Current thermal management solutions rarely perform optimally across this entire range, with most systems designed around moderate temperature conditions and struggling at the extremes.

Cost and sustainability concerns round out the major challenges. Advanced thermal management solutions often incorporate expensive materials and complex manufacturing processes, increasing overall system costs by 15-25%. Additionally, many current solutions utilize materials with significant environmental footprints, contradicting the sustainability goals of renewable energy systems.

Existing Thermal Management Approaches and Implementations

01 Liquid cooling systems for battery thermal management

Liquid cooling systems are employed in battery thermal management to efficiently control temperature. These systems utilize coolant circulation through channels or plates in direct contact with battery cells or modules. The liquid medium provides superior heat transfer capabilities compared to air cooling, allowing for more precise temperature control and uniform heat distribution across the battery pack. Advanced designs incorporate optimized flow paths, specialized coolants, and integrated heat exchangers to enhance cooling efficiency and maintain optimal battery operating temperatures.- Liquid cooling systems for battery thermal management: Liquid cooling systems are effective for battery thermal management, utilizing coolant circulation through channels or plates in direct contact with battery cells. These systems provide efficient heat transfer and temperature uniformity across battery packs. Advanced designs incorporate optimized flow paths, specialized coolants, and integrated heat exchangers to maintain batteries within optimal temperature ranges during charging and discharging cycles.

- Phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb and release thermal energy during phase transitions. These materials provide passive thermal regulation by absorbing excess heat during high-load operations and releasing it when temperatures drop. PCM-based solutions offer advantages in weight reduction, space efficiency, and can operate without external power, making them suitable for various battery applications from portable electronics to electric vehicles.

- Air cooling and ventilation techniques: Air cooling systems utilize forced or natural convection to manage battery temperature. These systems incorporate strategically placed fans, air channels, and heat sinks to direct airflow across battery modules. Advanced designs feature adaptive control systems that adjust airflow based on temperature sensors and operational conditions. Air cooling solutions are valued for their simplicity, low maintenance requirements, and cost-effectiveness, particularly in applications with moderate thermal management needs.

- Thermal management control systems and algorithms: Sophisticated control systems and algorithms optimize battery thermal management by continuously monitoring temperature distribution and adjusting cooling or heating parameters accordingly. These systems incorporate predictive models that anticipate thermal behavior based on usage patterns and environmental conditions. Advanced thermal management controllers integrate with battery management systems to coordinate thermal regulation with charging protocols, extending battery life and enhancing safety through precise temperature control across all operational scenarios.

- Integrated heating solutions for cold environments: Heating systems are essential components of battery thermal management in cold environments where battery performance significantly deteriorates. These solutions include resistive heating elements, positive temperature coefficient (PTC) heaters, and waste heat recovery systems. Advanced designs feature pre-conditioning capabilities that warm batteries before operation and maintain optimal temperature during use. Integrated heating solutions improve cold-weather performance, extend battery lifespan, and ensure consistent power delivery across varying environmental conditions.

02 Phase change materials for thermal regulation

Phase change materials (PCMs) are integrated into battery thermal management systems to provide passive temperature control. These materials absorb excess heat during battery operation by changing from solid to liquid state, and release stored heat when the battery temperature drops, helping maintain optimal operating temperature ranges. PCMs offer advantages including thermal buffering during peak loads, reduced energy consumption compared to active cooling systems, and the ability to operate without external power. Advanced PCM formulations are designed with specific melting points tailored to battery thermal requirements.Expand Specific Solutions03 Air cooling and ventilation systems

Air cooling systems utilize forced or natural convection to manage battery temperature. These systems incorporate strategically placed fans, ducts, and heat sinks to direct airflow across battery modules. Air cooling offers advantages including simplicity, lower weight, reduced cost, and elimination of potential fluid leakage risks. Advanced designs feature optimized air channels, variable-speed fans that adjust to thermal demands, and intelligent control algorithms that balance cooling performance with energy efficiency. Some systems integrate with vehicle HVAC systems to leverage existing air handling infrastructure.Expand Specific Solutions04 Thermal management control strategies and algorithms

Advanced control strategies and algorithms optimize battery thermal management system performance. These intelligent systems utilize real-time temperature monitoring from multiple sensors to predict thermal behavior and proactively adjust cooling or heating parameters. Machine learning algorithms adapt to battery usage patterns and environmental conditions to optimize energy efficiency while maintaining ideal temperature ranges. Control systems balance thermal management needs with overall energy consumption, extending battery life and improving performance through predictive thermal management rather than reactive responses.Expand Specific Solutions05 Integrated heating systems for cold weather operation

Integrated heating systems are crucial for battery thermal management in cold environments where battery performance significantly deteriorates. These systems employ various heating elements including resistive heaters, positive temperature coefficient (PTC) materials, and waste heat recovery mechanisms to raise battery temperature to optimal operating ranges. Advanced designs feature pre-conditioning capabilities that warm batteries before vehicle operation, intelligent power management to minimize energy consumption, and zonal heating approaches that target specific battery regions. Some systems integrate with vehicle cabin heating to optimize overall thermal efficiency.Expand Specific Solutions

Leading Companies in Renewable Energy Battery Thermal Solutions

The battery thermal management market in renewable energy systems is experiencing rapid growth, driven by increasing adoption of electric vehicles and grid-scale energy storage solutions. Currently in an expansion phase, the market is projected to reach significant scale as renewable integration accelerates globally. Leading players demonstrate varying levels of technological maturity, with established manufacturers like Samsung SDI, CATL, and Rimac Technology offering advanced thermal management solutions. Traditional automotive companies (GM, NIO, BJEV) are investing heavily to close the gap, while research institutions (Battelle Energy Alliance, University of Michigan) focus on next-generation technologies. The competitive landscape is diversifying with specialized players like Gentherm and Valeo Thermal Systems developing niche solutions, indicating a maturing but still-evolving market with substantial growth potential.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced battery thermal management system specifically adapted for renewable energy storage applications, leveraging expertise from their electric vehicle programs. Their system employs a dual-circuit cooling architecture that separates high and low-temperature cooling loops, optimizing efficiency across varying operational demands. The primary circuit utilizes a dielectric coolant in direct contact with battery cells, achieving thermal transfer coefficients up to 40% higher than conventional indirect cooling methods. GM's renewable energy BTMS incorporates smart thermal preconditioning that activates based on weather forecasting algorithms, preparing battery systems for anticipated renewable generation peaks or shortfalls. Their solution features adaptive flow control that modulates coolant circulation based on real-time temperature gradients across battery modules, minimizing parasitic energy losses while maintaining optimal temperature ranges. Field testing has demonstrated that this system can maintain temperature variations below 5°C across large battery arrays even during rapid charge/discharge cycles typical in solar and wind integration scenarios.

Strengths: Exceptional thermal transfer efficiency through direct cooling contact; intelligent preconditioning based on renewable generation forecasts; low parasitic energy consumption. Weaknesses: Higher system complexity increases potential failure points; dielectric coolant adds cost compared to water-glycol solutions; requires more sophisticated control systems and maintenance protocols.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered a comprehensive thermal management solution for renewable energy storage systems that combines both active and passive cooling technologies. Their system features a proprietary phase-change material (PCM) integrated directly into battery module design, providing thermal buffering during peak load conditions. This is complemented by a variable-flow liquid cooling circuit that adapts to changing environmental conditions and state-of-charge. Samsung's thermal management architecture incorporates dedicated thermal interface materials with conductivity exceeding 5 W/m·K, ensuring efficient heat transfer from cells to cooling systems. Their solution also features an intelligent thermal management controller that interfaces with battery management systems to optimize cooling based on real-time operational parameters and weather forecasting data. This integrated approach has demonstrated the ability to maintain batteries within ±2°C of optimal temperature even under extreme charging/discharging cycles common in renewable energy applications.

Strengths: Hybrid active-passive cooling approach provides redundancy; sophisticated thermal control algorithms optimize for renewable energy cycling patterns; excellent temperature uniformity across modules. Weaknesses: Higher manufacturing complexity due to PCM integration; increased weight compared to simpler cooling solutions; thermal interface materials may degrade over extended operational lifetimes.

Critical Patents and Research in Battery Cooling Technologies

Evaporative cooling based battery thermal management system

PatentInactiveIN202221000095A

Innovation

- A compact, evaporative cooling-based Battery Thermal Management System (BTMS) for VRLA batteries in E-bikes and E-vehicles, utilizing a cooling module with a wood-wool cooling pad and a control module with automatic temperature control, which consumes minimal power and is designed for easy assembly and corrosion resistance.

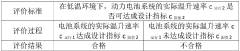

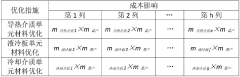

Power battery thermal management evaluation method, electronic device, and storage medium

PatentWO2024113642A1

Innovation

- Using the power battery thermal management evaluation method, by arranging the evaluation test bench, collecting signals and data, decomposing the vehicle working conditions, evaluating the cooling and heating effects, optimizing the design for unqualified solutions, and adjusting the water inlet temperature and cooling of the liquid cooling plate unit Function activation strategy, optimize the heat transfer medium, liquid cooling plate and cooling medium materials until the design specifications are met.

Environmental Impact and Sustainability Considerations

The environmental impact of battery thermal management systems (BTMS) in renewable energy applications extends far beyond operational efficiency. Life cycle assessment (LCA) studies indicate that poorly managed thermal systems can increase the carbon footprint of battery storage by up to 28% through premature degradation and replacement requirements. This environmental burden is particularly significant considering the resource-intensive nature of battery manufacturing, which typically accounts for 60-70% of a battery's lifetime emissions.

Water consumption presents another critical environmental consideration, especially for liquid cooling systems. Advanced BTMS solutions utilizing direct liquid cooling can require 2-5 liters of coolant per kWh of storage capacity, with additional water needed for coolant production and processing. In regions facing water scarcity, this represents a significant sustainability challenge that must be addressed through closed-loop recycling systems and alternative cooling approaches.

Material selection for thermal management components significantly influences the overall environmental profile of energy storage systems. Traditional phase change materials (PCMs) often contain petroleum derivatives with substantial environmental impacts, while newer bio-based PCMs can reduce environmental footprint by 40-60% compared to conventional alternatives. Similarly, the transition from aluminum to graphene-based heat sinks offers potential reductions in embodied energy while improving thermal performance.

End-of-life considerations for BTMS components remain underdeveloped in current sustainability frameworks. Coolants, thermal interface materials, and specialized heat exchange components often contain compounds that require specific recycling protocols. Industry data suggests that less than 15% of these materials are currently recovered effectively, representing a significant opportunity for sustainability improvement through design-for-recycling approaches.

The energy consumption of active cooling systems presents a paradoxical sustainability challenge. While active systems may consume 3-8% of stored energy, they can extend battery lifespans by 30-50% under extreme conditions. This trade-off necessitates sophisticated lifecycle optimization models that consider regional climate conditions, grid carbon intensity, and application-specific thermal profiles to determine the most environmentally beneficial approach.

Regulatory frameworks are increasingly recognizing the environmental implications of thermal management strategies. The EU Battery Directive revision and similar initiatives in Asia-Pacific markets are beginning to incorporate thermal management efficiency metrics into sustainability requirements, potentially creating market advantages for systems with optimized environmental performance profiles.

Water consumption presents another critical environmental consideration, especially for liquid cooling systems. Advanced BTMS solutions utilizing direct liquid cooling can require 2-5 liters of coolant per kWh of storage capacity, with additional water needed for coolant production and processing. In regions facing water scarcity, this represents a significant sustainability challenge that must be addressed through closed-loop recycling systems and alternative cooling approaches.

Material selection for thermal management components significantly influences the overall environmental profile of energy storage systems. Traditional phase change materials (PCMs) often contain petroleum derivatives with substantial environmental impacts, while newer bio-based PCMs can reduce environmental footprint by 40-60% compared to conventional alternatives. Similarly, the transition from aluminum to graphene-based heat sinks offers potential reductions in embodied energy while improving thermal performance.

End-of-life considerations for BTMS components remain underdeveloped in current sustainability frameworks. Coolants, thermal interface materials, and specialized heat exchange components often contain compounds that require specific recycling protocols. Industry data suggests that less than 15% of these materials are currently recovered effectively, representing a significant opportunity for sustainability improvement through design-for-recycling approaches.

The energy consumption of active cooling systems presents a paradoxical sustainability challenge. While active systems may consume 3-8% of stored energy, they can extend battery lifespans by 30-50% under extreme conditions. This trade-off necessitates sophisticated lifecycle optimization models that consider regional climate conditions, grid carbon intensity, and application-specific thermal profiles to determine the most environmentally beneficial approach.

Regulatory frameworks are increasingly recognizing the environmental implications of thermal management strategies. The EU Battery Directive revision and similar initiatives in Asia-Pacific markets are beginning to incorporate thermal management efficiency metrics into sustainability requirements, potentially creating market advantages for systems with optimized environmental performance profiles.

Safety Standards and Regulatory Framework

The regulatory landscape for battery thermal management systems in renewable energy applications has evolved significantly in response to safety incidents and technological advancements. International standards such as IEC 62619 and UL 1973 establish comprehensive requirements for lithium-ion battery safety in stationary applications, with specific provisions addressing thermal runaway prevention and management.

The National Fire Protection Association (NFPA) has developed NFPA 855, which specifically addresses the installation of energy storage systems, including detailed requirements for thermal management, fire detection, and suppression systems. This standard has become increasingly important as large-scale battery installations for renewable energy storage become more common.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize safety requirements with specific thermal management provisions. Meanwhile, China's GB/T 36276 standard focuses on thermal safety testing protocols for energy storage batteries, reflecting the country's growing renewable energy sector.

Testing and certification processes have become increasingly rigorous, with thermal abuse tests forming a critical component of safety certification. These tests simulate extreme conditions to evaluate thermal management system performance under worst-case scenarios, including external fire exposure, thermal propagation, and cycling under extreme temperatures.

Insurance requirements have emerged as an indirect regulatory force, with insurers demanding adherence to thermal management best practices beyond minimum regulatory standards. This market-driven regulation has accelerated the adoption of advanced thermal management technologies in commercial applications.

Regulatory gaps remain in addressing the unique thermal management challenges of renewable energy integration. The intermittent nature of renewable generation creates distinctive charge-discharge patterns that can affect thermal behavior, yet many standards still primarily address constant-load applications typical of traditional energy systems.

Industry self-regulation through organizations like the Energy Storage Association has established voluntary thermal management guidelines that often exceed regulatory minimums. These industry-led initiatives frequently serve as precursors to formal regulations, providing a preview of future compliance requirements for battery thermal management systems in renewable energy applications.

The National Fire Protection Association (NFPA) has developed NFPA 855, which specifically addresses the installation of energy storage systems, including detailed requirements for thermal management, fire detection, and suppression systems. This standard has become increasingly important as large-scale battery installations for renewable energy storage become more common.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize safety requirements with specific thermal management provisions. Meanwhile, China's GB/T 36276 standard focuses on thermal safety testing protocols for energy storage batteries, reflecting the country's growing renewable energy sector.

Testing and certification processes have become increasingly rigorous, with thermal abuse tests forming a critical component of safety certification. These tests simulate extreme conditions to evaluate thermal management system performance under worst-case scenarios, including external fire exposure, thermal propagation, and cycling under extreme temperatures.

Insurance requirements have emerged as an indirect regulatory force, with insurers demanding adherence to thermal management best practices beyond minimum regulatory standards. This market-driven regulation has accelerated the adoption of advanced thermal management technologies in commercial applications.

Regulatory gaps remain in addressing the unique thermal management challenges of renewable energy integration. The intermittent nature of renewable generation creates distinctive charge-discharge patterns that can affect thermal behavior, yet many standards still primarily address constant-load applications typical of traditional energy systems.

Industry self-regulation through organizations like the Energy Storage Association has established voluntary thermal management guidelines that often exceed regulatory minimums. These industry-led initiatives frequently serve as precursors to formal regulations, providing a preview of future compliance requirements for battery thermal management systems in renewable energy applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!