Why Efficient Thermal Management is Key for Battery Durability

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Background and Objectives

Battery thermal management has evolved significantly over the past three decades, paralleling the development of battery technologies themselves. Initially, thermal management was a secondary consideration in battery design, with focus primarily on energy density and charging capabilities. However, as applications expanded from consumer electronics to electric vehicles and grid storage systems, the critical role of temperature control in battery performance and longevity became increasingly apparent.

The evolution of battery thermal management systems (BTMS) can be traced through several key phases. In the 1990s, simple passive cooling methods dominated the landscape. By the early 2000s, the introduction of lithium-ion batteries in portable electronics necessitated more sophisticated approaches to heat dissipation. The electric vehicle revolution of the 2010s marked a paradigm shift, demanding integrated thermal management solutions capable of handling high-power applications and extreme operating conditions.

Current technological trends point toward increasingly sophisticated BTMS designs that incorporate multiple cooling mechanisms, advanced materials, and intelligent control systems. The integration of artificial intelligence and machine learning algorithms for predictive thermal management represents the cutting edge of this field, allowing for dynamic response to changing conditions and usage patterns.

The fundamental objective of battery thermal management is to maintain cells within their optimal temperature window—typically between 15°C and 35°C for most lithium-ion chemistries. This temperature range maximizes performance while minimizing degradation mechanisms such as SEI layer growth, lithium plating, and electrolyte decomposition that occur at temperature extremes.

Beyond temperature maintenance, modern BTMS aims to achieve several critical goals: minimizing temperature gradients across battery packs to prevent uneven aging and performance; enabling rapid charging capabilities without thermal damage; protecting batteries during extreme ambient conditions; and optimizing overall system efficiency by balancing cooling power consumption against battery performance gains.

The stakes for effective thermal management continue to rise as battery applications expand into more demanding environments and use cases. For electric vehicles, thermal management directly impacts range, charging speed, and vehicle lifetime. In grid storage applications, it affects system reliability, response time, and economic viability. For consumer electronics, it influences device performance, safety, and user experience.

As battery technologies continue to evolve toward higher energy densities and faster charging capabilities, the challenges of thermal management grow correspondingly more complex, making this field a critical enabler for the next generation of battery-powered applications.

The evolution of battery thermal management systems (BTMS) can be traced through several key phases. In the 1990s, simple passive cooling methods dominated the landscape. By the early 2000s, the introduction of lithium-ion batteries in portable electronics necessitated more sophisticated approaches to heat dissipation. The electric vehicle revolution of the 2010s marked a paradigm shift, demanding integrated thermal management solutions capable of handling high-power applications and extreme operating conditions.

Current technological trends point toward increasingly sophisticated BTMS designs that incorporate multiple cooling mechanisms, advanced materials, and intelligent control systems. The integration of artificial intelligence and machine learning algorithms for predictive thermal management represents the cutting edge of this field, allowing for dynamic response to changing conditions and usage patterns.

The fundamental objective of battery thermal management is to maintain cells within their optimal temperature window—typically between 15°C and 35°C for most lithium-ion chemistries. This temperature range maximizes performance while minimizing degradation mechanisms such as SEI layer growth, lithium plating, and electrolyte decomposition that occur at temperature extremes.

Beyond temperature maintenance, modern BTMS aims to achieve several critical goals: minimizing temperature gradients across battery packs to prevent uneven aging and performance; enabling rapid charging capabilities without thermal damage; protecting batteries during extreme ambient conditions; and optimizing overall system efficiency by balancing cooling power consumption against battery performance gains.

The stakes for effective thermal management continue to rise as battery applications expand into more demanding environments and use cases. For electric vehicles, thermal management directly impacts range, charging speed, and vehicle lifetime. In grid storage applications, it affects system reliability, response time, and economic viability. For consumer electronics, it influences device performance, safety, and user experience.

As battery technologies continue to evolve toward higher energy densities and faster charging capabilities, the challenges of thermal management grow correspondingly more complex, making this field a critical enabler for the next generation of battery-powered applications.

Market Demand Analysis for Advanced Battery Cooling Solutions

The global market for advanced battery cooling solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the thermal management systems market for EVs is projected to reach $5.7 billion by 2025, growing at a CAGR of 22.6% from 2020. This surge reflects the critical importance of efficient thermal management in ensuring battery durability and performance across various applications.

Consumer demand for longer-range electric vehicles has intensified the need for sophisticated cooling technologies. Range anxiety remains a significant barrier to EV adoption, with surveys showing that 78% of potential EV buyers consider battery longevity and range as their top concerns. This consumer sentiment has created substantial market pull for advanced thermal management solutions that can extend battery life and maintain consistent performance.

The industrial sector represents another significant market segment, with stationary energy storage systems requiring robust thermal management to ensure operational reliability and longevity. Grid-scale battery installations are projected to increase by 35% annually through 2025, creating additional demand for scalable cooling solutions that can operate efficiently in diverse environmental conditions.

Regulatory frameworks are also driving market growth, with increasingly stringent safety standards being implemented globally. Following several high-profile battery thermal runaway incidents, regulatory bodies have established more comprehensive safety requirements. The UN Global Technical Regulation No. 20 and similar regional standards have created immediate market demand for thermal management systems that can prevent catastrophic failure scenarios.

Market segmentation reveals varying needs across different applications. The passenger vehicle segment currently dominates demand, accounting for approximately 65% of the market share. However, commercial vehicle applications are growing at a faster rate (27% CAGR) due to the electrification of delivery fleets and public transportation systems, each with unique thermal management requirements.

Geographically, Asia-Pacific represents the largest market for advanced battery cooling solutions, with China alone accounting for 38% of global demand. This regional concentration aligns with the distribution of battery manufacturing capacity and EV production. However, North American and European markets are showing accelerated growth rates as domestic EV production increases and energy storage deployments expand.

Consumer willingness to pay for advanced thermal management features has also increased, with premium EV buyers demonstrating acceptance of price premiums for systems that guarantee longer battery warranties and improved performance in extreme conditions. This trend indicates a maturing market where value-based pricing strategies can be successfully implemented for superior thermal management technologies.

Consumer demand for longer-range electric vehicles has intensified the need for sophisticated cooling technologies. Range anxiety remains a significant barrier to EV adoption, with surveys showing that 78% of potential EV buyers consider battery longevity and range as their top concerns. This consumer sentiment has created substantial market pull for advanced thermal management solutions that can extend battery life and maintain consistent performance.

The industrial sector represents another significant market segment, with stationary energy storage systems requiring robust thermal management to ensure operational reliability and longevity. Grid-scale battery installations are projected to increase by 35% annually through 2025, creating additional demand for scalable cooling solutions that can operate efficiently in diverse environmental conditions.

Regulatory frameworks are also driving market growth, with increasingly stringent safety standards being implemented globally. Following several high-profile battery thermal runaway incidents, regulatory bodies have established more comprehensive safety requirements. The UN Global Technical Regulation No. 20 and similar regional standards have created immediate market demand for thermal management systems that can prevent catastrophic failure scenarios.

Market segmentation reveals varying needs across different applications. The passenger vehicle segment currently dominates demand, accounting for approximately 65% of the market share. However, commercial vehicle applications are growing at a faster rate (27% CAGR) due to the electrification of delivery fleets and public transportation systems, each with unique thermal management requirements.

Geographically, Asia-Pacific represents the largest market for advanced battery cooling solutions, with China alone accounting for 38% of global demand. This regional concentration aligns with the distribution of battery manufacturing capacity and EV production. However, North American and European markets are showing accelerated growth rates as domestic EV production increases and energy storage deployments expand.

Consumer willingness to pay for advanced thermal management features has also increased, with premium EV buyers demonstrating acceptance of price premiums for systems that guarantee longer battery warranties and improved performance in extreme conditions. This trend indicates a maturing market where value-based pricing strategies can be successfully implemented for superior thermal management technologies.

Current Thermal Management Technologies and Challenges

Battery thermal management systems (BTMS) have evolved significantly over the past decade, with several technologies currently dominating the market. Passive cooling systems, which rely on natural heat dissipation through materials with high thermal conductivity, represent the most basic approach. These systems typically employ phase change materials (PCMs) that absorb heat during phase transition, providing temperature regulation without external power requirements. While cost-effective and maintenance-free, passive systems often struggle to manage extreme temperature conditions, limiting their application in high-performance electric vehicles.

Active cooling technologies have become increasingly prevalent, with liquid cooling emerging as the industry standard for premium electric vehicles. These systems circulate coolant through channels integrated within or around battery cells, offering superior heat transfer capabilities compared to passive alternatives. Major manufacturers like Tesla, Porsche, and BMW have implemented sophisticated liquid cooling architectures that maintain optimal battery temperature ranges even under demanding operating conditions. However, these systems add complexity, weight, and cost to vehicle designs.

Air cooling systems, utilizing forced convection through strategically placed channels, represent a middle-ground solution adopted by manufacturers seeking balance between cost and performance. While less efficient than liquid cooling, modern air-based systems with advanced thermal management algorithms have demonstrated adequate performance for many consumer applications, particularly in moderate climate regions.

Despite these advancements, significant challenges persist in battery thermal management. Temperature gradients within battery packs remain problematic, with cells at different locations experiencing varying thermal conditions, leading to uneven aging and potential safety risks. Current technologies struggle to simultaneously address both overheating during fast charging and insufficient warming in cold environments, often requiring separate heating and cooling subsystems that increase system complexity.

Energy efficiency presents another critical challenge, as thermal management systems can consume 5-15% of a battery's total energy capacity, directly impacting vehicle range. This parasitic energy loss becomes particularly problematic in extreme weather conditions when thermal management demands peak. Additionally, the industry faces a fundamental design conflict between thermal performance and energy density, as the integration of cooling channels and thermal materials reduces the volumetric efficiency of battery packs.

Emerging markets and regulatory requirements have introduced additional complexities, with varying climate conditions across global markets necessitating adaptable thermal solutions. Meanwhile, fast-charging capabilities, increasingly demanded by consumers, generate substantial heat that exceeds the capacity of many current thermal management systems, creating a technological bottleneck for charging speed improvements.

Active cooling technologies have become increasingly prevalent, with liquid cooling emerging as the industry standard for premium electric vehicles. These systems circulate coolant through channels integrated within or around battery cells, offering superior heat transfer capabilities compared to passive alternatives. Major manufacturers like Tesla, Porsche, and BMW have implemented sophisticated liquid cooling architectures that maintain optimal battery temperature ranges even under demanding operating conditions. However, these systems add complexity, weight, and cost to vehicle designs.

Air cooling systems, utilizing forced convection through strategically placed channels, represent a middle-ground solution adopted by manufacturers seeking balance between cost and performance. While less efficient than liquid cooling, modern air-based systems with advanced thermal management algorithms have demonstrated adequate performance for many consumer applications, particularly in moderate climate regions.

Despite these advancements, significant challenges persist in battery thermal management. Temperature gradients within battery packs remain problematic, with cells at different locations experiencing varying thermal conditions, leading to uneven aging and potential safety risks. Current technologies struggle to simultaneously address both overheating during fast charging and insufficient warming in cold environments, often requiring separate heating and cooling subsystems that increase system complexity.

Energy efficiency presents another critical challenge, as thermal management systems can consume 5-15% of a battery's total energy capacity, directly impacting vehicle range. This parasitic energy loss becomes particularly problematic in extreme weather conditions when thermal management demands peak. Additionally, the industry faces a fundamental design conflict between thermal performance and energy density, as the integration of cooling channels and thermal materials reduces the volumetric efficiency of battery packs.

Emerging markets and regulatory requirements have introduced additional complexities, with varying climate conditions across global markets necessitating adaptable thermal solutions. Meanwhile, fast-charging capabilities, increasingly demanded by consumers, generate substantial heat that exceeds the capacity of many current thermal management systems, creating a technological bottleneck for charging speed improvements.

Existing Thermal Control Solutions for Battery Longevity

01 Thermal management system design for battery durability

Advanced thermal management system designs focus on maintaining optimal battery temperature ranges to extend battery life and ensure durability. These systems incorporate various cooling and heating mechanisms to prevent thermal runaway and degradation during extreme operating conditions. Effective thermal management designs balance cooling efficiency with energy consumption while providing uniform temperature distribution across battery packs.- Thermal management system design for battery durability: Advanced thermal management system designs can significantly enhance battery durability by maintaining optimal operating temperatures. These systems incorporate various cooling and heating mechanisms to prevent thermal runaway and extend battery life. Effective thermal management prevents degradation caused by temperature extremes, ensuring consistent performance over the battery's lifecycle and improving overall durability in various operating conditions.

- Cooling technologies for battery longevity: Specialized cooling technologies play a crucial role in maintaining battery durability by efficiently dissipating heat. These include liquid cooling systems, phase change materials, and air cooling mechanisms that prevent overheating during high-demand operations. By maintaining optimal temperature ranges, these cooling technologies minimize thermal stress on battery components, reduce degradation rates, and extend the operational lifespan of battery systems.

- Materials and coatings for thermal durability enhancement: Advanced materials and protective coatings can significantly improve the thermal durability of battery systems. These include thermally conductive materials, insulating compounds, and specialized coatings that enhance heat transfer or provide thermal isolation. By incorporating these materials into battery pack designs, manufacturers can improve thermal stability, reduce hotspots, and enhance overall system durability under various thermal stress conditions.

- Monitoring and control systems for thermal management: Sophisticated monitoring and control systems are essential for maintaining battery durability through active thermal management. These systems utilize temperature sensors, predictive algorithms, and adaptive control mechanisms to continuously monitor battery conditions and adjust cooling or heating as needed. By preventing thermal extremes and maintaining optimal operating temperatures, these intelligent systems significantly extend battery life and ensure reliable performance over time.

- Testing and validation methods for thermal durability: Comprehensive testing and validation protocols are critical for ensuring the long-term durability of battery thermal management systems. These include accelerated aging tests, thermal cycling, extreme temperature exposure, and real-world simulation testing. By subjecting battery systems to controlled stress conditions, manufacturers can identify potential failure points, optimize thermal management strategies, and validate the durability of their designs before deployment in commercial applications.

02 Cooling technologies for battery longevity

Various cooling technologies are employed to enhance battery durability, including liquid cooling, air cooling, phase change materials, and hybrid cooling systems. These technologies help dissipate heat efficiently from battery cells during high-load operations and fast charging, preventing premature aging and capacity loss. Advanced cooling systems are designed to provide uniform temperature distribution across battery modules to avoid localized hotspots that can accelerate degradation.Expand Specific Solutions03 Thermal insulation and protective materials

Specialized thermal insulation and protective materials are integrated into battery thermal management systems to enhance durability. These materials provide thermal barriers that protect batteries from external temperature fluctuations and help maintain stable internal temperatures. Advanced composites and phase change materials are used to absorb excess heat during peak operation and release it when needed, contributing to extended battery lifespan and improved performance under varying environmental conditions.Expand Specific Solutions04 Durability testing and validation methods

Comprehensive testing and validation methods are essential for ensuring the long-term durability of battery thermal management systems. These include accelerated aging tests, thermal cycling, vibration testing, and simulation of extreme environmental conditions. Advanced diagnostic tools monitor thermal performance over time, allowing for early detection of potential failure points. Testing protocols evaluate system performance under various load conditions and temperature extremes to verify that thermal management systems can maintain optimal battery conditions throughout the expected service life.Expand Specific Solutions05 Intelligent thermal management control systems

Intelligent control systems enhance battery thermal management durability through predictive algorithms and real-time monitoring. These systems use sensors to continuously track battery temperature, state of charge, and environmental conditions to optimize thermal management strategies. Adaptive control algorithms adjust cooling or heating parameters based on usage patterns and environmental factors, preventing unnecessary thermal stress. Machine learning capabilities enable the system to improve performance over time by learning from operational data and anticipating thermal management needs before critical thresholds are reached.Expand Specific Solutions

Leading Companies in Battery Thermal Management Industry

The thermal management technology for battery durability is currently in a growth phase, with the market expected to reach significant expansion as electric vehicle adoption accelerates globally. Key players like Contemporary Amperex Technology (CATL), BYD, and LG Energy Solution are leading commercial development, while QuantumScape and A123 Systems are advancing next-generation solutions. Academic institutions including Xi'an Jiaotong University and University of Michigan contribute fundamental research. The technology is approaching maturity in conventional lithium-ion applications but remains developmental for solid-state batteries. Automotive manufacturers such as Volvo, Ford, and Rivian are integrating advanced thermal management systems to enhance battery performance and longevity, indicating the technology's critical importance across the EV value chain.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive thermal management system for their battery packs that combines liquid cooling with phase change materials (PCMs). Their Cell-to-Pack (CTP) technology integrates thermal management directly into the battery structure, eliminating the need for separate modules and reducing thermal resistance between cells. CATL's system utilizes a network of cooling channels that distribute coolant uniformly across the battery pack, maintaining temperature differences between cells below 3°C even under high discharge rates. Their latest innovation includes intelligent thermal management algorithms that predict thermal behavior based on operating conditions and adjust cooling parameters proactively rather than reactively. CATL has also pioneered the use of dielectric coolants that can be in direct contact with electrical components, improving heat transfer efficiency by approximately 30% compared to traditional indirect cooling methods.

Strengths: Superior temperature uniformity across large battery packs, reduced thermal resistance through structural integration, and predictive thermal management capabilities. Weaknesses: Higher manufacturing complexity and cost compared to simpler cooling systems, and potential for coolant leakage issues in their liquid cooling implementations.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology with an integrated thermal management system specifically designed to prevent thermal runaway. Their approach uses a cell-level cooling strategy where each cell is surrounded by cooling plates on multiple sides, creating redundant thermal pathways. The Blade Battery's unique form factor (thin and long cells) inherently improves heat dissipation by increasing the surface-to-volume ratio. BYD's thermal management system incorporates a dual-loop liquid cooling circuit - a primary loop for normal operation and a secondary emergency cooling system that activates during potential thermal events. Their system also features thermal isolation barriers between cells that prevent heat propagation during failure scenarios. BYD has implemented advanced thermal monitoring with distributed temperature sensors that provide high-resolution thermal mapping of the entire battery pack, enabling precise cooling control based on real-time temperature gradients.

Strengths: Exceptional thermal runaway prevention, optimized cell geometry for passive heat dissipation, and redundant cooling systems for safety. Weaknesses: The specialized cell format limits manufacturing flexibility, and the complex dual-loop cooling system adds weight and maintenance requirements to the overall battery system.

Key Innovations in Battery Temperature Regulation

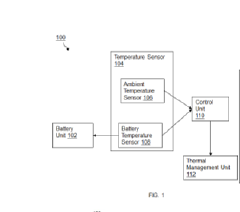

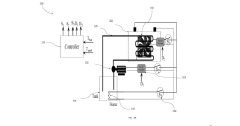

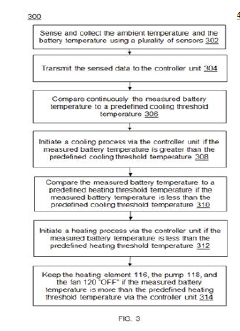

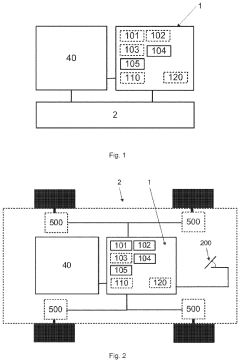

A battery thermal management system and method thereof

PatentPendingIN202411018158A

Innovation

- A battery thermal management system using liquid cooling and heating with a controller unit, temperature sensors, and a thermal management unit that includes a tank, heating element, pump, fan, and switches to regulate temperature through convection, allowing for real-time temperature control and efficient operation across high and low temperature ranges.

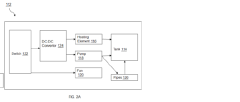

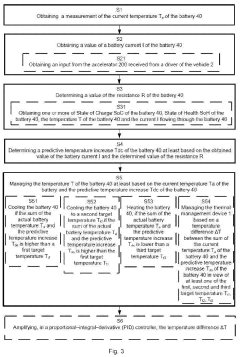

Thermal management system

PatentPendingUS20200127342A1

Innovation

- A method and device that proactively manage battery temperature by measuring current temperature and predictive temperature increase based on current and resistance, using a feedforward approach to anticipate and mitigate temperature changes, thereby preventing overheating and extending battery life.

Safety Standards and Compliance Requirements

Battery thermal management systems must adhere to rigorous safety standards and compliance requirements established by various regulatory bodies worldwide. The International Electrotechnical Commission (IEC) has developed specific standards such as IEC 62133 for portable batteries and IEC 61960 for lithium-ion batteries, which outline safety requirements including thermal management specifications. These standards mandate temperature control mechanisms and define acceptable operating temperature ranges to prevent thermal runaway incidents.

In the automotive sector, standards like ISO 6469-1 specifically address safety requirements for electrically propelled road vehicles, with detailed provisions for battery thermal management systems. These standards require manufacturers to implement robust thermal monitoring, control systems, and emergency response mechanisms to maintain battery temperatures within safe operational limits.

Underwriters Laboratories (UL) has established UL 2580 for batteries in electric vehicles, which includes comprehensive testing protocols for thermal abuse resistance. These tests evaluate how battery systems respond to extreme temperature conditions and thermal cycling, ensuring they can safely manage heat during various operational scenarios.

Regional regulations add another layer of compliance requirements. The United Nations Economic Commission for Europe (UNECE) Regulation No. 100 specifies safety provisions for electric power trains, including thermal management requirements. In the United States, the National Highway Traffic Safety Administration (NHTSA) has developed specific guidelines for electric vehicle battery safety that incorporate thermal management considerations.

For consumer electronics, standards like UL 1642 for lithium batteries establish safety criteria that manufacturers must meet, including thermal stability requirements. These standards are continuously evolving as battery technologies advance and new thermal management challenges emerge.

Compliance with these standards requires comprehensive testing regimes, including thermal shock tests, temperature cycling, and heat generation assessments under various load conditions. Manufacturers must document their thermal management strategies and demonstrate through testing that their systems can effectively prevent thermal runaway and maintain safe operating temperatures across the battery's lifecycle.

Failure to comply with these standards can result in significant legal and financial consequences, including product recalls, market access restrictions, and liability issues. Therefore, thermal management system design must prioritize not only performance and durability but also strict adherence to these evolving regulatory frameworks to ensure market acceptance and consumer safety.

In the automotive sector, standards like ISO 6469-1 specifically address safety requirements for electrically propelled road vehicles, with detailed provisions for battery thermal management systems. These standards require manufacturers to implement robust thermal monitoring, control systems, and emergency response mechanisms to maintain battery temperatures within safe operational limits.

Underwriters Laboratories (UL) has established UL 2580 for batteries in electric vehicles, which includes comprehensive testing protocols for thermal abuse resistance. These tests evaluate how battery systems respond to extreme temperature conditions and thermal cycling, ensuring they can safely manage heat during various operational scenarios.

Regional regulations add another layer of compliance requirements. The United Nations Economic Commission for Europe (UNECE) Regulation No. 100 specifies safety provisions for electric power trains, including thermal management requirements. In the United States, the National Highway Traffic Safety Administration (NHTSA) has developed specific guidelines for electric vehicle battery safety that incorporate thermal management considerations.

For consumer electronics, standards like UL 1642 for lithium batteries establish safety criteria that manufacturers must meet, including thermal stability requirements. These standards are continuously evolving as battery technologies advance and new thermal management challenges emerge.

Compliance with these standards requires comprehensive testing regimes, including thermal shock tests, temperature cycling, and heat generation assessments under various load conditions. Manufacturers must document their thermal management strategies and demonstrate through testing that their systems can effectively prevent thermal runaway and maintain safe operating temperatures across the battery's lifecycle.

Failure to comply with these standards can result in significant legal and financial consequences, including product recalls, market access restrictions, and liability issues. Therefore, thermal management system design must prioritize not only performance and durability but also strict adherence to these evolving regulatory frameworks to ensure market acceptance and consumer safety.

Environmental Impact of Thermal Management Systems

The environmental implications of battery thermal management systems extend far beyond their primary function of maintaining optimal operating temperatures. As global environmental concerns intensify, the ecological footprint of these systems has become a critical consideration in sustainable technology development.

Traditional cooling systems often rely on refrigerants with high global warming potential (GWP), contributing significantly to greenhouse gas emissions. For instance, conventional air conditioning systems in electric vehicles using hydrofluorocarbons (HFCs) can have a GWP thousands of times greater than CO2. The transition toward natural refrigerants and passive cooling technologies represents a substantial opportunity to mitigate these impacts.

Energy consumption presents another environmental challenge. Active cooling systems can consume 5-20% of a battery's stored energy, reducing vehicle range and efficiency while indirectly increasing carbon emissions from power generation. This parasitic energy loss translates to higher lifetime emissions, particularly in regions where electricity generation remains carbon-intensive.

Material selection for thermal management components raises additional environmental concerns. Many high-performance thermal interface materials contain rare earth elements or environmentally problematic substances. The mining and processing of these materials often involve significant water usage, habitat disruption, and potential toxic releases into local ecosystems.

End-of-life considerations further complicate the environmental assessment. Thermal management systems typically incorporate multiple materials that are difficult to separate during recycling processes. Coolants, in particular, require specialized handling to prevent environmental contamination, yet collection infrastructure remains inadequate in many regions.

Lifecycle assessment studies indicate that advanced thermal management solutions can reduce a battery's overall environmental impact by extending its useful life. A battery that lasts twice as long effectively halves the environmental burden of manufacturing replacement units. This relationship creates a compelling environmental case for investing in efficient thermal management, despite the initial material and energy investments.

Water consumption represents an often-overlooked environmental dimension. Liquid cooling systems require significant water resources during manufacturing and, in some cases, during operation. As water scarcity becomes more prevalent globally, the water footprint of thermal management technologies warrants greater attention in sustainability assessments.

Traditional cooling systems often rely on refrigerants with high global warming potential (GWP), contributing significantly to greenhouse gas emissions. For instance, conventional air conditioning systems in electric vehicles using hydrofluorocarbons (HFCs) can have a GWP thousands of times greater than CO2. The transition toward natural refrigerants and passive cooling technologies represents a substantial opportunity to mitigate these impacts.

Energy consumption presents another environmental challenge. Active cooling systems can consume 5-20% of a battery's stored energy, reducing vehicle range and efficiency while indirectly increasing carbon emissions from power generation. This parasitic energy loss translates to higher lifetime emissions, particularly in regions where electricity generation remains carbon-intensive.

Material selection for thermal management components raises additional environmental concerns. Many high-performance thermal interface materials contain rare earth elements or environmentally problematic substances. The mining and processing of these materials often involve significant water usage, habitat disruption, and potential toxic releases into local ecosystems.

End-of-life considerations further complicate the environmental assessment. Thermal management systems typically incorporate multiple materials that are difficult to separate during recycling processes. Coolants, in particular, require specialized handling to prevent environmental contamination, yet collection infrastructure remains inadequate in many regions.

Lifecycle assessment studies indicate that advanced thermal management solutions can reduce a battery's overall environmental impact by extending its useful life. A battery that lasts twice as long effectively halves the environmental burden of manufacturing replacement units. This relationship creates a compelling environmental case for investing in efficient thermal management, despite the initial material and energy investments.

Water consumption represents an often-overlooked environmental dimension. Liquid cooling systems require significant water resources during manufacturing and, in some cases, during operation. As water scarcity becomes more prevalent globally, the water footprint of thermal management technologies warrants greater attention in sustainability assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!