Why Thermal Stability is Crucial in Battery Thermal Management Systems

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Stability Background and Objectives

Battery thermal management has evolved significantly over the past decades, transitioning from simple cooling systems to sophisticated thermal regulation technologies. Initially, battery thermal concerns were minimal due to the limited energy density and power output of early battery technologies. However, with the rapid advancement of lithium-ion batteries in the 1990s and their widespread adoption in portable electronics, electric vehicles, and energy storage systems, thermal management has become a critical aspect of battery system design.

The evolution of battery thermal management systems (BTMS) has been driven by several factors, including increasing energy densities, faster charging capabilities, and the growing demand for longer battery life and enhanced safety. Historical incidents involving battery thermal runaway, such as the Boeing 787 Dreamliner battery fires in 2013 and numerous electric vehicle fires, have highlighted the critical importance of effective thermal management in battery systems.

Current technological trends in battery thermal management focus on active cooling systems, phase change materials, direct liquid cooling, and advanced thermal modeling techniques. These developments aim to address the challenges posed by next-generation battery chemistries, which offer higher energy densities but also present greater thermal management challenges.

The primary objective of battery thermal stability research is to develop systems that can maintain optimal operating temperatures across various usage conditions, from extreme ambient temperatures to high-power charging and discharging scenarios. This involves understanding the complex heat generation mechanisms within battery cells, including electrochemical reactions, joule heating, and entropy changes.

Another crucial goal is to prevent thermal runaway events, where uncontrolled temperature increases lead to catastrophic battery failure. This requires sophisticated early detection systems and effective heat dissipation strategies that can rapidly respond to thermal anomalies before they escalate.

Long-term objectives include the development of predictive thermal management systems that can anticipate thermal behavior based on usage patterns and environmental conditions, allowing for proactive rather than reactive thermal control. Additionally, there is a growing focus on creating more energy-efficient thermal management solutions that minimize parasitic power losses while maintaining optimal battery temperatures.

As battery technologies continue to evolve toward solid-state and other advanced chemistries, thermal management strategies must adapt accordingly. The ultimate aim is to create thermal management systems that enhance battery performance, extend operational lifetimes, ensure safety under all conditions, and contribute to the overall sustainability of battery-powered applications.

The evolution of battery thermal management systems (BTMS) has been driven by several factors, including increasing energy densities, faster charging capabilities, and the growing demand for longer battery life and enhanced safety. Historical incidents involving battery thermal runaway, such as the Boeing 787 Dreamliner battery fires in 2013 and numerous electric vehicle fires, have highlighted the critical importance of effective thermal management in battery systems.

Current technological trends in battery thermal management focus on active cooling systems, phase change materials, direct liquid cooling, and advanced thermal modeling techniques. These developments aim to address the challenges posed by next-generation battery chemistries, which offer higher energy densities but also present greater thermal management challenges.

The primary objective of battery thermal stability research is to develop systems that can maintain optimal operating temperatures across various usage conditions, from extreme ambient temperatures to high-power charging and discharging scenarios. This involves understanding the complex heat generation mechanisms within battery cells, including electrochemical reactions, joule heating, and entropy changes.

Another crucial goal is to prevent thermal runaway events, where uncontrolled temperature increases lead to catastrophic battery failure. This requires sophisticated early detection systems and effective heat dissipation strategies that can rapidly respond to thermal anomalies before they escalate.

Long-term objectives include the development of predictive thermal management systems that can anticipate thermal behavior based on usage patterns and environmental conditions, allowing for proactive rather than reactive thermal control. Additionally, there is a growing focus on creating more energy-efficient thermal management solutions that minimize parasitic power losses while maintaining optimal battery temperatures.

As battery technologies continue to evolve toward solid-state and other advanced chemistries, thermal management strategies must adapt accordingly. The ultimate aim is to create thermal management systems that enhance battery performance, extend operational lifetimes, ensure safety under all conditions, and contribute to the overall sustainability of battery-powered applications.

Market Demand Analysis for Advanced Thermal Management

The global market for advanced thermal management systems in batteries is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage solutions. Current market valuations indicate that the battery thermal management system (BTMS) sector is projected to reach $5.2 billion by 2025, with a compound annual growth rate of 22.4% from 2020. This remarkable growth trajectory reflects the increasing recognition of thermal stability as a critical factor in battery performance, safety, and longevity.

Consumer demand for EVs with extended range capabilities has intensified the need for more sophisticated thermal management solutions. Market research reveals that over 78% of potential EV buyers consider driving range as their primary concern, directly correlating with battery performance under various thermal conditions. Additionally, fast-charging capabilities, which generate significant heat and thermal stress, have become a standard expectation among consumers, with 65% of users indicating preference for vehicles offering charging times under 30 minutes.

The industrial and grid-scale energy storage sectors are similarly driving demand for advanced thermal management. As renewable energy integration accelerates globally, the energy storage market is expected to deploy over 741 GWh of capacity by 2030, all requiring robust thermal management systems to ensure operational efficiency and safety. Commercial applications, particularly in telecommunications and data centers, represent another significant market segment, with cooling solutions for battery backup systems becoming increasingly critical as data consumption continues to rise at 26% annually.

Regulatory frameworks are further catalyzing market growth. Safety standards such as UN 38.3, IEC 62133, and UL 1642 have established stringent requirements for battery thermal performance under extreme conditions. Moreover, insurance providers are increasingly differentiating premiums based on the quality of thermal management systems implemented, creating additional economic incentives for advanced solutions.

Regional analysis indicates that Asia-Pacific currently dominates the BTMS market with 42% share, followed by North America (28%) and Europe (24%). However, Europe is showing the fastest growth rate at 25.7% annually, driven by aggressive EV adoption policies and stringent safety regulations. Emerging markets in South America and Africa are expected to present significant opportunities as renewable energy and EV infrastructure expand in these regions.

The market is also witnessing a shift toward integrated thermal management approaches that address multiple vehicle systems simultaneously, optimizing overall energy efficiency. This trend is reflected in consumer willingness to pay premium prices for vehicles with advanced thermal management capabilities, with surveys indicating up to 15% price tolerance for systems that demonstrably extend battery life and improve performance.

Consumer demand for EVs with extended range capabilities has intensified the need for more sophisticated thermal management solutions. Market research reveals that over 78% of potential EV buyers consider driving range as their primary concern, directly correlating with battery performance under various thermal conditions. Additionally, fast-charging capabilities, which generate significant heat and thermal stress, have become a standard expectation among consumers, with 65% of users indicating preference for vehicles offering charging times under 30 minutes.

The industrial and grid-scale energy storage sectors are similarly driving demand for advanced thermal management. As renewable energy integration accelerates globally, the energy storage market is expected to deploy over 741 GWh of capacity by 2030, all requiring robust thermal management systems to ensure operational efficiency and safety. Commercial applications, particularly in telecommunications and data centers, represent another significant market segment, with cooling solutions for battery backup systems becoming increasingly critical as data consumption continues to rise at 26% annually.

Regulatory frameworks are further catalyzing market growth. Safety standards such as UN 38.3, IEC 62133, and UL 1642 have established stringent requirements for battery thermal performance under extreme conditions. Moreover, insurance providers are increasingly differentiating premiums based on the quality of thermal management systems implemented, creating additional economic incentives for advanced solutions.

Regional analysis indicates that Asia-Pacific currently dominates the BTMS market with 42% share, followed by North America (28%) and Europe (24%). However, Europe is showing the fastest growth rate at 25.7% annually, driven by aggressive EV adoption policies and stringent safety regulations. Emerging markets in South America and Africa are expected to present significant opportunities as renewable energy and EV infrastructure expand in these regions.

The market is also witnessing a shift toward integrated thermal management approaches that address multiple vehicle systems simultaneously, optimizing overall energy efficiency. This trend is reflected in consumer willingness to pay premium prices for vehicles with advanced thermal management capabilities, with surveys indicating up to 15% price tolerance for systems that demonstrably extend battery life and improve performance.

Current Challenges in Battery Thermal Management Systems

Battery Thermal Management Systems (BTMS) face numerous challenges in today's rapidly evolving energy storage landscape. The primary challenge remains achieving uniform temperature distribution across battery cells. Temperature gradients as small as 5°C between cells can lead to significant performance disparities, accelerated degradation, and potential safety hazards. This non-uniformity becomes increasingly problematic as battery packs grow in size and energy density to meet demands for longer range electric vehicles and larger energy storage systems.

Heat dissipation represents another critical challenge, particularly for high-power applications. Modern lithium-ion batteries can generate substantial heat during fast charging and discharging cycles, with thermal energy production sometimes exceeding 50W per cell under extreme conditions. Conventional cooling systems often struggle to remove this heat efficiently without adding significant weight, volume, or parasitic power consumption to the overall system.

The integration of BTMS with battery management systems (BMS) presents complex technical hurdles. While thermal management and electrical management are inherently interconnected, they frequently operate as separate systems with limited data exchange. This separation creates inefficiencies and missed opportunities for predictive thermal management based on electrical load forecasting.

Material limitations further constrain BTMS development. Current phase change materials, thermal interface materials, and coolants each present trade-offs between thermal conductivity, specific heat capacity, weight, cost, and environmental impact. For instance, many high-performance thermal interface materials contain environmentally problematic compounds, while safer alternatives often deliver inferior thermal performance.

Space and weight constraints pose significant design challenges, particularly in mobile applications. The automotive industry demands BTMS solutions that minimize volume and mass while maximizing thermal performance. This creates a complex optimization problem where thermal engineers must balance cooling capacity against the practical limitations of vehicle design.

Energy efficiency of the BTMS itself represents a growing concern. Active cooling systems can consume 1-3% of a battery's total energy capacity, creating a parasitic load that reduces overall system efficiency. This becomes particularly problematic in applications where energy conservation is paramount, such as in electric vehicles where every kilowatt-hour affects range.

Cost considerations remain a persistent challenge across all BTMS designs. Advanced thermal management solutions incorporating liquid cooling, heat pipes, or sophisticated control systems add significant cost to battery systems, sometimes accounting for 10-15% of total battery pack costs in high-performance applications.

Heat dissipation represents another critical challenge, particularly for high-power applications. Modern lithium-ion batteries can generate substantial heat during fast charging and discharging cycles, with thermal energy production sometimes exceeding 50W per cell under extreme conditions. Conventional cooling systems often struggle to remove this heat efficiently without adding significant weight, volume, or parasitic power consumption to the overall system.

The integration of BTMS with battery management systems (BMS) presents complex technical hurdles. While thermal management and electrical management are inherently interconnected, they frequently operate as separate systems with limited data exchange. This separation creates inefficiencies and missed opportunities for predictive thermal management based on electrical load forecasting.

Material limitations further constrain BTMS development. Current phase change materials, thermal interface materials, and coolants each present trade-offs between thermal conductivity, specific heat capacity, weight, cost, and environmental impact. For instance, many high-performance thermal interface materials contain environmentally problematic compounds, while safer alternatives often deliver inferior thermal performance.

Space and weight constraints pose significant design challenges, particularly in mobile applications. The automotive industry demands BTMS solutions that minimize volume and mass while maximizing thermal performance. This creates a complex optimization problem where thermal engineers must balance cooling capacity against the practical limitations of vehicle design.

Energy efficiency of the BTMS itself represents a growing concern. Active cooling systems can consume 1-3% of a battery's total energy capacity, creating a parasitic load that reduces overall system efficiency. This becomes particularly problematic in applications where energy conservation is paramount, such as in electric vehicles where every kilowatt-hour affects range.

Cost considerations remain a persistent challenge across all BTMS designs. Advanced thermal management solutions incorporating liquid cooling, heat pipes, or sophisticated control systems add significant cost to battery systems, sometimes accounting for 10-15% of total battery pack costs in high-performance applications.

Current Thermal Stability Management Approaches

01 Active cooling systems for battery thermal management

Active cooling systems utilize liquid or air circulation to regulate battery temperature and maintain thermal stability. These systems can include coolant channels, heat exchangers, and pumps to efficiently remove heat from battery cells. By actively controlling the temperature, these systems prevent thermal runaway and extend battery life while ensuring optimal performance under various operating conditions.- Active cooling systems for battery thermal management: Active cooling systems utilize liquid or air circulation to regulate battery temperature and maintain thermal stability. These systems can include coolant channels, heat exchangers, and pumps to efficiently remove heat from battery cells. By actively controlling the temperature, these systems prevent thermal runaway and extend battery life while ensuring optimal performance under various operating conditions.

- Phase change materials for thermal stability: Phase change materials (PCMs) absorb and release thermal energy during phase transitions, providing passive thermal management for batteries. When integrated into battery packs, PCMs absorb excess heat during high-load operations and release it when temperatures drop, maintaining optimal operating temperatures. This approach helps prevent thermal runaway and improves overall thermal stability without requiring continuous power input.

- Thermal insulation and isolation strategies: Thermal insulation and isolation strategies involve using specialized materials and designs to prevent heat transfer between battery cells and from external heat sources. These approaches include cell-to-cell barriers, insulating layers, and thermal breaks that contain potential thermal events within a limited area. By preventing thermal propagation, these systems enhance the overall safety and stability of battery packs even when individual cells fail.

- Intelligent thermal management control systems: Intelligent control systems use sensors, algorithms, and predictive modeling to dynamically manage battery thermal conditions. These systems continuously monitor temperature, voltage, and current to anticipate thermal issues before they occur. By adjusting cooling intensity, load distribution, and charging parameters in real-time, intelligent systems optimize thermal stability while minimizing energy consumption for thermal management functions.

- Structural design for enhanced heat dissipation: Innovative structural designs improve heat dissipation in battery packs through optimized cell arrangement, integrated heat sinks, and enhanced thermal pathways. These designs include honeycomb structures, finned surfaces, and thermally conductive materials strategically placed to maximize heat transfer efficiency. By addressing thermal management at the fundamental design level, these approaches provide passive thermal stability benefits that complement active cooling systems.

02 Phase change materials for thermal stability

Phase change materials (PCMs) absorb and release thermal energy during phase transitions, providing passive thermal management for batteries. When integrated into battery packs, PCMs absorb excess heat during high-load operations and release it when temperatures drop, maintaining optimal operating temperatures. This approach helps prevent thermal runaway events and improves overall thermal stability without requiring active energy consumption.Expand Specific Solutions03 Battery cell arrangement and thermal isolation techniques

Strategic arrangement of battery cells with thermal isolation barriers helps manage heat distribution within battery packs. By incorporating thermal interface materials, insulation layers, and optimized cell spacing, these designs prevent thermal propagation between cells. This approach minimizes the risk of cascading thermal events and enhances overall system stability, particularly important for high-energy density applications.Expand Specific Solutions04 Thermal monitoring and control systems

Advanced thermal monitoring systems use temperature sensors, thermal imaging, and predictive algorithms to detect potential thermal issues before they escalate. These systems continuously monitor battery temperature profiles and can trigger preventive measures when abnormal patterns are detected. Integration with battery management systems allows for real-time adjustments to charging/discharging rates based on thermal conditions, enhancing safety and stability.Expand Specific Solutions05 Hybrid thermal management approaches

Hybrid thermal management systems combine multiple cooling and heating methods to optimize battery thermal stability across diverse operating conditions. These systems may integrate liquid cooling, air cooling, phase change materials, and heating elements in a single solution. By dynamically switching between different thermal management strategies based on environmental conditions and battery state, these systems provide comprehensive thermal protection while maximizing energy efficiency.Expand Specific Solutions

Key Industry Players in Battery Thermal Solutions

The thermal battery management systems market is in a growth phase, characterized by increasing demand for safer and more efficient energy storage solutions. With an estimated market size exceeding $2 billion and projected CAGR of 15-20%, thermal stability has become a critical focus area. Leading players like Samsung SDI and LG Energy Solution are advancing commercial technologies, while automotive manufacturers (GM, Volvo, NIO) are integrating sophisticated thermal management into their EV designs. Research institutions including Shandong University and South China University of Technology are developing next-generation solutions, while specialized companies like Gentherm and A123 Systems focus on innovative cooling technologies. The competitive landscape shows a blend of established electronics giants, automotive OEMs, and specialized thermal management solution providers working to address thermal runaway challenges.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced Battery Thermal Management System (BTMS) that utilizes both active and passive cooling strategies. Their system incorporates a liquid cooling circuit with specialized heat exchangers that maintain optimal temperature distribution across battery modules. Samsung's approach includes phase-change materials (PCMs) integrated into battery packs to absorb excess heat during high-discharge operations. Their proprietary thermal interface materials improve heat transfer between cells and cooling plates, reducing thermal resistance by up to 30%. Samsung has also implemented predictive thermal management algorithms that anticipate temperature changes based on usage patterns and environmental conditions, allowing the system to proactively adjust cooling capacity before thermal issues arise. Recent innovations include their "Cell-to-Pack" design that eliminates module housings, improving thermal conductivity throughout the entire battery system.

Strengths: Superior thermal uniformity across large battery packs, reducing cell-to-cell temperature variations to under 3°C. Integrated safety features that can isolate thermal events before propagation. Weaknesses: Higher manufacturing complexity and cost compared to simpler air-cooled systems. Liquid cooling components add weight and require maintenance over vehicle lifetime.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed the Ultium battery platform with an integrated thermal management system designed for scalability across multiple vehicle types. Their approach utilizes a patented battery cell pouch design with cooling plates sandwiched between cells, maximizing surface contact for efficient heat transfer. GM's system employs a dedicated low-resistance cooling circuit separate from the vehicle's main cooling system, allowing for optimized coolant chemistry and flow rates specific to battery requirements. Their thermal management includes intelligent preconditioning capabilities that prepare the battery for optimal performance before driving or charging based on environmental conditions and scheduled activities. GM has implemented a multi-layer safety approach where thermal monitoring occurs at three levels: individual cells, modules, and the complete pack, with independent safety protocols at each level. Their latest innovation incorporates wireless temperature sensors embedded directly within cell groups, eliminating wiring harnesses and improving reliability while providing more granular thermal data. The system also features adaptive cooling that can concentrate cooling resources on specific modules experiencing higher loads during performance driving scenarios.

Strengths: Highly scalable architecture that maintains thermal performance across different battery sizes and vehicle platforms. Integrated approach to both heating and cooling that optimizes battery performance in all climate conditions. Weaknesses: Relatively high system complexity requiring sophisticated manufacturing processes. Cooling plate design adds some weight and volume compared to more compact cooling approaches.

Critical Patents and Research in Thermal Stability

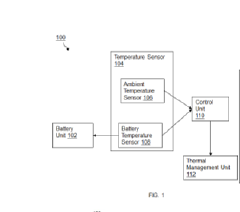

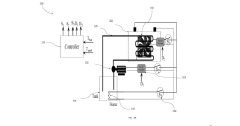

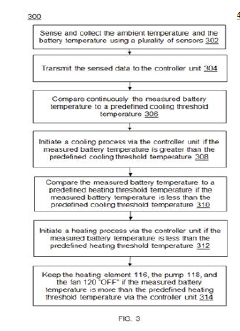

A battery thermal management system and method thereof

PatentPendingIN202411018158A

Innovation

- A battery thermal management system using liquid cooling and heating with a controller unit, temperature sensors, and a thermal management unit that includes a tank, heating element, pump, fan, and switches to regulate temperature through convection, allowing for real-time temperature control and efficient operation across high and low temperature ranges.

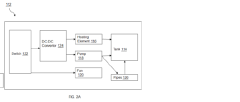

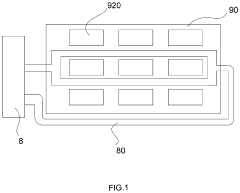

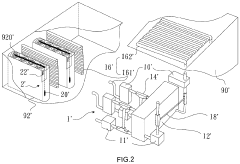

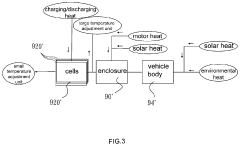

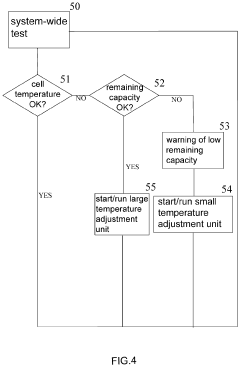

Thermal Management System for High Power Electrical Equipment

PatentActiveUS20210210810A1

Innovation

- A thermal management system that includes temperature and capacity sensors, a microcontroller, and adjustable cooling units (small and large) to dynamically control battery cell temperatures based on remaining capacity and environmental factors, optimizing energy use and extending battery life.

Safety Standards and Regulatory Requirements

The regulatory landscape governing battery thermal management systems (BTMS) has evolved significantly in response to high-profile thermal runaway incidents. International standards such as IEC 62133 and UL 1642 establish comprehensive safety requirements for batteries, with specific provisions addressing thermal stability. These standards mandate rigorous thermal testing, including exposure to extreme temperatures, thermal cycling, and thermal abuse conditions to verify system resilience.

The UN Transportation Testing (UN 38.3) specifically requires batteries to withstand altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge without dangerous effects. For electric vehicles, standards like ISO 6469 and SAE J2929 outline safety specifications with particular emphasis on thermal management requirements to prevent thermal propagation between cells.

Regional regulations add another layer of compliance complexity. The European Union's Battery Directive (2006/66/EC) and its upcoming replacement focus increasingly on safety performance metrics related to thermal stability. Similarly, China's GB/T 31485 standard mandates specific thermal runaway prevention measures, while the United States relies on a combination of federal regulations and industry standards through organizations like NHTSA.

Certification processes typically involve third-party testing against these standards, with documentation requirements becoming increasingly stringent. Manufacturers must demonstrate compliance through detailed thermal analysis, risk assessments, and validation testing. The certification pathway often includes thermal propagation testing, where a single cell is forced into thermal runaway to verify containment capabilities.

Emerging regulatory trends indicate a shift toward more prescriptive requirements for thermal management systems. Recent updates to standards increasingly specify minimum performance criteria rather than just testing methodologies. There is also growing emphasis on real-time thermal monitoring capabilities and early warning systems as mandatory components of battery systems in critical applications.

Insurance requirements and liability considerations further reinforce the importance of thermal stability compliance. Insurers increasingly require evidence of certification to recognized thermal safety standards before providing coverage for products containing large battery systems, creating additional market pressure for robust thermal management solutions beyond regulatory minimums.

The UN Transportation Testing (UN 38.3) specifically requires batteries to withstand altitude simulation, thermal testing, vibration, shock, external short circuit, impact, overcharge, and forced discharge without dangerous effects. For electric vehicles, standards like ISO 6469 and SAE J2929 outline safety specifications with particular emphasis on thermal management requirements to prevent thermal propagation between cells.

Regional regulations add another layer of compliance complexity. The European Union's Battery Directive (2006/66/EC) and its upcoming replacement focus increasingly on safety performance metrics related to thermal stability. Similarly, China's GB/T 31485 standard mandates specific thermal runaway prevention measures, while the United States relies on a combination of federal regulations and industry standards through organizations like NHTSA.

Certification processes typically involve third-party testing against these standards, with documentation requirements becoming increasingly stringent. Manufacturers must demonstrate compliance through detailed thermal analysis, risk assessments, and validation testing. The certification pathway often includes thermal propagation testing, where a single cell is forced into thermal runaway to verify containment capabilities.

Emerging regulatory trends indicate a shift toward more prescriptive requirements for thermal management systems. Recent updates to standards increasingly specify minimum performance criteria rather than just testing methodologies. There is also growing emphasis on real-time thermal monitoring capabilities and early warning systems as mandatory components of battery systems in critical applications.

Insurance requirements and liability considerations further reinforce the importance of thermal stability compliance. Insurers increasingly require evidence of certification to recognized thermal safety standards before providing coverage for products containing large battery systems, creating additional market pressure for robust thermal management solutions beyond regulatory minimums.

Environmental Impact of Thermal Management Solutions

The environmental implications of thermal management systems in batteries extend far beyond their primary function of maintaining optimal operating temperatures. As global environmental concerns intensify, the ecological footprint of these systems has become a critical consideration in their design and implementation.

Traditional cooling methods, particularly those utilizing hydrofluorocarbons (HFCs) and other synthetic refrigerants, contribute significantly to greenhouse gas emissions. These substances often possess global warming potentials hundreds or thousands of times greater than carbon dioxide. The lifecycle environmental impact of such systems begins with resource extraction and continues through manufacturing, operation, and eventual disposal.

Active cooling systems, while effective for thermal management, typically consume substantial energy, thereby increasing the carbon footprint of battery operation. This paradoxically diminishes the environmental benefits gained from electrification initiatives in transportation and energy storage sectors. Passive cooling alternatives generally offer lower environmental impact but may provide insufficient thermal regulation for high-performance applications.

Water-based cooling systems present their own environmental challenges, including water consumption in water-scarce regions and the potential for thermal pollution when heated water is discharged into natural water bodies. Additionally, the chemicals used to prevent corrosion and biological growth in these systems can introduce toxins into the environment if improperly managed.

The manufacturing processes for thermal management components often involve energy-intensive production and potentially hazardous materials. Phase change materials (PCMs), while promising for their energy efficiency, may contain compounds that pose environmental risks if released during disposal. Similarly, the production of specialized thermal interface materials frequently requires rare earth elements or petroleum derivatives with significant extraction impacts.

End-of-life considerations represent another critical environmental dimension. Many thermal management systems contain materials that are difficult to separate and recycle, contributing to electronic waste challenges. The composite nature of these systems often complicates recycling efforts, resulting in landfill disposal of potentially valuable or hazardous materials.

Recent innovations are addressing these environmental concerns through the development of biodegradable thermal interface materials, natural refrigerants, and designs that facilitate component recovery and recycling. Additionally, integrated approaches that utilize waste heat for beneficial purposes are reducing the overall environmental impact of thermal management systems while improving their efficiency.

Traditional cooling methods, particularly those utilizing hydrofluorocarbons (HFCs) and other synthetic refrigerants, contribute significantly to greenhouse gas emissions. These substances often possess global warming potentials hundreds or thousands of times greater than carbon dioxide. The lifecycle environmental impact of such systems begins with resource extraction and continues through manufacturing, operation, and eventual disposal.

Active cooling systems, while effective for thermal management, typically consume substantial energy, thereby increasing the carbon footprint of battery operation. This paradoxically diminishes the environmental benefits gained from electrification initiatives in transportation and energy storage sectors. Passive cooling alternatives generally offer lower environmental impact but may provide insufficient thermal regulation for high-performance applications.

Water-based cooling systems present their own environmental challenges, including water consumption in water-scarce regions and the potential for thermal pollution when heated water is discharged into natural water bodies. Additionally, the chemicals used to prevent corrosion and biological growth in these systems can introduce toxins into the environment if improperly managed.

The manufacturing processes for thermal management components often involve energy-intensive production and potentially hazardous materials. Phase change materials (PCMs), while promising for their energy efficiency, may contain compounds that pose environmental risks if released during disposal. Similarly, the production of specialized thermal interface materials frequently requires rare earth elements or petroleum derivatives with significant extraction impacts.

End-of-life considerations represent another critical environmental dimension. Many thermal management systems contain materials that are difficult to separate and recycle, contributing to electronic waste challenges. The composite nature of these systems often complicates recycling efforts, resulting in landfill disposal of potentially valuable or hazardous materials.

Recent innovations are addressing these environmental concerns through the development of biodegradable thermal interface materials, natural refrigerants, and designs that facilitate component recovery and recycling. Additionally, integrated approaches that utilize waste heat for beneficial purposes are reducing the overall environmental impact of thermal management systems while improving their efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!