How Battery Thermal Management Adapts to Market Regulations

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Evolution and Objectives

Battery Thermal Management Systems (BTMS) have evolved significantly over the past decades, transitioning from rudimentary cooling mechanisms to sophisticated thermal regulation technologies. The evolution began in the early 1990s with simple air cooling systems for nickel-metal hydride batteries in early hybrid vehicles. As lithium-ion batteries emerged in the early 2000s, more advanced cooling techniques became necessary due to their higher energy density and stricter thermal requirements.

The mid-2000s witnessed the introduction of liquid cooling systems in electric vehicles, marking a significant advancement in thermal management capabilities. By the 2010s, the industry had developed integrated thermal management solutions that combined multiple cooling methods, including air, liquid, phase-change materials, and thermoelectric cooling. This evolution has been primarily driven by the increasing energy density of batteries and the growing demand for faster charging capabilities.

Current BTMS technologies aim to maintain optimal battery temperature ranges (typically 15-35°C) across various operating conditions while minimizing energy consumption and system complexity. The primary objectives of modern BTMS include extending battery lifespan, enhancing safety by preventing thermal runaway, improving charging efficiency, and optimizing overall vehicle performance.

Market regulations have played a crucial role in shaping BTMS development trajectories. Safety standards such as UN ECE R100, ISO 6469, and IEC 62660 have established minimum requirements for thermal management in electric vehicles. Additionally, environmental regulations targeting emissions reduction have indirectly accelerated BTMS innovation by promoting electric vehicle adoption.

Recent regulatory frameworks in major markets like the EU, China, and the US have begun to specifically address battery thermal safety and performance. The EU Battery Directive revision and China's GB/T 31467 standard now include explicit thermal management requirements. These regulations are increasingly focusing on the entire battery lifecycle, including manufacturing, operation, and end-of-life considerations.

The technical objectives for future BTMS development include achieving uniform temperature distribution across battery packs, reducing thermal management energy consumption to less than 5% of total battery capacity, enabling ultra-fast charging capabilities while maintaining safe temperature limits, and developing predictive thermal management systems using AI and machine learning algorithms.

As electric vehicle markets mature globally, BTMS technologies must adapt to diverse climate conditions, from extreme cold in Nordic countries to intense heat in equatorial regions, while maintaining consistent performance and safety standards across all regulatory jurisdictions.

The mid-2000s witnessed the introduction of liquid cooling systems in electric vehicles, marking a significant advancement in thermal management capabilities. By the 2010s, the industry had developed integrated thermal management solutions that combined multiple cooling methods, including air, liquid, phase-change materials, and thermoelectric cooling. This evolution has been primarily driven by the increasing energy density of batteries and the growing demand for faster charging capabilities.

Current BTMS technologies aim to maintain optimal battery temperature ranges (typically 15-35°C) across various operating conditions while minimizing energy consumption and system complexity. The primary objectives of modern BTMS include extending battery lifespan, enhancing safety by preventing thermal runaway, improving charging efficiency, and optimizing overall vehicle performance.

Market regulations have played a crucial role in shaping BTMS development trajectories. Safety standards such as UN ECE R100, ISO 6469, and IEC 62660 have established minimum requirements for thermal management in electric vehicles. Additionally, environmental regulations targeting emissions reduction have indirectly accelerated BTMS innovation by promoting electric vehicle adoption.

Recent regulatory frameworks in major markets like the EU, China, and the US have begun to specifically address battery thermal safety and performance. The EU Battery Directive revision and China's GB/T 31467 standard now include explicit thermal management requirements. These regulations are increasingly focusing on the entire battery lifecycle, including manufacturing, operation, and end-of-life considerations.

The technical objectives for future BTMS development include achieving uniform temperature distribution across battery packs, reducing thermal management energy consumption to less than 5% of total battery capacity, enabling ultra-fast charging capabilities while maintaining safe temperature limits, and developing predictive thermal management systems using AI and machine learning algorithms.

As electric vehicle markets mature globally, BTMS technologies must adapt to diverse climate conditions, from extreme cold in Nordic countries to intense heat in equatorial regions, while maintaining consistent performance and safety standards across all regulatory jurisdictions.

Market Demand Analysis for Advanced Thermal Solutions

The global market for advanced battery thermal management systems (BTMS) is experiencing significant growth, driven by the rapid expansion of electric vehicle (EV) adoption and increasingly stringent regulatory frameworks. Current market analysis indicates that the BTMS market is projected to grow at a compound annual growth rate of 16.8% between 2023 and 2030, reaching approximately 12.3 billion USD by the end of the forecast period.

This growth is primarily fueled by regulatory pressures across major automotive markets. In Europe, the European Union's CO2 emission standards for new vehicles have become progressively more demanding, requiring manufacturers to implement sophisticated thermal management solutions to optimize battery performance and longevity. Similarly, China's New Energy Vehicle (NEV) mandate and dual-credit policy system have created substantial market demand for advanced thermal solutions that can ensure battery safety and performance in diverse operating conditions.

Consumer expectations are also evolving rapidly, with range anxiety remaining a significant barrier to EV adoption. Market research indicates that 78% of potential EV buyers consider battery range as their primary concern, followed by charging time (65%) and battery longevity (59%). Advanced thermal management systems directly address these concerns by optimizing battery performance across various temperature conditions, thereby extending range and battery life while reducing charging times.

The commercial vehicle sector represents an emerging high-growth segment for advanced thermal solutions. Fleet operators increasingly prioritize total cost of ownership calculations that factor in battery longevity and operational reliability. This has created demand for specialized thermal management systems capable of handling the unique duty cycles and power requirements of commercial electric vehicles.

Regional market analysis reveals varying demand patterns based on climate conditions. Northern markets with cold winters show stronger demand for heating-focused thermal solutions, while regions with hot climates prioritize cooling capabilities. This geographical variation is driving the development of adaptive thermal management systems that can automatically optimize for local conditions.

Energy storage systems (ESS) represent another significant growth vector, with grid-scale applications requiring increasingly sophisticated thermal management to ensure safety and longevity. The stationary storage market is expected to grow at 22% annually through 2030, creating substantial demand for thermal solutions optimized for these applications.

Market segmentation analysis indicates that liquid cooling systems currently dominate with approximately 65% market share, followed by air cooling (25%) and phase-change materials (10%). However, the fastest growth is occurring in immersion cooling technologies, which are gaining traction for high-performance applications despite their higher implementation costs.

This growth is primarily fueled by regulatory pressures across major automotive markets. In Europe, the European Union's CO2 emission standards for new vehicles have become progressively more demanding, requiring manufacturers to implement sophisticated thermal management solutions to optimize battery performance and longevity. Similarly, China's New Energy Vehicle (NEV) mandate and dual-credit policy system have created substantial market demand for advanced thermal solutions that can ensure battery safety and performance in diverse operating conditions.

Consumer expectations are also evolving rapidly, with range anxiety remaining a significant barrier to EV adoption. Market research indicates that 78% of potential EV buyers consider battery range as their primary concern, followed by charging time (65%) and battery longevity (59%). Advanced thermal management systems directly address these concerns by optimizing battery performance across various temperature conditions, thereby extending range and battery life while reducing charging times.

The commercial vehicle sector represents an emerging high-growth segment for advanced thermal solutions. Fleet operators increasingly prioritize total cost of ownership calculations that factor in battery longevity and operational reliability. This has created demand for specialized thermal management systems capable of handling the unique duty cycles and power requirements of commercial electric vehicles.

Regional market analysis reveals varying demand patterns based on climate conditions. Northern markets with cold winters show stronger demand for heating-focused thermal solutions, while regions with hot climates prioritize cooling capabilities. This geographical variation is driving the development of adaptive thermal management systems that can automatically optimize for local conditions.

Energy storage systems (ESS) represent another significant growth vector, with grid-scale applications requiring increasingly sophisticated thermal management to ensure safety and longevity. The stationary storage market is expected to grow at 22% annually through 2030, creating substantial demand for thermal solutions optimized for these applications.

Market segmentation analysis indicates that liquid cooling systems currently dominate with approximately 65% market share, followed by air cooling (25%) and phase-change materials (10%). However, the fastest growth is occurring in immersion cooling technologies, which are gaining traction for high-performance applications despite their higher implementation costs.

Current Challenges in Battery Thermal Management

Battery Thermal Management Systems (BTMS) face significant challenges in today's rapidly evolving regulatory landscape. The primary challenge stems from the inconsistent global regulatory framework, with different regions implementing varying standards for battery safety, thermal performance, and environmental impact. This regulatory fragmentation forces manufacturers to develop multiple BTMS variants to satisfy diverse market requirements, substantially increasing development costs and complexity.

Temperature control presents another critical challenge, as BTMS must maintain optimal battery operating temperatures (typically 20-40°C) across extreme ambient conditions ranging from -40°C to 60°C. This wide operational range demands sophisticated thermal management solutions that can both heat and cool battery systems efficiently while minimizing energy consumption.

Safety compliance requirements have become increasingly stringent following high-profile thermal runaway incidents. Regulations now mandate robust thermal runaway prevention and containment systems, requiring BTMS to detect temperature anomalies earlier and respond more effectively. These systems must demonstrate reliability through extensive testing under various abuse conditions, adding significant validation costs and development time.

Energy efficiency regulations present a paradoxical challenge, as BTMS must balance thermal management effectiveness against power consumption. The system itself consumes energy that could otherwise extend vehicle range, creating a complex optimization problem. Manufacturers must demonstrate that their BTMS meets efficiency targets while still providing adequate thermal protection.

Material restrictions and end-of-life regulations further complicate BTMS development. Many traditional thermal management materials face regulatory restrictions due to environmental concerns. For instance, certain refrigerants with high global warming potential are being phased out, forcing redesigns of active cooling systems. Additionally, regulations increasingly require BTMS components to be recyclable or reusable, constraining material selection and design approaches.

Manufacturing standardization remains elusive despite industry efforts. The lack of universally accepted testing protocols and performance metrics makes compliance verification challenging across different markets. This absence of standardization hinders economies of scale and technology transfer between regions, as solutions optimized for one regulatory environment may require significant modification for another.

Emerging fast-charging regulations create additional thermal management challenges. As markets push for shorter charging times, BTMS must handle significantly higher heat generation during charging while preventing degradation. These requirements often conflict with size and weight constraints, forcing engineers to develop increasingly sophisticated cooling architectures.

Temperature control presents another critical challenge, as BTMS must maintain optimal battery operating temperatures (typically 20-40°C) across extreme ambient conditions ranging from -40°C to 60°C. This wide operational range demands sophisticated thermal management solutions that can both heat and cool battery systems efficiently while minimizing energy consumption.

Safety compliance requirements have become increasingly stringent following high-profile thermal runaway incidents. Regulations now mandate robust thermal runaway prevention and containment systems, requiring BTMS to detect temperature anomalies earlier and respond more effectively. These systems must demonstrate reliability through extensive testing under various abuse conditions, adding significant validation costs and development time.

Energy efficiency regulations present a paradoxical challenge, as BTMS must balance thermal management effectiveness against power consumption. The system itself consumes energy that could otherwise extend vehicle range, creating a complex optimization problem. Manufacturers must demonstrate that their BTMS meets efficiency targets while still providing adequate thermal protection.

Material restrictions and end-of-life regulations further complicate BTMS development. Many traditional thermal management materials face regulatory restrictions due to environmental concerns. For instance, certain refrigerants with high global warming potential are being phased out, forcing redesigns of active cooling systems. Additionally, regulations increasingly require BTMS components to be recyclable or reusable, constraining material selection and design approaches.

Manufacturing standardization remains elusive despite industry efforts. The lack of universally accepted testing protocols and performance metrics makes compliance verification challenging across different markets. This absence of standardization hinders economies of scale and technology transfer between regions, as solutions optimized for one regulatory environment may require significant modification for another.

Emerging fast-charging regulations create additional thermal management challenges. As markets push for shorter charging times, BTMS must handle significantly higher heat generation during charging while preventing degradation. These requirements often conflict with size and weight constraints, forcing engineers to develop increasingly sophisticated cooling architectures.

Contemporary Approaches to Thermal Regulation

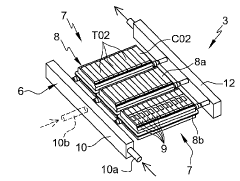

01 Liquid cooling systems for battery thermal management

Liquid cooling systems are used in battery thermal management to efficiently control temperature by circulating coolant through channels or plates in direct contact with battery cells. These systems provide superior heat transfer capabilities compared to air cooling, allowing for more precise temperature control and uniform cooling across battery packs. Advanced designs incorporate flow control mechanisms to adapt cooling intensity based on thermal loads and operating conditions.- Liquid cooling systems for battery thermal management: Liquid cooling systems are effective for battery thermal management, utilizing coolant circulation through channels or plates in direct contact with battery cells. These systems provide efficient heat transfer and temperature uniformity across battery packs. Advanced designs incorporate flow control mechanisms to adapt cooling intensity based on thermal conditions, ensuring optimal battery performance and longevity under varying operational demands.

- Phase change materials for thermal regulation: Phase change materials (PCMs) offer passive thermal management solutions for batteries by absorbing excess heat during operation and releasing it when temperatures drop. These materials change state at specific temperatures, helping maintain batteries within optimal temperature ranges. PCMs can be integrated into battery packs as dedicated layers or combined with other cooling technologies to create hybrid systems that adapt to different thermal loads and environmental conditions.

- Adaptive control systems for battery thermal management: Adaptive control systems optimize battery thermal management by continuously monitoring temperature, state of charge, and operational conditions. These intelligent systems adjust cooling or heating parameters in real-time based on predictive algorithms and thermal models. By anticipating thermal needs and dynamically allocating resources, adaptive control systems can significantly improve energy efficiency while maintaining optimal battery temperature ranges across diverse usage scenarios and environmental conditions.

- Air cooling and ventilation systems for batteries: Air cooling systems provide thermal management for batteries through forced or natural convection. These systems utilize strategically placed air channels, fans, and heat sinks to remove excess heat from battery modules. Modern designs incorporate adaptive features such as variable-speed fans and directional airflow control to respond to changing thermal loads. Air cooling solutions are particularly valuable for applications requiring lightweight, low-complexity thermal management with minimal maintenance requirements.

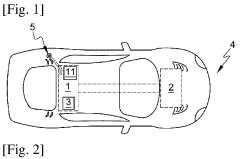

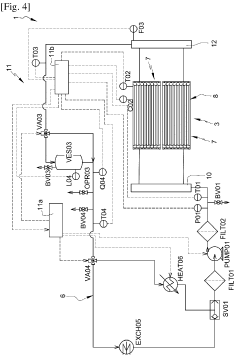

- Integrated thermal management for electric vehicle battery systems: Integrated thermal management systems for electric vehicles combine multiple cooling technologies and heat recovery mechanisms to optimize battery performance while enhancing overall vehicle efficiency. These systems coordinate battery thermal management with cabin climate control and powertrain cooling, allowing for heat exchange between different vehicle subsystems. Advanced designs adapt to driving conditions, ambient temperature, and battery state to balance thermal needs across the vehicle, maximizing range and battery longevity.

02 Adaptive thermal management based on operating conditions

Adaptive thermal management systems adjust cooling or heating strategies based on real-time operating conditions such as ambient temperature, battery state of charge, and power demand. These systems use sensors and control algorithms to optimize thermal performance while minimizing energy consumption. By dynamically adapting to changing conditions, these systems can extend battery life, improve efficiency, and enhance safety during various driving scenarios or charging processes.Expand Specific Solutions03 Phase change materials for thermal buffering

Phase change materials (PCMs) are incorporated into battery thermal management systems to provide thermal buffering capabilities. These materials absorb excess heat during high-load operations by changing phase, typically from solid to liquid, and release this stored heat when the battery temperature drops. This passive thermal regulation helps maintain optimal operating temperatures, reduce thermal gradients within battery packs, and protect against thermal runaway events without requiring continuous active cooling.Expand Specific Solutions04 Integrated heating systems for cold weather operation

Integrated heating systems are designed to warm batteries during cold weather operation when battery performance typically degrades. These systems may use electric heaters, waste heat recovery from other vehicle systems, or thermal storage solutions to bring batteries to optimal operating temperatures quickly. Advanced designs incorporate predictive controls that can pre-condition batteries based on weather forecasts or scheduled departure times, ensuring maximum range and performance in cold conditions.Expand Specific Solutions05 Smart thermal management control algorithms

Smart control algorithms optimize battery thermal management by using machine learning, predictive modeling, and real-time data analysis. These algorithms balance multiple objectives including temperature uniformity, energy efficiency, and battery longevity. They can anticipate thermal needs based on driving patterns, route information, and historical data, allowing the system to proactively adjust cooling or heating strategies. Some advanced systems incorporate cell-level thermal monitoring to address individual temperature variations within the battery pack.Expand Specific Solutions

Leading Companies in Battery Thermal Solutions

The Battery Thermal Management Systems (BTMS) market is currently in a growth phase, driven by stringent global emissions regulations and increasing electric vehicle adoption. The market is projected to expand significantly, with key players including established automotive giants and specialized battery manufacturers. Samsung SDI, LG Energy Solution, and BYD lead with mature technologies, while automotive OEMs like NIO, SAIC GM Wuling, and FAW are rapidly advancing their capabilities. Companies such as Johnson Controls and A123 Systems offer specialized thermal management solutions. The technological landscape shows varying maturity levels, with Asian manufacturers generally ahead in commercialization while Western companies focus on next-generation innovations to meet evolving regulatory requirements across different markets.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology with an integrated thermal management system specifically designed to meet stringent safety regulations across global markets. Their BTMS employs a multi-layer approach combining passive and active cooling strategies. The system features a proprietary cell-to-pack design that eliminates module housings, creating direct thermal pathways between cells and cooling plates. BYD's thermal management solution incorporates phase-change materials that absorb excess heat during rapid charging or high-power discharge events, maintaining optimal temperature ranges without requiring additional energy input. For regulatory compliance, BYD has implemented an intelligent thermal prediction system that anticipates thermal behavior based on driving patterns, environmental conditions, and charging profiles, allowing preemptive adjustments to meet varying regional safety standards. Their system includes dedicated thermal fuses and multiple redundant temperature sensors that can trigger emergency cooling protocols when abnormal temperature gradients are detected.

Strengths: Exceptional thermal stability during abuse conditions, minimal temperature differential between cells (typically <3°C), and reduced system complexity through integrated design. Weaknesses: Higher initial development costs and challenges in retrofitting the system to existing battery architectures not originally designed for this approach.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed a comprehensive Battery Thermal Management System that adapts to various regulatory frameworks through a modular architecture. Their system employs a hybrid cooling approach combining air and liquid cooling channels with intelligent flow distribution. The BTMS features adaptive control algorithms that continuously optimize thermal performance based on battery state, ambient conditions, and vehicle operation mode. Johnson Controls' solution incorporates a predictive thermal management strategy that uses machine learning to anticipate heating and cooling needs based on historical usage patterns and environmental data. To address evolving regulations, their system includes configurable safety thresholds that can be adjusted through over-the-air updates to comply with regional requirements. The company has also implemented a multi-zone cooling design that can independently manage thermal conditions in different sections of the battery pack, allowing for more precise temperature control and enhanced safety during extreme operating conditions or potential thermal events.

Strengths: Highly adaptable to different vehicle platforms and battery chemistries, excellent scalability from small to large battery systems, and robust compliance with diverse international standards. Weaknesses: Higher system complexity increases integration challenges with vehicle thermal systems and requires more sophisticated control algorithms to optimize performance across all operating conditions.

Key Patents in Battery Cooling Technologies

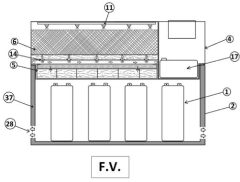

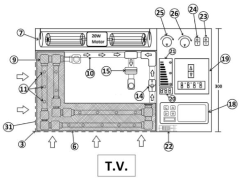

Evaporative cooling based battery thermal management system

PatentInactiveIN202221000095A

Innovation

- A compact, evaporative cooling-based Battery Thermal Management System (BTMS) for VRLA batteries in E-bikes and E-vehicles, utilizing a cooling module with a wood-wool cooling pad and a control module with automatic temperature control, which consumes minimal power and is designed for easy assembly and corrosion resistance.

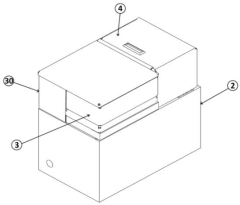

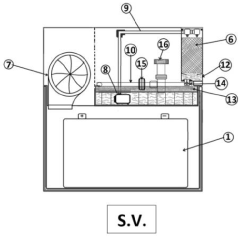

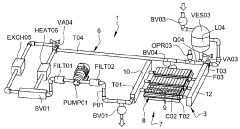

System for the thermal regulation of a battery

PatentWO2023203189A1

Innovation

- A closed hydraulic network using a single-phase dielectric heat transfer liquid for immersion-based thermal regulation, with a detection system monitoring physical values to control the thermal management, ensuring optimal temperature maintenance and preventing pollution, thereby enhancing safety and reliability.

Regulatory Framework Impact on Design Standards

The regulatory landscape for Battery Thermal Management Systems (BTMS) has evolved significantly in recent years, directly influencing design standards across the industry. Safety regulations such as UN ECE R100, ISO 6469, and IEC 62660 have established minimum requirements for thermal runaway prevention and containment, compelling manufacturers to implement more sophisticated cooling systems and temperature monitoring capabilities. These standards typically mandate that battery temperatures remain within specific operational ranges (usually between 15°C and 45°C) during both normal operation and charging cycles.

Environmental regulations have similarly transformed BTMS design approaches, particularly as governments worldwide implement stricter emissions standards. The EU's End-of-Life Vehicle Directive and similar regulations in North America and Asia have necessitated the development of BTMS designs that facilitate easier battery disassembly and material recovery. This has led to modular thermal management architectures that can be more readily disassembled at end-of-life.

Performance-oriented regulations, including those related to fast-charging infrastructure, have pushed BTMS designers toward more efficient cooling solutions. China's GB/T 18384 standard and the SAE J2929 safety standard in the United States both contain specific provisions regarding thermal management during rapid charging scenarios, requiring systems capable of handling higher heat loads without compromising battery longevity.

Regional variations in regulatory frameworks have created design challenges for global manufacturers. European regulations tend to emphasize safety and environmental considerations, while Chinese standards focus more heavily on performance metrics and charging capabilities. This regulatory divergence has prompted the development of adaptable BTMS platforms that can be configured to meet different regional requirements without complete redesigns.

The economic impact of these regulations cannot be overlooked. Compliance with increasingly stringent thermal management requirements has raised production costs by an estimated 5-15% depending on the vehicle segment. However, these regulations have also accelerated innovation, with manufacturers developing more cost-effective solutions such as immersion cooling and phase-change materials to meet requirements while controlling costs.

Looking forward, emerging regulations around battery second-life applications are beginning to influence BTMS design standards. Systems must now be designed not only for their primary automotive application but also with consideration for potential stationary storage applications after vehicle retirement. This has led to the incorporation of more sophisticated diagnostic capabilities and modular designs that can adapt to different thermal management needs across the battery lifecycle.

Environmental regulations have similarly transformed BTMS design approaches, particularly as governments worldwide implement stricter emissions standards. The EU's End-of-Life Vehicle Directive and similar regulations in North America and Asia have necessitated the development of BTMS designs that facilitate easier battery disassembly and material recovery. This has led to modular thermal management architectures that can be more readily disassembled at end-of-life.

Performance-oriented regulations, including those related to fast-charging infrastructure, have pushed BTMS designers toward more efficient cooling solutions. China's GB/T 18384 standard and the SAE J2929 safety standard in the United States both contain specific provisions regarding thermal management during rapid charging scenarios, requiring systems capable of handling higher heat loads without compromising battery longevity.

Regional variations in regulatory frameworks have created design challenges for global manufacturers. European regulations tend to emphasize safety and environmental considerations, while Chinese standards focus more heavily on performance metrics and charging capabilities. This regulatory divergence has prompted the development of adaptable BTMS platforms that can be configured to meet different regional requirements without complete redesigns.

The economic impact of these regulations cannot be overlooked. Compliance with increasingly stringent thermal management requirements has raised production costs by an estimated 5-15% depending on the vehicle segment. However, these regulations have also accelerated innovation, with manufacturers developing more cost-effective solutions such as immersion cooling and phase-change materials to meet requirements while controlling costs.

Looking forward, emerging regulations around battery second-life applications are beginning to influence BTMS design standards. Systems must now be designed not only for their primary automotive application but also with consideration for potential stationary storage applications after vehicle retirement. This has led to the incorporation of more sophisticated diagnostic capabilities and modular designs that can adapt to different thermal management needs across the battery lifecycle.

Environmental Sustainability in Thermal Solutions

Environmental sustainability has become a critical consideration in the development of Battery Thermal Management Systems (BTMS) as global markets increasingly prioritize eco-friendly technologies. Modern BTMS designs are evolving to incorporate materials and processes that minimize environmental impact while maintaining optimal thermal performance. Manufacturers are transitioning from traditional cooling fluids with high Global Warming Potential (GWP) to more environmentally benign alternatives, such as water-glycol mixtures and dielectric fluids with lower environmental footprints.

Lifecycle assessment (LCA) methodologies are now being integrated into BTMS development processes, allowing engineers to quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. This holistic approach has revealed opportunities for significant sustainability improvements, particularly in reducing embodied carbon and enhancing recyclability of thermal management components.

Renewable energy integration represents another frontier in sustainable BTMS design. Advanced systems are being engineered to operate efficiently with renewable power sources, reducing the carbon intensity of battery charging and cooling operations. Some cutting-edge designs incorporate phase-change materials derived from bio-based sources, offering thermal regulation capabilities with substantially lower environmental impacts compared to synthetic alternatives.

Waste heat recovery technologies are gaining prominence in sustainable BTMS solutions. Rather than simply dissipating excess heat, modern systems increasingly capture and repurpose thermal energy for cabin heating or preconditioning, improving overall energy efficiency while reducing environmental burden. This approach is particularly valuable in cold-climate operations where heating demands can significantly impact vehicle range.

Water conservation has emerged as a sustainability focus area, with closed-loop cooling systems replacing traditional once-through designs. These advanced systems minimize water consumption and prevent the discharge of potentially harmful thermal transfer fluids into the environment. Additionally, manufacturers are developing dry cooling technologies that dramatically reduce water requirements in industrial-scale battery installations.

End-of-life considerations are reshaping BTMS design philosophy, with increased emphasis on modular construction that facilitates component replacement, refurbishment, and material recovery. Design for disassembly principles are being applied to ensure valuable materials can be efficiently reclaimed when batteries reach end-of-service. This approach aligns with circular economy principles and helps address growing concerns about resource scarcity in battery technology supply chains.

Regulatory frameworks worldwide are increasingly mandating these sustainable approaches, with the European Union's Battery Directive and similar regulations in North America and Asia establishing clear sustainability requirements for battery systems, including their thermal management components. Forward-thinking BTMS developers are not merely complying with these regulations but anticipating future requirements, positioning their technologies at the forefront of sustainable innovation.

Lifecycle assessment (LCA) methodologies are now being integrated into BTMS development processes, allowing engineers to quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. This holistic approach has revealed opportunities for significant sustainability improvements, particularly in reducing embodied carbon and enhancing recyclability of thermal management components.

Renewable energy integration represents another frontier in sustainable BTMS design. Advanced systems are being engineered to operate efficiently with renewable power sources, reducing the carbon intensity of battery charging and cooling operations. Some cutting-edge designs incorporate phase-change materials derived from bio-based sources, offering thermal regulation capabilities with substantially lower environmental impacts compared to synthetic alternatives.

Waste heat recovery technologies are gaining prominence in sustainable BTMS solutions. Rather than simply dissipating excess heat, modern systems increasingly capture and repurpose thermal energy for cabin heating or preconditioning, improving overall energy efficiency while reducing environmental burden. This approach is particularly valuable in cold-climate operations where heating demands can significantly impact vehicle range.

Water conservation has emerged as a sustainability focus area, with closed-loop cooling systems replacing traditional once-through designs. These advanced systems minimize water consumption and prevent the discharge of potentially harmful thermal transfer fluids into the environment. Additionally, manufacturers are developing dry cooling technologies that dramatically reduce water requirements in industrial-scale battery installations.

End-of-life considerations are reshaping BTMS design philosophy, with increased emphasis on modular construction that facilitates component replacement, refurbishment, and material recovery. Design for disassembly principles are being applied to ensure valuable materials can be efficiently reclaimed when batteries reach end-of-service. This approach aligns with circular economy principles and helps address growing concerns about resource scarcity in battery technology supply chains.

Regulatory frameworks worldwide are increasingly mandating these sustainable approaches, with the European Union's Battery Directive and similar regulations in North America and Asia establishing clear sustainability requirements for battery systems, including their thermal management components. Forward-thinking BTMS developers are not merely complying with these regulations but anticipating future requirements, positioning their technologies at the forefront of sustainable innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!