Comparative Analysis of Anode Materials in Battery Thermal Management

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Anode Materials Evolution and Objectives

Battery anode materials have undergone significant evolution since the commercialization of lithium-ion batteries in the early 1990s. Initially, graphite dominated as the primary anode material due to its stable structure, good electrical conductivity, and relatively low cost. This carbon-based material offered a theoretical capacity of 372 mAh/g, which was sufficient for early portable electronics applications. However, as energy demands increased across various sectors, particularly in electric vehicles and grid storage, the limitations of graphite became apparent, especially regarding thermal management challenges.

The thermal behavior of anode materials represents a critical factor in battery performance and safety. Graphite anodes, while stable, exhibit thermal runaway risks at elevated temperatures, necessitating sophisticated thermal management systems. This limitation prompted research into alternative anode materials with enhanced thermal stability and higher energy densities.

Silicon emerged as a promising alternative, offering a theoretical capacity nearly ten times that of graphite (approximately 4,200 mAh/g). However, silicon anodes present significant thermal management challenges due to substantial volume changes during charge-discharge cycles, which generate heat and mechanical stress. These thermal issues have driven the development of silicon-carbon composites and nanostructured silicon materials designed to mitigate thermal expansion while maintaining high capacity.

Lithium titanate (Li₄Ti₅O₁₂) represents another evolutionary step, offering exceptional thermal stability and safety compared to graphite and silicon. With minimal volume change during cycling and excellent thermal conductivity, lithium titanate anodes significantly reduce thermal management requirements, though at the cost of lower energy density.

More recently, conversion-type anodes based on metal oxides and phosphides have gained attention for their high theoretical capacities. These materials undergo complex redox reactions that present unique thermal management challenges, including heat generation during phase transformations and potential thermal runaway under certain conditions.

The evolution of battery anode materials has been guided by several key objectives: increasing energy density, improving thermal stability, enhancing cycling performance, reducing cost, and ensuring environmental sustainability. Particularly for thermal management, objectives include developing materials with higher thermal conductivity, reduced heat generation during cycling, improved stability at elevated temperatures, and enhanced safety characteristics.

Current research aims to develop next-generation anode materials that balance these sometimes competing objectives. This includes exploring 2D materials like MXenes, which offer excellent thermal conductivity, and solid-state electrolyte-compatible anodes that could eliminate many thermal management issues associated with liquid electrolytes. The ultimate goal remains developing anode materials that deliver high energy density while minimizing thermal management requirements and maximizing safety across diverse operating conditions.

The thermal behavior of anode materials represents a critical factor in battery performance and safety. Graphite anodes, while stable, exhibit thermal runaway risks at elevated temperatures, necessitating sophisticated thermal management systems. This limitation prompted research into alternative anode materials with enhanced thermal stability and higher energy densities.

Silicon emerged as a promising alternative, offering a theoretical capacity nearly ten times that of graphite (approximately 4,200 mAh/g). However, silicon anodes present significant thermal management challenges due to substantial volume changes during charge-discharge cycles, which generate heat and mechanical stress. These thermal issues have driven the development of silicon-carbon composites and nanostructured silicon materials designed to mitigate thermal expansion while maintaining high capacity.

Lithium titanate (Li₄Ti₅O₁₂) represents another evolutionary step, offering exceptional thermal stability and safety compared to graphite and silicon. With minimal volume change during cycling and excellent thermal conductivity, lithium titanate anodes significantly reduce thermal management requirements, though at the cost of lower energy density.

More recently, conversion-type anodes based on metal oxides and phosphides have gained attention for their high theoretical capacities. These materials undergo complex redox reactions that present unique thermal management challenges, including heat generation during phase transformations and potential thermal runaway under certain conditions.

The evolution of battery anode materials has been guided by several key objectives: increasing energy density, improving thermal stability, enhancing cycling performance, reducing cost, and ensuring environmental sustainability. Particularly for thermal management, objectives include developing materials with higher thermal conductivity, reduced heat generation during cycling, improved stability at elevated temperatures, and enhanced safety characteristics.

Current research aims to develop next-generation anode materials that balance these sometimes competing objectives. This includes exploring 2D materials like MXenes, which offer excellent thermal conductivity, and solid-state electrolyte-compatible anodes that could eliminate many thermal management issues associated with liquid electrolytes. The ultimate goal remains developing anode materials that deliver high energy density while minimizing thermal management requirements and maximizing safety across diverse operating conditions.

Market Demand for Advanced Thermal Management Solutions

The global battery market is experiencing unprecedented growth, with electric vehicles (EVs) and renewable energy storage systems driving significant demand for advanced thermal management solutions. Market research indicates that the global battery thermal management system market is projected to reach $13.6 billion by 2027, growing at a CAGR of approximately 23% from 2022. This remarkable growth trajectory underscores the critical importance of effective thermal management in battery systems.

Consumer expectations for faster charging capabilities, longer battery life, and enhanced safety features are creating substantial market pressure for improved thermal management solutions. Fast charging technologies, which can reduce charging times to under 30 minutes, generate significant heat that must be efficiently managed to prevent battery degradation and safety hazards. Market surveys reveal that over 70% of potential EV buyers consider charging time a decisive factor in their purchasing decisions.

The automotive sector represents the largest market segment for advanced battery thermal management, with premium electric vehicle manufacturers implementing sophisticated thermal management systems to differentiate their products. Tesla, BMW, and Volkswagen have all made substantial investments in proprietary thermal management technologies, recognizing their strategic importance in achieving competitive advantage.

Energy storage systems for grid applications constitute another rapidly expanding market segment. As renewable energy integration accelerates globally, the demand for large-scale battery storage with reliable thermal management capabilities is growing exponentially. Market analysis shows that grid-scale battery deployments increased by 62% in 2022 compared to the previous year, with thermal management cited as a critical component for ensuring system reliability and longevity.

Safety concerns are driving regulatory changes that further stimulate market demand for advanced thermal management solutions. Following several high-profile battery fire incidents, regulatory bodies worldwide have implemented stricter safety standards for battery systems. These regulations have effectively created mandatory market demand for sophisticated thermal management technologies that can prevent thermal runaway events.

The consumer electronics sector presents additional market opportunities, particularly as fast-charging smartphones, tablets, and laptops become standard. Manufacturers are increasingly recognizing that effective thermal management is essential for maintaining device performance and extending battery lifespan, creating a substantial market for miniaturized thermal management solutions.

Regional analysis reveals that Asia-Pacific currently dominates the market for battery thermal management systems, accounting for approximately 45% of global demand. This regional concentration aligns with the geographic distribution of battery manufacturing capacity, suggesting that thermal management technologies must be developed with consideration for integration into existing production ecosystems.

Consumer expectations for faster charging capabilities, longer battery life, and enhanced safety features are creating substantial market pressure for improved thermal management solutions. Fast charging technologies, which can reduce charging times to under 30 minutes, generate significant heat that must be efficiently managed to prevent battery degradation and safety hazards. Market surveys reveal that over 70% of potential EV buyers consider charging time a decisive factor in their purchasing decisions.

The automotive sector represents the largest market segment for advanced battery thermal management, with premium electric vehicle manufacturers implementing sophisticated thermal management systems to differentiate their products. Tesla, BMW, and Volkswagen have all made substantial investments in proprietary thermal management technologies, recognizing their strategic importance in achieving competitive advantage.

Energy storage systems for grid applications constitute another rapidly expanding market segment. As renewable energy integration accelerates globally, the demand for large-scale battery storage with reliable thermal management capabilities is growing exponentially. Market analysis shows that grid-scale battery deployments increased by 62% in 2022 compared to the previous year, with thermal management cited as a critical component for ensuring system reliability and longevity.

Safety concerns are driving regulatory changes that further stimulate market demand for advanced thermal management solutions. Following several high-profile battery fire incidents, regulatory bodies worldwide have implemented stricter safety standards for battery systems. These regulations have effectively created mandatory market demand for sophisticated thermal management technologies that can prevent thermal runaway events.

The consumer electronics sector presents additional market opportunities, particularly as fast-charging smartphones, tablets, and laptops become standard. Manufacturers are increasingly recognizing that effective thermal management is essential for maintaining device performance and extending battery lifespan, creating a substantial market for miniaturized thermal management solutions.

Regional analysis reveals that Asia-Pacific currently dominates the market for battery thermal management systems, accounting for approximately 45% of global demand. This regional concentration aligns with the geographic distribution of battery manufacturing capacity, suggesting that thermal management technologies must be developed with consideration for integration into existing production ecosystems.

Current State and Challenges in Anode Material Technology

The global landscape of anode materials for battery thermal management systems reveals significant regional disparities in technological advancement. North America, particularly the United States, leads in silicon-based anode research, with companies like Tesla and research institutions such as Stanford University pioneering innovations in silicon-graphite composite anodes. The European Union focuses heavily on sustainable anode materials, with substantial investments in bio-derived carbon anodes and recycling technologies, while Japan and South Korea dominate in graphite anode optimization and manufacturing precision.

Current anode materials face several critical technical challenges that impede broader adoption in thermal management applications. Traditional graphite anodes, while commercially established, exhibit limited thermal conductivity (approximately 25-200 W/m·K depending on crystallinity), creating heat dissipation bottlenecks during rapid charging cycles. This limitation becomes particularly problematic as battery energy densities increase, with thermal runaway risks escalating proportionally to energy capacity.

Silicon-based anodes, despite offering theoretical capacity advantages (3,579 mAh/g versus graphite's 372 mAh/g), suffer from severe volume expansion issues (up to 300% during lithiation) that compromise thermal stability. This expansion-contraction cycle creates micro-fractures that increase internal resistance and generate localized heating points, complicating thermal management system design and reducing overall battery lifespan.

Lithium titanate (LTO) anodes demonstrate superior thermal stability but at the cost of significantly lower energy density, presenting an engineering trade-off between safety and performance that remains unresolved. Meanwhile, emerging materials like graphene and MXenes show promising thermal conductivity profiles (graphene exceeding 5,000 W/m·K) but face manufacturing scalability challenges and high production costs that currently limit commercial viability.

The integration of these anode materials into comprehensive thermal management systems presents additional complexities. Current liquid cooling systems designed for graphite anodes require substantial redesign to accommodate the different thermal expansion coefficients and heat generation profiles of alternative materials. This redesign necessity creates a technological inertia that slows adoption of potentially superior anode materials.

Manufacturing constraints further complicate advancement, with high-precision requirements for silicon-graphite composites and specialized equipment needs for novel materials adding significant production costs. These economic barriers, coupled with supply chain vulnerabilities for critical raw materials like natural graphite (70% globally sourced from China), create both technical and geopolitical challenges for widespread implementation of advanced anode technologies in thermal management systems.

Current anode materials face several critical technical challenges that impede broader adoption in thermal management applications. Traditional graphite anodes, while commercially established, exhibit limited thermal conductivity (approximately 25-200 W/m·K depending on crystallinity), creating heat dissipation bottlenecks during rapid charging cycles. This limitation becomes particularly problematic as battery energy densities increase, with thermal runaway risks escalating proportionally to energy capacity.

Silicon-based anodes, despite offering theoretical capacity advantages (3,579 mAh/g versus graphite's 372 mAh/g), suffer from severe volume expansion issues (up to 300% during lithiation) that compromise thermal stability. This expansion-contraction cycle creates micro-fractures that increase internal resistance and generate localized heating points, complicating thermal management system design and reducing overall battery lifespan.

Lithium titanate (LTO) anodes demonstrate superior thermal stability but at the cost of significantly lower energy density, presenting an engineering trade-off between safety and performance that remains unresolved. Meanwhile, emerging materials like graphene and MXenes show promising thermal conductivity profiles (graphene exceeding 5,000 W/m·K) but face manufacturing scalability challenges and high production costs that currently limit commercial viability.

The integration of these anode materials into comprehensive thermal management systems presents additional complexities. Current liquid cooling systems designed for graphite anodes require substantial redesign to accommodate the different thermal expansion coefficients and heat generation profiles of alternative materials. This redesign necessity creates a technological inertia that slows adoption of potentially superior anode materials.

Manufacturing constraints further complicate advancement, with high-precision requirements for silicon-graphite composites and specialized equipment needs for novel materials adding significant production costs. These economic barriers, coupled with supply chain vulnerabilities for critical raw materials like natural graphite (70% globally sourced from China), create both technical and geopolitical challenges for widespread implementation of advanced anode technologies in thermal management systems.

Existing Anode Material Solutions for Thermal Management

01 Heat dissipation systems for anode materials

Various heat dissipation systems are employed to manage thermal issues in anode materials. These systems include cooling channels, heat sinks, and thermal interface materials that efficiently transfer heat away from the anode. Advanced designs incorporate phase change materials and liquid cooling systems to maintain optimal operating temperatures and prevent thermal runaway, which is crucial for extending the lifespan and maintaining the performance of battery and electronic components using these anode materials.- Thermal management systems for battery anodes: Various thermal management systems are designed specifically for battery anodes to maintain optimal operating temperatures. These systems include cooling channels, heat sinks, and thermal interface materials that efficiently dissipate heat generated during battery operation. Advanced thermal management designs help prevent thermal runaway, extend battery life, and maintain consistent performance across varying operational conditions.

- Novel anode materials with improved thermal properties: Development of innovative anode materials that inherently possess superior thermal conductivity and stability. These materials include modified graphite structures, silicon-carbon composites, and metal alloys that can withstand high temperatures while maintaining electrochemical performance. The improved thermal properties of these materials reduce hotspot formation and enable more efficient heat distribution throughout the anode structure.

- Cooling techniques for anode heat dissipation: Specialized cooling techniques designed for effective heat dissipation from anode materials during operation. These include liquid cooling systems, phase change materials, and air cooling designs that target the anode specifically. Advanced cooling approaches incorporate microchannels, heat pipes, or thermally conductive coatings to rapidly remove heat from critical anode components and maintain temperature uniformity.

- Thermal interface materials for anode connections: Development of specialized thermal interface materials that enhance heat transfer between anode components and cooling systems. These materials include thermally conductive adhesives, pastes, pads, and coatings that minimize thermal resistance at connection points. Advanced interface materials are designed to maintain performance over time despite thermal cycling and mechanical stress, ensuring consistent heat dissipation from anode structures.

- Integrated thermal monitoring and control systems: Comprehensive systems that combine temperature sensors, control algorithms, and active thermal management components to monitor and regulate anode temperatures in real-time. These systems can detect thermal anomalies, adjust cooling parameters, and implement protective measures to prevent overheating. Advanced monitoring solutions incorporate predictive models that anticipate thermal behavior based on operating conditions and adjust thermal management strategies proactively.

02 Thermally conductive anode material compositions

Specialized anode material compositions are designed with enhanced thermal conductivity properties. These compositions often incorporate carbon-based materials like graphene, carbon nanotubes, or metal particles that improve heat transfer within the anode structure. By engineering the microstructure and composition of these materials, thermal management is improved while maintaining or enhancing electrochemical performance. These thermally optimized materials help prevent hotspot formation and ensure more uniform temperature distribution.Expand Specific Solutions03 Thermal management coatings and interfaces

Protective coatings and interface materials are applied to anode surfaces to improve thermal management. These specialized layers can include ceramic coatings, polymer composites, or metallic films that help regulate heat flow while providing additional benefits such as corrosion resistance or improved electrical conductivity. The interface design between the anode and adjacent components is optimized to minimize thermal resistance and ensure efficient heat transfer across boundaries, which is essential for high-power applications.Expand Specific Solutions04 Structural design for thermal optimization

The physical structure and geometry of anode materials are engineered specifically for thermal management. This includes porous structures, finned designs, and microchannels that increase surface area for heat dissipation. Three-dimensional architectures allow for better heat distribution throughout the material. Advanced manufacturing techniques like 3D printing enable the creation of complex thermal management structures within the anode that would be impossible with traditional manufacturing methods, resulting in more efficient thermal regulation.Expand Specific Solutions05 Active thermal management systems

Active thermal management systems are implemented to dynamically control the temperature of anode materials during operation. These systems include thermoelectric coolers, intelligent thermal management controllers, and adaptive cooling mechanisms that respond to changing thermal loads. Sensors monitor temperature in real-time, allowing the system to adjust cooling parameters accordingly. This approach is particularly important for high-power applications where thermal conditions can change rapidly, ensuring that anode materials remain within optimal temperature ranges even under variable operating conditions.Expand Specific Solutions

Key Industry Players in Battery Anode Materials

The battery thermal management technology landscape is currently in a growth phase, with the market expanding rapidly due to increasing electric vehicle adoption. Major players like Samsung SDI, LG Chem, and SK On are leading innovation in anode materials for thermal management, with established electronics giants Sony and Panasonic also maintaining significant market presence. The technology is approaching maturity in consumer electronics applications but remains in development for automotive use cases. Companies like BTR New Material Group and Echion Technologies are advancing specialized anode materials that address thermal challenges, while research institutions like Forschungszentrum Jülich and Johns Hopkins University contribute fundamental breakthroughs. The competitive landscape is characterized by both vertical integration from automotive manufacturers and specialized material science innovators.

BTR New Material Group Co., Ltd.

Technical Solution: BTR New Material Group has developed a comprehensive thermal management solution centered around their advanced artificial graphite and silicon-carbon composite anode materials. Their approach integrates material-level innovations with system engineering to address thermal challenges in high-energy density batteries. The company's silicon-carbon composite anodes feature a hierarchical porous structure that facilitates both lithium-ion diffusion and heat dissipation. BTR has implemented a proprietary surface modification technique that reduces interfacial resistance between the anode and electrolyte, thereby decreasing heat generation during cycling. Their thermal management system incorporates a network of micro-channels embedded within the anode current collector, creating direct thermal pathways from heat generation sites. The company utilizes phase-change materials (PCMs) with tailored melting points matched to the thermal characteristics of their specific anode compositions. Laboratory testing has demonstrated that batteries incorporating BTR's thermal management solution maintain temperature gradients below 3.5°C even under high discharge rates (>2C), resulting in significantly improved cycle life and safety performance compared to conventional designs.

Strengths: The hierarchical porous structure provides excellent thermal conductivity while maintaining high energy density. The integrated micro-channel design addresses heat generation directly at the anode surface where thermal issues typically originate. Weaknesses: The complex anode structure requires precise manufacturing controls, potentially limiting production scalability. The system's effectiveness is somewhat dependent on specific electrolyte formulations, reducing flexibility in battery design.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced battery thermal management system (BTMS) utilizing silicon-carbon composite anode materials. Their approach integrates a direct liquid cooling system with optimized cell spacing and coolant flow patterns to address thermal challenges in high-capacity batteries. The silicon-carbon composite anodes offer higher capacity (up to 3-4 times that of traditional graphite) while maintaining structural stability during charge-discharge cycles. LG's system employs a sophisticated thermal modeling approach that predicts hotspot formation and implements targeted cooling strategies. Their proprietary electrolyte additives work synergistically with the anode materials to form stable SEI layers that reduce exothermic reactions during cycling. Recent implementations show temperature gradients maintained below 3°C across battery packs even under high discharge rates (>3C), significantly extending battery life and improving safety metrics.

Strengths: Superior thermal conductivity compared to traditional graphite anodes, allowing more efficient heat dissipation. The silicon-carbon composite structure provides higher energy density while maintaining thermal stability. Weaknesses: Higher manufacturing costs associated with silicon-carbon composite materials. Potential for capacity fade over extended cycling due to silicon's volume expansion characteristics despite thermal management improvements.

Critical Patents and Research in Anode Material Innovation

Thermal management material and applications thereof in thermal management module of cylindrical battery

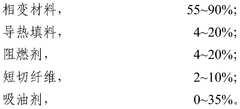

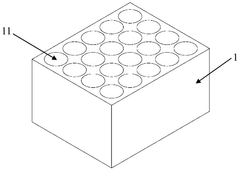

PatentWO2018103305A1

Innovation

- A thermal management material based on phase change materials is used, consisting of 55 to 90% phase change materials, 4 to 20% thermally conductive fillers, 4 to 20% flame retardants, 2 to 10% chopped fibers and 0 ~35% oil absorbent, a thermal management module is prepared through a molding method, which is used for thermal management of cylindrical batteries to ensure temperature uniformity and safety.

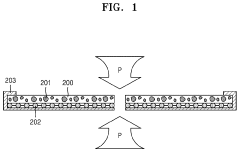

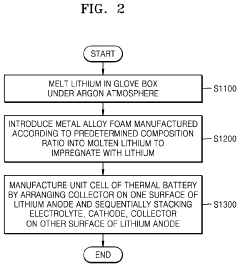

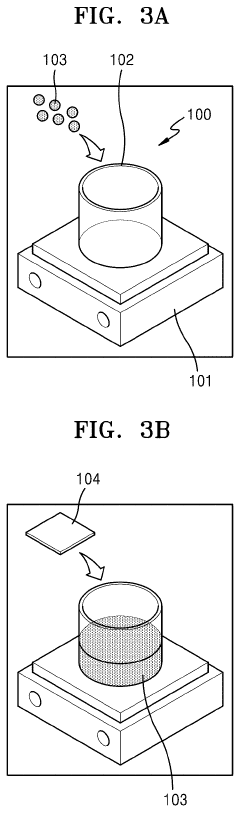

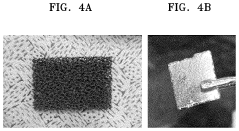

Anode for thermal battery, apparatus for manufacturing the anode for thermal battery, and method of manufacturing the anode for thermal battery

PatentPendingUS20230411590A1

Innovation

- A lithium anode is manufactured by immersing a metal alloy foam with predetermined compositions of nickel, iron, chromium, aluminum, and molybdenum in molten lithium, facilitating lithium impregnation and reducing reactivity, thereby enhancing specific capacity and stability without the need for additional surface treatments or structural supports.

Safety Standards and Regulatory Compliance

The regulatory landscape for battery thermal management systems (BTMS) has evolved significantly with the growing adoption of lithium-ion batteries across industries. International standards such as IEC 62133 and UL 1642 establish comprehensive safety requirements for batteries, with specific provisions addressing thermal management aspects. These standards mandate rigorous testing protocols including thermal abuse tests, overcharge protection, and short circuit prevention mechanisms that directly impact anode material selection and design.

The UN Transportation Testing requirements (UN 38.3) impose additional constraints on battery thermal characteristics during transportation, requiring batteries to withstand extreme temperature variations without thermal runaway. This has significant implications for anode materials, as their thermal stability directly affects compliance with these regulations. Materials with lower thermal expansion coefficients and higher thermal stability are increasingly preferred to meet these stringent transportation requirements.

Regional variations in safety standards present additional complexity for manufacturers. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize recyclability and environmental impact alongside safety considerations. Meanwhile, China's GB/T 31485 standard implements particularly stringent thermal propagation requirements that influence anode material selection. These regional differences necessitate careful consideration when designing battery systems for global markets.

Industry-specific regulations further complicate the regulatory landscape. Automotive applications must comply with additional standards such as ISO 6469 and SAE J2929, which establish specific thermal management requirements for electric vehicle batteries. These standards often necessitate more thermally stable anode materials than those used in consumer electronics applications.

Emerging regulations are increasingly focusing on the entire lifecycle of battery systems. The proposed EU Battery Regulation aims to establish a comprehensive framework addressing sustainability, carbon footprint, and end-of-life management alongside safety considerations. This regulatory trend is driving research toward anode materials with improved thermal characteristics that simultaneously offer enhanced environmental performance.

Compliance testing methodologies for anode materials have become more sophisticated, with accelerated life testing and thermal cycling protocols now standard industry practice. These tests evaluate how different anode materials perform under thermal stress over extended periods, providing critical data for regulatory compliance. Advanced computational modeling techniques are increasingly accepted by regulatory bodies as complementary evidence for safety certification, allowing manufacturers to optimize anode material selection before physical testing.

The UN Transportation Testing requirements (UN 38.3) impose additional constraints on battery thermal characteristics during transportation, requiring batteries to withstand extreme temperature variations without thermal runaway. This has significant implications for anode materials, as their thermal stability directly affects compliance with these regulations. Materials with lower thermal expansion coefficients and higher thermal stability are increasingly preferred to meet these stringent transportation requirements.

Regional variations in safety standards present additional complexity for manufacturers. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize recyclability and environmental impact alongside safety considerations. Meanwhile, China's GB/T 31485 standard implements particularly stringent thermal propagation requirements that influence anode material selection. These regional differences necessitate careful consideration when designing battery systems for global markets.

Industry-specific regulations further complicate the regulatory landscape. Automotive applications must comply with additional standards such as ISO 6469 and SAE J2929, which establish specific thermal management requirements for electric vehicle batteries. These standards often necessitate more thermally stable anode materials than those used in consumer electronics applications.

Emerging regulations are increasingly focusing on the entire lifecycle of battery systems. The proposed EU Battery Regulation aims to establish a comprehensive framework addressing sustainability, carbon footprint, and end-of-life management alongside safety considerations. This regulatory trend is driving research toward anode materials with improved thermal characteristics that simultaneously offer enhanced environmental performance.

Compliance testing methodologies for anode materials have become more sophisticated, with accelerated life testing and thermal cycling protocols now standard industry practice. These tests evaluate how different anode materials perform under thermal stress over extended periods, providing critical data for regulatory compliance. Advanced computational modeling techniques are increasingly accepted by regulatory bodies as complementary evidence for safety certification, allowing manufacturers to optimize anode material selection before physical testing.

Environmental Impact and Sustainability Considerations

The environmental impact of anode materials in battery thermal management systems represents a critical consideration in the sustainable development of energy storage technologies. Different anode materials exhibit varying ecological footprints throughout their lifecycle, from raw material extraction to manufacturing, utilization, and eventual disposal. Silicon-based anodes, while offering higher energy density than traditional graphite, require energy-intensive processing methods that contribute significantly to carbon emissions during production. Conversely, graphite anodes present lower manufacturing emissions but face sustainability challenges related to mining practices and resource depletion.

Life cycle assessment (LCA) studies indicate that lithium titanate oxide (LTO) anodes demonstrate superior environmental performance in several categories, including reduced greenhouse gas emissions and lower ecotoxicity potential during operation. This advantage stems primarily from their exceptional thermal stability, which minimizes the risk of thermal runaway events and reduces the need for extensive cooling systems that consume additional energy and resources.

Water consumption represents another significant environmental concern in anode material production. Manufacturing processes for advanced materials such as silicon-carbon composites and metal alloys typically require substantial water resources for purification and processing. This water footprint becomes particularly problematic in regions experiencing water scarcity, necessitating the development of more water-efficient production techniques.

Recycling capabilities vary considerably among different anode materials, directly impacting their end-of-life environmental impact. Materials containing toxic heavy metals present significant challenges for safe disposal and recycling, while newer organic anode materials offer promising biodegradability characteristics. Current recycling technologies can recover approximately 50-80% of materials from conventional anodes, though recovery rates for newer composite materials remain substantially lower.

The environmental implications extend beyond direct material impacts to include the efficiency of thermal management systems themselves. Anodes with superior thermal conductivity properties enable more efficient heat dissipation, reducing the energy requirements for active cooling systems throughout battery operation. This operational efficiency translates to lower lifetime carbon emissions, particularly for grid storage and electric vehicle applications where batteries undergo thousands of charge-discharge cycles.

Regulatory frameworks increasingly incorporate environmental performance metrics into battery material standards, with several jurisdictions implementing extended producer responsibility policies that hold manufacturers accountable for the entire lifecycle environmental impact of their products. These evolving regulations are driving innovation toward more sustainable anode materials that balance performance requirements with reduced environmental footprints.

Life cycle assessment (LCA) studies indicate that lithium titanate oxide (LTO) anodes demonstrate superior environmental performance in several categories, including reduced greenhouse gas emissions and lower ecotoxicity potential during operation. This advantage stems primarily from their exceptional thermal stability, which minimizes the risk of thermal runaway events and reduces the need for extensive cooling systems that consume additional energy and resources.

Water consumption represents another significant environmental concern in anode material production. Manufacturing processes for advanced materials such as silicon-carbon composites and metal alloys typically require substantial water resources for purification and processing. This water footprint becomes particularly problematic in regions experiencing water scarcity, necessitating the development of more water-efficient production techniques.

Recycling capabilities vary considerably among different anode materials, directly impacting their end-of-life environmental impact. Materials containing toxic heavy metals present significant challenges for safe disposal and recycling, while newer organic anode materials offer promising biodegradability characteristics. Current recycling technologies can recover approximately 50-80% of materials from conventional anodes, though recovery rates for newer composite materials remain substantially lower.

The environmental implications extend beyond direct material impacts to include the efficiency of thermal management systems themselves. Anodes with superior thermal conductivity properties enable more efficient heat dissipation, reducing the energy requirements for active cooling systems throughout battery operation. This operational efficiency translates to lower lifetime carbon emissions, particularly for grid storage and electric vehicle applications where batteries undergo thousands of charge-discharge cycles.

Regulatory frameworks increasingly incorporate environmental performance metrics into battery material standards, with several jurisdictions implementing extended producer responsibility policies that hold manufacturers accountable for the entire lifecycle environmental impact of their products. These evolving regulations are driving innovation toward more sustainable anode materials that balance performance requirements with reduced environmental footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!