Battery Thermal Management in Relation to Semiconductor Materials

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Background and Objectives

Battery thermal management has evolved significantly over the past decades, transitioning from simple passive cooling systems to sophisticated active thermal management solutions. The integration of semiconductor materials in battery thermal management represents a critical technological advancement that addresses the increasing demands for higher energy density, faster charging capabilities, and enhanced safety in battery systems. Historically, thermal management focused primarily on preventing thermal runaway in lead-acid batteries, but with the proliferation of lithium-ion batteries in consumer electronics, electric vehicles, and renewable energy storage, the complexity and importance of thermal management have grown exponentially.

The evolution of battery thermal management technologies has been driven by several factors, including the miniaturization of electronic devices, the push for longer-range electric vehicles, and the need for more efficient grid-scale energy storage solutions. Early thermal management systems relied heavily on mechanical cooling methods, but recent advancements have incorporated semiconductor materials to enable more precise temperature control, reduced system size, and improved energy efficiency.

Current technological trends indicate a shift towards integrated thermal management solutions that leverage the unique properties of semiconductor materials. These materials offer advantages in thermal conductivity, electrical insulation, and compatibility with battery chemistries. The development of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has opened new possibilities for high-temperature operation and more efficient power conversion in battery management systems.

The primary objective of incorporating semiconductor materials in battery thermal management is to achieve optimal operating temperatures across various usage conditions while minimizing energy consumption and system complexity. Specific goals include maintaining battery temperature within the ideal range of 15-35°C during operation, reducing thermal gradients within battery packs to less than 5°C, extending battery lifespan by at least 20%, and enabling fast charging capabilities without compromising safety or longevity.

Additionally, semiconductor-based thermal management aims to address key challenges in the battery industry, including thermal runaway prevention, weight and volume reduction, cost-effectiveness, and adaptability to different battery chemistries and form factors. The integration of semiconductor materials also supports the development of smart thermal management systems that can predict and respond to changing thermal conditions in real-time, optimizing battery performance and safety.

As battery technologies continue to advance, thermal management systems must evolve to meet increasingly stringent requirements for efficiency, safety, and reliability. The convergence of semiconductor technology and battery thermal management represents a promising frontier for innovation that could significantly impact the future of energy storage and utilization across multiple industries.

The evolution of battery thermal management technologies has been driven by several factors, including the miniaturization of electronic devices, the push for longer-range electric vehicles, and the need for more efficient grid-scale energy storage solutions. Early thermal management systems relied heavily on mechanical cooling methods, but recent advancements have incorporated semiconductor materials to enable more precise temperature control, reduced system size, and improved energy efficiency.

Current technological trends indicate a shift towards integrated thermal management solutions that leverage the unique properties of semiconductor materials. These materials offer advantages in thermal conductivity, electrical insulation, and compatibility with battery chemistries. The development of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has opened new possibilities for high-temperature operation and more efficient power conversion in battery management systems.

The primary objective of incorporating semiconductor materials in battery thermal management is to achieve optimal operating temperatures across various usage conditions while minimizing energy consumption and system complexity. Specific goals include maintaining battery temperature within the ideal range of 15-35°C during operation, reducing thermal gradients within battery packs to less than 5°C, extending battery lifespan by at least 20%, and enabling fast charging capabilities without compromising safety or longevity.

Additionally, semiconductor-based thermal management aims to address key challenges in the battery industry, including thermal runaway prevention, weight and volume reduction, cost-effectiveness, and adaptability to different battery chemistries and form factors. The integration of semiconductor materials also supports the development of smart thermal management systems that can predict and respond to changing thermal conditions in real-time, optimizing battery performance and safety.

As battery technologies continue to advance, thermal management systems must evolve to meet increasingly stringent requirements for efficiency, safety, and reliability. The convergence of semiconductor technology and battery thermal management represents a promising frontier for innovation that could significantly impact the future of energy storage and utilization across multiple industries.

Market Analysis for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions in battery systems is experiencing robust growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. Current market valuations indicate that the battery thermal management system (BTMS) sector reached approximately 3.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 22% through 2030. This exceptional growth trajectory significantly outpaces many other automotive and energy technology segments.

Semiconductor materials play a crucial role in this market, as they form the foundation for next-generation thermal management solutions. Silicon carbide (SiC) and gallium nitride (GaN) based thermal management components are gaining substantial market share, with their segment growing at nearly 30% annually due to superior thermal conductivity properties compared to traditional materials.

Regional analysis reveals that Asia-Pacific currently dominates the market with over 45% share, led by China, Japan, and South Korea where major battery and EV manufacturing is concentrated. North America and Europe follow with approximately 25% and 20% market shares respectively, with particularly strong growth in regions with aggressive electrification policies.

By application segment, passenger EVs represent the largest market for advanced thermal management solutions at 58% of total demand, followed by commercial EVs (15%), stationary energy storage (14%), and consumer electronics (13%). The premium EV segment demonstrates the highest adoption rate of semiconductor-based thermal management systems, though mid-market vehicles are rapidly increasing implementation as costs decrease.

Customer demand patterns indicate a strong preference for thermal management solutions that extend battery life and enable faster charging capabilities. Market research shows that consumers are willing to pay a premium of 5-8% for vehicles with advanced thermal management systems that can reduce charging times by 30% or more.

Key market drivers include increasingly stringent safety regulations following high-profile battery thermal incidents, the push for greater energy density in batteries, and the competitive advantage gained through extended range and faster charging capabilities. The market is also being shaped by sustainability concerns, with solutions that reduce overall energy consumption for thermal management gaining preference among environmentally conscious consumers and manufacturers committed to carbon reduction targets.

Supply chain analysis reveals potential constraints in semiconductor material availability, with current production capacity struggling to meet rapidly growing demand. This supply-demand imbalance is creating opportunities for new market entrants, particularly those with innovative approaches to thermal management that reduce reliance on scarce materials.

Semiconductor materials play a crucial role in this market, as they form the foundation for next-generation thermal management solutions. Silicon carbide (SiC) and gallium nitride (GaN) based thermal management components are gaining substantial market share, with their segment growing at nearly 30% annually due to superior thermal conductivity properties compared to traditional materials.

Regional analysis reveals that Asia-Pacific currently dominates the market with over 45% share, led by China, Japan, and South Korea where major battery and EV manufacturing is concentrated. North America and Europe follow with approximately 25% and 20% market shares respectively, with particularly strong growth in regions with aggressive electrification policies.

By application segment, passenger EVs represent the largest market for advanced thermal management solutions at 58% of total demand, followed by commercial EVs (15%), stationary energy storage (14%), and consumer electronics (13%). The premium EV segment demonstrates the highest adoption rate of semiconductor-based thermal management systems, though mid-market vehicles are rapidly increasing implementation as costs decrease.

Customer demand patterns indicate a strong preference for thermal management solutions that extend battery life and enable faster charging capabilities. Market research shows that consumers are willing to pay a premium of 5-8% for vehicles with advanced thermal management systems that can reduce charging times by 30% or more.

Key market drivers include increasingly stringent safety regulations following high-profile battery thermal incidents, the push for greater energy density in batteries, and the competitive advantage gained through extended range and faster charging capabilities. The market is also being shaped by sustainability concerns, with solutions that reduce overall energy consumption for thermal management gaining preference among environmentally conscious consumers and manufacturers committed to carbon reduction targets.

Supply chain analysis reveals potential constraints in semiconductor material availability, with current production capacity struggling to meet rapidly growing demand. This supply-demand imbalance is creating opportunities for new market entrants, particularly those with innovative approaches to thermal management that reduce reliance on scarce materials.

Current Challenges in Semiconductor-Based Thermal Management

Despite significant advancements in semiconductor-based thermal management for batteries, several critical challenges persist that impede optimal performance and widespread adoption. The primary challenge remains the thermal conductivity limitations of current semiconductor materials. While materials like silicon carbide and gallium nitride offer improved thermal properties compared to traditional silicon, they still struggle to efficiently dissipate heat generated during high-power battery operations, particularly in fast-charging scenarios where thermal loads increase exponentially.

Integration complexity presents another significant hurdle. The incorporation of semiconductor-based thermal management systems into existing battery architectures requires sophisticated design approaches that must balance thermal performance with space constraints, especially in compact applications like electric vehicles and portable electronics. This integration often necessitates complete redesign of battery packs, increasing development costs and time-to-market.

Cost factors continue to be prohibitive for mass-market adoption. Advanced semiconductor materials with superior thermal properties typically involve complex manufacturing processes, resulting in substantially higher production costs compared to conventional cooling solutions. The economic viability of these systems remains questionable for consumer-grade applications, creating a significant barrier to widespread implementation.

Reliability under extreme conditions poses another challenge. Semiconductor-based thermal management systems must maintain consistent performance across wide temperature ranges and operational conditions. Current solutions often exhibit performance degradation under extreme thermal cycling, raising concerns about long-term durability and safety in critical applications like electric vehicles and grid storage systems.

Power consumption of active semiconductor cooling systems presents an efficiency paradox. These systems require electrical power to operate, which can reduce the overall energy efficiency of the battery system they are designed to protect. This parasitic power draw becomes particularly problematic in energy-constrained applications where battery life is a critical performance metric.

Scalability issues further complicate implementation across different battery sizes and configurations. Solutions that work effectively for small-scale batteries often cannot be linearly scaled to larger systems without significant redesign and optimization. This lack of scalability hampers standardization efforts and increases engineering complexity for manufacturers working across multiple product lines.

Interfacial thermal resistance between semiconductor cooling elements and battery cells remains a persistent technical challenge. Even with high-conductivity semiconductor materials, the thermal interface between components can create bottlenecks that limit overall heat transfer efficiency, necessitating advanced interface materials and bonding techniques that add complexity and cost.

Integration complexity presents another significant hurdle. The incorporation of semiconductor-based thermal management systems into existing battery architectures requires sophisticated design approaches that must balance thermal performance with space constraints, especially in compact applications like electric vehicles and portable electronics. This integration often necessitates complete redesign of battery packs, increasing development costs and time-to-market.

Cost factors continue to be prohibitive for mass-market adoption. Advanced semiconductor materials with superior thermal properties typically involve complex manufacturing processes, resulting in substantially higher production costs compared to conventional cooling solutions. The economic viability of these systems remains questionable for consumer-grade applications, creating a significant barrier to widespread implementation.

Reliability under extreme conditions poses another challenge. Semiconductor-based thermal management systems must maintain consistent performance across wide temperature ranges and operational conditions. Current solutions often exhibit performance degradation under extreme thermal cycling, raising concerns about long-term durability and safety in critical applications like electric vehicles and grid storage systems.

Power consumption of active semiconductor cooling systems presents an efficiency paradox. These systems require electrical power to operate, which can reduce the overall energy efficiency of the battery system they are designed to protect. This parasitic power draw becomes particularly problematic in energy-constrained applications where battery life is a critical performance metric.

Scalability issues further complicate implementation across different battery sizes and configurations. Solutions that work effectively for small-scale batteries often cannot be linearly scaled to larger systems without significant redesign and optimization. This lack of scalability hampers standardization efforts and increases engineering complexity for manufacturers working across multiple product lines.

Interfacial thermal resistance between semiconductor cooling elements and battery cells remains a persistent technical challenge. Even with high-conductivity semiconductor materials, the thermal interface between components can create bottlenecks that limit overall heat transfer efficiency, necessitating advanced interface materials and bonding techniques that add complexity and cost.

Current Semiconductor Solutions for Battery Thermal Control

01 Silicon-based semiconductor materials for thermal management

Silicon-based semiconductor materials are widely used in battery thermal management systems due to their excellent thermal conductivity and compatibility with existing manufacturing processes. These materials can efficiently dissipate heat generated during battery operation, preventing thermal runaway and extending battery life. Silicon-based thermal interface materials can be integrated into battery packs to create effective heat transfer pathways, ensuring uniform temperature distribution across battery cells.- Silicon-based semiconductor materials for thermal management: Silicon-based semiconductor materials are utilized in battery thermal management systems due to their excellent thermal conductivity properties. These materials help in efficiently dissipating heat generated during battery operation, preventing overheating and maintaining optimal operating temperatures. Silicon-based thermal interface materials can be integrated into battery packs to create effective heat transfer pathways, enhancing overall thermal management efficiency and battery performance.

- Graphene and carbon-based thermal management solutions: Graphene and other carbon-based materials offer superior thermal conductivity for battery thermal management applications. These materials can be incorporated as thermal interface materials, heat spreaders, or cooling fins to efficiently transfer heat away from battery cells. The two-dimensional structure of graphene allows for rapid heat dissipation across surfaces, while carbon composites can be engineered to provide directional heat transfer according to specific battery pack designs, significantly improving thermal regulation.

- Phase change semiconductor materials for thermal regulation: Phase change semiconductor materials provide effective thermal management through their ability to absorb and release heat during phase transitions. These materials can be integrated into battery systems to maintain stable operating temperatures by absorbing excess heat during high-load operations and releasing it when temperatures drop. This passive thermal regulation approach helps prevent thermal runaway conditions and extends battery life by maintaining optimal temperature ranges without requiring additional energy input.

- Semiconductor-based thermal sensors and control systems: Advanced semiconductor-based thermal sensors and control systems enable real-time monitoring and management of battery temperatures. These integrated systems utilize temperature-sensitive semiconductor materials to detect thermal variations across battery cells and modules. The data collected is processed by control algorithms that can activate cooling mechanisms or adjust charging/discharging rates to maintain optimal thermal conditions. This active thermal management approach helps prevent localized hotspots and ensures uniform temperature distribution throughout the battery pack.

- Hybrid semiconductor thermal management architectures: Hybrid thermal management systems combine multiple semiconductor materials with complementary properties to achieve optimal thermal regulation in battery packs. These architectures may integrate silicon-based heat spreaders with graphene thermal interfaces and phase change materials to create comprehensive thermal solutions. By leveraging the unique advantages of different semiconductor materials, these hybrid systems can address various thermal challenges simultaneously, including heat generation during charging, temperature gradients across cells, and thermal runaway prevention.

02 Graphene and carbon-based thermal management solutions

Graphene and other carbon-based materials offer superior thermal conductivity for battery thermal management applications. These materials can be incorporated into thermal interface materials, heat spreaders, or cooling systems to efficiently transfer heat away from battery cells. Carbon nanotubes, graphene sheets, and carbon composites provide lightweight yet highly effective thermal management solutions that can be integrated into various battery designs, helping to maintain optimal operating temperatures even under high discharge rates.Expand Specific Solutions03 Phase change materials with semiconductor components

Phase change materials (PCMs) integrated with semiconductor components create advanced thermal management systems for batteries. These hybrid materials can absorb excess heat during battery operation through phase transition processes and release it when the battery temperature decreases. By incorporating semiconductor elements into PCMs, the thermal conductivity and heat storage capacity can be significantly enhanced, providing more efficient temperature regulation and preventing thermal hotspots in battery packs.Expand Specific Solutions04 Thermoelectric semiconductor cooling systems

Thermoelectric semiconductor materials utilize the Peltier effect to actively cool battery systems by converting electrical energy into a temperature gradient. These materials can be integrated into battery thermal management systems to provide precise temperature control, especially in extreme operating conditions. Bismuth telluride and other semiconductor thermoelectric materials enable active cooling without moving parts, increasing reliability while maintaining optimal battery temperature ranges to maximize performance and longevity.Expand Specific Solutions05 Semiconductor-based thermal sensors and control systems

Advanced semiconductor-based thermal sensors and control systems enable real-time monitoring and management of battery temperatures. These integrated systems use temperature-sensitive semiconductor materials to detect thermal variations across battery cells and trigger appropriate cooling responses. The combination of semiconductor sensors with intelligent control algorithms allows for predictive thermal management, preventing potential thermal issues before they occur and optimizing battery performance under varying load conditions.Expand Specific Solutions

Leading Companies in Battery Thermal Management Semiconductors

The battery thermal management landscape in relation to semiconductor materials is evolving rapidly, currently positioned in the growth phase with an estimated market value exceeding $5 billion annually. Major automotive players like Samsung SDI, NIO, and Rimac Technology are driving innovation alongside semiconductor specialists such as GlobalFoundries and IBM. The technology maturity varies significantly across applications, with companies like Gentherm and Aspen Aerogels leading in thermal management solutions while newer entrants focus on semiconductor integration. Research institutions including Illinois Institute of Technology and Guangdong University of Technology are accelerating development through industry partnerships, particularly in areas of wide-bandgap semiconductors and advanced thermal interface materials for next-generation battery systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced semiconductor-based battery thermal management system (BTMS) that integrates silicon carbide (SiC) and gallium nitride (GaN) power semiconductors into their battery modules. Their solution employs a multi-layered approach where semiconductor materials are strategically placed between battery cells to facilitate efficient heat dissipation. The system utilizes phase-change materials (PCMs) combined with semiconductor thermal interface materials that optimize thermal conductivity while maintaining electrical isolation. Samsung's BTMS incorporates intelligent thermal sensors embedded within semiconductor substrates that provide real-time temperature monitoring across the battery pack, enabling dynamic thermal management. Their system adjusts cooling intensity based on operational conditions, battery state of charge, and ambient temperature, significantly improving energy efficiency and battery longevity.

Strengths: Superior thermal conductivity of semiconductor materials enables more efficient heat dissipation; integrated sensor network allows for precise temperature control; system adaptability to various operating conditions. Weaknesses: Higher production costs compared to conventional thermal management systems; increased complexity in manufacturing processes; potential reliability concerns with long-term semiconductor material degradation under thermal cycling.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered a semiconductor-based thermoelectric battery thermal management system that leverages the Peltier effect to provide both heating and cooling capabilities for EV batteries. Their proprietary technology utilizes bismuth telluride semiconductor materials configured in a matrix of thermoelectric modules that can be selectively activated to create temperature differentials. The system incorporates a network of semiconductor temperature sensors and microcontrollers that continuously monitor battery cell temperatures and adjust thermal management parameters accordingly. Gentherm's solution includes specialized semiconductor thermal interface materials that maximize heat transfer between battery cells and cooling elements while minimizing electrical interference. Their advanced algorithm optimizes power consumption by the thermal management system based on driving conditions, battery usage patterns, and environmental factors, resulting in extended driving range and battery lifespan.

Strengths: Bidirectional thermal management capability (both heating and cooling); precise temperature control at individual cell level; energy-efficient operation that minimizes impact on vehicle range. Weaknesses: Higher initial cost compared to traditional cooling systems; complexity of thermoelectric semiconductor manufacturing; potential reliability issues in extreme temperature environments.

Key Patents in Semiconductor Thermal Interface Materials

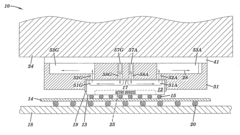

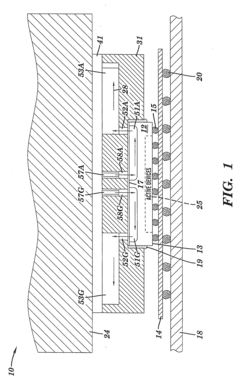

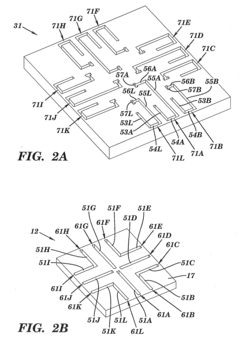

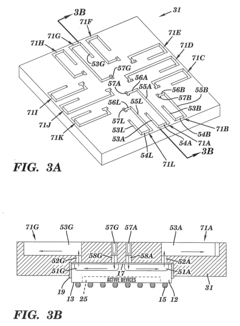

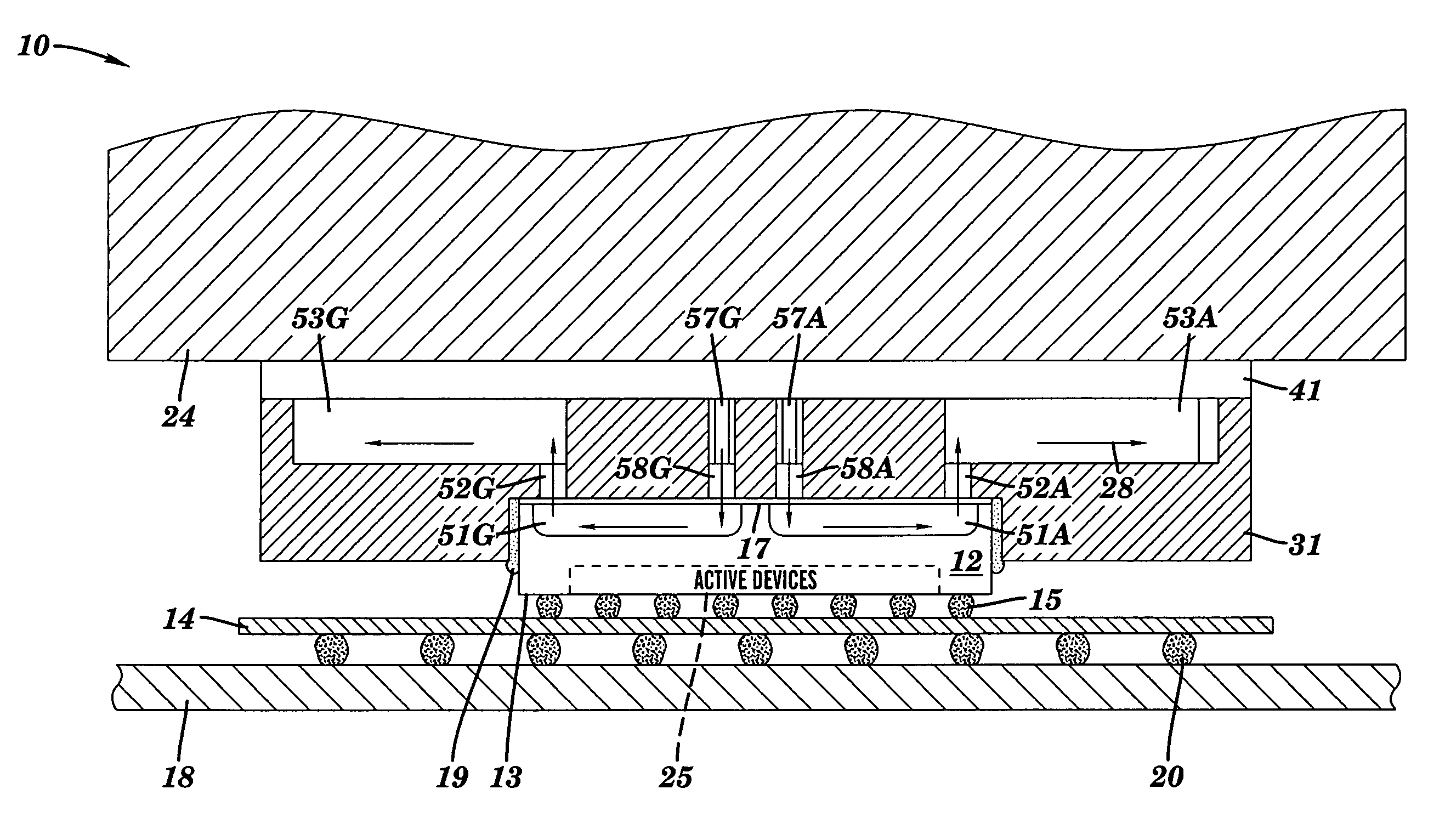

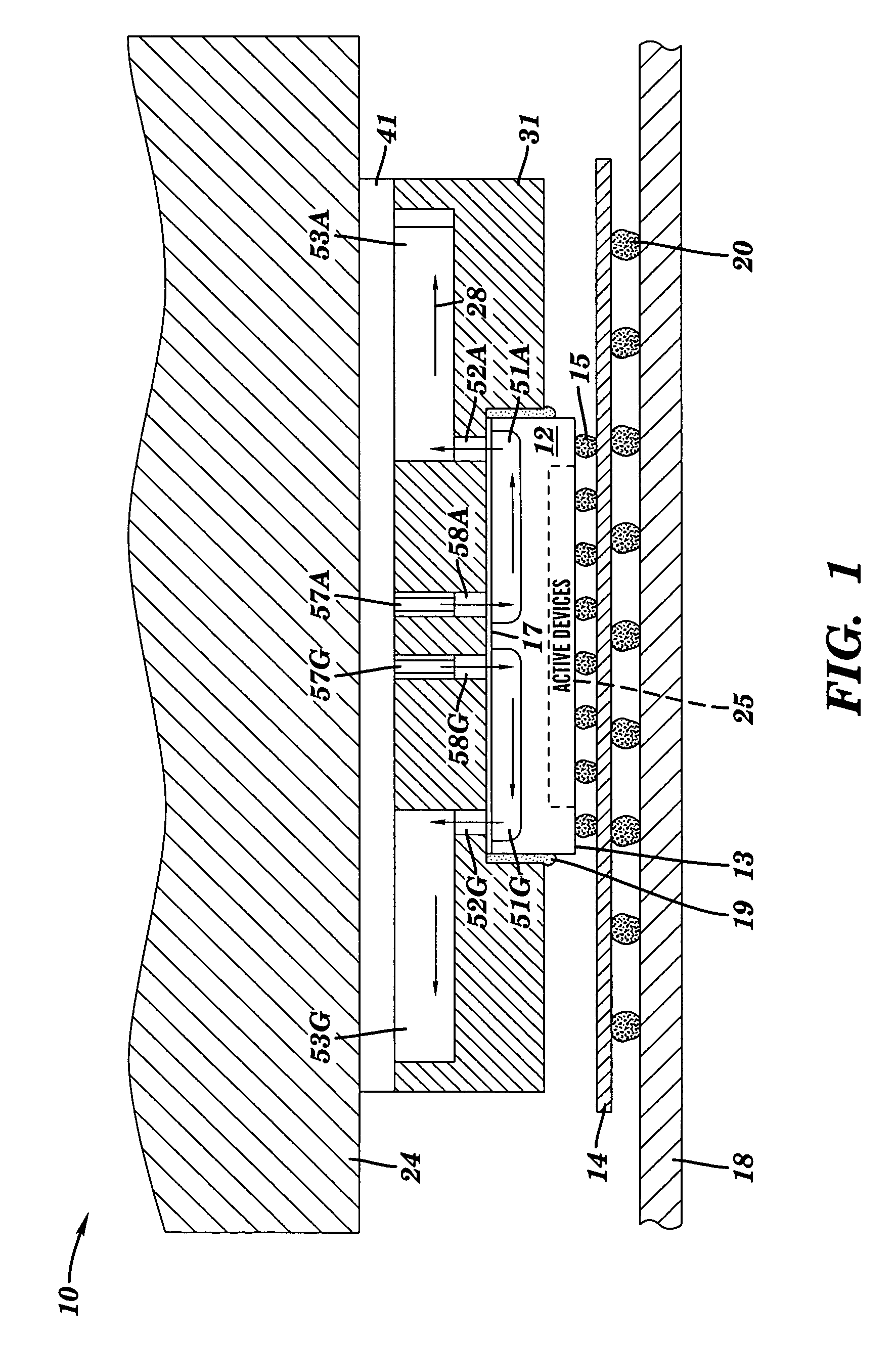

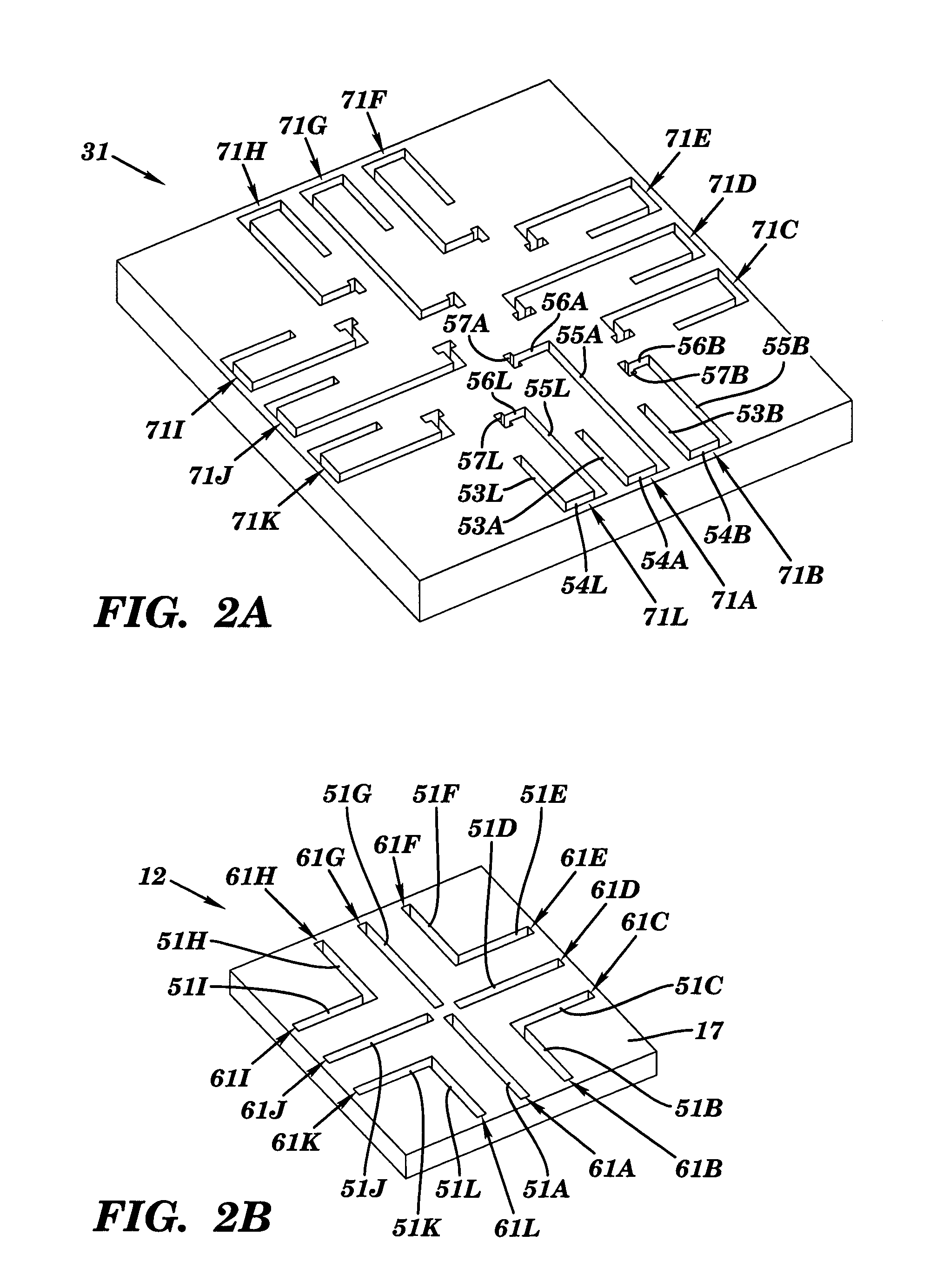

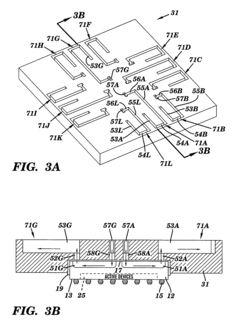

Cooling of substrate using interposer channels

PatentInactiveUS20090008129A1

Innovation

- A structure comprising a substrate with continuous channels and an interposer forming alternating loops of substrate and interposer channels, thermally coupled to a heat sink, facilitating efficient heat transfer through fluid flow and phase change mechanisms to dissipate heat effectively.

Cooling of substrate using interposer channels

PatentActiveUS7434308B2

Innovation

- A structure comprising a substrate with continuous channels and an interposer forming alternating loops, thermally coupled to a heat sink, where a thermally conductive foam material with serpentine channels is used to transfer heat from the chip to the sink via fluid circulation.

Environmental Impact and Sustainability Considerations

The environmental footprint of battery thermal management systems (BTMS) is increasingly scrutinized as electric vehicle adoption accelerates globally. Semiconductor materials used in these systems present both environmental challenges and opportunities. Traditional silicon-based power electronics in BTMS generate significant waste during manufacturing, with estimates suggesting that semiconductor production requires up to 300 times the weight of the final product in raw materials. Wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), while offering superior thermal performance, introduce new environmental considerations regarding resource extraction and processing.

The lifecycle assessment of semiconductor materials in BTMS reveals concerning energy intensity. Manufacturing processes for advanced semiconductor components typically consume between 1,000-2,000 kWh per kilogram of finished product, substantially higher than conventional materials. However, this initial environmental investment can be offset through operational efficiency gains, as these materials enable more precise thermal management and reduced energy consumption throughout battery life.

Water usage presents another critical environmental concern, with semiconductor fabrication facilities consuming millions of gallons daily. Recent innovations in closed-loop cooling systems have demonstrated potential water usage reductions of 30-45% compared to conventional manufacturing processes, though implementation remains limited to leading manufacturers.

End-of-life considerations for semiconductor components in BTMS present both challenges and opportunities. Currently, less than 20% of semiconductor materials are effectively recovered from discarded electronic systems. Emerging recycling technologies specifically targeting wide-bandgap semiconductors show promise, with laboratory-scale processes achieving recovery rates of up to 85% for gallium and 70% for silicon carbide, though commercial-scale implementation remains limited.

The carbon footprint of semiconductor-based BTMS must be evaluated holistically. While production processes generate significant emissions, advanced semiconductor materials enable more efficient thermal management that extends battery lifespan by 15-30% according to recent field studies. This extension directly reduces the environmental impact associated with battery production and disposal, creating a net positive environmental effect despite higher initial emissions.

Regulatory frameworks are evolving to address these environmental considerations. The European Union's proposed Battery Regulation includes specific provisions for thermal management systems, requiring lifecycle assessments and minimum recycled content requirements that will significantly impact semiconductor material selection and design approaches. Similar regulations are emerging in North America and Asia, creating a global shift toward environmentally optimized BTMS designs.

The lifecycle assessment of semiconductor materials in BTMS reveals concerning energy intensity. Manufacturing processes for advanced semiconductor components typically consume between 1,000-2,000 kWh per kilogram of finished product, substantially higher than conventional materials. However, this initial environmental investment can be offset through operational efficiency gains, as these materials enable more precise thermal management and reduced energy consumption throughout battery life.

Water usage presents another critical environmental concern, with semiconductor fabrication facilities consuming millions of gallons daily. Recent innovations in closed-loop cooling systems have demonstrated potential water usage reductions of 30-45% compared to conventional manufacturing processes, though implementation remains limited to leading manufacturers.

End-of-life considerations for semiconductor components in BTMS present both challenges and opportunities. Currently, less than 20% of semiconductor materials are effectively recovered from discarded electronic systems. Emerging recycling technologies specifically targeting wide-bandgap semiconductors show promise, with laboratory-scale processes achieving recovery rates of up to 85% for gallium and 70% for silicon carbide, though commercial-scale implementation remains limited.

The carbon footprint of semiconductor-based BTMS must be evaluated holistically. While production processes generate significant emissions, advanced semiconductor materials enable more efficient thermal management that extends battery lifespan by 15-30% according to recent field studies. This extension directly reduces the environmental impact associated with battery production and disposal, creating a net positive environmental effect despite higher initial emissions.

Regulatory frameworks are evolving to address these environmental considerations. The European Union's proposed Battery Regulation includes specific provisions for thermal management systems, requiring lifecycle assessments and minimum recycled content requirements that will significantly impact semiconductor material selection and design approaches. Similar regulations are emerging in North America and Asia, creating a global shift toward environmentally optimized BTMS designs.

Safety Standards and Regulatory Compliance

The regulatory landscape for battery thermal management systems incorporating semiconductor materials has evolved significantly in response to safety incidents and technological advancements. International standards such as IEC 62133 and UL 1642 establish baseline requirements for lithium-ion battery safety, with specific provisions addressing thermal runaway prevention and management. These standards mandate temperature monitoring systems, thermal cutoff mechanisms, and specific testing protocols to ensure batteries remain within safe operating temperature ranges.

The automotive sector faces particularly stringent regulations, with UN ECE R100 and ISO 26262 governing electric vehicle battery safety. These standards require comprehensive thermal management systems with redundant safety features and fault detection capabilities. Semiconductor materials used in these systems must demonstrate reliability under extreme temperature conditions and maintain functionality during thermal events.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive emphasizes environmental considerations alongside safety, while China's GB/T standards focus on high-temperature performance and thermal stability. The United States, through agencies like NHTSA and CPSC, has established recall thresholds based on thermal management failures, creating de facto standards for the industry.

Compliance testing for semiconductor-based thermal management systems involves rigorous thermal cycling, extreme temperature operation, and thermal shock resistance. Materials must maintain their electrical and thermal properties across the battery's full operating temperature range while preventing thermal propagation between cells. Certification processes typically require extensive documentation of thermal simulation models, material properties, and failure mode analyses.

Emerging regulations are increasingly focusing on the semiconductor materials themselves, with restrictions on certain compounds and requirements for thermal conductivity performance. The EU's REACH regulation and RoHS Directive limit the use of specific semiconductor materials based on environmental and health concerns, driving innovation in alternative thermal management solutions.

Industry self-regulation complements formal standards, with organizations like the Responsible Battery Coalition developing best practices for thermal management that often exceed regulatory minimums. These voluntary standards frequently address semiconductor material selection, thermal interface materials, and cooling system design parameters to optimize both safety and performance.

Future regulatory trends point toward more prescriptive requirements for active thermal management systems, particularly for high-energy-density batteries. Proposed standards include real-time temperature monitoring with semiconductor-based sensors, thermal runaway prevention algorithms, and material-specific thermal conductivity requirements. Manufacturers investing in advanced semiconductor materials for thermal management must remain vigilant regarding this evolving regulatory landscape.

The automotive sector faces particularly stringent regulations, with UN ECE R100 and ISO 26262 governing electric vehicle battery safety. These standards require comprehensive thermal management systems with redundant safety features and fault detection capabilities. Semiconductor materials used in these systems must demonstrate reliability under extreme temperature conditions and maintain functionality during thermal events.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive emphasizes environmental considerations alongside safety, while China's GB/T standards focus on high-temperature performance and thermal stability. The United States, through agencies like NHTSA and CPSC, has established recall thresholds based on thermal management failures, creating de facto standards for the industry.

Compliance testing for semiconductor-based thermal management systems involves rigorous thermal cycling, extreme temperature operation, and thermal shock resistance. Materials must maintain their electrical and thermal properties across the battery's full operating temperature range while preventing thermal propagation between cells. Certification processes typically require extensive documentation of thermal simulation models, material properties, and failure mode analyses.

Emerging regulations are increasingly focusing on the semiconductor materials themselves, with restrictions on certain compounds and requirements for thermal conductivity performance. The EU's REACH regulation and RoHS Directive limit the use of specific semiconductor materials based on environmental and health concerns, driving innovation in alternative thermal management solutions.

Industry self-regulation complements formal standards, with organizations like the Responsible Battery Coalition developing best practices for thermal management that often exceed regulatory minimums. These voluntary standards frequently address semiconductor material selection, thermal interface materials, and cooling system design parameters to optimize both safety and performance.

Future regulatory trends point toward more prescriptive requirements for active thermal management systems, particularly for high-energy-density batteries. Proposed standards include real-time temperature monitoring with semiconductor-based sensors, thermal runaway prevention algorithms, and material-specific thermal conductivity requirements. Manufacturers investing in advanced semiconductor materials for thermal management must remain vigilant regarding this evolving regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!