Comparative Study of Thermal Management in Aerospace vs EV Batteries

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Objectives

Thermal management technologies have evolved significantly over the past decades, driven by the increasing demands of both aerospace and electric vehicle applications. In aerospace, thermal management systems date back to the early days of aviation, with rudimentary cooling systems for piston engines. The jet age brought new challenges, requiring more sophisticated approaches to manage the extreme temperatures generated by turbine engines and high-speed aerodynamics. By the 1960s, spacecraft thermal management became critical, as vehicles needed to withstand both the vacuum of space and atmospheric re-entry.

The evolution accelerated in the 1980s and 1990s with the development of advanced composite materials and computational fluid dynamics, enabling more precise thermal modeling. Aerospace thermal management systems progressively incorporated active cooling loops, heat pipes, and phase-change materials to handle increasingly complex thermal loads while minimizing weight penalties.

In parallel, the electric vehicle sector has experienced its own thermal management revolution. Early EVs in the 1990s featured simple air or liquid cooling systems for batteries. The introduction of lithium-ion technology in the 2000s created new thermal challenges, as these batteries require precise temperature control to prevent thermal runaway and optimize performance. This led to the development of dedicated battery thermal management systems (BTMS) incorporating liquid cooling circuits, heat exchangers, and sophisticated control algorithms.

The objectives of thermal management in both sectors share fundamental similarities while addressing domain-specific requirements. Both aim to maintain optimal operating temperatures for system components, prevent thermal runaway conditions, extend component lifespan, and maximize energy efficiency. However, aerospace applications typically prioritize reliability and safety under extreme conditions, while EV applications focus on balancing performance with cost-effectiveness for mass-market deployment.

Current objectives in aerospace thermal management include developing systems capable of handling hypersonic flight conditions, improving efficiency in space applications, and reducing overall system mass. For EVs, objectives center on enabling faster charging rates, improving cold-weather performance, extending battery life, and reducing system complexity and cost.

The convergence of these two fields presents opportunities for cross-pollination of technologies. Aerospace-derived thermal management approaches, such as advanced phase-change materials and heat pipe technologies, are increasingly finding applications in high-performance EV battery systems. Conversely, the mass-market scale of EV production is driving cost reductions in thermal management components that may benefit aerospace applications.

The evolution accelerated in the 1980s and 1990s with the development of advanced composite materials and computational fluid dynamics, enabling more precise thermal modeling. Aerospace thermal management systems progressively incorporated active cooling loops, heat pipes, and phase-change materials to handle increasingly complex thermal loads while minimizing weight penalties.

In parallel, the electric vehicle sector has experienced its own thermal management revolution. Early EVs in the 1990s featured simple air or liquid cooling systems for batteries. The introduction of lithium-ion technology in the 2000s created new thermal challenges, as these batteries require precise temperature control to prevent thermal runaway and optimize performance. This led to the development of dedicated battery thermal management systems (BTMS) incorporating liquid cooling circuits, heat exchangers, and sophisticated control algorithms.

The objectives of thermal management in both sectors share fundamental similarities while addressing domain-specific requirements. Both aim to maintain optimal operating temperatures for system components, prevent thermal runaway conditions, extend component lifespan, and maximize energy efficiency. However, aerospace applications typically prioritize reliability and safety under extreme conditions, while EV applications focus on balancing performance with cost-effectiveness for mass-market deployment.

Current objectives in aerospace thermal management include developing systems capable of handling hypersonic flight conditions, improving efficiency in space applications, and reducing overall system mass. For EVs, objectives center on enabling faster charging rates, improving cold-weather performance, extending battery life, and reducing system complexity and cost.

The convergence of these two fields presents opportunities for cross-pollination of technologies. Aerospace-derived thermal management approaches, such as advanced phase-change materials and heat pipe technologies, are increasingly finding applications in high-performance EV battery systems. Conversely, the mass-market scale of EV production is driving cost reductions in thermal management components that may benefit aerospace applications.

Market Drivers for Advanced Thermal Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and increasing demands in aerospace applications. The EV battery market alone is projected to reach $127 billion by 2027, with thermal management systems constituting approximately 15% of this value. This growth trajectory is creating substantial demand for innovative thermal solutions that can address the unique challenges in both sectors.

Safety concerns represent the foremost market driver, particularly following high-profile incidents involving thermal runaway in EV batteries and aerospace systems. These incidents have prompted regulatory bodies worldwide to implement stricter safety standards, compelling manufacturers to invest in sophisticated thermal management technologies. The European Union's Battery Directive and NASA's enhanced safety protocols for spacecraft exemplify this regulatory push, creating market opportunities for companies offering compliant thermal solutions.

Energy efficiency requirements constitute another significant market driver. In the EV sector, effective thermal management can extend range by up to 15% by optimizing battery operating temperatures. Similarly, aerospace applications benefit from weight reduction and improved fuel efficiency through advanced thermal management. As global energy costs continue to rise and environmental regulations tighten, the market value proposition for energy-efficient thermal solutions strengthens considerably.

Consumer expectations regarding performance and reliability are evolving rapidly. EV owners increasingly demand faster charging capabilities, which generate substantial heat requiring management. The aerospace industry faces similar challenges with higher power electronics and more compact designs generating greater thermal loads. Market research indicates that consumers are willing to pay premium prices for products offering superior thermal performance, creating opportunities for differentiation through advanced thermal technologies.

Manufacturing economics also drive market development, with companies seeking thermal management solutions that can be mass-produced cost-effectively. The transition from custom-engineered solutions to standardized thermal management platforms represents a significant market trend, particularly as production volumes increase in both sectors. This standardization is enabling economies of scale that make advanced thermal technologies more accessible across price points.

Emerging technologies such as solid-state batteries and hydrogen fuel cells are creating new market segments for specialized thermal management solutions. These technologies present unique thermal challenges that cannot be addressed with conventional approaches, opening opportunities for innovative companies. Market forecasts suggest that these emerging segments could represent 25% of the total thermal management market by 2030, offering substantial growth potential for early movers.

Safety concerns represent the foremost market driver, particularly following high-profile incidents involving thermal runaway in EV batteries and aerospace systems. These incidents have prompted regulatory bodies worldwide to implement stricter safety standards, compelling manufacturers to invest in sophisticated thermal management technologies. The European Union's Battery Directive and NASA's enhanced safety protocols for spacecraft exemplify this regulatory push, creating market opportunities for companies offering compliant thermal solutions.

Energy efficiency requirements constitute another significant market driver. In the EV sector, effective thermal management can extend range by up to 15% by optimizing battery operating temperatures. Similarly, aerospace applications benefit from weight reduction and improved fuel efficiency through advanced thermal management. As global energy costs continue to rise and environmental regulations tighten, the market value proposition for energy-efficient thermal solutions strengthens considerably.

Consumer expectations regarding performance and reliability are evolving rapidly. EV owners increasingly demand faster charging capabilities, which generate substantial heat requiring management. The aerospace industry faces similar challenges with higher power electronics and more compact designs generating greater thermal loads. Market research indicates that consumers are willing to pay premium prices for products offering superior thermal performance, creating opportunities for differentiation through advanced thermal technologies.

Manufacturing economics also drive market development, with companies seeking thermal management solutions that can be mass-produced cost-effectively. The transition from custom-engineered solutions to standardized thermal management platforms represents a significant market trend, particularly as production volumes increase in both sectors. This standardization is enabling economies of scale that make advanced thermal technologies more accessible across price points.

Emerging technologies such as solid-state batteries and hydrogen fuel cells are creating new market segments for specialized thermal management solutions. These technologies present unique thermal challenges that cannot be addressed with conventional approaches, opening opportunities for innovative companies. Market forecasts suggest that these emerging segments could represent 25% of the total thermal management market by 2030, offering substantial growth potential for early movers.

Current Challenges in Aerospace and EV Battery Cooling

Despite significant advancements in thermal management technologies, both aerospace and electric vehicle battery cooling systems face substantial challenges that limit performance, safety, and efficiency. In aerospace applications, the extreme operating conditions present unique thermal management hurdles. Aircraft batteries must function reliably across dramatic temperature variations, from the intense cold at high altitudes (-50°C) to potential overheating during high-power discharge events. The limited space and weight constraints in aircraft further complicate cooling system design, requiring innovative approaches that minimize mass while maximizing thermal efficiency.

For aerospace applications, the need for redundancy and fail-safe mechanisms adds another layer of complexity. Any thermal management failure could have catastrophic consequences, necessitating multiple backup systems that increase weight and complexity. Additionally, aerospace batteries must maintain performance during rapid altitude changes where ambient pressure and temperature fluctuate dramatically, creating thermal gradients that are difficult to manage with conventional cooling technologies.

In the electric vehicle sector, different but equally challenging issues exist. High-capacity EV batteries generate substantial heat during fast charging and high-power discharge scenarios, with thermal runaway remaining a critical safety concern. Current liquid cooling systems add significant weight and complexity to vehicles, reducing overall energy efficiency and driving range. The uneven heat distribution within large battery packs creates hotspots that accelerate degradation and reduce battery lifespan.

EV manufacturers also struggle with the trade-off between cooling system effectiveness and energy consumption. Active cooling systems can consume 5-15% of the battery's energy, directly impacting vehicle range. Furthermore, the varying operating conditions—from sub-zero winter temperatures to extreme summer heat—require adaptive thermal management solutions that can both heat and cool batteries efficiently.

Both sectors face materials challenges, with current thermal interface materials and heat transfer fluids approaching their physical limits. The development of new nanomaterials and phase change materials shows promise but faces hurdles in manufacturing scalability and long-term reliability. Additionally, the integration of thermal management with battery management systems remains suboptimal, with limited real-time thermal modeling capabilities hampering predictive cooling approaches.

Regulatory requirements add further complexity, with aerospace thermal management systems subject to rigorous certification processes that slow innovation adoption. Meanwhile, EV manufacturers face evolving safety standards and increasing pressure to develop fast-charging capabilities that intensify thermal management challenges. The balance between performance, safety, cost, and environmental impact creates a multifaceted problem requiring interdisciplinary solutions.

For aerospace applications, the need for redundancy and fail-safe mechanisms adds another layer of complexity. Any thermal management failure could have catastrophic consequences, necessitating multiple backup systems that increase weight and complexity. Additionally, aerospace batteries must maintain performance during rapid altitude changes where ambient pressure and temperature fluctuate dramatically, creating thermal gradients that are difficult to manage with conventional cooling technologies.

In the electric vehicle sector, different but equally challenging issues exist. High-capacity EV batteries generate substantial heat during fast charging and high-power discharge scenarios, with thermal runaway remaining a critical safety concern. Current liquid cooling systems add significant weight and complexity to vehicles, reducing overall energy efficiency and driving range. The uneven heat distribution within large battery packs creates hotspots that accelerate degradation and reduce battery lifespan.

EV manufacturers also struggle with the trade-off between cooling system effectiveness and energy consumption. Active cooling systems can consume 5-15% of the battery's energy, directly impacting vehicle range. Furthermore, the varying operating conditions—from sub-zero winter temperatures to extreme summer heat—require adaptive thermal management solutions that can both heat and cool batteries efficiently.

Both sectors face materials challenges, with current thermal interface materials and heat transfer fluids approaching their physical limits. The development of new nanomaterials and phase change materials shows promise but faces hurdles in manufacturing scalability and long-term reliability. Additionally, the integration of thermal management with battery management systems remains suboptimal, with limited real-time thermal modeling capabilities hampering predictive cooling approaches.

Regulatory requirements add further complexity, with aerospace thermal management systems subject to rigorous certification processes that slow innovation adoption. Meanwhile, EV manufacturers face evolving safety standards and increasing pressure to develop fast-charging capabilities that intensify thermal management challenges. The balance between performance, safety, cost, and environmental impact creates a multifaceted problem requiring interdisciplinary solutions.

Contemporary Thermal Control Methodologies

01 Liquid cooling systems for thermal management

Liquid cooling systems utilize fluids to transfer heat away from critical components. These systems often include pumps, heat exchangers, and coolant channels to efficiently dissipate heat from high-power electronic devices. The liquid coolant absorbs heat and carries it to a radiator or heat sink where it can be released into the ambient environment. This approach provides superior cooling performance compared to air-based systems, especially for high-density electronics.- Liquid cooling systems for thermal management: Liquid cooling systems utilize fluids to transfer heat away from critical components. These systems often include circulation pumps, heat exchangers, and coolant channels that efficiently dissipate heat from high-temperature areas. The liquid medium provides superior thermal conductivity compared to air-based systems, making it particularly effective for high-power density applications where temperature control is crucial for operational stability and component longevity.

- Heat sink and passive cooling technologies: Passive cooling technologies utilize heat sinks, thermal spreaders, and other non-powered components to manage temperature through conduction and natural convection. These systems feature optimized fin designs, advanced thermal interface materials, and strategic component placement to maximize heat dissipation without requiring additional energy input. Such passive approaches are valued for their reliability, maintenance-free operation, and application in space-constrained or noise-sensitive environments.

- Active thermal management with intelligent control systems: Intelligent thermal management systems incorporate sensors, microcontrollers, and adaptive algorithms to dynamically respond to changing thermal conditions. These systems monitor temperature across multiple points, analyze thermal patterns, and automatically adjust cooling parameters to maintain optimal operating temperatures. The integration of predictive models and machine learning enables preemptive cooling adjustments based on anticipated workloads, significantly improving energy efficiency while preventing thermal throttling or component damage.

- Phase change materials for thermal regulation: Phase change materials (PCMs) absorb and release thermal energy during their transition between solid and liquid states, providing effective temperature regulation. When integrated into thermal management systems, these materials can absorb excess heat during peak operation and release it during lower demand periods, effectively dampening temperature fluctuations. This approach is particularly valuable for applications with intermittent heat loads, offering passive thermal buffering without requiring continuous power for cooling.

- Integrated cooling solutions for electronic devices: Integrated cooling solutions combine multiple thermal management technologies tailored specifically for electronic devices. These comprehensive systems may incorporate heat pipes, vapor chambers, forced air convection, and strategic thermal pathways designed to address hotspots while maintaining overall device temperature. The integration of cooling elements directly into device architecture during the design phase enables more efficient heat dissipation while minimizing space requirements and power consumption.

02 Heat sink and heat pipe technologies

Heat sinks and heat pipes are passive thermal management solutions that enhance heat dissipation through conduction and convection. Heat sinks increase the surface area available for heat transfer, while heat pipes utilize phase change properties of working fluids to transport heat efficiently from source to sink. These technologies can be combined with fins, thermal interface materials, and optimized geometries to maximize thermal performance without requiring power input for operation.Expand Specific Solutions03 Active cooling with fans and blowers

Active cooling systems employ fans, blowers, and air movers to enhance convective heat transfer. These systems force air across heat-generating components or heat sinks to increase the rate of heat dissipation. The design includes optimized airflow paths, strategic component placement, and variable speed control to maintain target temperatures while minimizing noise and power consumption. This approach is widely used in electronics cooling due to its cost-effectiveness and adaptability.Expand Specific Solutions04 Thermal management for battery systems

Specialized thermal management solutions for battery systems focus on maintaining optimal operating temperatures to ensure safety, longevity, and performance. These systems may incorporate cooling plates, thermal interface materials, phase change materials, and temperature sensors to regulate battery temperature. Advanced designs feature integrated cooling channels, intelligent thermal control algorithms, and insulation strategies to prevent thermal runaway and extend battery life in various operating conditions.Expand Specific Solutions05 Smart thermal management control systems

Intelligent control systems for thermal management utilize sensors, microcontrollers, and algorithms to dynamically adjust cooling parameters based on real-time temperature data. These systems implement predictive cooling, adaptive fan speed control, and power management to optimize thermal performance while minimizing energy consumption. Advanced implementations incorporate machine learning techniques to anticipate thermal loads and preemptively adjust cooling resources, ensuring consistent performance under varying operating conditions.Expand Specific Solutions

Leading Organizations in Thermal Management Systems

The thermal management landscape for aerospace and EV batteries is evolving rapidly, currently in a growth phase with market projections exceeding $8 billion by 2030. While aerospace thermal solutions are more mature, EV battery thermal management is experiencing accelerated innovation. Key aerospace players like Rolls-Royce, Lockheed Martin, and Joby Aero focus on high-performance, lightweight systems, while automotive leaders including Ford, GM, NIO, and Hyundai are advancing liquid cooling technologies. Research institutions such as Xi'an Jiaotong University and University of Michigan are bridging knowledge gaps between these sectors, with cross-industry collaboration emerging as companies like Battelle Energy Alliance develop technologies applicable to both domains.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced thermal management systems for aerospace applications that utilize integrated cooling circuits with multi-phase heat transfer mechanisms. Their technology employs a combination of active and passive cooling strategies, including liquid cooling loops that circulate specialized coolants through critical battery components. The system incorporates phase-change materials (PCMs) that absorb excess heat during high-power operations and release it during lower demand periods, effectively dampening thermal spikes. Rolls-Royce's aerospace thermal management solutions feature sophisticated predictive thermal modeling that anticipates heat generation patterns based on flight profiles and environmental conditions, allowing for preemptive cooling adjustments. Their systems also implement redundant cooling pathways to ensure safety-critical operations can continue even if primary cooling systems are compromised, a requirement in aerospace applications that exceeds typical EV safety margins.

Strengths: Superior reliability and redundancy features essential for aerospace safety standards; advanced materials science expertise allowing for lightweight yet effective thermal solutions; extensive experience with extreme operating environments. Weaknesses: Higher cost structure compared to automotive-focused solutions; systems often overengineered for EV applications; greater complexity requiring specialized maintenance protocols.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a comprehensive thermal management approach for EV batteries that integrates both active and passive cooling systems. Their solution utilizes a dual-circuit liquid cooling system where one circuit manages battery temperature while the second handles power electronics and motor cooling, with intelligent thermal crossover capabilities between circuits to optimize overall system efficiency. Ford's system incorporates thin cooling plates positioned between battery cells that maximize surface contact while minimizing added weight and volume. The company has developed proprietary coolant formulations that offer enhanced thermal conductivity and reduced electrical conductivity for safety. Their thermal management controller employs predictive algorithms that anticipate heating patterns based on driving conditions, navigation data, and historical usage patterns, preemptively adjusting cooling capacity. Ford has also implemented innovative cell-level temperature monitoring with distributed sensors throughout the pack to identify and address hotspots before they become problematic.

Strengths: Highly optimized for automotive cost constraints while maintaining performance; extensive real-world validation across diverse climate conditions; integration with vehicle-wide thermal systems for holistic efficiency. Weaknesses: Less robust redundancy compared to aerospace solutions; designed primarily for terrestrial environmental conditions rather than extreme altitude variations; thermal management prioritizes battery longevity over absolute maximum performance.

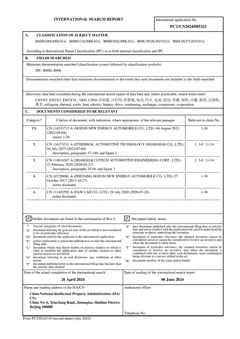

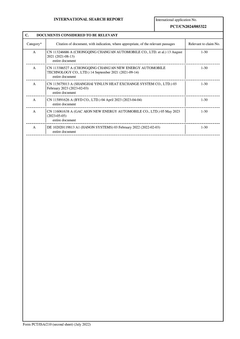

Critical Patents in Thermal Management Innovation

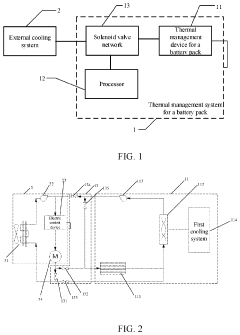

Thermal management system for battery pack and thermal management system for electric vehicle

PatentActiveUS11904728B2

Innovation

- A thermal management system that integrates a thermal management device for the battery pack with a processor and solenoid valve network connected to an external cooling system, allowing for efficient heat transfer and energy recycling by utilizing waste heat from the electric motor and control cooling system.

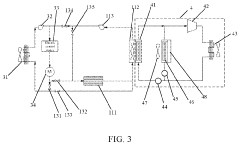

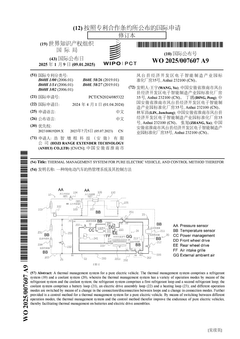

Thermal management system for pure electric vehicle, and control method therefor

PatentWO2025007607A9

Innovation

- Integration of dual refrigerant loops (first and second) with multiple coolant loops (battery, electric drive assembly, and heating) in a single thermal management system for pure electric vehicles.

- Dynamic operation mode switching capability between different loops through variable connection/disconnection mechanisms to address diverse thermal management requirements.

- Comprehensive thermal management approach that simultaneously addresses battery and electric drive assembly cooling needs, improving overall vehicle endurance.

Cross-Industry Technology Transfer Opportunities

The aerospace and electric vehicle industries have developed distinct thermal management solutions based on their unique operational requirements. This presents significant opportunities for cross-industry technology transfer that could accelerate innovation in both sectors. Aerospace thermal management systems, designed for extreme temperature variations and high reliability standards, offer valuable insights for EV battery applications.

Heat pipe technology, widely used in spacecraft thermal control systems, represents a prime transfer opportunity. These passive heat transfer devices operate with high efficiency and minimal maintenance requirements - characteristics highly desirable for EV battery thermal management. The miniaturization and weight optimization techniques developed for aerospace applications could help reduce the overall weight of EV battery cooling systems.

Phase change materials (PCMs) utilized in satellite thermal regulation demonstrate another promising transfer pathway. These materials, which absorb and release thermal energy during phase transitions, could enhance thermal buffering in EV batteries during rapid charge/discharge cycles. The aerospace industry's extensive research on PCM composition and encapsulation techniques could be adapted to automotive requirements.

Advanced thermal modeling and simulation methodologies from aerospace engineering offer substantial value for EV battery development. Computational fluid dynamics (CFD) approaches refined for complex aerospace thermal environments could improve prediction accuracy for battery thermal behavior under various operating conditions, potentially reducing development cycles and costs.

Aerospace-grade thermal interface materials, designed to maintain performance under extreme conditions, present opportunities for enhancing thermal conductivity between battery cells and cooling systems in EVs. These specialized materials could improve heat transfer efficiency while maintaining long-term reliability.

Redundancy and fault-tolerance design principles from aerospace systems could inform more robust EV battery thermal management architectures. The implementation of multiple cooling pathways and intelligent thermal management algorithms could enhance safety and reliability in electric vehicles.

Knowledge transfer mechanisms between these industries remain underdeveloped, suggesting the need for collaborative research initiatives, joint industry standards, and cross-sector innovation hubs. Regulatory frameworks that encourage such collaboration could accelerate the adoption of aerospace thermal technologies in the automotive sector, potentially leading to significant advancements in EV battery performance, safety, and longevity.

Heat pipe technology, widely used in spacecraft thermal control systems, represents a prime transfer opportunity. These passive heat transfer devices operate with high efficiency and minimal maintenance requirements - characteristics highly desirable for EV battery thermal management. The miniaturization and weight optimization techniques developed for aerospace applications could help reduce the overall weight of EV battery cooling systems.

Phase change materials (PCMs) utilized in satellite thermal regulation demonstrate another promising transfer pathway. These materials, which absorb and release thermal energy during phase transitions, could enhance thermal buffering in EV batteries during rapid charge/discharge cycles. The aerospace industry's extensive research on PCM composition and encapsulation techniques could be adapted to automotive requirements.

Advanced thermal modeling and simulation methodologies from aerospace engineering offer substantial value for EV battery development. Computational fluid dynamics (CFD) approaches refined for complex aerospace thermal environments could improve prediction accuracy for battery thermal behavior under various operating conditions, potentially reducing development cycles and costs.

Aerospace-grade thermal interface materials, designed to maintain performance under extreme conditions, present opportunities for enhancing thermal conductivity between battery cells and cooling systems in EVs. These specialized materials could improve heat transfer efficiency while maintaining long-term reliability.

Redundancy and fault-tolerance design principles from aerospace systems could inform more robust EV battery thermal management architectures. The implementation of multiple cooling pathways and intelligent thermal management algorithms could enhance safety and reliability in electric vehicles.

Knowledge transfer mechanisms between these industries remain underdeveloped, suggesting the need for collaborative research initiatives, joint industry standards, and cross-sector innovation hubs. Regulatory frameworks that encourage such collaboration could accelerate the adoption of aerospace thermal technologies in the automotive sector, potentially leading to significant advancements in EV battery performance, safety, and longevity.

Safety Standards and Regulatory Framework

The regulatory landscape governing thermal management systems in aerospace and electric vehicle batteries reflects the critical safety concerns in both industries, though with distinct emphases and historical development paths. Aerospace thermal management regulations have evolved over decades through organizations like the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO), establishing comprehensive frameworks that prioritize redundancy and fail-safe mechanisms.

For aerospace battery systems, standards such as RTCA DO-311A and MIL-STD-810 specify rigorous thermal testing requirements, including extreme temperature cycling, thermal runaway containment, and heat dissipation capabilities under various flight conditions. These standards mandate multiple layers of protection against thermal events, reflecting the catastrophic consequences of failures in aerospace applications.

In contrast, EV battery thermal management regulations have developed more recently but are evolving rapidly. Standards like UN ECE R100, ISO 6469, and IEC 62660 address thermal management specifically for electric vehicle applications. These frameworks focus on preventing thermal propagation between cells, thermal runaway mitigation, and establishing safe operating temperature ranges for lithium-ion battery packs.

A notable difference appears in testing protocols: aerospace standards typically require demonstration of safety under more extreme conditions and for longer durations than automotive standards. For instance, aerospace thermal management systems must maintain functionality during rapid decompression scenarios and extended operation in sub-zero temperatures at high altitudes – conditions not typically addressed in EV regulations.

Regulatory convergence is emerging in certain areas, particularly regarding fire suppression systems and thermal runaway containment. Both industries are adopting similar approaches to thermal monitoring, with requirements for multiple temperature sensors and automated thermal management intervention systems. The automotive industry is increasingly adopting aerospace-inspired safety margins and redundancy principles as EV battery capacities and charging rates increase.

Recent regulatory developments in both sectors emphasize predictive thermal management capabilities, with requirements for systems that can anticipate and prevent thermal events rather than merely responding to them. This shift reflects the growing sophistication of thermal modeling and real-time monitoring technologies, as well as the increasing energy densities in modern battery systems that leave smaller margins for thermal management errors.

For aerospace battery systems, standards such as RTCA DO-311A and MIL-STD-810 specify rigorous thermal testing requirements, including extreme temperature cycling, thermal runaway containment, and heat dissipation capabilities under various flight conditions. These standards mandate multiple layers of protection against thermal events, reflecting the catastrophic consequences of failures in aerospace applications.

In contrast, EV battery thermal management regulations have developed more recently but are evolving rapidly. Standards like UN ECE R100, ISO 6469, and IEC 62660 address thermal management specifically for electric vehicle applications. These frameworks focus on preventing thermal propagation between cells, thermal runaway mitigation, and establishing safe operating temperature ranges for lithium-ion battery packs.

A notable difference appears in testing protocols: aerospace standards typically require demonstration of safety under more extreme conditions and for longer durations than automotive standards. For instance, aerospace thermal management systems must maintain functionality during rapid decompression scenarios and extended operation in sub-zero temperatures at high altitudes – conditions not typically addressed in EV regulations.

Regulatory convergence is emerging in certain areas, particularly regarding fire suppression systems and thermal runaway containment. Both industries are adopting similar approaches to thermal monitoring, with requirements for multiple temperature sensors and automated thermal management intervention systems. The automotive industry is increasingly adopting aerospace-inspired safety margins and redundancy principles as EV battery capacities and charging rates increase.

Recent regulatory developments in both sectors emphasize predictive thermal management capabilities, with requirements for systems that can anticipate and prevent thermal events rather than merely responding to them. This shift reflects the growing sophistication of thermal modeling and real-time monitoring technologies, as well as the increasing energy densities in modern battery systems that leave smaller margins for thermal management errors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!