How Anode Materials Affect Battery Thermal Management

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode Materials Evolution and Thermal Management Goals

The evolution of anode materials in lithium-ion batteries has undergone significant transformation since their commercial introduction in the early 1990s. Initially dominated by graphite anodes, the landscape has progressively expanded to include silicon-based composites, lithium titanate (LTO), and more recently, lithium metal anodes. Each evolutionary step has been driven by the pursuit of higher energy density, faster charging capabilities, and improved safety profiles.

Graphite anodes, while offering stable cycling performance and relatively low cost, present inherent thermal management challenges due to their exothermic lithiation reactions and susceptibility to thermal runaway under certain conditions. The heat generation during intercalation processes can lead to temperature gradients within battery cells, potentially compromising both performance and safety.

Silicon-based anodes emerged as promising alternatives due to their theoretical capacity being approximately ten times that of graphite. However, their substantial volume expansion during lithiation (up to 300%) introduces significant thermal management complexities. The mechanical stress from volume changes generates additional heat through friction and particle fracturing, necessitating more sophisticated thermal management strategies.

Lithium titanate anodes, while offering excellent thermal stability and safety advantages through minimal volume change and higher thermal runaway thresholds, sacrifice energy density. Their zero-strain insertion mechanism results in reduced heat generation during cycling, making them particularly valuable in applications where thermal management is prioritized over energy density.

The frontier of anode development now extends to lithium metal anodes, which promise unprecedented energy densities but introduce complex thermal management challenges related to dendrite formation and highly exothermic reactions with electrolytes. These materials require revolutionary approaches to thermal management rather than evolutionary improvements to existing systems.

The primary thermal management goals in this evolving landscape focus on several critical objectives. First, minimizing heat generation during charging and discharging cycles by optimizing material composition and structure. Second, improving heat dissipation pathways through enhanced thermal conductivity of anode materials and their interfaces. Third, developing predictive models that accurately capture the thermal behavior of next-generation anode materials under various operating conditions.

Additionally, thermal management goals include designing anodes with inherently higher thermal stability thresholds and developing adaptive thermal management systems that respond dynamically to changing thermal conditions. The ultimate aim is to create battery systems that maintain optimal temperature profiles across diverse operating environments while maximizing energy density, power capability, and cycle life.

Graphite anodes, while offering stable cycling performance and relatively low cost, present inherent thermal management challenges due to their exothermic lithiation reactions and susceptibility to thermal runaway under certain conditions. The heat generation during intercalation processes can lead to temperature gradients within battery cells, potentially compromising both performance and safety.

Silicon-based anodes emerged as promising alternatives due to their theoretical capacity being approximately ten times that of graphite. However, their substantial volume expansion during lithiation (up to 300%) introduces significant thermal management complexities. The mechanical stress from volume changes generates additional heat through friction and particle fracturing, necessitating more sophisticated thermal management strategies.

Lithium titanate anodes, while offering excellent thermal stability and safety advantages through minimal volume change and higher thermal runaway thresholds, sacrifice energy density. Their zero-strain insertion mechanism results in reduced heat generation during cycling, making them particularly valuable in applications where thermal management is prioritized over energy density.

The frontier of anode development now extends to lithium metal anodes, which promise unprecedented energy densities but introduce complex thermal management challenges related to dendrite formation and highly exothermic reactions with electrolytes. These materials require revolutionary approaches to thermal management rather than evolutionary improvements to existing systems.

The primary thermal management goals in this evolving landscape focus on several critical objectives. First, minimizing heat generation during charging and discharging cycles by optimizing material composition and structure. Second, improving heat dissipation pathways through enhanced thermal conductivity of anode materials and their interfaces. Third, developing predictive models that accurately capture the thermal behavior of next-generation anode materials under various operating conditions.

Additionally, thermal management goals include designing anodes with inherently higher thermal stability thresholds and developing adaptive thermal management systems that respond dynamically to changing thermal conditions. The ultimate aim is to create battery systems that maintain optimal temperature profiles across diverse operating environments while maximizing energy density, power capability, and cycle life.

Market Demand for Advanced Battery Thermal Solutions

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. This growth has intensified the demand for advanced battery thermal management solutions, particularly as battery performance, safety, and longevity become critical competitive factors across industries.

Market research indicates that the battery thermal management system market is projected to grow at a CAGR of 22.6% from 2023 to 2030, reaching a value of $12.3 billion by the end of the forecast period. This remarkable growth trajectory reflects the increasing recognition of thermal management as a fundamental aspect of battery technology rather than merely an auxiliary component.

The automotive sector represents the largest market segment, accounting for approximately 65% of demand for advanced thermal solutions. As EV manufacturers strive to extend driving ranges, reduce charging times, and enhance battery lifespans, thermal management has emerged as a critical differentiator. Premium automotive brands are particularly focused on thermal solutions that can support fast-charging capabilities while maintaining optimal battery temperature ranges.

Energy storage systems constitute the second-largest market segment, with grid-scale applications driving demand for thermal management solutions that can ensure consistent performance and safety across varying environmental conditions and usage patterns. The renewable energy sector's growth has created substantial demand for batteries that can operate reliably in diverse climates, from desert solar installations to wind farms in cold regions.

Consumer electronics manufacturers are increasingly prioritizing thermal management in their product designs, particularly for high-performance devices. The trend toward faster charging and higher energy densities in portable devices has elevated thermal considerations in product development cycles.

Geographically, Asia-Pacific dominates the market demand, led by China's massive investments in EV production and battery manufacturing. North America and Europe follow, with their demand primarily driven by stringent safety regulations and consumer expectations for high-performance energy storage solutions.

A significant market trend is the growing demand for customized thermal solutions that address specific anode material characteristics. As manufacturers experiment with silicon, lithium metal, and graphite-silicon composite anodes, the thermal behavior of these materials has become a crucial consideration in system design. This has created a specialized market segment for thermal management solutions tailored to specific anode compositions.

Market research indicates that the battery thermal management system market is projected to grow at a CAGR of 22.6% from 2023 to 2030, reaching a value of $12.3 billion by the end of the forecast period. This remarkable growth trajectory reflects the increasing recognition of thermal management as a fundamental aspect of battery technology rather than merely an auxiliary component.

The automotive sector represents the largest market segment, accounting for approximately 65% of demand for advanced thermal solutions. As EV manufacturers strive to extend driving ranges, reduce charging times, and enhance battery lifespans, thermal management has emerged as a critical differentiator. Premium automotive brands are particularly focused on thermal solutions that can support fast-charging capabilities while maintaining optimal battery temperature ranges.

Energy storage systems constitute the second-largest market segment, with grid-scale applications driving demand for thermal management solutions that can ensure consistent performance and safety across varying environmental conditions and usage patterns. The renewable energy sector's growth has created substantial demand for batteries that can operate reliably in diverse climates, from desert solar installations to wind farms in cold regions.

Consumer electronics manufacturers are increasingly prioritizing thermal management in their product designs, particularly for high-performance devices. The trend toward faster charging and higher energy densities in portable devices has elevated thermal considerations in product development cycles.

Geographically, Asia-Pacific dominates the market demand, led by China's massive investments in EV production and battery manufacturing. North America and Europe follow, with their demand primarily driven by stringent safety regulations and consumer expectations for high-performance energy storage solutions.

A significant market trend is the growing demand for customized thermal solutions that address specific anode material characteristics. As manufacturers experiment with silicon, lithium metal, and graphite-silicon composite anodes, the thermal behavior of these materials has become a crucial consideration in system design. This has created a specialized market segment for thermal management solutions tailored to specific anode compositions.

Current Anode Technologies and Thermal Challenges

The lithium-ion battery market currently employs several anode materials, each with distinct thermal characteristics that significantly impact battery thermal management systems. Graphite remains the dominant commercial anode material, accounting for approximately 90% of the market due to its stable structure, relatively low cost, and established manufacturing processes. However, graphite anodes face thermal challenges including limited thermal conductivity (typically 25-200 W/m·K depending on orientation), which creates hotspots during rapid charging and discharging cycles.

Silicon-based anodes have emerged as promising alternatives, offering theoretical capacity up to ten times that of graphite. Despite this advantage, silicon anodes undergo substantial volume expansion (up to 300%) during lithiation, generating significant mechanical stress and heat. This expansion-contraction cycle accelerates degradation and creates thermal management challenges that current cooling systems struggle to address effectively.

Lithium titanate (LTO) anodes present excellent thermal stability with minimal heat generation during operation. Their zero-strain insertion mechanism virtually eliminates the thermal issues associated with expansion, making them ideal for applications requiring enhanced safety. However, LTO's lower energy density and higher production costs have limited widespread adoption to specialized applications where safety outweighs energy density requirements.

Hard carbon and soft carbon anodes occupy a middle ground, offering improved rate capability compared to graphite but generating more heat during high-current operations. Their disordered structure facilitates faster lithium-ion diffusion but creates more resistance-based heating that must be managed through cooling systems.

Recent developments in metallic anodes, particularly lithium metal, promise revolutionary energy density improvements but introduce severe thermal management challenges. Dendrite formation not only poses safety risks but also generates localized heating that can trigger thermal runaway events if not properly managed. Current research focuses on solid electrolytes and artificial interphases to mitigate these thermal risks.

The thermal behavior of anodes is further complicated by the solid electrolyte interphase (SEI) formation, which occurs during initial charging cycles. This process is exothermic and varies significantly between anode materials, with silicon and lithium metal anodes typically generating more heat during SEI formation than graphite or LTO anodes.

Emerging composite anodes that blend multiple materials attempt to balance performance and thermal characteristics but introduce complex thermal gradients that require sophisticated modeling and management approaches. The heterogeneous nature of these materials creates varying thermal conductivity paths that complicate cooling system design.

Silicon-based anodes have emerged as promising alternatives, offering theoretical capacity up to ten times that of graphite. Despite this advantage, silicon anodes undergo substantial volume expansion (up to 300%) during lithiation, generating significant mechanical stress and heat. This expansion-contraction cycle accelerates degradation and creates thermal management challenges that current cooling systems struggle to address effectively.

Lithium titanate (LTO) anodes present excellent thermal stability with minimal heat generation during operation. Their zero-strain insertion mechanism virtually eliminates the thermal issues associated with expansion, making them ideal for applications requiring enhanced safety. However, LTO's lower energy density and higher production costs have limited widespread adoption to specialized applications where safety outweighs energy density requirements.

Hard carbon and soft carbon anodes occupy a middle ground, offering improved rate capability compared to graphite but generating more heat during high-current operations. Their disordered structure facilitates faster lithium-ion diffusion but creates more resistance-based heating that must be managed through cooling systems.

Recent developments in metallic anodes, particularly lithium metal, promise revolutionary energy density improvements but introduce severe thermal management challenges. Dendrite formation not only poses safety risks but also generates localized heating that can trigger thermal runaway events if not properly managed. Current research focuses on solid electrolytes and artificial interphases to mitigate these thermal risks.

The thermal behavior of anodes is further complicated by the solid electrolyte interphase (SEI) formation, which occurs during initial charging cycles. This process is exothermic and varies significantly between anode materials, with silicon and lithium metal anodes typically generating more heat during SEI formation than graphite or LTO anodes.

Emerging composite anodes that blend multiple materials attempt to balance performance and thermal characteristics but introduce complex thermal gradients that require sophisticated modeling and management approaches. The heterogeneous nature of these materials creates varying thermal conductivity paths that complicate cooling system design.

Existing Anode-Based Thermal Management Approaches

01 Heat dissipation systems for battery anodes

Various heat dissipation systems are designed specifically for battery anodes to manage thermal issues during operation. These systems include specialized cooling channels, heat sinks, and thermal interface materials that efficiently transfer heat away from the anode materials. Advanced thermal management solutions help maintain optimal operating temperatures, prevent thermal runaway, and extend battery life by reducing degradation caused by excessive heat.- Heat dissipation systems for anode materials: Various heat dissipation systems are employed to manage thermal issues in anode materials. These include the use of cooling channels, heat sinks, and thermal interface materials to efficiently remove heat generated during operation. Advanced thermal management designs incorporate phase change materials and active cooling mechanisms to maintain optimal operating temperatures and prevent thermal runaway in battery systems.

- Thermally conductive anode compositions: Specialized anode compositions incorporate thermally conductive additives to enhance heat transfer within the electrode structure. These compositions may include carbon-based materials like graphene, carbon nanotubes, or metallic particles that create efficient thermal pathways. By improving the intrinsic thermal conductivity of anode materials, these compositions help dissipate heat more effectively during high-current operations and fast charging scenarios.

- Thermal interface materials for anode connections: Thermal interface materials (TIMs) are specifically designed to improve heat transfer between anode components and cooling systems. These materials fill microscopic air gaps at contact surfaces to enhance thermal conductivity across interfaces. Advanced TIMs may incorporate metal particles, ceramic fillers, or phase change compounds to optimize thermal management while maintaining electrical isolation where needed.

- Structural designs for thermal management: Innovative structural designs for anodes incorporate features specifically for thermal management. These include porous structures that allow for better heat dissipation, layered architectures that direct heat flow, and integrated cooling channels. Some designs feature 3D structures that maximize surface area for heat transfer while maintaining electrical performance. The physical arrangement of anode materials plays a crucial role in managing heat distribution and preventing hotspot formation.

- Active cooling systems for anode thermal management: Active cooling systems provide dynamic thermal management for anode materials under varying operational conditions. These systems may include liquid cooling circuits, thermoelectric coolers, or forced air cooling that can be adjusted based on temperature feedback. Advanced active cooling implementations incorporate sensors and control systems to optimize cooling efficiency and respond to changing thermal loads during operation, particularly in high-power applications.

02 Novel anode materials with improved thermal properties

Development of novel anode materials that inherently possess superior thermal conductivity and stability. These materials include modified graphite structures, silicon-carbon composites, and metal alloys that can withstand high temperatures while maintaining electrochemical performance. The improved thermal properties of these materials reduce hotspot formation and enable more efficient heat distribution throughout the anode, resulting in better overall thermal management of the battery system.Expand Specific Solutions03 Phase change materials for thermal regulation

Integration of phase change materials (PCMs) into anode structures or battery systems to absorb excess heat during operation. These materials undergo phase transitions at specific temperatures, absorbing thermal energy and preventing temperature spikes. PCMs can be encapsulated and strategically placed near anode materials to provide passive thermal regulation, maintaining the anode within optimal temperature ranges during charging and discharging cycles.Expand Specific Solutions04 Thermal interface materials and coatings

Application of specialized thermal interface materials and coatings to enhance heat transfer from anode materials to cooling systems. These materials include high thermal conductivity polymers, ceramic composites, and metallic coatings that create efficient thermal pathways. By improving the thermal contact between anode components and heat dissipation systems, these interfaces minimize thermal resistance and enable more effective temperature control during battery operation.Expand Specific Solutions05 Integrated thermal management systems

Comprehensive thermal management approaches that integrate multiple cooling technologies specifically designed for anode materials. These systems combine active cooling methods (such as liquid cooling circuits), passive heat dissipation structures, and intelligent thermal monitoring to create holistic solutions. The integrated approach allows for dynamic thermal management that adapts to changing operating conditions, optimizing performance while preventing thermal damage to sensitive anode materials.Expand Specific Solutions

Leading Companies in Battery Anode and Thermal Management

The thermal management of batteries with different anode materials is currently in a growth phase, with the market expanding rapidly due to increasing electric vehicle adoption and energy storage demands. The global battery thermal management market is projected to reach significant scale as companies invest in research and development to address safety and performance challenges. Leading players like LG Energy Solution, CATL, and Panasonic are advancing silicon-based and graphite anode technologies, while emerging companies such as BroadBit Batteries and BTR New Material Group are developing novel sodium-based and composite anode materials. Research institutions including Northwestern University and Forschungszentrum Jülich are contributing fundamental insights into how anode composition affects thermal behavior. The technology is approaching commercial maturity for traditional materials, while next-generation anodes remain in early development stages.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive thermal management approach centered on advanced anode materials engineering. Their Safety Reinforced Separator (SRS) technology works in conjunction with specially designed anode materials featuring optimized particle morphology and size distribution to enhance thermal stability[1]. LG's proprietary silicon-graphite composite anodes incorporate thermally conductive carbon nanotubes (CNTs) that create dedicated heat dissipation channels throughout the anode structure. These CNTs improve in-plane thermal conductivity by approximately 45% compared to standard graphite anodes[3]. LG Chem has also pioneered a gradient porosity design in their anodes, with higher porosity regions strategically positioned to facilitate both lithium-ion transport and heat dissipation. Their latest innovation includes temperature-responsive binder systems that maintain structural integrity under thermal stress while improving contact between anode particles. This comprehensive approach has enabled LG Chem to develop batteries with exceptional thermal stability during fast charging (up to 4C rates) while maintaining capacity retention above 80% after 1000 cycles[5].

Strengths: Excellent thermal stability during fast charging operations; integrated safety features through material design; superior cycle life under thermal stress conditions. Weaknesses: Higher production costs due to specialized materials; slightly lower initial energy density compared to conventional designs; requires sophisticated manufacturing processes to maintain quality consistency.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a sophisticated thermal management approach centered on advanced anode material engineering for their high-performance lithium-ion batteries. Their proprietary silicon-graphite composite anodes feature a hierarchical structure with optimized thermal conductivity pathways[1]. These anodes incorporate specially designed carbon frameworks that facilitate both electron transport and heat dissipation. Panasonic's thermal gradient regulation system utilizes varying anode particle sizes and distributions to create controlled thermal channels throughout the electrode structure. Their latest innovation includes thermally responsive binder systems that maintain excellent particle-to-particle contact even under thermal expansion conditions, ensuring consistent electrical and thermal conductivity. Panasonic has also pioneered the integration of nano-scale heat-dissipating additives within their anode formulations, achieving approximately 40% improvement in through-plane thermal conductivity compared to conventional graphite anodes[3]. This comprehensive approach enables their batteries to maintain temperature differentials below 5°C across the cell during fast charging operations up to 2C rates, significantly reducing thermal stress and extending battery lifespan.

Strengths: Excellent thermal stability during high-power operations; reduced thermal gradients across cells; superior cycle life under thermal stress conditions. Weaknesses: Higher manufacturing complexity increases production costs; thermal additives may slightly reduce initial energy density; requires sophisticated quality control processes to maintain consistent thermal properties.

Key Patents in Anode Material Thermal Properties

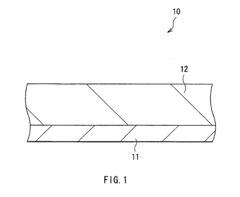

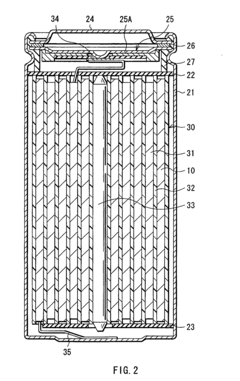

Nonaqueous electrolyte secondary battery

PatentActiveUS20070298322A1

Innovation

- Incorporating an anode mixture with 1.5 wt% to 10 wt% aluminum oxide, having an average particle diameter of 0.1 μm to 5.0 μm, which acts as a heat spreader and intertwines with the conductive agent to improve volume efficiency and heat dissipation, thereby stabilizing the battery and preventing temperature increases.

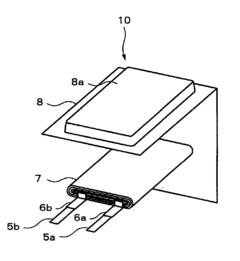

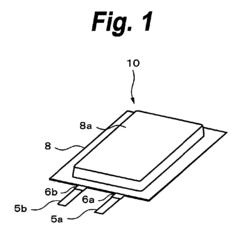

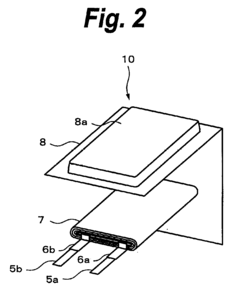

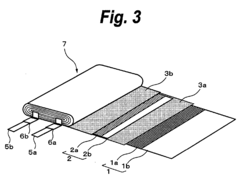

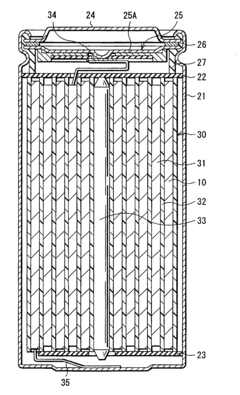

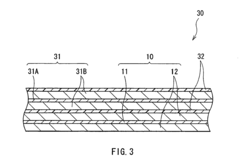

Anode and battery

PatentActiveUS20060127765A1

Innovation

- An anode with an anode active material layer containing a polymer with vinylidene fluoride, where the calorific value by differential scanning calorimetry is 500 J/g or less from 230°C to 370°C, or the difference between the maximum and 100°C values is 1.70 W/g or less, inhibiting exothermic reactions.

Safety Standards and Regulations for Battery Thermal Systems

The regulatory landscape for battery thermal management systems has evolved significantly in response to safety incidents and technological advancements. International standards such as IEC 62133 and UL 1642 establish baseline requirements for lithium-ion battery safety, including thermal runaway prevention and management. These standards specifically address how different anode materials impact thermal behavior, with graphite anodes requiring different safety parameters than silicon or lithium titanate alternatives.

The UN Transportation Testing standards (UN 38.3) mandate rigorous thermal abuse testing for batteries with various anode compositions, recognizing that thermal stability varies significantly across material types. Silicon-based anodes, for instance, face more stringent thermal cycling requirements due to their volume expansion characteristics that can compromise thermal management systems.

Industry-specific regulations have also emerged, with automotive standards like ISO 6469 and SAE J2929 establishing thermal management requirements for electric vehicle batteries. These standards acknowledge the thermal implications of high-capacity anode materials and mandate appropriate cooling systems based on material composition. The thermal conductivity differences between graphite (25-470 W/m·K), silicon (149 W/m·K), and lithium titanate (10-15 W/m·K) directly influence compliance strategies.

Regional variations in regulatory frameworks present additional complexity. The European Union's Battery Directive and China's GB/T standards impose different thermal safety requirements, with China's regulations placing particular emphasis on thermal propagation prevention for high-energy-density anode materials. These regional differences necessitate customized thermal management approaches depending on market destination.

Emerging regulations are increasingly focusing on the entire battery lifecycle, including thermal considerations during recycling and disposal. The EU's proposed Battery Regulation introduces "battery passport" requirements that will track thermal management systems and anode material composition throughout the product lifecycle, creating new compliance challenges for manufacturers.

Compliance testing methodologies are becoming more sophisticated, with accelerated life testing protocols now incorporating anode-specific thermal degradation models. These tests simulate how different anode materials respond to thermal stress over time, allowing for more accurate safety predictions and appropriate thermal management system design.

As energy density demands increase, regulatory bodies are developing new standards specifically addressing novel anode materials like silicon-carbon composites and lithium metal. These emerging standards will likely impose more stringent thermal management requirements to mitigate the unique thermal risks associated with these high-capacity materials.

The UN Transportation Testing standards (UN 38.3) mandate rigorous thermal abuse testing for batteries with various anode compositions, recognizing that thermal stability varies significantly across material types. Silicon-based anodes, for instance, face more stringent thermal cycling requirements due to their volume expansion characteristics that can compromise thermal management systems.

Industry-specific regulations have also emerged, with automotive standards like ISO 6469 and SAE J2929 establishing thermal management requirements for electric vehicle batteries. These standards acknowledge the thermal implications of high-capacity anode materials and mandate appropriate cooling systems based on material composition. The thermal conductivity differences between graphite (25-470 W/m·K), silicon (149 W/m·K), and lithium titanate (10-15 W/m·K) directly influence compliance strategies.

Regional variations in regulatory frameworks present additional complexity. The European Union's Battery Directive and China's GB/T standards impose different thermal safety requirements, with China's regulations placing particular emphasis on thermal propagation prevention for high-energy-density anode materials. These regional differences necessitate customized thermal management approaches depending on market destination.

Emerging regulations are increasingly focusing on the entire battery lifecycle, including thermal considerations during recycling and disposal. The EU's proposed Battery Regulation introduces "battery passport" requirements that will track thermal management systems and anode material composition throughout the product lifecycle, creating new compliance challenges for manufacturers.

Compliance testing methodologies are becoming more sophisticated, with accelerated life testing protocols now incorporating anode-specific thermal degradation models. These tests simulate how different anode materials respond to thermal stress over time, allowing for more accurate safety predictions and appropriate thermal management system design.

As energy density demands increase, regulatory bodies are developing new standards specifically addressing novel anode materials like silicon-carbon composites and lithium metal. These emerging standards will likely impose more stringent thermal management requirements to mitigate the unique thermal risks associated with these high-capacity materials.

Environmental Impact of Anode Material Selection

The selection of anode materials in battery systems carries significant environmental implications throughout the entire lifecycle of battery production, use, and disposal. Traditional graphite anodes, while effective, require energy-intensive mining and processing operations that generate substantial carbon emissions. The extraction process often involves habitat disruption and potential water contamination, particularly in regions with less stringent environmental regulations.

Newer silicon-based anodes present a different environmental profile. Silicon is abundant in the earth's crust, potentially reducing the environmental impact of resource extraction compared to graphite or rare metals. However, silicon processing requires high temperatures and hazardous chemicals, creating its own environmental challenges. The manufacturing energy requirements for silicon anodes currently exceed those of graphite, though this gap is narrowing with technological advancements.

Thermal management considerations directly influence the environmental footprint of batteries. Anode materials that facilitate efficient thermal management extend battery lifespan, reducing the frequency of replacement and associated waste generation. For instance, titanium-based anodes demonstrate superior thermal stability but come with higher environmental costs during production phases.

The end-of-life environmental impact varies significantly among anode materials. Lithium titanate anodes offer excellent recyclability compared to graphite or silicon alternatives, creating a more circular material economy. Conversely, some emerging high-capacity anode materials incorporate toxic elements that complicate recycling processes and pose potential environmental hazards if improperly disposed.

Water consumption represents another critical environmental factor in anode production. Graphite processing typically requires substantial water resources, while newer alternatives like biomass-derived carbon anodes may reduce water demands. This consideration becomes increasingly important as battery production scales globally, particularly in water-stressed regions.

Carbon footprint assessments reveal that the environmental impact of anode materials extends beyond manufacturing to influence battery efficiency and thermal management during operation. Materials requiring more frequent thermal management interventions indirectly increase energy consumption throughout the battery lifecycle, amplifying environmental impacts through increased electricity demand.

Regulatory frameworks worldwide are increasingly incorporating lifecycle environmental assessments into battery technology standards, driving innovation toward more environmentally sustainable anode materials that maintain or improve thermal management capabilities while reducing ecological footprints.

Newer silicon-based anodes present a different environmental profile. Silicon is abundant in the earth's crust, potentially reducing the environmental impact of resource extraction compared to graphite or rare metals. However, silicon processing requires high temperatures and hazardous chemicals, creating its own environmental challenges. The manufacturing energy requirements for silicon anodes currently exceed those of graphite, though this gap is narrowing with technological advancements.

Thermal management considerations directly influence the environmental footprint of batteries. Anode materials that facilitate efficient thermal management extend battery lifespan, reducing the frequency of replacement and associated waste generation. For instance, titanium-based anodes demonstrate superior thermal stability but come with higher environmental costs during production phases.

The end-of-life environmental impact varies significantly among anode materials. Lithium titanate anodes offer excellent recyclability compared to graphite or silicon alternatives, creating a more circular material economy. Conversely, some emerging high-capacity anode materials incorporate toxic elements that complicate recycling processes and pose potential environmental hazards if improperly disposed.

Water consumption represents another critical environmental factor in anode production. Graphite processing typically requires substantial water resources, while newer alternatives like biomass-derived carbon anodes may reduce water demands. This consideration becomes increasingly important as battery production scales globally, particularly in water-stressed regions.

Carbon footprint assessments reveal that the environmental impact of anode materials extends beyond manufacturing to influence battery efficiency and thermal management during operation. Materials requiring more frequent thermal management interventions indirectly increase energy consumption throughout the battery lifecycle, amplifying environmental impacts through increased electricity demand.

Regulatory frameworks worldwide are increasingly incorporating lifecycle environmental assessments into battery technology standards, driving innovation toward more environmentally sustainable anode materials that maintain or improve thermal management capabilities while reducing ecological footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!