The Role of Thermal Management in Extending Battery Lifespan

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Background and Objectives

Thermal management has emerged as a critical factor in battery technology development, particularly as energy storage demands continue to grow across industries. The evolution of thermal management for batteries traces back to the early 1990s when lithium-ion batteries first entered commercial markets. Initially, thermal considerations were rudimentary, focusing primarily on preventing catastrophic failures rather than optimizing performance or extending lifespan.

As battery applications expanded from consumer electronics to electric vehicles and grid storage systems, the importance of sophisticated thermal management became increasingly apparent. Research has demonstrated that batteries operated outside their optimal temperature range (typically 15-35°C) experience accelerated degradation mechanisms, including SEI layer growth, lithium plating, and structural changes in electrode materials.

The technical evolution in this field has progressed from passive cooling systems to advanced active thermal management solutions incorporating liquid cooling, phase change materials, and intelligent thermal control algorithms. This progression reflects the growing understanding of the complex relationship between temperature and electrochemical processes within battery cells.

Current objectives in battery thermal management focus on several key areas. First, achieving uniform temperature distribution across cell arrays to prevent localized degradation and thermal runaway risks. Studies indicate that temperature gradients as small as 5°C within a battery pack can lead to capacity imbalances exceeding 20% over the battery's lifetime.

Second, developing adaptive thermal management systems capable of responding to varying operational conditions, from high-power discharge events to extreme ambient temperatures. These systems aim to maintain optimal cell temperatures regardless of external factors or usage patterns.

Third, integrating predictive thermal modeling with battery management systems to anticipate thermal behavior and proactively adjust cooling or heating parameters. This approach represents a shift from reactive to preventive thermal management strategies.

The ultimate goal of advanced thermal management is to extend battery lifespan while simultaneously improving safety, performance, and charging capabilities. Research indicates that effective thermal management can potentially increase battery cycle life by 15-40%, depending on the application and battery chemistry. This significant improvement directly translates to reduced total cost of ownership and enhanced sustainability through reduced material consumption and waste.

As energy density continues to increase in next-generation battery technologies, the challenges of heat generation and dissipation become more pronounced, making thermal management an increasingly critical component of battery system design and a key enabler for future energy storage innovations.

As battery applications expanded from consumer electronics to electric vehicles and grid storage systems, the importance of sophisticated thermal management became increasingly apparent. Research has demonstrated that batteries operated outside their optimal temperature range (typically 15-35°C) experience accelerated degradation mechanisms, including SEI layer growth, lithium plating, and structural changes in electrode materials.

The technical evolution in this field has progressed from passive cooling systems to advanced active thermal management solutions incorporating liquid cooling, phase change materials, and intelligent thermal control algorithms. This progression reflects the growing understanding of the complex relationship between temperature and electrochemical processes within battery cells.

Current objectives in battery thermal management focus on several key areas. First, achieving uniform temperature distribution across cell arrays to prevent localized degradation and thermal runaway risks. Studies indicate that temperature gradients as small as 5°C within a battery pack can lead to capacity imbalances exceeding 20% over the battery's lifetime.

Second, developing adaptive thermal management systems capable of responding to varying operational conditions, from high-power discharge events to extreme ambient temperatures. These systems aim to maintain optimal cell temperatures regardless of external factors or usage patterns.

Third, integrating predictive thermal modeling with battery management systems to anticipate thermal behavior and proactively adjust cooling or heating parameters. This approach represents a shift from reactive to preventive thermal management strategies.

The ultimate goal of advanced thermal management is to extend battery lifespan while simultaneously improving safety, performance, and charging capabilities. Research indicates that effective thermal management can potentially increase battery cycle life by 15-40%, depending on the application and battery chemistry. This significant improvement directly translates to reduced total cost of ownership and enhanced sustainability through reduced material consumption and waste.

As energy density continues to increase in next-generation battery technologies, the challenges of heat generation and dissipation become more pronounced, making thermal management an increasingly critical component of battery system design and a key enabler for future energy storage innovations.

Market Demand for Extended Battery Lifespan

The global market for battery thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and portable electronics sectors. Current market research indicates that the battery thermal management system market is projected to reach $5.2 billion by 2025, growing at a CAGR of 16.6% from 2020. This remarkable growth reflects the increasing recognition of thermal management's critical role in extending battery lifespan across multiple industries.

Consumer demand for longer-lasting batteries has become a significant market driver, particularly in the EV sector where battery replacement costs can represent up to 40% of the vehicle's value. A recent industry survey revealed that 78% of potential EV buyers consider battery longevity as a "very important" factor in their purchasing decisions, ranking it above features like acceleration and even driving range in some segments.

In the consumer electronics market, thermal management solutions are increasingly becoming a competitive differentiator. Manufacturers who can demonstrate superior battery longevity through effective thermal management systems command premium pricing, with consumers willing to pay 15-20% more for devices with proven extended battery life. This trend is particularly pronounced in high-performance computing devices and premium smartphones.

Industrial applications represent another significant market segment, where unplanned downtime due to battery failure can cost thousands of dollars per hour. The industrial battery management system market is expected to grow at 18.3% CAGR through 2026, with thermal management components accounting for approximately 30% of this growth.

Geographically, Asia-Pacific dominates the market demand, accounting for 45% of global consumption, followed by North America (28%) and Europe (22%). China, in particular, has emerged as both the largest consumer and producer of battery thermal management systems, driven by its dominant position in global battery manufacturing and EV production.

Regulatory pressures are further accelerating market demand, with new standards being implemented across major markets that mandate minimum battery performance and longevity requirements. The European Union's proposed Battery Directive revision includes specific provisions for thermal management capabilities in EV batteries, while similar regulations are being considered in North America and Asia.

Market analysis indicates that the demand for passive thermal management solutions currently outpaces active systems by a ratio of approximately 3:2, though this gap is narrowing as active systems demonstrate superior performance in extreme operating conditions. Liquid cooling systems, in particular, are experiencing the fastest growth rate at 22.4% annually, reflecting their superior efficiency in high-discharge applications.

Consumer demand for longer-lasting batteries has become a significant market driver, particularly in the EV sector where battery replacement costs can represent up to 40% of the vehicle's value. A recent industry survey revealed that 78% of potential EV buyers consider battery longevity as a "very important" factor in their purchasing decisions, ranking it above features like acceleration and even driving range in some segments.

In the consumer electronics market, thermal management solutions are increasingly becoming a competitive differentiator. Manufacturers who can demonstrate superior battery longevity through effective thermal management systems command premium pricing, with consumers willing to pay 15-20% more for devices with proven extended battery life. This trend is particularly pronounced in high-performance computing devices and premium smartphones.

Industrial applications represent another significant market segment, where unplanned downtime due to battery failure can cost thousands of dollars per hour. The industrial battery management system market is expected to grow at 18.3% CAGR through 2026, with thermal management components accounting for approximately 30% of this growth.

Geographically, Asia-Pacific dominates the market demand, accounting for 45% of global consumption, followed by North America (28%) and Europe (22%). China, in particular, has emerged as both the largest consumer and producer of battery thermal management systems, driven by its dominant position in global battery manufacturing and EV production.

Regulatory pressures are further accelerating market demand, with new standards being implemented across major markets that mandate minimum battery performance and longevity requirements. The European Union's proposed Battery Directive revision includes specific provisions for thermal management capabilities in EV batteries, while similar regulations are being considered in North America and Asia.

Market analysis indicates that the demand for passive thermal management solutions currently outpaces active systems by a ratio of approximately 3:2, though this gap is narrowing as active systems demonstrate superior performance in extreme operating conditions. Liquid cooling systems, in particular, are experiencing the fastest growth rate at 22.4% annually, reflecting their superior efficiency in high-discharge applications.

Current Thermal Management Challenges

Despite significant advancements in battery technology, thermal management remains one of the most critical challenges in extending battery lifespan. Modern lithium-ion batteries operate optimally within a narrow temperature range of 15-35°C, with performance and longevity significantly compromised outside this window. Current thermal management systems face substantial limitations in maintaining consistent temperature control across diverse operating conditions, from extreme cold to intense heat.

Heat generation during fast charging represents a particularly pressing challenge. As the industry pushes toward shorter charging times, the resulting thermal stress accelerates degradation mechanisms including SEI layer growth, lithium plating, and structural changes within electrode materials. Existing cooling systems often struggle to dissipate this heat effectively, especially in compact device designs where space constraints limit cooling solutions.

Temperature gradients within battery packs present another significant obstacle. In large-scale applications such as electric vehicles and grid storage, uneven temperature distribution leads to differential aging of cells, reducing overall system performance and creating potential safety risks. Current thermal management approaches frequently fail to address these gradients adequately, resulting in premature capacity fade in certain cells and system-wide inefficiencies.

The integration of thermal management with battery management systems (BMS) remains suboptimal in many implementations. While BMS can monitor temperature, the response mechanisms are often reactive rather than predictive, limiting their effectiveness in preventing thermal events before they occur. This disconnect between sensing and response capabilities represents a significant gap in current technology.

Energy efficiency of thermal management systems themselves poses another challenge. Active cooling systems, particularly in mobile applications, can consume substantial power, creating a parasitic load that reduces overall system efficiency. This energy consumption paradoxically contributes to additional heat generation, potentially exacerbating the very problem these systems aim to solve.

Material limitations further constrain thermal management solutions. Current thermal interface materials, phase change materials, and heat spreaders often represent compromises between thermal conductivity, weight, cost, and manufacturability. The search for materials that excel across all these parameters continues to challenge researchers and engineers alike.

Finally, cost considerations remain a significant barrier to implementing advanced thermal management solutions. Sophisticated systems with precise temperature control capabilities add substantial expense to battery products, creating market resistance particularly in cost-sensitive applications. Balancing performance requirements with economic constraints represents an ongoing challenge for manufacturers across the battery ecosystem.

Heat generation during fast charging represents a particularly pressing challenge. As the industry pushes toward shorter charging times, the resulting thermal stress accelerates degradation mechanisms including SEI layer growth, lithium plating, and structural changes within electrode materials. Existing cooling systems often struggle to dissipate this heat effectively, especially in compact device designs where space constraints limit cooling solutions.

Temperature gradients within battery packs present another significant obstacle. In large-scale applications such as electric vehicles and grid storage, uneven temperature distribution leads to differential aging of cells, reducing overall system performance and creating potential safety risks. Current thermal management approaches frequently fail to address these gradients adequately, resulting in premature capacity fade in certain cells and system-wide inefficiencies.

The integration of thermal management with battery management systems (BMS) remains suboptimal in many implementations. While BMS can monitor temperature, the response mechanisms are often reactive rather than predictive, limiting their effectiveness in preventing thermal events before they occur. This disconnect between sensing and response capabilities represents a significant gap in current technology.

Energy efficiency of thermal management systems themselves poses another challenge. Active cooling systems, particularly in mobile applications, can consume substantial power, creating a parasitic load that reduces overall system efficiency. This energy consumption paradoxically contributes to additional heat generation, potentially exacerbating the very problem these systems aim to solve.

Material limitations further constrain thermal management solutions. Current thermal interface materials, phase change materials, and heat spreaders often represent compromises between thermal conductivity, weight, cost, and manufacturability. The search for materials that excel across all these parameters continues to challenge researchers and engineers alike.

Finally, cost considerations remain a significant barrier to implementing advanced thermal management solutions. Sophisticated systems with precise temperature control capabilities add substantial expense to battery products, creating market resistance particularly in cost-sensitive applications. Balancing performance requirements with economic constraints represents an ongoing challenge for manufacturers across the battery ecosystem.

Current Thermal Solution Approaches

01 Temperature control systems for battery longevity

Effective temperature control systems are crucial for maintaining optimal battery operating conditions. These systems regulate battery temperature within a specific range to prevent overheating and excessive cooling, both of which can significantly reduce battery lifespan. Advanced thermal management solutions include liquid cooling circuits, heat exchangers, and intelligent temperature monitoring systems that adjust cooling intensity based on real-time battery conditions.- Active cooling systems for battery thermal management: Active cooling systems utilize forced circulation of cooling fluids or air to maintain optimal battery temperature ranges. These systems can include liquid cooling circuits, refrigeration cycles, or forced air cooling that actively remove heat from battery cells during operation and charging. By preventing overheating, these systems significantly extend battery lifespan by reducing degradation mechanisms that occur at elevated temperatures, maintaining capacity and performance over time.

- Passive thermal management solutions: Passive thermal management solutions rely on materials and design elements that naturally conduct, distribute, or dissipate heat without requiring power input. These include phase change materials, heat sinks, thermal interface materials, and strategic cell spacing. These solutions provide consistent temperature regulation with high reliability due to the absence of moving parts or complex control systems, helping to maintain uniform temperature distribution across battery packs and extending overall battery lifespan.

- Intelligent battery management systems: Intelligent battery management systems incorporate advanced algorithms and sensors to monitor and control battery temperature in real-time. These systems can predict thermal behavior, adjust charging/discharging rates based on temperature conditions, and implement protective measures when thermal anomalies are detected. By optimizing operating conditions and preventing thermal runaway scenarios, these intelligent systems significantly extend battery lifespan while enhancing safety and performance.

- Thermal insulation and heat distribution technologies: Thermal insulation and heat distribution technologies focus on managing heat flow within battery systems through specialized materials and designs. These include thermal barriers between cells, heat spreading materials, aerogel insulation, and thermally conductive adhesives. By preventing thermal hotspots and ensuring uniform temperature distribution across battery packs, these technologies reduce stress on individual cells and minimize degradation mechanisms that would otherwise shorten battery lifespan.

- Hybrid thermal management approaches: Hybrid thermal management approaches combine multiple cooling and heating methods to optimize battery temperature control across various operating conditions. These systems might integrate liquid cooling with air cooling, or combine active systems with passive elements like phase change materials. By leveraging the strengths of different thermal management techniques, hybrid systems provide robust temperature control in extreme environments and varying load conditions, maximizing battery lifespan while maintaining performance and safety.

02 Battery cell arrangement and thermal isolation techniques

The physical arrangement of battery cells and thermal isolation techniques play a significant role in managing heat distribution. Strategic placement of cells with appropriate spacing allows for better heat dissipation, while thermal isolation barriers prevent heat transfer between cells. These design considerations help maintain uniform temperature across the battery pack, reducing thermal stress and extending overall battery lifespan.Expand Specific Solutions03 Intelligent battery management systems

Intelligent battery management systems (BMS) incorporate advanced algorithms to optimize charging and discharging cycles based on temperature conditions. These systems monitor battery temperature in real-time and adjust power flow to prevent thermal runaway situations. By implementing predictive thermal management strategies, the BMS can anticipate temperature fluctuations and take preemptive actions to maintain optimal operating conditions, thereby extending battery lifespan.Expand Specific Solutions04 Phase change materials for thermal regulation

Phase change materials (PCMs) offer passive thermal regulation for battery systems by absorbing excess heat during high-load operations and releasing it when temperatures drop. This helps maintain a more consistent battery temperature, reducing thermal cycling stress. PCMs can be integrated into battery pack designs as thermal buffers, providing an additional layer of temperature control that requires no external power, making them particularly valuable for extending battery lifespan in various operating conditions.Expand Specific Solutions05 Cooling system integration with vehicle architecture

The integration of battery cooling systems with overall vehicle thermal management architecture enables more efficient use of available cooling resources. These integrated systems can share cooling circuits with other vehicle components, allowing for optimized thermal management across the entire vehicle. Advanced designs incorporate multiple cooling loops with varying temperature requirements, smart valves for flow control, and heat recovery systems that repurpose waste heat, all contributing to improved battery thermal conditions and extended lifespan.Expand Specific Solutions

Key Players in Thermal Management Industry

The thermal management market for battery lifespan extension is in a growth phase, with increasing demand driven by electric vehicle adoption and energy storage applications. The market is projected to expand significantly as battery technologies evolve. Leading players include established automotive manufacturers like BYD, Volvo, and Renault, alongside specialized battery producers such as CATL and EVE Energy. Technology maturity varies across segments, with companies like Gentherm and Hanon Systems offering advanced thermal solutions. Chinese manufacturers including NIO and Geely are rapidly advancing their capabilities, while research partnerships with institutions like the University of Michigan are accelerating innovation. The competitive landscape features both traditional automotive suppliers and emerging technology-focused entrants, creating a dynamic ecosystem of thermal management solutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative liquid cooling thermal management system for their battery packs that utilizes a network of cooling plates with serpentine channels positioned between battery cells. This design ensures uniform temperature distribution across the entire battery pack, preventing hotspots that accelerate degradation. Their Cell-to-Pack (CTP) technology integrates thermal management directly into the structural design, eliminating the need for separate module housings and improving thermal efficiency. CATL's system employs intelligent thermal management algorithms that dynamically adjust cooling intensity based on real-time temperature monitoring, battery state of charge, and operational demands. The company has also pioneered phase-change materials within their battery packs that absorb excess heat during high-load operations and release it gradually during rest periods, maintaining optimal temperature ranges.

Strengths: Industry-leading energy density while maintaining effective thermal control; integrated cooling systems reduce overall weight and volume; advanced temperature prediction algorithms optimize performance. Weaknesses: Higher initial manufacturing costs compared to simpler cooling solutions; complex liquid cooling systems require additional maintenance and introduce potential leak points.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology with an integrated thermal management system specifically designed to address safety and longevity concerns. The Blade Battery utilizes a cell-to-pack design where long, thin cells are arranged parallel to each other with cooling channels integrated between them. This arrangement maximizes the surface area available for cooling while minimizing thermal gradients across cells. BYD's thermal management solution incorporates a liquid cooling system that circulates coolant through aluminum cooling plates positioned between battery cells, ensuring uniform temperature distribution. Their system features intelligent thermal control algorithms that proactively manage battery temperature based on driving conditions, ambient temperature, and battery state of charge. Additionally, BYD has implemented thermal insulation materials surrounding the battery pack to minimize the impact of extreme external temperatures, protecting cells from thermal shock during rapid temperature changes.

Strengths: Exceptional thermal stability even under extreme conditions; integrated cooling design maximizes energy density while maintaining optimal temperature control; proven safety record with minimal thermal runaway incidents. Weaknesses: The specialized blade design may limit flexibility for different vehicle configurations; higher manufacturing complexity compared to traditional battery designs.

Core Thermal Management Technologies

Thermal management system

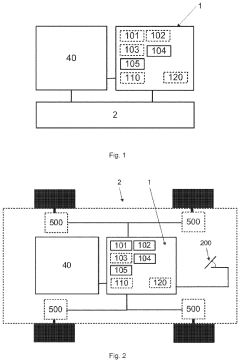

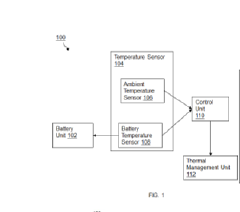

PatentPendingUS20200127342A1

Innovation

- A method and device that proactively manage battery temperature by measuring current temperature and predictive temperature increase based on current and resistance, using a feedforward approach to anticipate and mitigate temperature changes, thereby preventing overheating and extending battery life.

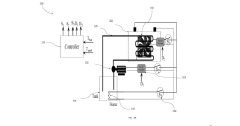

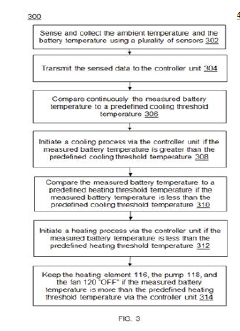

A battery thermal management system and method thereof

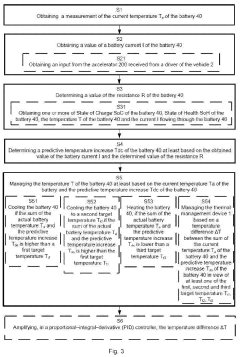

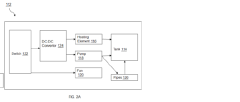

PatentPendingIN202411018158A

Innovation

- A battery thermal management system using liquid cooling and heating with a controller unit, temperature sensors, and a thermal management unit that includes a tank, heating element, pump, fan, and switches to regulate temperature through convection, allowing for real-time temperature control and efficient operation across high and low temperature ranges.

Environmental Impact Assessment

The environmental impact of thermal management systems in battery technology extends far beyond the immediate performance benefits. As battery technologies become increasingly prevalent in electric vehicles, renewable energy storage, and consumer electronics, their ecological footprint demands thorough examination. Thermal management systems, while crucial for battery longevity, contribute significantly to this environmental equation.

The production phase of thermal management components involves resource extraction and manufacturing processes that generate considerable carbon emissions. Materials commonly used in these systems, such as aluminum heat sinks, copper heat pipes, and specialized cooling fluids, require energy-intensive mining and processing operations. Additionally, the manufacturing of sophisticated thermal management electronics contributes to industrial waste and chemical byproducts that may pose environmental hazards if not properly managed.

During operational phases, active cooling systems consume additional energy, potentially offsetting some of the environmental benefits gained from battery-powered technologies. This parasitic energy consumption represents a hidden environmental cost that varies significantly based on system design efficiency. Passive cooling solutions generally offer lower environmental impact during operation but may provide less effective thermal management in extreme conditions.

End-of-life considerations present another critical environmental dimension. Many thermal management components contain materials that require specialized recycling processes or present disposal challenges. Cooling fluids, in particular, may contain compounds that pose environmental risks if improperly disposed of. The recyclability of these systems varies widely, with some designs incorporating easily recoverable materials while others present significant separation challenges.

Recent lifecycle assessments reveal that optimized thermal management can actually reduce overall environmental impact by extending battery lifespans. A battery that lasts twice as long effectively halves the environmental burden of battery production and disposal. This relationship creates an important sustainability equation: the environmental cost of implementing robust thermal management versus the environmental benefit of reduced battery replacement frequency.

Regulatory frameworks worldwide are increasingly addressing these environmental considerations. The European Union's Battery Directive and similar regulations in other regions are evolving to include provisions for thermal management systems, particularly regarding recyclability requirements and restricted substances. Manufacturers are responding with eco-design approaches that consider environmental impact throughout the product lifecycle.

Innovation in bio-based cooling fluids, recyclable heat dissipation materials, and energy-efficient cooling algorithms represents promising directions for reducing the environmental footprint of thermal management systems. These advancements, coupled with holistic lifecycle design approaches, will be essential for developing truly sustainable battery technologies for our increasingly electrified future.

The production phase of thermal management components involves resource extraction and manufacturing processes that generate considerable carbon emissions. Materials commonly used in these systems, such as aluminum heat sinks, copper heat pipes, and specialized cooling fluids, require energy-intensive mining and processing operations. Additionally, the manufacturing of sophisticated thermal management electronics contributes to industrial waste and chemical byproducts that may pose environmental hazards if not properly managed.

During operational phases, active cooling systems consume additional energy, potentially offsetting some of the environmental benefits gained from battery-powered technologies. This parasitic energy consumption represents a hidden environmental cost that varies significantly based on system design efficiency. Passive cooling solutions generally offer lower environmental impact during operation but may provide less effective thermal management in extreme conditions.

End-of-life considerations present another critical environmental dimension. Many thermal management components contain materials that require specialized recycling processes or present disposal challenges. Cooling fluids, in particular, may contain compounds that pose environmental risks if improperly disposed of. The recyclability of these systems varies widely, with some designs incorporating easily recoverable materials while others present significant separation challenges.

Recent lifecycle assessments reveal that optimized thermal management can actually reduce overall environmental impact by extending battery lifespans. A battery that lasts twice as long effectively halves the environmental burden of battery production and disposal. This relationship creates an important sustainability equation: the environmental cost of implementing robust thermal management versus the environmental benefit of reduced battery replacement frequency.

Regulatory frameworks worldwide are increasingly addressing these environmental considerations. The European Union's Battery Directive and similar regulations in other regions are evolving to include provisions for thermal management systems, particularly regarding recyclability requirements and restricted substances. Manufacturers are responding with eco-design approaches that consider environmental impact throughout the product lifecycle.

Innovation in bio-based cooling fluids, recyclable heat dissipation materials, and energy-efficient cooling algorithms represents promising directions for reducing the environmental footprint of thermal management systems. These advancements, coupled with holistic lifecycle design approaches, will be essential for developing truly sustainable battery technologies for our increasingly electrified future.

Safety Standards and Regulations

The regulatory landscape for battery thermal management systems has evolved significantly in response to high-profile safety incidents involving lithium-ion batteries. International standards such as IEC 62133 and UL 1642 establish comprehensive safety requirements for batteries, with specific provisions addressing thermal runaway prevention and management. These standards mandate rigorous testing protocols including thermal abuse tests, where batteries must demonstrate resilience against extreme temperature conditions without catastrophic failure.

The automotive sector has developed particularly stringent regulations, with standards like UN ECE R100 and ISO 6469 specifically addressing thermal management in electric vehicle battery systems. These regulations require manufacturers to implement robust thermal monitoring systems and emergency response mechanisms to prevent thermal propagation between cells during failure events.

Consumer electronics face increasingly strict regulatory oversight, with the IEC 61960 standard requiring manufacturers to implement thermal protection circuits that can disconnect batteries when temperatures exceed safe operating ranges. Similarly, the aviation industry has established special requirements through standards like RTCA DO-311A, which mandates enhanced thermal management systems for lithium batteries used in aircraft applications.

Regulatory bodies worldwide are continuously updating these standards as battery technology evolves. The European Union's Battery Directive is currently being revised to include more specific thermal management requirements, while China's GB/T 31485 standard has recently been updated with enhanced thermal safety provisions for electric vehicle batteries.

Compliance with these regulations necessitates sophisticated thermal management solutions that can actively monitor and control battery temperatures across various operating conditions. Many standards now require real-time temperature monitoring systems with multiple redundancies and fail-safe mechanisms that can detect and respond to thermal anomalies before they escalate into safety incidents.

The regulatory framework also increasingly emphasizes end-of-life considerations, with standards beginning to address thermal management during battery recycling and disposal processes. This holistic approach recognizes that thermal risks exist throughout the entire battery lifecycle, not just during normal operation.

For manufacturers, navigating this complex regulatory landscape requires continuous investment in thermal management research and development. Companies must not only comply with current standards but also anticipate future regulatory developments, as safety requirements typically become more stringent following incidents or as new research identifies previously unknown thermal risks.

The automotive sector has developed particularly stringent regulations, with standards like UN ECE R100 and ISO 6469 specifically addressing thermal management in electric vehicle battery systems. These regulations require manufacturers to implement robust thermal monitoring systems and emergency response mechanisms to prevent thermal propagation between cells during failure events.

Consumer electronics face increasingly strict regulatory oversight, with the IEC 61960 standard requiring manufacturers to implement thermal protection circuits that can disconnect batteries when temperatures exceed safe operating ranges. Similarly, the aviation industry has established special requirements through standards like RTCA DO-311A, which mandates enhanced thermal management systems for lithium batteries used in aircraft applications.

Regulatory bodies worldwide are continuously updating these standards as battery technology evolves. The European Union's Battery Directive is currently being revised to include more specific thermal management requirements, while China's GB/T 31485 standard has recently been updated with enhanced thermal safety provisions for electric vehicle batteries.

Compliance with these regulations necessitates sophisticated thermal management solutions that can actively monitor and control battery temperatures across various operating conditions. Many standards now require real-time temperature monitoring systems with multiple redundancies and fail-safe mechanisms that can detect and respond to thermal anomalies before they escalate into safety incidents.

The regulatory framework also increasingly emphasizes end-of-life considerations, with standards beginning to address thermal management during battery recycling and disposal processes. This holistic approach recognizes that thermal risks exist throughout the entire battery lifecycle, not just during normal operation.

For manufacturers, navigating this complex regulatory landscape requires continuous investment in thermal management research and development. Companies must not only comply with current standards but also anticipate future regulatory developments, as safety requirements typically become more stringent following incidents or as new research identifies previously unknown thermal risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!