Thermal Management of Lithium-Ion vs Solid-State Batteries

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Evolution and Objectives

Battery thermal management has evolved significantly over the past decades, transitioning from simple passive cooling systems to sophisticated active thermal management solutions. The earliest lithium-ion battery applications in portable electronics relied primarily on natural convection and minimal thermal considerations. As battery capacities increased and applications expanded to electric vehicles and grid storage in the early 2000s, the limitations of these basic approaches became evident through incidents of thermal runaway and reduced battery performance.

The evolution accelerated around 2010 when major automotive manufacturers began mass-producing electric vehicles, necessitating more advanced thermal management systems. This period saw the development of liquid cooling circuits, phase-change materials, and intelligent battery management systems capable of real-time temperature monitoring and control. By 2015, thermal management had become a critical design consideration in battery system architecture rather than an afterthought.

Current lithium-ion battery thermal management systems typically aim to maintain cell temperatures between 15-35°C, the optimal range for balancing performance, safety, and longevity. These systems must address multiple challenges: preventing thermal runaway, minimizing temperature gradients across battery packs, managing heat generation during fast charging, and operating efficiently across diverse environmental conditions.

The emergence of solid-state battery technology introduces a paradigm shift in thermal management objectives. While solid-state batteries generally exhibit improved thermal stability compared to conventional lithium-ion cells, they present unique thermal challenges. Operating temperature windows for solid-state electrolytes often differ significantly from liquid electrolytes, with some solid electrolytes requiring elevated temperatures (60-80°C) to achieve optimal ionic conductivity.

Looking forward, thermal management objectives are evolving toward more predictive and adaptive systems. The integration of artificial intelligence and machine learning algorithms enables thermal management systems to anticipate thermal events based on usage patterns and environmental conditions. Additionally, there is growing emphasis on sustainability, with objectives expanding to include waste heat recovery and reduced environmental impact of cooling systems.

The ultimate goal of modern battery thermal management is to achieve a balance between seemingly contradictory requirements: maximizing performance and charging speeds while ensuring safety and longevity, all while minimizing system complexity, weight, and cost. This balance becomes increasingly critical as battery technologies advance and applications diversify across transportation, renewable energy storage, and portable electronics sectors.

The evolution accelerated around 2010 when major automotive manufacturers began mass-producing electric vehicles, necessitating more advanced thermal management systems. This period saw the development of liquid cooling circuits, phase-change materials, and intelligent battery management systems capable of real-time temperature monitoring and control. By 2015, thermal management had become a critical design consideration in battery system architecture rather than an afterthought.

Current lithium-ion battery thermal management systems typically aim to maintain cell temperatures between 15-35°C, the optimal range for balancing performance, safety, and longevity. These systems must address multiple challenges: preventing thermal runaway, minimizing temperature gradients across battery packs, managing heat generation during fast charging, and operating efficiently across diverse environmental conditions.

The emergence of solid-state battery technology introduces a paradigm shift in thermal management objectives. While solid-state batteries generally exhibit improved thermal stability compared to conventional lithium-ion cells, they present unique thermal challenges. Operating temperature windows for solid-state electrolytes often differ significantly from liquid electrolytes, with some solid electrolytes requiring elevated temperatures (60-80°C) to achieve optimal ionic conductivity.

Looking forward, thermal management objectives are evolving toward more predictive and adaptive systems. The integration of artificial intelligence and machine learning algorithms enables thermal management systems to anticipate thermal events based on usage patterns and environmental conditions. Additionally, there is growing emphasis on sustainability, with objectives expanding to include waste heat recovery and reduced environmental impact of cooling systems.

The ultimate goal of modern battery thermal management is to achieve a balance between seemingly contradictory requirements: maximizing performance and charging speeds while ensuring safety and longevity, all while minimizing system complexity, weight, and cost. This balance becomes increasingly critical as battery technologies advance and applications diversify across transportation, renewable energy storage, and portable electronics sectors.

Market Demand Analysis for Advanced Battery Cooling Solutions

The global market for advanced battery cooling solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Current projections indicate the market will reach approximately $5.6 billion by 2027, growing at a compound annual growth rate of 13.7% from 2022. This surge is directly correlated with increasing consumer demand for EVs with longer ranges, faster charging capabilities, and improved safety profiles - all factors heavily dependent on effective thermal management systems.

Lithium-ion battery cooling solutions currently dominate the market, accounting for over 85% of implemented thermal management systems in commercial applications. However, as solid-state battery technology advances toward commercialization, a significant shift in cooling requirements and solutions is anticipated within the next 5-7 years, creating new market opportunities for specialized thermal management systems.

Consumer expectations regarding battery performance are evolving rapidly, with surveys indicating that 73% of potential EV buyers consider battery longevity and safety as critical purchasing factors. This consumer sentiment is driving manufacturers to invest heavily in advanced cooling technologies that can extend battery life while maintaining optimal performance parameters. The market is particularly responsive to solutions that can demonstrate measurable improvements in battery cycle life, with data suggesting that effective thermal management can extend battery lifespan by 25-40%.

Regional market analysis reveals significant differences in demand patterns. Asia-Pacific represents the largest market share at 42%, driven by China's aggressive EV manufacturing sector and supportive government policies. North America follows at 28%, with particularly strong demand for premium cooling solutions in the luxury and performance EV segments. Europe accounts for 24% of the market, characterized by stringent safety regulations that are accelerating adoption of sophisticated thermal management systems.

The commercial vehicle sector is emerging as a high-growth segment for advanced cooling solutions, with demand increasing at 18.2% annually as fleet operators prioritize total cost of ownership calculations that favor extended battery life. Similarly, the energy storage system market is creating new demand for scalable cooling solutions, particularly for grid-scale applications where thermal runaway prevention is critical.

Market forecasts indicate that liquid cooling systems will continue to dominate through 2025, but air cooling and phase change material solutions are gaining market share in specific applications where weight and space constraints are paramount. The emerging solid-state battery segment is creating demand for entirely new cooling approaches, with early adopters willing to pay premium prices for solutions that address the unique thermal characteristics of these next-generation energy storage devices.

Lithium-ion battery cooling solutions currently dominate the market, accounting for over 85% of implemented thermal management systems in commercial applications. However, as solid-state battery technology advances toward commercialization, a significant shift in cooling requirements and solutions is anticipated within the next 5-7 years, creating new market opportunities for specialized thermal management systems.

Consumer expectations regarding battery performance are evolving rapidly, with surveys indicating that 73% of potential EV buyers consider battery longevity and safety as critical purchasing factors. This consumer sentiment is driving manufacturers to invest heavily in advanced cooling technologies that can extend battery life while maintaining optimal performance parameters. The market is particularly responsive to solutions that can demonstrate measurable improvements in battery cycle life, with data suggesting that effective thermal management can extend battery lifespan by 25-40%.

Regional market analysis reveals significant differences in demand patterns. Asia-Pacific represents the largest market share at 42%, driven by China's aggressive EV manufacturing sector and supportive government policies. North America follows at 28%, with particularly strong demand for premium cooling solutions in the luxury and performance EV segments. Europe accounts for 24% of the market, characterized by stringent safety regulations that are accelerating adoption of sophisticated thermal management systems.

The commercial vehicle sector is emerging as a high-growth segment for advanced cooling solutions, with demand increasing at 18.2% annually as fleet operators prioritize total cost of ownership calculations that favor extended battery life. Similarly, the energy storage system market is creating new demand for scalable cooling solutions, particularly for grid-scale applications where thermal runaway prevention is critical.

Market forecasts indicate that liquid cooling systems will continue to dominate through 2025, but air cooling and phase change material solutions are gaining market share in specific applications where weight and space constraints are paramount. The emerging solid-state battery segment is creating demand for entirely new cooling approaches, with early adopters willing to pay premium prices for solutions that address the unique thermal characteristics of these next-generation energy storage devices.

Current Thermal Management Challenges in Battery Technologies

Lithium-ion batteries currently dominate the energy storage market, but their thermal management remains a significant challenge. These batteries operate optimally within a narrow temperature range (20-40°C), with performance degradation and safety risks occurring outside this window. During charging and discharging, lithium-ion cells generate substantial heat through various mechanisms, including ohmic heating, entropic heating, and reaction heat, necessitating effective thermal control systems.

The primary thermal management challenge for lithium-ion batteries is preventing thermal runaway—a catastrophic failure mode where increasing temperature triggers exothermic reactions, creating a dangerous feedback loop. This phenomenon can lead to cell venting, fire, or explosion, particularly concerning in high-energy-density applications like electric vehicles and grid storage systems.

Current lithium-ion battery thermal management systems (BTMS) employ various cooling strategies, each with limitations. Air cooling systems, while simple and cost-effective, struggle with cooling efficiency and temperature uniformity across large battery packs. Liquid cooling offers superior heat transfer but introduces complexity, weight, and potential leakage concerns. Phase change materials provide passive thermal regulation but face challenges in complete regeneration and long-term stability.

Solid-state batteries present a different thermal management paradigm. These next-generation energy storage devices replace flammable liquid electrolytes with solid conductors, inherently reducing fire risks. However, they introduce unique thermal challenges. The solid electrolyte interfaces create higher internal resistance, potentially generating more heat during high-current operations. Additionally, many solid electrolytes require elevated operating temperatures (60-80°C) to achieve optimal ionic conductivity, necessitating heating systems rather than cooling in certain conditions.

Temperature uniformity remains critical for both technologies. Uneven temperature distribution leads to differential aging, localized degradation, and reduced overall battery lifespan. This challenge is particularly pronounced in large-format batteries for automotive and stationary applications, where thermal gradients can develop across cells and modules.

Extreme environmental conditions further complicate thermal management. Cold temperatures significantly reduce lithium-ion performance and can lead to lithium plating during charging. Solid-state batteries may require preheating in cold environments, adding energy consumption and system complexity. Conversely, high ambient temperatures accelerate degradation mechanisms in both technologies, though solid-state batteries generally demonstrate better high-temperature stability.

The integration of thermal management with battery management systems represents another frontier challenge. Advanced sensing, predictive modeling, and adaptive control strategies are needed to optimize thermal conditions throughout battery life cycles, balancing performance, safety, and longevity requirements across diverse operating scenarios.

The primary thermal management challenge for lithium-ion batteries is preventing thermal runaway—a catastrophic failure mode where increasing temperature triggers exothermic reactions, creating a dangerous feedback loop. This phenomenon can lead to cell venting, fire, or explosion, particularly concerning in high-energy-density applications like electric vehicles and grid storage systems.

Current lithium-ion battery thermal management systems (BTMS) employ various cooling strategies, each with limitations. Air cooling systems, while simple and cost-effective, struggle with cooling efficiency and temperature uniformity across large battery packs. Liquid cooling offers superior heat transfer but introduces complexity, weight, and potential leakage concerns. Phase change materials provide passive thermal regulation but face challenges in complete regeneration and long-term stability.

Solid-state batteries present a different thermal management paradigm. These next-generation energy storage devices replace flammable liquid electrolytes with solid conductors, inherently reducing fire risks. However, they introduce unique thermal challenges. The solid electrolyte interfaces create higher internal resistance, potentially generating more heat during high-current operations. Additionally, many solid electrolytes require elevated operating temperatures (60-80°C) to achieve optimal ionic conductivity, necessitating heating systems rather than cooling in certain conditions.

Temperature uniformity remains critical for both technologies. Uneven temperature distribution leads to differential aging, localized degradation, and reduced overall battery lifespan. This challenge is particularly pronounced in large-format batteries for automotive and stationary applications, where thermal gradients can develop across cells and modules.

Extreme environmental conditions further complicate thermal management. Cold temperatures significantly reduce lithium-ion performance and can lead to lithium plating during charging. Solid-state batteries may require preheating in cold environments, adding energy consumption and system complexity. Conversely, high ambient temperatures accelerate degradation mechanisms in both technologies, though solid-state batteries generally demonstrate better high-temperature stability.

The integration of thermal management with battery management systems represents another frontier challenge. Advanced sensing, predictive modeling, and adaptive control strategies are needed to optimize thermal conditions throughout battery life cycles, balancing performance, safety, and longevity requirements across diverse operating scenarios.

Existing Thermal Management Architectures and Approaches

01 Thermal management systems for lithium-ion batteries

Various thermal management systems are designed specifically for lithium-ion batteries to maintain optimal operating temperatures. These systems include liquid cooling circuits, heat exchangers, and thermal interface materials that efficiently dissipate heat generated during charging and discharging cycles. Advanced control algorithms monitor battery temperature and adjust cooling parameters accordingly to prevent thermal runaway and extend battery life.- Thermal management systems for lithium-ion batteries: Various thermal management systems are designed specifically for lithium-ion batteries to maintain optimal operating temperatures. These systems include liquid cooling circuits, air cooling mechanisms, and heat exchangers that efficiently dissipate heat generated during charging and discharging cycles. Advanced thermal management solutions help prevent thermal runaway, extend battery life, and maintain consistent performance across varying operational conditions.

- Solid-state battery cooling technologies: Solid-state batteries require specialized thermal management approaches due to their unique structure and thermal characteristics. These technologies include integrated cooling plates, thermal interface materials, and phase change materials that address the specific heat distribution patterns in solid-state cells. Effective thermal management for solid-state batteries focuses on uniform temperature distribution and prevention of hotspots that could compromise the solid electrolyte integrity.

- Phase change materials for battery thermal regulation: Phase change materials (PCMs) are increasingly used in battery thermal management systems to absorb excess heat during operation and release it when temperatures drop. These materials provide passive thermal regulation by changing state at specific temperatures, helping to maintain batteries within optimal temperature ranges. PCMs can be integrated into battery modules or packs to provide efficient thermal buffering without requiring active cooling systems.

- Integrated cooling systems for battery packs: Integrated cooling systems combine multiple thermal management technologies within battery pack designs to optimize temperature control. These systems may incorporate liquid cooling channels, heat pipes, thermal fins, and smart thermal management controllers that adapt to changing conditions. The integration of cooling systems directly into battery pack structures allows for more efficient heat transfer and compact designs suitable for electric vehicles and energy storage applications.

- Thermal management control strategies and algorithms: Advanced control strategies and algorithms optimize battery thermal management by dynamically adjusting cooling or heating based on real-time temperature monitoring. These intelligent systems use predictive models, machine learning, and sensor networks to anticipate thermal needs and efficiently allocate cooling resources. Smart thermal management controls can balance performance, safety, and energy efficiency while extending battery lifespan through precise temperature regulation.

02 Solid-state battery cooling technologies

Solid-state batteries require specialized thermal management approaches due to their unique structure and heat generation characteristics. Innovations include integrated cooling plates, phase change materials, and thermally conductive layers embedded within the battery architecture. These technologies address the specific thermal challenges of solid-state batteries, such as hotspot formation and thermal gradient management, while maintaining the safety advantages of solid electrolytes.Expand Specific Solutions03 Phase change materials for battery thermal regulation

Phase change materials (PCMs) are increasingly used in battery thermal management systems to absorb and release thermal energy during phase transitions. These materials can maintain battery temperature within optimal ranges by absorbing excess heat during operation and releasing it when temperatures drop. PCM-based solutions are particularly valuable for applications requiring passive thermal management with minimal energy consumption and can be integrated into both lithium-ion and solid-state battery systems.Expand Specific Solutions04 Integrated battery-vehicle thermal management systems

Advanced thermal management approaches integrate battery cooling with vehicle-level thermal systems to optimize overall energy efficiency. These systems leverage waste heat recovery, cabin climate control integration, and intelligent thermal routing to balance battery temperature requirements with other vehicle thermal needs. Such integrated approaches reduce the total energy required for thermal management and can significantly extend electric vehicle range, particularly in extreme climate conditions.Expand Specific Solutions05 AI and predictive thermal management for batteries

Artificial intelligence and machine learning algorithms are being applied to battery thermal management to predict thermal behavior and optimize cooling strategies. These systems analyze battery usage patterns, environmental conditions, and internal battery parameters to anticipate thermal needs before critical temperatures are reached. Predictive thermal management reduces energy consumption, extends battery lifespan, and enhances safety by preventing thermal events through proactive rather than reactive cooling approaches.Expand Specific Solutions

Key Industry Players in Battery Thermal Solutions

The thermal management landscape for lithium-ion versus solid-state batteries is evolving rapidly, with the market currently in a transitional phase. The global battery thermal management market is expanding significantly, driven by electric vehicle adoption and renewable energy storage demands. While lithium-ion technology is mature with established thermal management solutions from companies like Toyota, Bosch, and GM, solid-state battery thermal management represents an emerging frontier. Research institutions like University of Nottingham Ningbo China and Chinese Academy of Science Guangzhou Energy Research Institute are advancing fundamental research, while commercial players including QuantumScape, Murata Manufacturing, and Ola Electric are developing practical implementations. The competitive advantage lies in managing the distinct thermal characteristics of solid-state batteries, which promise higher energy density and improved safety but present unique thermal challenges compared to traditional lithium-ion systems.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a sophisticated thermal management platform applicable to both lithium-ion and emerging solid-state battery technologies. Their system features a modular architecture that can be configured for different battery chemistries and form factors. For lithium-ion batteries, Bosch employs a direct cooling approach where specialized coolant channels contact individual cells, achieving temperature uniformity within 2°C across large packs. Their system incorporates smart valves that dynamically adjust coolant flow based on real-time thermal mapping of the battery. For solid-state batteries, Bosch has developed a scaled-down thermal management solution that capitalizes on the reduced cooling requirements while addressing the unique thermal characteristics of solid electrolytes. The system includes ultra-thin cooling plates with microchannels that provide targeted cooling only where needed, reducing system weight by approximately 40% compared to conventional lithium-ion cooling systems. Bosch's approach also features integrated thermal barriers that prevent thermal propagation between cells, enhancing safety in both battery types.

Strengths: Highly scalable solutions applicable across vehicle segments; extensive supplier network for system integration; advanced manufacturing capabilities; comprehensive testing facilities. Weaknesses: Higher initial system cost; complex manufacturing process for microchannel cooling plates; requires precise integration with battery cell design.

GM Global Technology Operations LLC

Technical Solution: GM has developed the Ultium battery platform with an advanced thermal management system that bridges current lithium-ion technology and future solid-state implementations. Their system employs a patented heat exchanger design that surrounds each battery cell, providing uniform cooling and heating capability. For lithium-ion batteries, GM utilizes a refrigerant-based system that achieves temperature control within ±2°C across the entire pack, significantly extending battery life and performance. The system incorporates intelligent thermal preconditioning that optimizes battery temperature before charging, reducing fast-charging times by up to 30% in cold conditions. For solid-state battery development, GM is designing a simplified thermal architecture that maintains the precise temperature control capabilities while reducing system complexity by approximately 40%. Their approach includes specialized phase-change materials embedded within the battery structure that provide passive thermal regulation, supplemented by a reduced active cooling system. GM's thermal management also features AI-driven predictive controls that optimize energy usage based on driving patterns and environmental conditions.

Strengths: Highly integrated with vehicle thermal systems; scalable across multiple vehicle platforms; extensive cold-weather performance optimization; forward-compatible design philosophy. Weaknesses: Current system complexity adds weight and cost; transition strategy to solid-state requires significant redesign; high dependence on sophisticated control algorithms.

Critical Patents and Research in Battery Cooling Technologies

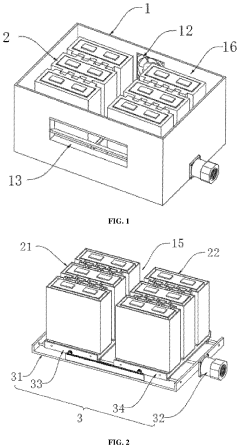

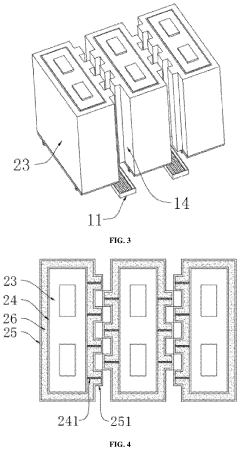

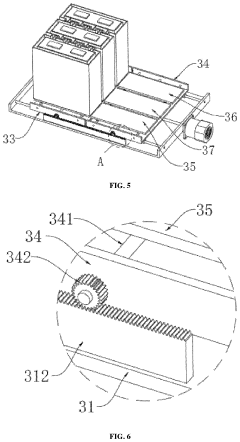

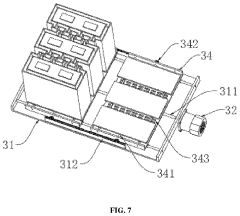

Lithium-ion battery thermal management system and method based on phase change material and mutually embedded fins

PatentActiveUS11804625B2

Innovation

- A lithium-ion battery thermal management system utilizing phase change materials (PCMs) and mutually embedded fins, where the fins on adjacent cells can move to form heat exchange or thermal preservation channels, combined with air cooling and heating units to enhance heat dissipation and retention, ensuring optimal temperature control across different operating conditions.

Safety Standards and Regulatory Requirements for Battery Systems

The regulatory landscape for battery systems has evolved significantly in response to safety concerns and technological advancements. For lithium-ion batteries, established standards such as IEC 62133, UL 1642, and UN 38.3 govern safety requirements for transportation, testing, and operation. These standards address thermal runaway risks through specific temperature control parameters and thermal management system requirements.

Solid-state batteries face an evolving regulatory framework as the technology matures. Current standards are being adapted to address their unique characteristics, with organizations like ISO and IEC developing specialized guidelines. The absence of flammable liquid electrolytes in solid-state batteries has prompted regulatory bodies to reconsider thermal management requirements, potentially allowing for less stringent cooling systems.

Thermal management aspects feature prominently in safety regulations for both battery types. For lithium-ion systems, standards mandate specific temperature monitoring capabilities, thermal runaway prevention measures, and cooling system redundancies. These requirements often translate to additional system complexity and cost. Solid-state battery regulations are expected to focus more on preventing mechanical stress-induced thermal events rather than electrolyte-based failures.

Regional variations in regulatory approaches present challenges for global manufacturers. The European Union's Battery Directive and China's GB standards impose different thermal management requirements compared to North American UL standards. These differences necessitate market-specific thermal management solutions, impacting design and manufacturing processes.

Emerging regulations increasingly address battery lifecycle management, including thermal considerations during recycling and disposal. End-of-life thermal risks differ significantly between lithium-ion and solid-state technologies, with the former requiring more stringent controls during disassembly and recycling processes due to residual energy and electrolyte reactivity.

Compliance testing methodologies for thermal management systems vary by battery chemistry. Lithium-ion batteries undergo rigorous thermal abuse testing, including nail penetration and external heating tests. Solid-state battery testing protocols are still evolving but generally focus on mechanical integrity under thermal stress rather than electrolyte-based thermal events.

Industry self-regulation complements formal standards, with organizations like the PRBA (Portable Rechargeable Battery Association) developing thermal management best practices. These voluntary guidelines often exceed minimum regulatory requirements and drive innovation in thermal management technologies for both battery types.

Solid-state batteries face an evolving regulatory framework as the technology matures. Current standards are being adapted to address their unique characteristics, with organizations like ISO and IEC developing specialized guidelines. The absence of flammable liquid electrolytes in solid-state batteries has prompted regulatory bodies to reconsider thermal management requirements, potentially allowing for less stringent cooling systems.

Thermal management aspects feature prominently in safety regulations for both battery types. For lithium-ion systems, standards mandate specific temperature monitoring capabilities, thermal runaway prevention measures, and cooling system redundancies. These requirements often translate to additional system complexity and cost. Solid-state battery regulations are expected to focus more on preventing mechanical stress-induced thermal events rather than electrolyte-based failures.

Regional variations in regulatory approaches present challenges for global manufacturers. The European Union's Battery Directive and China's GB standards impose different thermal management requirements compared to North American UL standards. These differences necessitate market-specific thermal management solutions, impacting design and manufacturing processes.

Emerging regulations increasingly address battery lifecycle management, including thermal considerations during recycling and disposal. End-of-life thermal risks differ significantly between lithium-ion and solid-state technologies, with the former requiring more stringent controls during disassembly and recycling processes due to residual energy and electrolyte reactivity.

Compliance testing methodologies for thermal management systems vary by battery chemistry. Lithium-ion batteries undergo rigorous thermal abuse testing, including nail penetration and external heating tests. Solid-state battery testing protocols are still evolving but generally focus on mechanical integrity under thermal stress rather than electrolyte-based thermal events.

Industry self-regulation complements formal standards, with organizations like the PRBA (Portable Rechargeable Battery Association) developing thermal management best practices. These voluntary guidelines often exceed minimum regulatory requirements and drive innovation in thermal management technologies for both battery types.

Environmental Impact of Different Cooling Technologies

The environmental impact of cooling technologies for battery thermal management systems represents a critical consideration in the sustainable development of electric vehicle (EV) and energy storage industries. Different cooling methods employed for lithium-ion and solid-state batteries exhibit varying ecological footprints throughout their lifecycle.

Air cooling systems, while energy-efficient and simple, may require larger battery spacing and housing designs, resulting in increased material usage and manufacturing emissions. However, they typically consume less energy during operation compared to active liquid cooling systems, which can offset their initial environmental impact over the battery's lifetime.

Liquid cooling technologies demonstrate superior thermal management efficiency but introduce additional environmental considerations. The production and eventual disposal of coolants, particularly those containing glycol compounds, can contribute to water and soil contamination if not properly managed. Furthermore, the manufacturing of complex liquid cooling components requires more resources and energy, increasing the embedded carbon footprint of the battery system.

Phase change materials (PCMs) offer a promising alternative with potentially lower environmental impact. These passive systems require no energy input during operation and can be designed using bio-based materials. Research indicates that PCM cooling solutions can reduce lifecycle greenhouse gas emissions by 15-20% compared to conventional liquid cooling systems when properly implemented.

For solid-state batteries, which generally produce less heat during operation, simpler cooling technologies may be sufficient. This presents an opportunity for significant reduction in cooling system complexity and associated environmental impacts. Studies suggest that solid-state battery systems may require up to 40% less cooling infrastructure than comparable lithium-ion systems, translating to proportional reductions in material usage and manufacturing emissions.

The end-of-life considerations also differ substantially between cooling technologies. Liquid cooling systems contain components that require specialized recycling processes, while simpler air cooling or PCM-based systems may be more easily disassembled and recycled. The recyclability of cooling system components directly impacts the overall sustainability profile of battery thermal management solutions.

Energy consumption during operation represents another significant environmental factor. Active cooling systems for lithium-ion batteries can consume 3-7% of the battery's stored energy, reducing overall efficiency and increasing the carbon footprint of each charging cycle. In contrast, the more thermally stable solid-state batteries with passive cooling solutions may reduce this operational energy penalty to less than 1%.

Emerging hybrid cooling technologies that combine multiple approaches show promise in optimizing both performance and environmental impact, potentially offering the best compromise between effective thermal management and ecological sustainability.

Air cooling systems, while energy-efficient and simple, may require larger battery spacing and housing designs, resulting in increased material usage and manufacturing emissions. However, they typically consume less energy during operation compared to active liquid cooling systems, which can offset their initial environmental impact over the battery's lifetime.

Liquid cooling technologies demonstrate superior thermal management efficiency but introduce additional environmental considerations. The production and eventual disposal of coolants, particularly those containing glycol compounds, can contribute to water and soil contamination if not properly managed. Furthermore, the manufacturing of complex liquid cooling components requires more resources and energy, increasing the embedded carbon footprint of the battery system.

Phase change materials (PCMs) offer a promising alternative with potentially lower environmental impact. These passive systems require no energy input during operation and can be designed using bio-based materials. Research indicates that PCM cooling solutions can reduce lifecycle greenhouse gas emissions by 15-20% compared to conventional liquid cooling systems when properly implemented.

For solid-state batteries, which generally produce less heat during operation, simpler cooling technologies may be sufficient. This presents an opportunity for significant reduction in cooling system complexity and associated environmental impacts. Studies suggest that solid-state battery systems may require up to 40% less cooling infrastructure than comparable lithium-ion systems, translating to proportional reductions in material usage and manufacturing emissions.

The end-of-life considerations also differ substantially between cooling technologies. Liquid cooling systems contain components that require specialized recycling processes, while simpler air cooling or PCM-based systems may be more easily disassembled and recycled. The recyclability of cooling system components directly impacts the overall sustainability profile of battery thermal management solutions.

Energy consumption during operation represents another significant environmental factor. Active cooling systems for lithium-ion batteries can consume 3-7% of the battery's stored energy, reducing overall efficiency and increasing the carbon footprint of each charging cycle. In contrast, the more thermally stable solid-state batteries with passive cooling solutions may reduce this operational energy penalty to less than 1%.

Emerging hybrid cooling technologies that combine multiple approaches show promise in optimizing both performance and environmental impact, potentially offering the best compromise between effective thermal management and ecological sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!