Research on Battery Thermal Management for EV Applications

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Thermal Management Background and Objectives

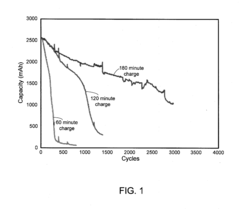

Battery thermal management systems (BTMS) have emerged as a critical component in electric vehicle (EV) technology development over the past decade. The evolution of battery technology has progressed from lead-acid to nickel-metal hydride and now predominantly lithium-ion chemistries, each presenting unique thermal management challenges. This technological progression has been driven by the increasing demand for higher energy density, faster charging capabilities, and longer battery life in EVs.

The thermal behavior of EV batteries represents a fundamental challenge in vehicle electrification. Lithium-ion batteries, which power most modern EVs, operate optimally within a narrow temperature range of 20-40°C. Deviations from this range significantly impact performance, safety, and longevity. At low temperatures, battery capacity and power output decrease dramatically, while high temperatures accelerate degradation mechanisms and increase safety risks, including thermal runaway.

Historical data indicates that thermal management solutions have evolved from simple air cooling systems in early EVs to sophisticated liquid cooling, phase change materials, and hybrid approaches in contemporary vehicles. This evolution reflects the industry's growing understanding of the complex relationship between temperature, battery performance, and safety. The technological trajectory suggests continued innovation toward more efficient, compact, and intelligent thermal management solutions.

Market pressures and regulatory requirements have accelerated research in this domain. Consumers demand EVs with longer ranges, faster charging capabilities, and improved safety profiles—all directly influenced by thermal management effectiveness. Simultaneously, stringent safety regulations worldwide have established temperature control as a non-negotiable aspect of EV design.

The primary objectives of current BTMS research include developing systems that maintain optimal temperature uniformity across battery packs, minimize parasitic energy consumption, reduce system weight and volume, and function effectively across extreme environmental conditions. Additionally, research aims to create predictive thermal management strategies that can anticipate and mitigate thermal issues before they impact performance or safety.

Emerging research directions include the integration of artificial intelligence for predictive thermal management, advanced materials with superior thermal properties, immersion cooling technologies, and thermal management systems specifically designed for ultra-fast charging scenarios. These innovations seek to address the fundamental limitations of current approaches while accommodating the increasing energy density and charging rates of next-generation batteries.

The ultimate goal of BTMS research is to develop solutions that maximize battery performance and longevity while ensuring safety across all operating conditions, thereby accelerating the global transition to electric mobility by addressing one of its most significant technical challenges.

The thermal behavior of EV batteries represents a fundamental challenge in vehicle electrification. Lithium-ion batteries, which power most modern EVs, operate optimally within a narrow temperature range of 20-40°C. Deviations from this range significantly impact performance, safety, and longevity. At low temperatures, battery capacity and power output decrease dramatically, while high temperatures accelerate degradation mechanisms and increase safety risks, including thermal runaway.

Historical data indicates that thermal management solutions have evolved from simple air cooling systems in early EVs to sophisticated liquid cooling, phase change materials, and hybrid approaches in contemporary vehicles. This evolution reflects the industry's growing understanding of the complex relationship between temperature, battery performance, and safety. The technological trajectory suggests continued innovation toward more efficient, compact, and intelligent thermal management solutions.

Market pressures and regulatory requirements have accelerated research in this domain. Consumers demand EVs with longer ranges, faster charging capabilities, and improved safety profiles—all directly influenced by thermal management effectiveness. Simultaneously, stringent safety regulations worldwide have established temperature control as a non-negotiable aspect of EV design.

The primary objectives of current BTMS research include developing systems that maintain optimal temperature uniformity across battery packs, minimize parasitic energy consumption, reduce system weight and volume, and function effectively across extreme environmental conditions. Additionally, research aims to create predictive thermal management strategies that can anticipate and mitigate thermal issues before they impact performance or safety.

Emerging research directions include the integration of artificial intelligence for predictive thermal management, advanced materials with superior thermal properties, immersion cooling technologies, and thermal management systems specifically designed for ultra-fast charging scenarios. These innovations seek to address the fundamental limitations of current approaches while accommodating the increasing energy density and charging rates of next-generation batteries.

The ultimate goal of BTMS research is to develop solutions that maximize battery performance and longevity while ensuring safety across all operating conditions, thereby accelerating the global transition to electric mobility by addressing one of its most significant technical challenges.

Market Demand Analysis for Advanced Battery Cooling Systems

The global market for advanced battery cooling systems in electric vehicles is experiencing unprecedented growth, driven by the rapid expansion of the EV sector. As of 2023, the market value for thermal management systems in EVs has reached approximately 3.5 billion USD, with projections indicating a compound annual growth rate of 22% through 2030. This surge is primarily attributed to increasing consumer demand for faster charging capabilities, extended battery life, and improved vehicle range - all factors directly impacted by effective thermal management.

Consumer expectations regarding EV performance have evolved significantly, with surveys indicating that over 70% of potential EV buyers consider fast charging capability as a critical purchasing factor. Advanced cooling systems that can maintain optimal battery temperatures during rapid charging sessions are therefore becoming essential rather than optional features. Additionally, the market is witnessing growing demand for systems that can extend battery longevity, as replacement costs remain a significant concern for consumers.

Geographically, the demand distribution shows notable regional variations. North American and European markets are increasingly focused on premium cooling solutions that maximize performance and battery life, while emerging markets in Asia prioritize cost-effective systems that balance performance with affordability. China, as the world's largest EV market, represents approximately 45% of the global demand for advanced battery cooling technologies.

From an industry perspective, automotive OEMs are increasingly viewing sophisticated thermal management as a competitive differentiator. This has led to growing investments in R&D for proprietary cooling technologies, with major manufacturers allocating an average of 15% of their EV development budgets specifically to thermal management solutions. The trend is particularly pronounced in the premium vehicle segment, where thermal efficiency is marketed as a key performance indicator.

Regulatory factors are also significantly influencing market demand. Stringent safety standards regarding battery thermal runaway prevention have been implemented across major markets, with the EU's Battery Regulation and similar frameworks in North America mandating advanced thermal management systems. These regulations are expected to become more comprehensive, further driving demand for sophisticated cooling technologies.

The aftermarket segment is emerging as another significant demand driver, with retrofit cooling solutions gaining popularity among early EV adopters looking to extend the usable life of their vehicles. This segment is projected to grow at 18% annually through 2028, creating opportunities for specialized thermal management providers beyond the OEM supply chain.

Consumer expectations regarding EV performance have evolved significantly, with surveys indicating that over 70% of potential EV buyers consider fast charging capability as a critical purchasing factor. Advanced cooling systems that can maintain optimal battery temperatures during rapid charging sessions are therefore becoming essential rather than optional features. Additionally, the market is witnessing growing demand for systems that can extend battery longevity, as replacement costs remain a significant concern for consumers.

Geographically, the demand distribution shows notable regional variations. North American and European markets are increasingly focused on premium cooling solutions that maximize performance and battery life, while emerging markets in Asia prioritize cost-effective systems that balance performance with affordability. China, as the world's largest EV market, represents approximately 45% of the global demand for advanced battery cooling technologies.

From an industry perspective, automotive OEMs are increasingly viewing sophisticated thermal management as a competitive differentiator. This has led to growing investments in R&D for proprietary cooling technologies, with major manufacturers allocating an average of 15% of their EV development budgets specifically to thermal management solutions. The trend is particularly pronounced in the premium vehicle segment, where thermal efficiency is marketed as a key performance indicator.

Regulatory factors are also significantly influencing market demand. Stringent safety standards regarding battery thermal runaway prevention have been implemented across major markets, with the EU's Battery Regulation and similar frameworks in North America mandating advanced thermal management systems. These regulations are expected to become more comprehensive, further driving demand for sophisticated cooling technologies.

The aftermarket segment is emerging as another significant demand driver, with retrofit cooling solutions gaining popularity among early EV adopters looking to extend the usable life of their vehicles. This segment is projected to grow at 18% annually through 2028, creating opportunities for specialized thermal management providers beyond the OEM supply chain.

Current Thermal Management Technologies and Challenges

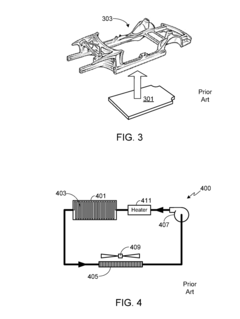

Battery thermal management systems (BTMS) in electric vehicles currently employ several key technologies, each with distinct advantages and limitations. Air cooling systems represent the simplest approach, utilizing forced convection to remove heat from battery packs. While cost-effective and lightweight, these systems struggle with thermal uniformity and efficiency, particularly in extreme temperature conditions or during rapid charging scenarios.

Liquid cooling has emerged as the dominant technology in premium EVs, offering superior heat transfer capabilities through direct contact with battery cells or modules. Manufacturers like Tesla, Porsche, and BMW implement sophisticated liquid cooling circuits using water-glycol mixtures or specialized dielectric fluids. These systems achieve more uniform temperature distribution but introduce complexity, weight, and potential leak concerns that must be carefully managed.

Phase change materials (PCMs) represent an innovative passive approach, absorbing heat during phase transition to maintain stable battery temperatures. While promising for their energy density and maintenance-free operation, PCMs face challenges in thermal conductivity and long-term stability, limiting widespread adoption despite ongoing research advancements.

Heat pipe technologies offer excellent thermal conductivity with minimal energy consumption, utilizing the principles of evaporation and condensation. Their implementation in EVs remains limited due to manufacturing complexity and integration challenges with existing battery architectures.

Thermoelectric cooling, based on the Peltier effect, provides precise temperature control without moving parts but suffers from low efficiency and high power consumption, making it suitable primarily for specialized applications rather than whole-pack thermal management.

The industry faces several critical challenges in advancing BTMS technology. Thermal uniformity remains problematic, with temperature gradients across battery packs accelerating degradation and reducing overall performance. Energy efficiency presents another significant hurdle, as thermal management systems can consume 5-15% of available battery capacity, directly impacting vehicle range.

Integration complexity increases as manufacturers pursue higher energy density batteries, creating packaging constraints that limit cooling system design options. Cost considerations further complicate implementation, particularly for mass-market vehicles where every dollar impacts consumer pricing. Additionally, the industry lacks standardized testing protocols and performance metrics for thermal management systems, hampering comparative analysis and optimization efforts.

Climate resilience represents perhaps the most pressing challenge, as batteries must maintain optimal performance across increasingly extreme temperature environments, from arctic cold to desert heat, while supporting faster charging capabilities that generate significant thermal loads.

Liquid cooling has emerged as the dominant technology in premium EVs, offering superior heat transfer capabilities through direct contact with battery cells or modules. Manufacturers like Tesla, Porsche, and BMW implement sophisticated liquid cooling circuits using water-glycol mixtures or specialized dielectric fluids. These systems achieve more uniform temperature distribution but introduce complexity, weight, and potential leak concerns that must be carefully managed.

Phase change materials (PCMs) represent an innovative passive approach, absorbing heat during phase transition to maintain stable battery temperatures. While promising for their energy density and maintenance-free operation, PCMs face challenges in thermal conductivity and long-term stability, limiting widespread adoption despite ongoing research advancements.

Heat pipe technologies offer excellent thermal conductivity with minimal energy consumption, utilizing the principles of evaporation and condensation. Their implementation in EVs remains limited due to manufacturing complexity and integration challenges with existing battery architectures.

Thermoelectric cooling, based on the Peltier effect, provides precise temperature control without moving parts but suffers from low efficiency and high power consumption, making it suitable primarily for specialized applications rather than whole-pack thermal management.

The industry faces several critical challenges in advancing BTMS technology. Thermal uniformity remains problematic, with temperature gradients across battery packs accelerating degradation and reducing overall performance. Energy efficiency presents another significant hurdle, as thermal management systems can consume 5-15% of available battery capacity, directly impacting vehicle range.

Integration complexity increases as manufacturers pursue higher energy density batteries, creating packaging constraints that limit cooling system design options. Cost considerations further complicate implementation, particularly for mass-market vehicles where every dollar impacts consumer pricing. Additionally, the industry lacks standardized testing protocols and performance metrics for thermal management systems, hampering comparative analysis and optimization efforts.

Climate resilience represents perhaps the most pressing challenge, as batteries must maintain optimal performance across increasingly extreme temperature environments, from arctic cold to desert heat, while supporting faster charging capabilities that generate significant thermal loads.

Current Technical Solutions for Battery Temperature Control

01 Liquid cooling systems for battery thermal management

Liquid cooling systems are used to efficiently manage battery temperature by circulating coolant through channels or plates in direct contact with battery cells or modules. These systems provide superior heat transfer capabilities compared to air cooling, allowing for more precise temperature control and higher cooling capacity. The designs often incorporate specialized flow paths, heat exchangers, and pumps to optimize thermal performance while maintaining uniform temperature distribution across the battery pack.- Liquid cooling systems for battery thermal management: Liquid cooling systems are effective for battery thermal management, utilizing coolant circulation through channels or plates in direct contact with battery cells. These systems provide efficient heat transfer and temperature uniformity across battery packs. Advanced designs incorporate optimized flow paths, specialized coolants, and integrated heat exchangers to maintain batteries within optimal temperature ranges during charging and discharging cycles.

- Phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb and release thermal energy during phase transitions. These materials provide passive temperature control by absorbing excess heat during high-load operations and releasing it when temperatures drop. PCM-based solutions can be integrated with battery modules to maintain optimal operating temperatures, extend battery life, and improve safety by preventing thermal runaway events.

- Air cooling and ventilation systems: Air cooling systems utilize forced or natural convection to manage battery temperatures. These systems incorporate strategically placed fans, ducts, and heat sinks to direct airflow across battery modules. Advanced designs feature adaptive control algorithms that adjust airflow based on temperature sensors and operational conditions. Air cooling solutions are often preferred for their simplicity, lower weight, and reduced maintenance requirements compared to liquid-based systems.

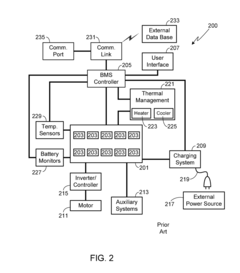

- Intelligent thermal management control systems: Intelligent control systems optimize battery thermal management through real-time monitoring and adaptive response. These systems utilize temperature sensors, predictive algorithms, and machine learning to anticipate thermal needs based on usage patterns and environmental conditions. Advanced controllers can balance cooling resources across battery modules, prioritize critical areas, and integrate with vehicle energy management systems to optimize overall efficiency while maintaining battery health.

- Integrated heating solutions for cold environments: Heating systems are essential for battery operation in cold environments, as low temperatures significantly reduce battery performance and charging capabilities. These solutions include resistive heating elements, positive temperature coefficient (PTC) heaters, and waste heat recovery systems. Advanced designs feature preconditioning capabilities that warm batteries before operation and maintain optimal temperatures during charging. Integrated approaches combine heating and cooling functions in unified thermal management systems.

02 Phase change materials for thermal regulation

Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb and release thermal energy during phase transitions. These materials can absorb excess heat during battery operation and release it when temperatures drop, helping to maintain optimal operating temperatures. PCMs provide passive thermal regulation, reducing the need for active cooling systems and improving energy efficiency. They are particularly effective for stabilizing temperature fluctuations during high-power discharge or rapid charging scenarios.Expand Specific Solutions03 Integrated thermal management control systems

Advanced control systems are implemented to optimize battery thermal management by monitoring temperature sensors, predicting thermal behavior, and dynamically adjusting cooling or heating parameters. These intelligent systems use algorithms to balance thermal performance with energy efficiency, extending battery life while ensuring safe operation. The control architecture often integrates with the vehicle's broader energy management system, allowing for coordinated operation with other vehicle systems and predictive thermal management based on driving conditions and battery usage patterns.Expand Specific Solutions04 Air cooling and ventilation designs

Air-based thermal management systems utilize forced or natural convection to regulate battery temperature. These designs incorporate strategically placed air channels, fans, and heat sinks to maximize cooling efficiency while minimizing power consumption. Air cooling systems are often preferred for their simplicity, lower cost, and reduced maintenance requirements compared to liquid cooling alternatives. Advanced designs may include variable speed fans, ducting configurations that optimize airflow distribution, and heat exchangers to enhance cooling performance under various operating conditions.Expand Specific Solutions05 Thermal insulation and heat dissipation structures

Specialized thermal insulation and heat dissipation structures are designed to protect batteries from external temperature fluctuations while efficiently removing internal heat. These structures may include multi-layer insulation materials, heat spreaders, thermal interface materials, and innovative housing designs. The combination of insulation and targeted heat dissipation helps maintain uniform temperature distribution across battery cells, preventing hotspots and thermal runaway conditions. These passive thermal management approaches complement active cooling systems and improve overall thermal stability of battery packs.Expand Specific Solutions

Key Industry Players in EV Battery Thermal Management

The Battery Thermal Management for EV Applications market is currently in a growth phase, with increasing adoption of electric vehicles driving demand for advanced thermal solutions. The market size is expanding rapidly, projected to reach significant value as EV penetration increases globally. Technologically, the field shows varying maturity levels, with established automotive players like Ford, GM, Hyundai, and Kia implementing proven systems, while newer entrants such as NIO, Rivian, and Nikola are introducing innovative approaches. Chinese manufacturers including Geely, CHERY, and FAW are rapidly advancing their capabilities. Research institutions like Shandong University and University of Michigan collaborate with industry partners to develop next-generation solutions. Specialized technology providers such as Qdot Technology and Valeo Thermal Systems Japan are emerging as important players offering dedicated thermal management innovations.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an innovative battery thermal management system leveraging their expertise in telecommunications and power management. Their approach centers on a "smart thermal matrix" architecture that combines liquid cooling with advanced thermal materials and intelligent control algorithms. The system features a network of ultra-thin cooling channels integrated directly into the battery module structure, reducing thermal resistance between cells and coolant. Huawei's technology incorporates graphene-enhanced thermal interface materials that improve heat transfer efficiency by up to 30% compared to conventional materials. Their system utilizes AI-driven predictive thermal management that continuously optimizes coolant flow rates and temperature setpoints based on usage patterns, environmental conditions, and battery state of health. A distinctive feature is Huawei's bidirectional thermal management capability, which can both cool and heat the battery as needed using a heat pump arrangement. The system also integrates with charging infrastructure to coordinate thermal management during fast charging sessions, allowing for optimal charging rates while maintaining safe operating temperatures.

Strengths: Advanced materials science approach with graphene-enhanced thermal interfaces; sophisticated AI-driven control algorithms optimize performance across various conditions; excellent integration with charging infrastructure. Weaknesses: Relatively new to automotive applications with limited long-term validation data; higher manufacturing complexity for specialized thermal materials; requires substantial computing resources for AI-driven control systems.

Rivian Holdings LLC

Technical Solution: Rivian has engineered a distinctive immersion cooling system for their EV battery packs that represents a significant departure from conventional plate cooling approaches. Their technology submerges battery modules in a dielectric fluid that provides direct contact cooling to each cell, eliminating thermal interfaces that typically reduce heat transfer efficiency. The system incorporates a closed-loop circulation design with external heat exchangers that can interface with both the vehicle's cooling system and charging infrastructure. Rivian's immersion cooling technology maintains temperature differentials between cells to within 2°C even under extreme charging and discharging conditions, significantly reducing battery degradation from thermal stress. Their system features adaptive cooling capacity that can rapidly remove heat during fast charging sessions exceeding 150kW. The dielectric fluid used has been specially formulated to maintain optimal viscosity and thermal properties across the wide temperature range experienced in automotive applications. Rivian has integrated this cooling system with their vehicle thermal management architecture to enable waste heat recovery for cabin heating and battery preconditioning.

Strengths: Superior temperature uniformity through direct cell contact; excellent thermal performance during fast charging; eliminates thermal interfaces that typically reduce cooling efficiency. Weaknesses: Higher system complexity and weight compared to conventional cooling methods; requires specialized dielectric fluids that must be contained and maintained; more challenging service and repair procedures.

Critical Patents and Innovations in Thermal Management

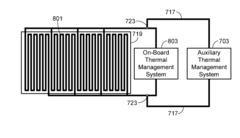

External Auxiliary Thermal Management System for an Electric Vehicle

PatentInactiveUS20170088007A1

Innovation

- An external auxiliary thermal management system is introduced, comprising a refrigerant-based thermal control loop, a thermal transfer fluid loop with a fluid pump, and a refrigerant-fluid heat exchanger, which can be temporarily coupled to the battery pack during charging, providing supplemental cooling and potentially using water or water-based additives as thermal transfer fluids.

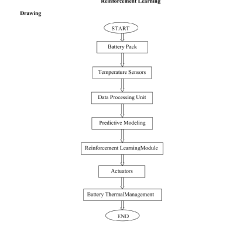

Battery temperature management system in electric vehicles using reinforcement learning

PatentPendingIN202321043947A

Innovation

- A reinforcement learning-based system that combines real-time sensor data, predictive modeling, and actuators to actively regulate battery temperature, using a network of temperature sensors, data processing, and a reinforcement learning module to optimize cooling and heating processes.

Safety Standards and Regulatory Framework for EV Batteries

The regulatory landscape for electric vehicle (EV) battery thermal management systems has evolved significantly in response to safety incidents and technological advancements. Key international standards include UN ECE R100, which specifically addresses battery safety requirements including thermal management parameters for vehicles in the European market. This regulation mandates specific temperature thresholds and cooling system performance metrics that manufacturers must adhere to.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established FMVSS 305, which outlines electrical safety requirements with provisions related to thermal runaway prevention. Additionally, SAE J2929 provides comprehensive testing procedures for evaluating battery thermal management systems under various operating conditions and potential failure modes.

The International Electrotechnical Commission (IEC) has developed IEC 62660 series standards that specify test methods for lithium-ion batteries in EVs, including thermal performance evaluation protocols. These standards define precise methodologies for measuring temperature distribution, thermal runaway propagation, and cooling system efficiency.

China's GB/T 31467 standard has emerged as another influential regulatory framework, establishing stringent requirements for thermal management systems in EV batteries. This standard is particularly notable for its detailed specifications regarding temperature uniformity across battery packs and thermal runaway containment strategies.

Regulatory bodies are increasingly focusing on thermal propagation prevention, with recent updates to standards requiring demonstration that thermal events in one cell cannot cascade throughout the entire battery system. This has driven innovation in cell-to-cell thermal isolation technologies and advanced cooling architectures.

Insurance organizations and certification bodies have also established their own testing protocols, such as UL 2580, which evaluates battery thermal management systems under extreme conditions. These standards often exceed minimum regulatory requirements and have become de facto industry benchmarks.

Emerging regulations are beginning to address specific thermal management technologies, with separate provisions for air cooling, liquid cooling, and phase-change material systems. This technology-specific approach represents a shift from earlier performance-based standards that were agnostic to the cooling method employed.

The global regulatory framework continues to evolve, with increasing harmonization efforts between major markets to establish consistent safety standards for thermal management systems in EV batteries. This convergence is facilitating more efficient product development cycles for manufacturers operating in multiple regions.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established FMVSS 305, which outlines electrical safety requirements with provisions related to thermal runaway prevention. Additionally, SAE J2929 provides comprehensive testing procedures for evaluating battery thermal management systems under various operating conditions and potential failure modes.

The International Electrotechnical Commission (IEC) has developed IEC 62660 series standards that specify test methods for lithium-ion batteries in EVs, including thermal performance evaluation protocols. These standards define precise methodologies for measuring temperature distribution, thermal runaway propagation, and cooling system efficiency.

China's GB/T 31467 standard has emerged as another influential regulatory framework, establishing stringent requirements for thermal management systems in EV batteries. This standard is particularly notable for its detailed specifications regarding temperature uniformity across battery packs and thermal runaway containment strategies.

Regulatory bodies are increasingly focusing on thermal propagation prevention, with recent updates to standards requiring demonstration that thermal events in one cell cannot cascade throughout the entire battery system. This has driven innovation in cell-to-cell thermal isolation technologies and advanced cooling architectures.

Insurance organizations and certification bodies have also established their own testing protocols, such as UL 2580, which evaluates battery thermal management systems under extreme conditions. These standards often exceed minimum regulatory requirements and have become de facto industry benchmarks.

Emerging regulations are beginning to address specific thermal management technologies, with separate provisions for air cooling, liquid cooling, and phase-change material systems. This technology-specific approach represents a shift from earlier performance-based standards that were agnostic to the cooling method employed.

The global regulatory framework continues to evolve, with increasing harmonization efforts between major markets to establish consistent safety standards for thermal management systems in EV batteries. This convergence is facilitating more efficient product development cycles for manufacturers operating in multiple regions.

Environmental Impact of Thermal Management Systems

The environmental impact of battery thermal management systems (BTMS) in electric vehicles represents a critical consideration in the overall sustainability assessment of EV technology. Traditional thermal management approaches often rely on refrigerants with high global warming potential (GWP), contributing significantly to greenhouse gas emissions when leakage occurs. Modern BTMS designs increasingly incorporate environmentally friendly refrigerants with lower GWP values, though this transition presents engineering challenges related to efficiency and performance.

Material selection for thermal management components carries substantial environmental implications throughout the product lifecycle. Conventional systems frequently utilize aluminum and copper for heat exchangers and thermal conductors, materials whose extraction and processing are energy-intensive and generate considerable carbon emissions. The manufacturing processes for specialized thermal interface materials and phase change materials also contribute to the environmental footprint of BTMS technology.

End-of-life considerations present both challenges and opportunities for BTMS environmental impact. The complex integration of thermal management systems with battery packs complicates disassembly and recycling processes. Coolants and thermal fluids require proper disposal protocols to prevent environmental contamination. However, advanced design approaches focusing on modularity and material selection can significantly improve recyclability rates and reduce waste generation.

Energy consumption during operation constitutes another significant environmental factor. Passive thermal management systems generally offer environmental advantages through reduced parasitic energy losses, though they may provide less precise temperature control. Active systems, while more energy-intensive, can optimize battery performance and longevity, potentially offsetting their operational environmental impact through extended battery life and improved vehicle efficiency.

Lifecycle assessment (LCA) studies indicate that the environmental benefits of extending battery lifespan through effective thermal management typically outweigh the environmental costs of BTMS production and operation. Research shows that batteries maintained within optimal temperature ranges can experience 15-20% longer service lives, reducing the environmental burden associated with battery manufacturing and disposal.

Emerging technologies present promising pathways for reducing environmental impact. Phase change materials derived from bio-based sources, biodegradable thermal fluids, and systems designed for circular economy principles represent frontier developments in environmentally conscious BTMS design. Additionally, integration with renewable energy systems for BTMS power requirements offers further potential for environmental impact reduction in charging infrastructure contexts.

Material selection for thermal management components carries substantial environmental implications throughout the product lifecycle. Conventional systems frequently utilize aluminum and copper for heat exchangers and thermal conductors, materials whose extraction and processing are energy-intensive and generate considerable carbon emissions. The manufacturing processes for specialized thermal interface materials and phase change materials also contribute to the environmental footprint of BTMS technology.

End-of-life considerations present both challenges and opportunities for BTMS environmental impact. The complex integration of thermal management systems with battery packs complicates disassembly and recycling processes. Coolants and thermal fluids require proper disposal protocols to prevent environmental contamination. However, advanced design approaches focusing on modularity and material selection can significantly improve recyclability rates and reduce waste generation.

Energy consumption during operation constitutes another significant environmental factor. Passive thermal management systems generally offer environmental advantages through reduced parasitic energy losses, though they may provide less precise temperature control. Active systems, while more energy-intensive, can optimize battery performance and longevity, potentially offsetting their operational environmental impact through extended battery life and improved vehicle efficiency.

Lifecycle assessment (LCA) studies indicate that the environmental benefits of extending battery lifespan through effective thermal management typically outweigh the environmental costs of BTMS production and operation. Research shows that batteries maintained within optimal temperature ranges can experience 15-20% longer service lives, reducing the environmental burden associated with battery manufacturing and disposal.

Emerging technologies present promising pathways for reducing environmental impact. Phase change materials derived from bio-based sources, biodegradable thermal fluids, and systems designed for circular economy principles represent frontier developments in environmentally conscious BTMS design. Additionally, integration with renewable energy systems for BTMS power requirements offers further potential for environmental impact reduction in charging infrastructure contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!