How Interface Engineering Enhances Battery Thermal Performance

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Interface Engineering Background and Objectives

Battery interface engineering has emerged as a critical frontier in energy storage technology development over the past decade. The interfaces between different battery components—electrodes, electrolytes, and current collectors—represent crucial regions where electrochemical reactions, ion transport, and heat generation occur. Historically, battery development focused primarily on active materials, with interfaces receiving less attention despite their significant impact on overall performance.

The evolution of battery technology has revealed that thermal management represents one of the most significant challenges limiting battery performance, safety, and longevity. As energy densities increase to meet market demands for longer-lasting and faster-charging batteries, the heat generated during operation has become a critical concern. Interface engineering has consequently evolved from a peripheral consideration to a central focus in battery research.

Recent technological advancements have demonstrated that strategic modification of interfaces can dramatically improve thermal conductivity pathways, reduce interfacial resistance, and mitigate hotspot formation. These improvements directly address the thermal runaway risks that have plagued high-energy battery systems and limited their commercial viability in applications ranging from electric vehicles to grid-scale energy storage.

The primary objective of battery interface engineering for thermal performance enhancement is to develop systematic approaches that can precisely control the physical, chemical, and electrochemical properties of interfaces to optimize heat dissipation while maintaining or improving other battery performance metrics. This includes designing interfaces that can efficiently transfer heat away from reaction sites, creating thermally conductive networks within battery structures, and developing interface materials that remain stable under thermal stress.

Secondary objectives include establishing standardized methodologies for characterizing interface thermal properties, developing scalable manufacturing processes for interface-engineered batteries, and creating predictive models that can accurately simulate the thermal behavior of complex interface structures under various operating conditions.

The technological trajectory indicates a shift toward multifunctional interfaces that simultaneously address multiple performance parameters. Future interface engineering approaches will likely integrate thermal management with other critical functions such as mechanical stabilization, ion transport facilitation, and dendrite suppression, creating synergistic effects that enhance overall battery performance beyond what could be achieved by addressing these challenges independently.

As battery applications continue to diversify and performance requirements become more demanding, interface engineering represents a promising pathway to overcome current limitations and enable the next generation of high-performance, thermally stable energy storage systems that can safely operate under increasingly demanding conditions.

The evolution of battery technology has revealed that thermal management represents one of the most significant challenges limiting battery performance, safety, and longevity. As energy densities increase to meet market demands for longer-lasting and faster-charging batteries, the heat generated during operation has become a critical concern. Interface engineering has consequently evolved from a peripheral consideration to a central focus in battery research.

Recent technological advancements have demonstrated that strategic modification of interfaces can dramatically improve thermal conductivity pathways, reduce interfacial resistance, and mitigate hotspot formation. These improvements directly address the thermal runaway risks that have plagued high-energy battery systems and limited their commercial viability in applications ranging from electric vehicles to grid-scale energy storage.

The primary objective of battery interface engineering for thermal performance enhancement is to develop systematic approaches that can precisely control the physical, chemical, and electrochemical properties of interfaces to optimize heat dissipation while maintaining or improving other battery performance metrics. This includes designing interfaces that can efficiently transfer heat away from reaction sites, creating thermally conductive networks within battery structures, and developing interface materials that remain stable under thermal stress.

Secondary objectives include establishing standardized methodologies for characterizing interface thermal properties, developing scalable manufacturing processes for interface-engineered batteries, and creating predictive models that can accurately simulate the thermal behavior of complex interface structures under various operating conditions.

The technological trajectory indicates a shift toward multifunctional interfaces that simultaneously address multiple performance parameters. Future interface engineering approaches will likely integrate thermal management with other critical functions such as mechanical stabilization, ion transport facilitation, and dendrite suppression, creating synergistic effects that enhance overall battery performance beyond what could be achieved by addressing these challenges independently.

As battery applications continue to diversify and performance requirements become more demanding, interface engineering represents a promising pathway to overcome current limitations and enable the next generation of high-performance, thermally stable energy storage systems that can safely operate under increasingly demanding conditions.

Market Analysis for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions in battery systems is experiencing robust growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. Current market valuations indicate that the battery thermal management system market reached approximately 3.5 billion USD in 2022 and is projected to grow at a compound annual growth rate of 22-25% through 2030, potentially reaching 15-18 billion USD by the end of the decade.

This accelerated growth is largely attributed to the increasing energy density requirements of modern battery systems, which generate more heat during operation and require sophisticated thermal management solutions. The market is particularly strong in regions with aggressive EV adoption targets, including China, Europe, and North America, which collectively account for over 80% of the global market share.

Consumer demand for faster charging capabilities has emerged as a significant market driver, as high-power charging generates substantial thermal loads that must be efficiently managed to prevent battery degradation. Additionally, safety concerns following high-profile thermal runaway incidents have heightened industry focus on advanced thermal management technologies, with regulatory bodies worldwide implementing stricter safety standards.

Interface engineering solutions represent a high-growth segment within this market, with an estimated annual growth rate of 28-30%, outpacing the broader thermal management market. This premium growth is driven by the superior performance characteristics of engineered interfaces, which can reduce thermal resistance by 40-60% compared to conventional methods.

Market segmentation reveals distinct approaches across different vehicle segments. Premium EV manufacturers are increasingly adopting advanced interface materials such as phase change materials and specialized thermal interface materials, willing to absorb the 15-20% cost premium for performance advantages. Meanwhile, mass-market manufacturers are seeking cost-effective interface engineering solutions that balance performance with economic constraints.

The competitive landscape features traditional automotive thermal management suppliers expanding their capabilities alongside specialized materials science companies entering the market with novel interface engineering solutions. Strategic partnerships between battery manufacturers and thermal management specialists have increased by approximately 35% in the past two years, indicating industry recognition of thermal interface engineering as a critical competitive advantage.

Market forecasts suggest that interface engineering technologies will capture an increasing share of the thermal management market, potentially representing 30-35% of the total market value by 2028, up from the current 18-20%. This growth trajectory is supported by ongoing research breakthroughs in nanomaterials and composite interfaces that promise further performance improvements while addressing cost concerns.

This accelerated growth is largely attributed to the increasing energy density requirements of modern battery systems, which generate more heat during operation and require sophisticated thermal management solutions. The market is particularly strong in regions with aggressive EV adoption targets, including China, Europe, and North America, which collectively account for over 80% of the global market share.

Consumer demand for faster charging capabilities has emerged as a significant market driver, as high-power charging generates substantial thermal loads that must be efficiently managed to prevent battery degradation. Additionally, safety concerns following high-profile thermal runaway incidents have heightened industry focus on advanced thermal management technologies, with regulatory bodies worldwide implementing stricter safety standards.

Interface engineering solutions represent a high-growth segment within this market, with an estimated annual growth rate of 28-30%, outpacing the broader thermal management market. This premium growth is driven by the superior performance characteristics of engineered interfaces, which can reduce thermal resistance by 40-60% compared to conventional methods.

Market segmentation reveals distinct approaches across different vehicle segments. Premium EV manufacturers are increasingly adopting advanced interface materials such as phase change materials and specialized thermal interface materials, willing to absorb the 15-20% cost premium for performance advantages. Meanwhile, mass-market manufacturers are seeking cost-effective interface engineering solutions that balance performance with economic constraints.

The competitive landscape features traditional automotive thermal management suppliers expanding their capabilities alongside specialized materials science companies entering the market with novel interface engineering solutions. Strategic partnerships between battery manufacturers and thermal management specialists have increased by approximately 35% in the past two years, indicating industry recognition of thermal interface engineering as a critical competitive advantage.

Market forecasts suggest that interface engineering technologies will capture an increasing share of the thermal management market, potentially representing 30-35% of the total market value by 2028, up from the current 18-20%. This growth trajectory is supported by ongoing research breakthroughs in nanomaterials and composite interfaces that promise further performance improvements while addressing cost concerns.

Current Challenges in Battery Thermal Interface Materials

Despite significant advancements in battery technology, thermal interface materials (TIMs) continue to face substantial challenges that limit overall battery thermal performance. The primary issue remains the thermal contact resistance at material interfaces, which creates bottlenecks for efficient heat dissipation. Current commercial TIMs struggle to simultaneously achieve high thermal conductivity, mechanical compliance, and long-term reliability under the dynamic thermal cycling conditions typical in battery operations.

Conventional polymer-based TIMs exhibit thermal conductivity values typically below 5 W/m·K, which proves insufficient for high-power battery applications where heat generation rates continue to increase with faster charging capabilities. The trade-off between thermal performance and mechanical properties presents a persistent engineering dilemma, as materials with higher thermal conductivity often lack the compliance necessary to maintain good interfacial contact under thermal expansion and contraction cycles.

Chemical stability represents another critical challenge, particularly in the aggressive electrochemical environment of batteries. Many high-performance TIMs degrade over time when exposed to battery electrolytes or outgassing components, leading to performance deterioration and potential safety risks. This degradation accelerates under elevated temperatures, creating a negative feedback loop that compounds thermal management problems.

Manufacturing integration poses significant hurdles as well. The application of TIMs in battery pack assembly requires processes compatible with high-volume production while maintaining consistent material properties and interfacial contact quality. Current dispensing and application methods often result in thickness variations, air gaps, and pump-out issues that compromise thermal performance in real-world applications.

Cost considerations further constrain TIM selection, particularly for mass-market electric vehicles and consumer electronics. High-performance materials like metal-based TIMs or advanced composites remain prohibitively expensive for widespread adoption, forcing manufacturers to compromise on thermal performance to meet economic constraints.

Emerging battery technologies with higher energy densities and faster charging capabilities are exacerbating these challenges by generating more heat in smaller volumes. The thermal management requirements for solid-state batteries, silicon-anode batteries, and other next-generation technologies will demand TIMs with significantly improved performance metrics that current materials cannot satisfy.

Environmental and regulatory concerns add another dimension to the challenge, as many high-performance TIMs contain environmentally problematic components such as silicones or metal fillers that complicate end-of-life recycling and disposal. The industry faces increasing pressure to develop sustainable alternatives that maintain thermal performance while reducing environmental impact.

Conventional polymer-based TIMs exhibit thermal conductivity values typically below 5 W/m·K, which proves insufficient for high-power battery applications where heat generation rates continue to increase with faster charging capabilities. The trade-off between thermal performance and mechanical properties presents a persistent engineering dilemma, as materials with higher thermal conductivity often lack the compliance necessary to maintain good interfacial contact under thermal expansion and contraction cycles.

Chemical stability represents another critical challenge, particularly in the aggressive electrochemical environment of batteries. Many high-performance TIMs degrade over time when exposed to battery electrolytes or outgassing components, leading to performance deterioration and potential safety risks. This degradation accelerates under elevated temperatures, creating a negative feedback loop that compounds thermal management problems.

Manufacturing integration poses significant hurdles as well. The application of TIMs in battery pack assembly requires processes compatible with high-volume production while maintaining consistent material properties and interfacial contact quality. Current dispensing and application methods often result in thickness variations, air gaps, and pump-out issues that compromise thermal performance in real-world applications.

Cost considerations further constrain TIM selection, particularly for mass-market electric vehicles and consumer electronics. High-performance materials like metal-based TIMs or advanced composites remain prohibitively expensive for widespread adoption, forcing manufacturers to compromise on thermal performance to meet economic constraints.

Emerging battery technologies with higher energy densities and faster charging capabilities are exacerbating these challenges by generating more heat in smaller volumes. The thermal management requirements for solid-state batteries, silicon-anode batteries, and other next-generation technologies will demand TIMs with significantly improved performance metrics that current materials cannot satisfy.

Environmental and regulatory concerns add another dimension to the challenge, as many high-performance TIMs contain environmentally problematic components such as silicones or metal fillers that complicate end-of-life recycling and disposal. The industry faces increasing pressure to develop sustainable alternatives that maintain thermal performance while reducing environmental impact.

State-of-the-Art Interface Engineering Solutions

01 Thermal interface materials for electronic devices

Specialized materials designed to enhance heat transfer between electronic components and heat sinks. These materials fill microscopic air gaps at interfaces to improve thermal conductivity. Advanced formulations include polymer matrices with high thermal conductivity fillers, phase change materials, and metal-based composites that optimize the balance between thermal performance and mechanical properties such as compliance and reliability.- Thermal interface materials for electronic devices: Specialized materials designed to enhance heat transfer between electronic components and heat sinks. These materials fill microscopic air gaps at interfaces to improve thermal conductivity. Advanced formulations may include phase change materials, metal-filled polymers, or graphene-based composites that maintain performance over thermal cycling while providing electrical isolation where needed.

- Layered interface structures for thermal management: Multi-layered interface designs that optimize heat dissipation through strategic arrangement of materials with complementary thermal properties. These structures may incorporate gradient layers, thermal spreaders, or specialized bonding techniques to minimize thermal resistance across interfaces. The layered approach allows for customization based on specific thermal loads and space constraints.

- Surface modification techniques for improved thermal contact: Methods to enhance thermal performance by modifying interface surfaces at micro or nano scales. Techniques include surface texturing, chemical treatments, or plasma processing to increase effective contact area and reduce thermal boundary resistance. These modifications can significantly improve heat transfer efficiency without increasing the overall device footprint.

- Cooling systems with engineered fluid interfaces: Advanced cooling solutions that utilize engineered fluid-solid interfaces to enhance heat transfer. These systems may employ microchannels, jet impingement, or two-phase cooling with specially designed interface geometries to maximize thermal performance. The fluid dynamics at these interfaces are carefully engineered to optimize heat removal from high-power density components.

- Computational methods for thermal interface optimization: Simulation and modeling approaches to predict and optimize thermal interface performance. These methods include finite element analysis, machine learning algorithms, and multi-physics simulations that account for thermal, mechanical, and electrical interactions at interfaces. Computational techniques enable rapid iteration and optimization of interface designs before physical prototyping.

02 Cooling systems with engineered interfaces

Cooling systems that incorporate specially designed interface structures to enhance thermal dissipation. These systems feature optimized contact surfaces, microchannels, heat pipes, or vapor chambers with engineered interfaces to maximize heat transfer efficiency. The designs focus on reducing thermal resistance at critical junctions while maintaining structural integrity under thermal cycling conditions.Expand Specific Solutions03 Nanomaterial-enhanced thermal interfaces

Thermal interface solutions incorporating nanomaterials such as carbon nanotubes, graphene, or metallic nanoparticles to dramatically improve thermal conductivity. These nanomaterials create highly efficient thermal pathways across interfaces, reducing thermal resistance. The nanoscale structures can be aligned, patterned, or functionalized to optimize heat transfer while maintaining flexibility and durability at the interface.Expand Specific Solutions04 Simulation and modeling of thermal interfaces

Computational methods and software tools for predicting and optimizing thermal interface performance. These approaches include finite element analysis, computational fluid dynamics, and machine learning algorithms to model heat transfer across complex interfaces. The simulation techniques enable engineers to evaluate design alternatives, identify thermal bottlenecks, and optimize interface geometries before physical prototyping.Expand Specific Solutions05 Surface treatment techniques for thermal interfaces

Methods for modifying surface properties to enhance thermal contact and heat transfer across interfaces. These techniques include chemical treatments, plasma processing, laser texturing, and deposition of specialized coatings that alter surface roughness, wettability, or chemical affinity. The treatments create optimized surface topographies that maximize contact area and minimize thermal resistance at material interfaces.Expand Specific Solutions

Leading Companies in Battery Interface Engineering

The thermal management of batteries represents a critical technological frontier, currently in a growth phase with an estimated market size of $2-3 billion and projected CAGR of 15-20%. Leading the competitive landscape are established players like CATL and Samsung SDI who have developed advanced interface engineering solutions for EV batteries, while Intel and Apple bring expertise from consumer electronics. Automotive manufacturers (Audi, Volvo, Ford) are increasingly investing in proprietary thermal management technologies. Research institutions (Northwestern Polytechnical University, Dalian University of Technology) are driving fundamental innovations, while materials specialists (Henkel, Wacker Chemie) are developing specialized thermal interface materials. The ecosystem is maturing with collaborative approaches between battery manufacturers, automotive OEMs, and materials suppliers becoming increasingly common.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced interface engineering solutions for battery thermal management, focusing on multi-layer composite thermal interface materials (TIMs) that enhance heat dissipation between cells and cooling systems. Their Cell-to-Pack (CTP) technology incorporates specialized interface materials with high thermal conductivity (>5 W/m·K) while maintaining electrical isolation properties. CATL's approach includes nano-enhanced thermal interface materials containing graphene and boron nitride particles dispersed in polymer matrices, creating efficient thermal pathways at critical battery interfaces. Their liquid cooling plate design features optimized interface contact with cells through pressure-sensitive adhesive layers that minimize air gaps and thermal resistance. Recent developments include phase change materials (PCMs) integrated at interfaces that absorb heat during high-load operations and release it during idle periods, maintaining more uniform temperature distribution across battery packs.

Strengths: Superior thermal conductivity with minimal electrical conductivity risk; excellent conformability to uneven surfaces reducing interface resistance; long-term stability under thermal cycling conditions. Weaknesses: Higher manufacturing costs compared to conventional solutions; potential for thermal interface material degradation over extended battery lifecycle; requires precise application processes to ensure consistent performance.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a comprehensive interface engineering approach for battery thermal management centered around their "Multi-Barrier Thermal Interface System." This technology employs specially formulated thermal interface materials with thermal conductivity exceeding 8 W/m·K at critical battery component junctions. Their system incorporates gradient-engineered interfaces where material composition transitions from highly thermally conductive near heat sources to more mechanically compliant at outer surfaces. Samsung's solution includes proprietary silicone-based composites with ceramic fillers that maintain performance across wide temperature ranges (-40°C to 85°C) while providing necessary dielectric properties. The company has developed automated precision application methods ensuring consistent interface material thickness (typically 100-200μm) and coverage, eliminating air gaps that would otherwise create thermal bottlenecks. Their latest innovation involves self-healing thermal interface materials that can recover from mechanical stress and maintain contact integrity throughout battery lifecycle.

Strengths: Exceptional thermal conductivity combined with electrical isolation properties; automated precision application ensuring manufacturing consistency; self-healing capabilities maintaining performance over time. Weaknesses: Higher material costs compared to standard thermal compounds; requires specialized application equipment; potential for performance degradation in extreme environmental conditions.

Key Patents and Research in Thermal Interface Materials

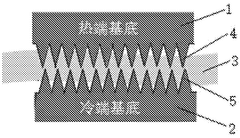

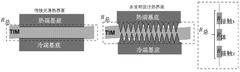

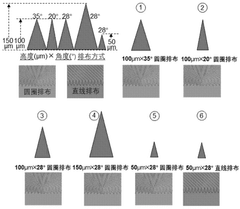

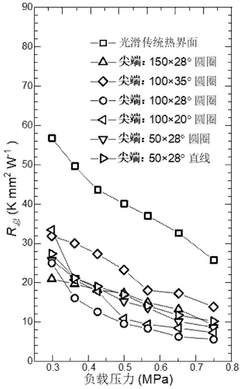

Mechanical interface for enhancing thermal contact

PatentWO2025011544A1

Innovation

- Design a mechanical interface that strengthens thermal contact, improves contact heat conductivity by machining the tip array on the surface of the hot-end substrate and the cold-end substrate and clamping the thermal interface material between the two. performance.

Thermal interconnect and interface materials, methods of production and uses thereof

PatentWO2008147825A3

Innovation

- Integration of material modification agents in thermal interface materials to improve thermal performance, compatibility, and physical quality of battery interfaces.

- Development of a composite thermal interface material combining matrix materials, high conductivity fillers, solder materials, and modification agents in a single solution for battery thermal management.

- Creation of modified thermal filler profiles through material modification agents to optimize the interface thermal properties for specific battery applications.

Safety Standards and Regulations for Battery Systems

Battery safety standards and regulations have evolved significantly in response to the growing concerns about thermal incidents in battery systems. The International Electrotechnical Commission (IEC) has established comprehensive standards such as IEC 62133 for portable batteries and IEC 62619 for larger industrial applications, both addressing thermal runaway prevention through interface engineering requirements. These standards mandate specific thermal management protocols and interface design specifications to ensure heat dissipation efficiency.

In the United States, UL 1642 and UL 2580 provide detailed guidelines for battery cell safety and electric vehicle battery systems respectively, with particular emphasis on thermal interface materials and their implementation. The standards require rigorous thermal cycling tests to evaluate interface stability under varying temperature conditions, directly impacting how engineers approach interface design for thermal performance enhancement.

The European Union's Battery Directive (2006/66/EC) and its recent updates incorporate thermal safety requirements that specifically address interface engineering aspects. These regulations increasingly recognize the critical role of interface engineering in preventing thermal propagation between cells, requiring manufacturers to implement advanced interface solutions that can withstand extreme thermal conditions.

China's GB/T 31485 standard for electric vehicle batteries includes detailed specifications for thermal interface materials and designs, reflecting the country's growing focus on battery safety in its rapidly expanding electric vehicle market. This standard has been instrumental in driving innovation in interface engineering solutions specifically tailored to high-energy density applications.

Transportation regulations such as UN 38.3 include tests for thermal stability during shipping and handling, requiring battery systems to maintain interface integrity under vibration and external heating conditions. These requirements have led to the development of more resilient thermal interface materials that maintain performance under mechanical stress.

Industry-specific standards like those from EUCAR and USABC provide hazard classification systems and performance requirements that directly influence interface engineering practices. These standards establish thermal runaway propagation prevention as a key safety metric, driving research into advanced interface materials with superior thermal conductivity and stability properties.

The regulatory landscape continues to evolve, with emerging standards increasingly focusing on the entire battery lifecycle, including recycling considerations for thermal interface materials. This holistic approach is pushing manufacturers to develop environmentally sustainable interface solutions that maintain thermal performance while meeting end-of-life requirements.

In the United States, UL 1642 and UL 2580 provide detailed guidelines for battery cell safety and electric vehicle battery systems respectively, with particular emphasis on thermal interface materials and their implementation. The standards require rigorous thermal cycling tests to evaluate interface stability under varying temperature conditions, directly impacting how engineers approach interface design for thermal performance enhancement.

The European Union's Battery Directive (2006/66/EC) and its recent updates incorporate thermal safety requirements that specifically address interface engineering aspects. These regulations increasingly recognize the critical role of interface engineering in preventing thermal propagation between cells, requiring manufacturers to implement advanced interface solutions that can withstand extreme thermal conditions.

China's GB/T 31485 standard for electric vehicle batteries includes detailed specifications for thermal interface materials and designs, reflecting the country's growing focus on battery safety in its rapidly expanding electric vehicle market. This standard has been instrumental in driving innovation in interface engineering solutions specifically tailored to high-energy density applications.

Transportation regulations such as UN 38.3 include tests for thermal stability during shipping and handling, requiring battery systems to maintain interface integrity under vibration and external heating conditions. These requirements have led to the development of more resilient thermal interface materials that maintain performance under mechanical stress.

Industry-specific standards like those from EUCAR and USABC provide hazard classification systems and performance requirements that directly influence interface engineering practices. These standards establish thermal runaway propagation prevention as a key safety metric, driving research into advanced interface materials with superior thermal conductivity and stability properties.

The regulatory landscape continues to evolve, with emerging standards increasingly focusing on the entire battery lifecycle, including recycling considerations for thermal interface materials. This holistic approach is pushing manufacturers to develop environmentally sustainable interface solutions that maintain thermal performance while meeting end-of-life requirements.

Sustainability Impact of Advanced Interface Materials

The integration of advanced interface materials in battery systems represents a significant opportunity for enhancing sustainability across multiple dimensions. These materials, designed to optimize thermal management and extend battery life, contribute substantially to reducing the environmental footprint of energy storage technologies throughout their lifecycle.

Advanced interface materials enable more efficient heat dissipation and thermal regulation, directly translating to extended battery operational lifespans. This longevity effect decreases the frequency of battery replacements, subsequently reducing raw material extraction demands and manufacturing-related emissions. Studies indicate that effective thermal management through engineered interfaces can extend lithium-ion battery lifespans by 20-40% under typical usage conditions.

The environmental benefits extend to operational efficiency as well. Batteries with optimized thermal interfaces demonstrate improved energy efficiency during charge-discharge cycles, reducing energy losses as heat. This efficiency gain translates to lower overall energy consumption for the same functional output, decreasing the carbon footprint associated with battery operation in various applications from electric vehicles to grid storage systems.

From a circular economy perspective, advanced interface materials can be designed with recyclability and recoverability in mind. Novel approaches incorporate bio-based or easily separable components that facilitate end-of-life processing. Some cutting-edge interface materials utilize renewable resources or recycled content, further enhancing their sustainability profile compared to conventional options.

The water footprint reduction potential of these materials is also noteworthy. Traditional battery cooling systems often rely on liquid cooling mechanisms that require significant water resources. Advanced interface materials that enable passive or semi-passive cooling reduce dependence on water-intensive cooling systems, particularly relevant in water-stressed regions where battery manufacturing and usage are expanding.

Additionally, these materials contribute to safety enhancement by preventing thermal runaway conditions, reducing the incidence of catastrophic failures that result in toxic material releases. This safety improvement represents an often overlooked sustainability benefit, as it prevents environmental contamination events and extends the safe operational envelope of energy storage systems.

The economic sustainability dimension cannot be overlooked. By extending battery lifespans and improving performance, advanced interface materials improve the total cost of ownership for energy storage systems, making renewable energy integration more economically viable across various applications and markets.

Advanced interface materials enable more efficient heat dissipation and thermal regulation, directly translating to extended battery operational lifespans. This longevity effect decreases the frequency of battery replacements, subsequently reducing raw material extraction demands and manufacturing-related emissions. Studies indicate that effective thermal management through engineered interfaces can extend lithium-ion battery lifespans by 20-40% under typical usage conditions.

The environmental benefits extend to operational efficiency as well. Batteries with optimized thermal interfaces demonstrate improved energy efficiency during charge-discharge cycles, reducing energy losses as heat. This efficiency gain translates to lower overall energy consumption for the same functional output, decreasing the carbon footprint associated with battery operation in various applications from electric vehicles to grid storage systems.

From a circular economy perspective, advanced interface materials can be designed with recyclability and recoverability in mind. Novel approaches incorporate bio-based or easily separable components that facilitate end-of-life processing. Some cutting-edge interface materials utilize renewable resources or recycled content, further enhancing their sustainability profile compared to conventional options.

The water footprint reduction potential of these materials is also noteworthy. Traditional battery cooling systems often rely on liquid cooling mechanisms that require significant water resources. Advanced interface materials that enable passive or semi-passive cooling reduce dependence on water-intensive cooling systems, particularly relevant in water-stressed regions where battery manufacturing and usage are expanding.

Additionally, these materials contribute to safety enhancement by preventing thermal runaway conditions, reducing the incidence of catastrophic failures that result in toxic material releases. This safety improvement represents an often overlooked sustainability benefit, as it prevents environmental contamination events and extends the safe operational envelope of energy storage systems.

The economic sustainability dimension cannot be overlooked. By extending battery lifespans and improving performance, advanced interface materials improve the total cost of ownership for energy storage systems, making renewable energy integration more economically viable across various applications and markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!