Evaluation of Interface Engineering in Battery Thermal Management

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Interface Engineering Background and Objectives

Battery thermal management has evolved significantly over the past decades, transitioning from simple passive cooling systems to sophisticated active thermal management solutions. The interface between battery cells and cooling systems represents a critical junction that determines overall thermal performance. Historically, thermal interface materials (TIMs) began as basic thermal greases in the 1990s, evolving through phase change materials in the early 2000s, to today's advanced composites incorporating nanomaterials and engineered structures.

The technological trajectory shows a clear trend toward materials with higher thermal conductivity, improved mechanical stability, and enhanced long-term reliability. Recent developments have focused on addressing the unique challenges posed by electric vehicle (EV) battery packs, including thermal runaway prevention, temperature uniformity across large cell arrays, and performance maintenance under extreme operating conditions.

Current research objectives in battery thermal interface engineering center on achieving thermal conductivity values exceeding 10 W/m·K while maintaining flexibility, minimizing interface resistance, and ensuring cost-effectiveness for mass production. Additionally, there is growing emphasis on developing environmentally sustainable TIMs that reduce reliance on rare earth elements and facilitate end-of-life recycling.

The integration of thermal interface engineering with battery design represents a paradigm shift from treating thermal management as an afterthought to incorporating it as a fundamental design parameter. This holistic approach aims to optimize the entire thermal pathway from heat generation within cells to ultimate heat rejection to the environment.

Emerging objectives include the development of "smart" thermal interfaces that can adapt their properties based on operating conditions, potentially incorporating phase-change mechanisms or variable conductivity pathways. These adaptive interfaces would provide optimal performance across the wide temperature ranges experienced in real-world applications, from sub-zero cold starts to high-rate discharge scenarios.

Another critical goal is standardization of testing methodologies for thermal interface performance in battery applications. Current evaluation methods vary significantly across industry and academia, making direct comparisons challenging and potentially misleading. Establishing consistent testing protocols would accelerate innovation by enabling meaningful benchmarking and validation of new technologies.

The ultimate objective remains achieving the delicate balance between thermal performance, cost, manufacturability, and reliability—a challenge that continues to drive innovation in this field. As battery energy densities increase and fast-charging capabilities advance, the demands on thermal interface materials will only intensify, highlighting the strategic importance of this technology area for the future of energy storage systems.

The technological trajectory shows a clear trend toward materials with higher thermal conductivity, improved mechanical stability, and enhanced long-term reliability. Recent developments have focused on addressing the unique challenges posed by electric vehicle (EV) battery packs, including thermal runaway prevention, temperature uniformity across large cell arrays, and performance maintenance under extreme operating conditions.

Current research objectives in battery thermal interface engineering center on achieving thermal conductivity values exceeding 10 W/m·K while maintaining flexibility, minimizing interface resistance, and ensuring cost-effectiveness for mass production. Additionally, there is growing emphasis on developing environmentally sustainable TIMs that reduce reliance on rare earth elements and facilitate end-of-life recycling.

The integration of thermal interface engineering with battery design represents a paradigm shift from treating thermal management as an afterthought to incorporating it as a fundamental design parameter. This holistic approach aims to optimize the entire thermal pathway from heat generation within cells to ultimate heat rejection to the environment.

Emerging objectives include the development of "smart" thermal interfaces that can adapt their properties based on operating conditions, potentially incorporating phase-change mechanisms or variable conductivity pathways. These adaptive interfaces would provide optimal performance across the wide temperature ranges experienced in real-world applications, from sub-zero cold starts to high-rate discharge scenarios.

Another critical goal is standardization of testing methodologies for thermal interface performance in battery applications. Current evaluation methods vary significantly across industry and academia, making direct comparisons challenging and potentially misleading. Establishing consistent testing protocols would accelerate innovation by enabling meaningful benchmarking and validation of new technologies.

The ultimate objective remains achieving the delicate balance between thermal performance, cost, manufacturability, and reliability—a challenge that continues to drive innovation in this field. As battery energy densities increase and fast-charging capabilities advance, the demands on thermal interface materials will only intensify, highlighting the strategic importance of this technology area for the future of energy storage systems.

Market Demand Analysis for Advanced Battery Thermal Solutions

The global market for advanced battery thermal management solutions is experiencing robust growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Current market valuations indicate that the battery thermal management system market reached approximately 3.5 billion USD in 2022 and is projected to grow at a compound annual growth rate of 22-25% through 2030. This acceleration is particularly evident in regions with aggressive electrification targets such as Europe, North America, and parts of Asia.

Consumer demand for EVs with extended range capabilities, faster charging times, and longer battery lifespans has directly intensified the need for more sophisticated thermal management solutions. Market research indicates that over 70% of EV consumers consider battery longevity as a critical purchasing factor, while 65% express concerns about charging speed limitations. These consumer priorities translate directly into technical requirements for advanced thermal interface materials and engineering solutions.

The industrial sector represents another significant market segment, with stationary energy storage systems (ESS) deployments increasing by 35% annually. These systems require robust thermal management to ensure optimal performance in varied environmental conditions, from utility-scale installations to commercial and residential applications.

Regulatory frameworks are also substantially influencing market demand. Stringent safety standards following high-profile battery thermal runaway incidents have prompted automotive manufacturers to invest heavily in thermal management technologies. The implementation of regulations such as UN ECE R100 in Europe and similar standards in other regions has established minimum requirements for battery thermal safety, effectively creating mandatory market demand for advanced solutions.

From a geographical perspective, China currently leads the market with approximately 40% share of global battery thermal management system demand, followed by Europe (30%) and North America (20%). However, emerging markets in India and Southeast Asia are showing the fastest growth rates, albeit from smaller bases.

The market is increasingly segmenting based on technological sophistication, with premium automotive manufacturers willing to pay significant premiums for thermal interface materials and engineering solutions that can deliver measurable improvements in battery performance metrics. This has created a two-tier market where cost-sensitive mass-market applications coexist with high-performance premium solutions commanding price premiums of 30-50%.

Industry forecasts suggest that interface engineering specifically will represent approximately 25% of the overall battery thermal management market value by 2025, highlighting its growing importance as a critical subsegment within the broader thermal management ecosystem.

Consumer demand for EVs with extended range capabilities, faster charging times, and longer battery lifespans has directly intensified the need for more sophisticated thermal management solutions. Market research indicates that over 70% of EV consumers consider battery longevity as a critical purchasing factor, while 65% express concerns about charging speed limitations. These consumer priorities translate directly into technical requirements for advanced thermal interface materials and engineering solutions.

The industrial sector represents another significant market segment, with stationary energy storage systems (ESS) deployments increasing by 35% annually. These systems require robust thermal management to ensure optimal performance in varied environmental conditions, from utility-scale installations to commercial and residential applications.

Regulatory frameworks are also substantially influencing market demand. Stringent safety standards following high-profile battery thermal runaway incidents have prompted automotive manufacturers to invest heavily in thermal management technologies. The implementation of regulations such as UN ECE R100 in Europe and similar standards in other regions has established minimum requirements for battery thermal safety, effectively creating mandatory market demand for advanced solutions.

From a geographical perspective, China currently leads the market with approximately 40% share of global battery thermal management system demand, followed by Europe (30%) and North America (20%). However, emerging markets in India and Southeast Asia are showing the fastest growth rates, albeit from smaller bases.

The market is increasingly segmenting based on technological sophistication, with premium automotive manufacturers willing to pay significant premiums for thermal interface materials and engineering solutions that can deliver measurable improvements in battery performance metrics. This has created a two-tier market where cost-sensitive mass-market applications coexist with high-performance premium solutions commanding price premiums of 30-50%.

Industry forecasts suggest that interface engineering specifically will represent approximately 25% of the overall battery thermal management market value by 2025, highlighting its growing importance as a critical subsegment within the broader thermal management ecosystem.

Current Status and Challenges in Battery Thermal Interface Materials

The global battery market has witnessed exponential growth, driven primarily by electric vehicles and renewable energy storage systems. However, thermal management remains a critical challenge, particularly at material interfaces where heat transfer efficiency significantly impacts overall system performance. Current thermal interface materials (TIMs) used in battery systems face substantial limitations in thermal conductivity, long-term reliability, and compatibility with battery components.

Commercially available TIMs for battery applications predominantly include thermal greases, gap fillers, phase change materials (PCMs), and graphite sheets. Thermal greases offer good initial performance (1-5 W/m·K) but suffer from pump-out effects and drying over time, creating reliability concerns for long-term battery operation. Gap fillers provide better mechanical compliance but typically deliver lower thermal conductivity than required for high-power battery systems.

Advanced materials research has introduced promising candidates including graphene-enhanced composites achieving thermal conductivities of 10-20 W/m·K in laboratory settings. However, these materials face significant manufacturing scalability challenges and cost barriers, limiting widespread commercial adoption. Carbon nanotube (CNT) arrays have demonstrated exceptional thermal conductivity (50-100 W/m·K) along their axis, but integration challenges and anisotropic thermal properties restrict their practical implementation.

A fundamental challenge lies in the competing requirements for TIMs in battery systems: high thermal conductivity typically requires rigid materials with strong internal bonding, while battery interfaces demand compliance to accommodate expansion and contraction during charge-discharge cycles. This inherent contradiction has yet to be effectively resolved in commercial products.

Interface engineering at the molecular level represents another significant challenge. Current manufacturing processes struggle to create consistent, defect-free interfaces between TIMs and battery components. Research indicates that up to 60% of thermal resistance in battery cooling systems occurs at these material interfaces rather than within the TIMs themselves, highlighting the critical importance of interface quality.

Geographical distribution of TIM technology development shows concentration in East Asia (particularly Japan, South Korea, and China) for manufacturing scale-up, while fundamental research remains strong in North America and Europe. This geographical disparity creates challenges in translating laboratory innovations to commercial products.

Environmental and regulatory constraints further complicate TIM development, with increasing pressure to eliminate environmentally harmful components like certain flame retardants and metal fillers, while maintaining thermal performance and safety standards. Additionally, end-of-life considerations and recyclability requirements are becoming increasingly important design factors that current TIM solutions inadequately address.

Commercially available TIMs for battery applications predominantly include thermal greases, gap fillers, phase change materials (PCMs), and graphite sheets. Thermal greases offer good initial performance (1-5 W/m·K) but suffer from pump-out effects and drying over time, creating reliability concerns for long-term battery operation. Gap fillers provide better mechanical compliance but typically deliver lower thermal conductivity than required for high-power battery systems.

Advanced materials research has introduced promising candidates including graphene-enhanced composites achieving thermal conductivities of 10-20 W/m·K in laboratory settings. However, these materials face significant manufacturing scalability challenges and cost barriers, limiting widespread commercial adoption. Carbon nanotube (CNT) arrays have demonstrated exceptional thermal conductivity (50-100 W/m·K) along their axis, but integration challenges and anisotropic thermal properties restrict their practical implementation.

A fundamental challenge lies in the competing requirements for TIMs in battery systems: high thermal conductivity typically requires rigid materials with strong internal bonding, while battery interfaces demand compliance to accommodate expansion and contraction during charge-discharge cycles. This inherent contradiction has yet to be effectively resolved in commercial products.

Interface engineering at the molecular level represents another significant challenge. Current manufacturing processes struggle to create consistent, defect-free interfaces between TIMs and battery components. Research indicates that up to 60% of thermal resistance in battery cooling systems occurs at these material interfaces rather than within the TIMs themselves, highlighting the critical importance of interface quality.

Geographical distribution of TIM technology development shows concentration in East Asia (particularly Japan, South Korea, and China) for manufacturing scale-up, while fundamental research remains strong in North America and Europe. This geographical disparity creates challenges in translating laboratory innovations to commercial products.

Environmental and regulatory constraints further complicate TIM development, with increasing pressure to eliminate environmentally harmful components like certain flame retardants and metal fillers, while maintaining thermal performance and safety standards. Additionally, end-of-life considerations and recyclability requirements are becoming increasingly important design factors that current TIM solutions inadequately address.

Current Technical Solutions for Battery Thermal Interface Management

01 Thermal interface materials for electronic devices

Advanced thermal interface materials are used to improve heat transfer between electronic components and heat sinks. These materials fill microscopic air gaps at contact surfaces, enhancing thermal conductivity and reducing thermal resistance. Innovations include phase-change materials, metal-based composites, and polymer matrices with high thermal conductivity fillers that maintain performance under thermal cycling and mechanical stress.- Thermal Interface Materials for Electronic Devices: Advanced thermal interface materials are designed to enhance heat transfer between electronic components and heat sinks. These materials fill microscopic air gaps at the interface, significantly improving thermal conductivity. Innovations include phase-change materials, metal-based composites, and carbon-based solutions that maintain performance under thermal cycling and mechanical stress while providing electrical isolation where needed.

- Heat Dissipation Structures for Computing Systems: Specialized heat dissipation structures are engineered to manage thermal loads in computing environments. These designs incorporate optimized airflow channels, heat pipes, vapor chambers, and liquid cooling solutions. The structures are particularly important for high-performance computing systems, data centers, and compact electronic devices where thermal management directly impacts system reliability and performance.

- Thermal Management in Network Infrastructure: Network infrastructure requires specialized thermal management solutions to maintain optimal operating temperatures. These systems incorporate intelligent cooling controls, redundant thermal pathways, and adaptive cooling responses based on network load. The designs focus on maintaining system reliability while optimizing energy consumption in telecommunications equipment, servers, and network switches.

- Thermal Interface Design for Portable Electronics: Portable electronic devices present unique thermal management challenges due to their compact form factors and varying usage patterns. Interface designs for these devices focus on ultra-thin thermal solutions, flexible heat spreaders, and graphene-based materials. These interfaces must balance thermal performance with weight, thickness constraints, and power efficiency considerations while maintaining user comfort during extended operation.

- Industrial Cooling Interface Systems: Industrial applications require robust thermal interface systems capable of handling extreme conditions and high heat loads. These interfaces incorporate specialized materials and designs for durability in harsh environments, including high-temperature operations, vibration resistance, and chemical exposure. The systems often feature modular designs for maintenance accessibility and integrate with facility-wide thermal management infrastructure for comprehensive heat control.

02 Heat dissipation structures for electronic systems

Specialized heat dissipation structures are designed to manage thermal loads in compact electronic systems. These include advanced heat sink designs, vapor chambers, and heat pipes that efficiently transfer heat away from critical components. The structures incorporate optimized fin arrangements, surface treatments, and airflow channels to maximize cooling efficiency while minimizing space requirements and power consumption.Expand Specific Solutions03 Thermal management for communication equipment

Communication equipment requires specialized thermal management solutions due to high power density and reliability requirements. These solutions include passive and active cooling systems designed for network infrastructure, data centers, and telecommunications equipment. Advanced designs incorporate airflow optimization, thermal isolation techniques, and intelligent thermal monitoring to maintain optimal operating temperatures under varying load conditions.Expand Specific Solutions04 Cooling systems for power electronics

Power electronics require robust cooling solutions to handle high heat loads generated during operation. These systems employ liquid cooling, direct-to-chip cooling, and advanced heat exchanger designs to maintain safe operating temperatures. Innovations include integrated cooling channels, dielectric coolants, and hybrid cooling approaches that combine multiple heat transfer mechanisms to achieve optimal thermal performance in high-power applications.Expand Specific Solutions05 Thermal management for portable and wearable devices

Portable and wearable devices present unique thermal management challenges due to size constraints, user comfort requirements, and battery life considerations. Solutions include ultra-thin vapor chambers, graphene-based heat spreaders, and thermally conductive enclosures that efficiently dissipate heat while maintaining compact form factors. These approaches balance thermal performance with weight, thickness, and power consumption to enable advanced functionality in space-constrained designs.Expand Specific Solutions

Key Industry Players in Battery Thermal Interface Engineering

The battery thermal management interface engineering market is currently in a growth phase, characterized by increasing demand for efficient thermal solutions in electric vehicles. The market size is expanding rapidly, driven by the global shift towards electrification, with projections indicating substantial growth over the next decade. Technologically, the field shows varying maturity levels across different approaches, with companies like Tesla, BYD, and Contemporary Amperex Technology leading innovation in battery cooling systems. Traditional automotive manufacturers including Ford, GM, Audi, and Renault are actively developing proprietary thermal management solutions, while specialized thermal management companies such as Gentherm and Valeo Thermal Systems are providing expertise in interface materials and cooling technologies. Academic institutions like the University of Michigan and University of California are contributing fundamental research, creating a competitive landscape balanced between established players and emerging specialists.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive battery thermal management system (BTMS) utilizing a multi-layered interface engineering approach. Their solution incorporates phase change materials (PCMs) integrated directly between battery cells with optimized thermal conductivity enhancers. The system features a composite thermal interface material with nano-carbon additives that achieves thermal conductivity exceeding 5 W/m·K while maintaining flexibility for battery expansion. CATL's design includes micro-channeled cooling plates with specialized surface treatments to enhance heat transfer coefficients by up to 40% compared to conventional designs. Their latest generation implements a cell-to-pack (CTP) architecture with integrated cooling channels that reduces thermal interfaces by 60%, significantly decreasing thermal resistance across the battery system. The company has also pioneered adaptive thermal management algorithms that dynamically adjust cooling intensity based on real-time temperature gradients and state-of-charge conditions, optimizing energy consumption while maintaining cell temperature uniformity within 3°C across the pack.

Strengths: Superior thermal conductivity at interfaces reduces hotspots; integrated CTP design minimizes thermal resistance pathways; adaptive control algorithms optimize energy efficiency. Weaknesses: Higher manufacturing complexity increases production costs; specialized materials may face supply chain constraints; system adds weight compared to simpler cooling solutions.

Gentherm, Inc.

Technical Solution: Gentherm has developed the "Adaptive Thermal Interface System" (ATIS) specifically designed for electric vehicle battery thermal management. Their approach focuses on dynamic interface materials that respond to changing thermal conditions. The core technology utilizes a proprietary composite material with temperature-dependent thermal conductivity that increases from 2 W/m·K at low temperatures to over 8 W/m·K during high-load conditions, ensuring efficient heat transfer precisely when needed. Gentherm's system incorporates a network of micro-thermistors embedded within interface materials that provide real-time temperature mapping with resolution of 5mm across battery surfaces. This data feeds into their predictive thermal management algorithms that can anticipate hotspot formation before critical temperatures are reached. Their interface engineering extends to the cooling plate design, which features variable-thickness channels that distribute coolant flow proportionally to heat generation patterns across the battery pack. Gentherm has also pioneered electrically conductive thermal interfaces that serve dual purposes as both thermal pathways and as part of the battery pack's electrical architecture, reducing overall system complexity and weight by eliminating redundant components.

Strengths: Adaptive materials optimize performance across operating conditions; embedded sensing provides unprecedented thermal visibility; multi-functional interfaces reduce system complexity and weight. Weaknesses: Advanced materials increase component costs significantly; embedded sensors add complexity to manufacturing process; system requires sophisticated control algorithms that demand substantial computational resources.

Critical Technologies in Battery Thermal Interface Materials

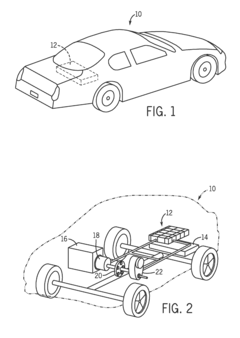

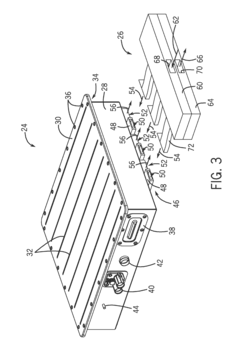

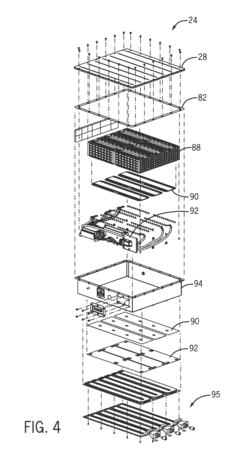

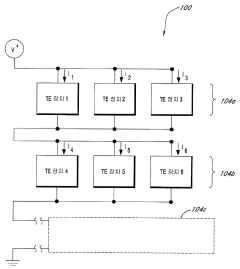

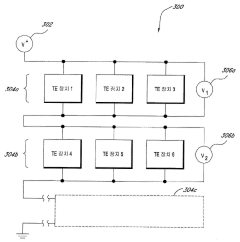

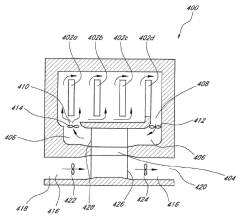

Battery system having an external thermal management system

PatentActiveUS20120263988A1

Innovation

- A battery system with an external thermal management system that includes a heat transfer side wall, a thermal interface, and a heat sink, allowing for efficient heat transfer from electrochemical cells to a heat sink, while keeping the thermal management fluid separate from the battery module to prevent leakage and condensation.

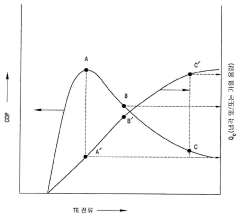

Battery thermal management system

PatentInactiveKR1020200055802A

Innovation

- A battery thermal management system utilizing thermoelectric assemblies for temperature control, incorporating redundancy and independent flow control devices to maintain optimal battery conditions, and monitoring systems for failure detection and parameter adjustment.

Safety Standards and Compliance in Battery Thermal Management

Safety standards and compliance frameworks play a critical role in the development and implementation of battery thermal management systems (BTMS), particularly as they relate to interface engineering. The evolution of these standards has been driven by increasing concerns about battery safety incidents, with regulatory bodies worldwide establishing comprehensive guidelines to mitigate risks associated with thermal runaway and other thermal-related failures.

International standards such as IEC 62133, UL 1642, and UN 38.3 have established baseline requirements for battery safety, with specific provisions addressing thermal management interfaces. These standards mandate specific temperature thresholds, thermal cycling requirements, and heat dissipation capabilities that directly impact interface design decisions in BTMS.

The automotive sector has developed particularly rigorous standards through ISO 26262 and SAE J2929, which outline functional safety requirements for electric vehicle battery systems. These standards specifically address thermal interface materials (TIMs) and their role in maintaining safe operating temperatures across battery module interfaces, requiring extensive validation testing under various thermal conditions.

Compliance testing for interface engineering in BTMS typically involves thermal shock tests, temperature gradient measurements, and long-term thermal cycling to evaluate interface degradation. These tests assess the durability of thermal interfaces under extreme conditions, ensuring they maintain performance throughout the battery's operational lifetime.

Recent regulatory developments have placed increased emphasis on the fire resistance properties of interface materials, with standards like UL 94 becoming increasingly relevant for BTMS designers. This has driven innovation in flame-retardant TIMs that maintain thermal conductivity while meeting stringent flammability requirements.

Regional variations in safety standards present significant challenges for global BTMS deployment. European regulations through ECE R100 impose different requirements than China's GB/T 31467 or North America's NFPA standards, necessitating adaptable interface engineering approaches that can satisfy multiple compliance frameworks simultaneously.

The emergence of fast-charging technologies has prompted regulatory bodies to develop new testing protocols specifically addressing the thermal management challenges at battery interfaces during high-power charging events. These protocols evaluate the thermal stability of interfaces under rapid heat generation scenarios, ensuring safety during increasingly common fast-charging use cases.

Looking forward, standards organizations are working to harmonize global requirements for battery thermal interfaces, with particular focus on establishing consistent methodologies for evaluating interface degradation over time. This harmonization effort aims to streamline compliance processes while maintaining the highest safety standards for battery systems across diverse applications and operating environments.

International standards such as IEC 62133, UL 1642, and UN 38.3 have established baseline requirements for battery safety, with specific provisions addressing thermal management interfaces. These standards mandate specific temperature thresholds, thermal cycling requirements, and heat dissipation capabilities that directly impact interface design decisions in BTMS.

The automotive sector has developed particularly rigorous standards through ISO 26262 and SAE J2929, which outline functional safety requirements for electric vehicle battery systems. These standards specifically address thermal interface materials (TIMs) and their role in maintaining safe operating temperatures across battery module interfaces, requiring extensive validation testing under various thermal conditions.

Compliance testing for interface engineering in BTMS typically involves thermal shock tests, temperature gradient measurements, and long-term thermal cycling to evaluate interface degradation. These tests assess the durability of thermal interfaces under extreme conditions, ensuring they maintain performance throughout the battery's operational lifetime.

Recent regulatory developments have placed increased emphasis on the fire resistance properties of interface materials, with standards like UL 94 becoming increasingly relevant for BTMS designers. This has driven innovation in flame-retardant TIMs that maintain thermal conductivity while meeting stringent flammability requirements.

Regional variations in safety standards present significant challenges for global BTMS deployment. European regulations through ECE R100 impose different requirements than China's GB/T 31467 or North America's NFPA standards, necessitating adaptable interface engineering approaches that can satisfy multiple compliance frameworks simultaneously.

The emergence of fast-charging technologies has prompted regulatory bodies to develop new testing protocols specifically addressing the thermal management challenges at battery interfaces during high-power charging events. These protocols evaluate the thermal stability of interfaces under rapid heat generation scenarios, ensuring safety during increasingly common fast-charging use cases.

Looking forward, standards organizations are working to harmonize global requirements for battery thermal interfaces, with particular focus on establishing consistent methodologies for evaluating interface degradation over time. This harmonization effort aims to streamline compliance processes while maintaining the highest safety standards for battery systems across diverse applications and operating environments.

Environmental Impact and Sustainability Considerations

The environmental implications of interface engineering in battery thermal management systems extend far beyond operational efficiency. As thermal management technologies evolve, their ecological footprint becomes increasingly significant in the broader context of sustainable energy solutions. Current interface materials often contain environmentally problematic components such as heavy metals, volatile organic compounds, and non-biodegradable polymers that pose end-of-life disposal challenges.

Life cycle assessment studies reveal that advanced thermal interface materials can reduce the overall environmental impact of battery systems by extending battery lifespan and improving energy efficiency. However, manufacturing processes for high-performance thermal interfaces frequently involve energy-intensive production methods and environmentally harmful chemical treatments. The carbon footprint associated with producing nanomaterials and specialized composites for interface engineering must be weighed against their operational benefits.

Water consumption represents another critical environmental consideration, particularly in the production of ceramic-based and metal-organic interface materials. Some manufacturing processes require significant water resources for synthesis, purification, and quality control. Additionally, certain thermal interface materials may leach harmful substances during their operational lifetime or after disposal, potentially contaminating soil and water systems.

Recycling and circular economy principles are increasingly being integrated into thermal interface material design. Bio-based thermal interface materials derived from renewable resources show promising thermal performance while offering improved end-of-life management options. Recent innovations include thermally conductive materials synthesized from cellulose derivatives, agricultural waste products, and other biodegradable substances that maintain competitive thermal conductivity values.

Regulatory frameworks worldwide are evolving to address the environmental aspects of battery technologies, including thermal management systems. The European Union's Battery Directive and similar regulations in Asia and North America are beginning to incorporate specific provisions for thermal management components, emphasizing reduced toxicity and improved recyclability. These regulatory trends are driving research toward environmentally benign alternatives to traditional interface materials.

Energy payback analysis indicates that optimized interface engineering can significantly reduce the environmental burden of battery systems through improved efficiency and extended service life. Studies suggest that advanced thermal interface materials can reduce the carbon footprint of large-scale battery installations by 15-20% over their operational lifetime when compared to conventional solutions, primarily through reduced cooling energy requirements and decreased replacement frequency.

Life cycle assessment studies reveal that advanced thermal interface materials can reduce the overall environmental impact of battery systems by extending battery lifespan and improving energy efficiency. However, manufacturing processes for high-performance thermal interfaces frequently involve energy-intensive production methods and environmentally harmful chemical treatments. The carbon footprint associated with producing nanomaterials and specialized composites for interface engineering must be weighed against their operational benefits.

Water consumption represents another critical environmental consideration, particularly in the production of ceramic-based and metal-organic interface materials. Some manufacturing processes require significant water resources for synthesis, purification, and quality control. Additionally, certain thermal interface materials may leach harmful substances during their operational lifetime or after disposal, potentially contaminating soil and water systems.

Recycling and circular economy principles are increasingly being integrated into thermal interface material design. Bio-based thermal interface materials derived from renewable resources show promising thermal performance while offering improved end-of-life management options. Recent innovations include thermally conductive materials synthesized from cellulose derivatives, agricultural waste products, and other biodegradable substances that maintain competitive thermal conductivity values.

Regulatory frameworks worldwide are evolving to address the environmental aspects of battery technologies, including thermal management systems. The European Union's Battery Directive and similar regulations in Asia and North America are beginning to incorporate specific provisions for thermal management components, emphasizing reduced toxicity and improved recyclability. These regulatory trends are driving research toward environmentally benign alternatives to traditional interface materials.

Energy payback analysis indicates that optimized interface engineering can significantly reduce the environmental burden of battery systems through improved efficiency and extended service life. Studies suggest that advanced thermal interface materials can reduce the carbon footprint of large-scale battery installations by 15-20% over their operational lifetime when compared to conventional solutions, primarily through reduced cooling energy requirements and decreased replacement frequency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!