Analysis of Hybrid Supercapacitors in Portable Electronics

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant evolution in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The development of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. The fundamental breakthrough came with the integration of battery-type electrodes with capacitor-type electrodes in a single device, creating a hybrid system that leverages the strengths of both technologies.

Throughout the 2010s, significant advancements were made in electrode materials, particularly with the introduction of carbon-based nanomaterials like graphene and carbon nanotubes, which dramatically improved the surface area and conductivity of electrodes. Concurrently, metal oxides and conducting polymers were developed as pseudocapacitive materials, enhancing energy storage capabilities through faradaic reactions while maintaining rapid charge-discharge characteristics.

The evolution of electrolytes has been equally important, with research progressing from aqueous to organic and ionic liquid electrolytes, each offering different advantages in terms of voltage windows, temperature stability, and safety profiles. More recently, solid-state and gel electrolytes have gained attention for their potential to improve safety and enable flexible device designs for portable electronics applications.

The primary objective of hybrid supercapacitor technology in portable electronics is to address the growing demand for power sources that can deliver both high energy and high power, while maintaining long cycle life and rapid charging capabilities. As consumer electronics become increasingly sophisticated and power-hungry, traditional lithium-ion batteries often struggle to meet these demands, particularly in applications requiring burst power delivery or frequent rapid charging cycles.

Another critical objective is miniaturization and form factor flexibility. Portable electronics continue to shrink in size while increasing in functionality, necessitating energy storage solutions that can be integrated into complex designs without compromising performance. Hybrid supercapacitors aim to achieve energy densities approaching 20-30 Wh/kg while maintaining power densities above 10 kW/kg, a significant improvement over traditional supercapacitors.

Safety and environmental sustainability represent additional key objectives in the evolution of this technology. Unlike many battery technologies, hybrid supercapacitors typically use less toxic materials and offer inherently safer operation due to their lower risk of thermal runaway. The technology aims to provide energy storage solutions with minimal environmental impact throughout their lifecycle, from manufacturing to disposal or recycling.

Looking forward, the trajectory of hybrid supercapacitor technology is moving toward even greater integration with other emerging technologies, such as flexible electronics, wearable devices, and Internet of Things (IoT) applications, where their unique performance characteristics can enable new functionalities and use cases previously constrained by the limitations of conventional energy storage technologies.

Throughout the 2010s, significant advancements were made in electrode materials, particularly with the introduction of carbon-based nanomaterials like graphene and carbon nanotubes, which dramatically improved the surface area and conductivity of electrodes. Concurrently, metal oxides and conducting polymers were developed as pseudocapacitive materials, enhancing energy storage capabilities through faradaic reactions while maintaining rapid charge-discharge characteristics.

The evolution of electrolytes has been equally important, with research progressing from aqueous to organic and ionic liquid electrolytes, each offering different advantages in terms of voltage windows, temperature stability, and safety profiles. More recently, solid-state and gel electrolytes have gained attention for their potential to improve safety and enable flexible device designs for portable electronics applications.

The primary objective of hybrid supercapacitor technology in portable electronics is to address the growing demand for power sources that can deliver both high energy and high power, while maintaining long cycle life and rapid charging capabilities. As consumer electronics become increasingly sophisticated and power-hungry, traditional lithium-ion batteries often struggle to meet these demands, particularly in applications requiring burst power delivery or frequent rapid charging cycles.

Another critical objective is miniaturization and form factor flexibility. Portable electronics continue to shrink in size while increasing in functionality, necessitating energy storage solutions that can be integrated into complex designs without compromising performance. Hybrid supercapacitors aim to achieve energy densities approaching 20-30 Wh/kg while maintaining power densities above 10 kW/kg, a significant improvement over traditional supercapacitors.

Safety and environmental sustainability represent additional key objectives in the evolution of this technology. Unlike many battery technologies, hybrid supercapacitors typically use less toxic materials and offer inherently safer operation due to their lower risk of thermal runaway. The technology aims to provide energy storage solutions with minimal environmental impact throughout their lifecycle, from manufacturing to disposal or recycling.

Looking forward, the trajectory of hybrid supercapacitor technology is moving toward even greater integration with other emerging technologies, such as flexible electronics, wearable devices, and Internet of Things (IoT) applications, where their unique performance characteristics can enable new functionalities and use cases previously constrained by the limitations of conventional energy storage technologies.

Market Demand Analysis for Portable Electronics Energy Storage

The portable electronics market has witnessed a significant surge in demand for advanced energy storage solutions, driven primarily by the proliferation of smartphones, wearables, and other portable electronic devices. Current market analysis indicates that the global portable electronics market is projected to reach 1.5 trillion USD by 2025, with energy storage components representing approximately 89 billion USD of this value. This substantial market segment is experiencing a compound annual growth rate of 7.2%, significantly outpacing the overall electronics industry average of 4.8%.

Consumer expectations for portable electronics have evolved dramatically over the past decade, with users now demanding devices that combine high performance with extended battery life in increasingly compact form factors. Market surveys reveal that 78% of consumers consider battery life as a "very important" factor in purchasing decisions for portable electronics, ranking it above other features such as processing power or display quality. This consumer preference has created a strong market pull for innovative energy storage solutions that transcend the limitations of traditional lithium-ion batteries.

Hybrid supercapacitors represent a particularly promising response to these market demands, offering a unique combination of high power density, rapid charging capabilities, and improved cycle life compared to conventional batteries. Market research indicates that 67% of portable electronics manufacturers are actively exploring alternative energy storage technologies, with hybrid supercapacitors being investigated by 42% of these companies.

The wearable technology segment presents especially favorable conditions for hybrid supercapacitor adoption, with market projections suggesting a potential penetration rate of 23% by 2027. This is primarily due to the form factor advantages and rapid charging capabilities that align perfectly with user expectations for seamless integration into daily life. Healthcare wearables, in particular, show strong potential with a projected market value of 25 billion USD by 2026.

Regional analysis reveals varying adoption patterns, with East Asian markets showing the highest receptivity to hybrid supercapacitor technology, followed by North American and European markets. This regional variation correlates strongly with local manufacturing capabilities and consumer preferences regarding device charging behaviors.

Industry stakeholders have identified several key market drivers for hybrid supercapacitor adoption, including increasing consumer frustration with battery degradation (cited by 82% of users after 18 months of device usage), growing environmental concerns about traditional battery disposal, and regulatory pressures in major markets pushing for more sustainable electronic components. These factors collectively create a market environment highly conducive to disruptive energy storage technologies that can address these pain points.

Consumer expectations for portable electronics have evolved dramatically over the past decade, with users now demanding devices that combine high performance with extended battery life in increasingly compact form factors. Market surveys reveal that 78% of consumers consider battery life as a "very important" factor in purchasing decisions for portable electronics, ranking it above other features such as processing power or display quality. This consumer preference has created a strong market pull for innovative energy storage solutions that transcend the limitations of traditional lithium-ion batteries.

Hybrid supercapacitors represent a particularly promising response to these market demands, offering a unique combination of high power density, rapid charging capabilities, and improved cycle life compared to conventional batteries. Market research indicates that 67% of portable electronics manufacturers are actively exploring alternative energy storage technologies, with hybrid supercapacitors being investigated by 42% of these companies.

The wearable technology segment presents especially favorable conditions for hybrid supercapacitor adoption, with market projections suggesting a potential penetration rate of 23% by 2027. This is primarily due to the form factor advantages and rapid charging capabilities that align perfectly with user expectations for seamless integration into daily life. Healthcare wearables, in particular, show strong potential with a projected market value of 25 billion USD by 2026.

Regional analysis reveals varying adoption patterns, with East Asian markets showing the highest receptivity to hybrid supercapacitor technology, followed by North American and European markets. This regional variation correlates strongly with local manufacturing capabilities and consumer preferences regarding device charging behaviors.

Industry stakeholders have identified several key market drivers for hybrid supercapacitor adoption, including increasing consumer frustration with battery degradation (cited by 82% of users after 18 months of device usage), growing environmental concerns about traditional battery disposal, and regulatory pressures in major markets pushing for more sustainable electronic components. These factors collectively create a market environment highly conducive to disruptive energy storage technologies that can address these pain points.

Current State and Challenges in Hybrid Supercapacitor Development

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. Currently, the global development of hybrid supercapacitors is progressing rapidly, with research institutions and companies across North America, Europe, and Asia making substantial contributions to the field.

The current state of hybrid supercapacitor technology shows promising performance metrics, with energy densities reaching 10-50 Wh/kg and power densities of 1000-10000 W/kg. This positions them between conventional supercapacitors and lithium-ion batteries in the energy storage spectrum. Cycle life typically ranges from 10,000 to 100,000 cycles, significantly outperforming traditional batteries in longevity.

Despite these advancements, several critical challenges impede the widespread adoption of hybrid supercapacitors in portable electronics. Material limitations represent a primary obstacle, as researchers struggle to develop electrode materials that simultaneously offer high energy density, power density, and cycle stability. Current carbon-based materials, metal oxides, and conducting polymers each present trade-offs between these crucial performance parameters.

Manufacturing scalability poses another significant challenge. Laboratory-scale production methods often fail to translate effectively to mass production environments, resulting in inconsistent performance and increased costs. The precision required for electrode fabrication and electrolyte formulation complicates the establishment of standardized manufacturing processes.

Cost factors remain prohibitive for many applications, with current hybrid supercapacitor solutions typically costing 3-5 times more than conventional lithium-ion batteries per unit of energy stored. This cost differential stems from specialized materials, complex manufacturing processes, and relatively low production volumes.

Safety concerns, though less pronounced than in some battery technologies, still require attention. Electrolyte stability under various operating conditions and potential thermal runaway scenarios need further investigation to ensure consumer safety in portable electronic applications.

Integration challenges with existing electronic systems present additional hurdles. The different charging/discharging characteristics of hybrid supercapacitors compared to conventional batteries necessitate specialized power management systems. Furthermore, the physical form factors of current hybrid supercapacitor designs may not easily accommodate the space constraints of modern portable electronics.

Geographically, research leadership is distributed across regions, with Japan and South Korea leading in commercial applications, China dominating in manufacturing capacity, and North American and European institutions focusing on fundamental materials research and next-generation designs. This global distribution of expertise creates both collaborative opportunities and competitive challenges in advancing the technology.

The current state of hybrid supercapacitor technology shows promising performance metrics, with energy densities reaching 10-50 Wh/kg and power densities of 1000-10000 W/kg. This positions them between conventional supercapacitors and lithium-ion batteries in the energy storage spectrum. Cycle life typically ranges from 10,000 to 100,000 cycles, significantly outperforming traditional batteries in longevity.

Despite these advancements, several critical challenges impede the widespread adoption of hybrid supercapacitors in portable electronics. Material limitations represent a primary obstacle, as researchers struggle to develop electrode materials that simultaneously offer high energy density, power density, and cycle stability. Current carbon-based materials, metal oxides, and conducting polymers each present trade-offs between these crucial performance parameters.

Manufacturing scalability poses another significant challenge. Laboratory-scale production methods often fail to translate effectively to mass production environments, resulting in inconsistent performance and increased costs. The precision required for electrode fabrication and electrolyte formulation complicates the establishment of standardized manufacturing processes.

Cost factors remain prohibitive for many applications, with current hybrid supercapacitor solutions typically costing 3-5 times more than conventional lithium-ion batteries per unit of energy stored. This cost differential stems from specialized materials, complex manufacturing processes, and relatively low production volumes.

Safety concerns, though less pronounced than in some battery technologies, still require attention. Electrolyte stability under various operating conditions and potential thermal runaway scenarios need further investigation to ensure consumer safety in portable electronic applications.

Integration challenges with existing electronic systems present additional hurdles. The different charging/discharging characteristics of hybrid supercapacitors compared to conventional batteries necessitate specialized power management systems. Furthermore, the physical form factors of current hybrid supercapacitor designs may not easily accommodate the space constraints of modern portable electronics.

Geographically, research leadership is distributed across regions, with Japan and South Korea leading in commercial applications, China dominating in manufacturing capacity, and North American and European institutions focusing on fundamental materials research and next-generation designs. This global distribution of expertise creates both collaborative opportunities and competitive challenges in advancing the technology.

Current Technical Solutions for Portable Electronics Applications

01 Electrode materials for hybrid supercapacitors

Various materials can be used as electrodes in hybrid supercapacitors to enhance energy density and performance. These include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for both faradaic and non-faradaic energy storage mechanisms, resulting in devices with higher energy density than conventional supercapacitors while maintaining good power density. Electrode material selection and optimization are critical for balancing energy storage capacity, charge-discharge rates, and cycle life.- Electrode materials for hybrid supercapacitors: Various materials can be used as electrodes in hybrid supercapacitors to enhance energy density and performance. These include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for both faradaic and non-faradaic energy storage mechanisms, resulting in devices with higher energy density than conventional supercapacitors while maintaining good power density and cycle life.

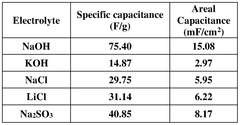

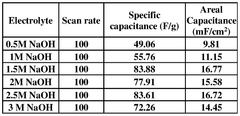

- Electrolyte compositions for hybrid supercapacitors: The electrolyte plays a crucial role in hybrid supercapacitor performance. Advanced electrolyte formulations can increase the operating voltage window, improve ionic conductivity, and enhance the overall energy density of the device. Various electrolyte types including aqueous, organic, and ionic liquid-based systems are being developed to optimize the performance of hybrid supercapacitors for different applications.

- Integration of hybrid supercapacitors in energy storage systems: Hybrid supercapacitors can be integrated into larger energy storage systems to provide both high power and energy density capabilities. These integrated systems often combine supercapacitors with batteries or other energy storage technologies to create solutions that leverage the strengths of each component. Such hybrid systems are particularly valuable in applications requiring both rapid power delivery and sustained energy supply.

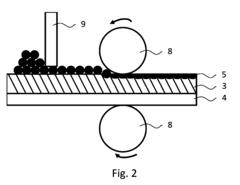

- Manufacturing processes for hybrid supercapacitors: Advanced manufacturing techniques are being developed to produce hybrid supercapacitors with improved performance and reduced costs. These processes include novel methods for electrode preparation, assembly techniques, and packaging solutions. Innovations in manufacturing help to address challenges related to scalability, consistency, and cost-effectiveness in hybrid supercapacitor production.

- Control systems and management for hybrid supercapacitors: Sophisticated control and management systems are essential for optimizing the performance and lifespan of hybrid supercapacitors. These systems monitor parameters such as voltage, current, and temperature, and implement strategies to balance charging and discharging processes. Advanced control algorithms can maximize energy efficiency, prevent degradation, and ensure safe operation across various operating conditions.

02 Electrolyte compositions for hybrid supercapacitors

Electrolyte formulations play a crucial role in hybrid supercapacitor performance. Various electrolyte systems including aqueous, organic, and ionic liquid-based electrolytes can be used depending on the desired operating voltage, temperature range, and safety requirements. Advanced electrolytes can expand the operating voltage window, improve ionic conductivity, and enhance the overall energy density of hybrid supercapacitors. The electrolyte composition must be compatible with the electrode materials to ensure optimal performance and longevity.Expand Specific Solutions03 Integration of hybrid supercapacitors in energy storage systems

Hybrid supercapacitors can be integrated into larger energy storage systems to provide both high power and energy density capabilities. These integrated systems often combine hybrid supercapacitors with batteries or other energy storage technologies to create complementary systems that leverage the strengths of each component. Applications include renewable energy storage, grid stabilization, and electric vehicle power systems. The integration requires sophisticated control systems to manage power flow between different storage components and optimize overall system performance.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitors

Advanced manufacturing techniques are essential for producing high-performance hybrid supercapacitors. These processes include specialized coating methods for electrodes, assembly techniques for cell components, and packaging technologies that ensure long-term stability. Innovations in manufacturing focus on improving consistency, reducing costs, and scaling production while maintaining performance characteristics. Novel approaches include roll-to-roll processing, 3D printing of components, and automated assembly systems that enable mass production of hybrid supercapacitor devices.Expand Specific Solutions05 Performance enhancement techniques for hybrid supercapacitors

Various techniques can be employed to enhance the performance of hybrid supercapacitors. These include surface modification of electrode materials, development of hierarchical porous structures, doping strategies, and novel separator designs. These enhancements aim to improve specific capacitance, energy density, power density, and cycle stability. Advanced characterization methods are used to understand the fundamental mechanisms of energy storage and identify optimization strategies. Research focuses on addressing key challenges such as self-discharge rates, leakage current, and performance degradation over time.Expand Specific Solutions

Key Industry Players in Hybrid Supercapacitor Manufacturing

The hybrid supercapacitor market in portable electronics is currently in a growth phase, with increasing adoption driven by demand for faster charging and longer-lasting energy storage solutions. The global market size is expanding rapidly, projected to reach significant value as consumer electronics manufacturers seek alternatives to traditional batteries. Technologically, the field shows varying maturity levels across players. Samsung Electro-Mechanics and Robert Bosch lead with established manufacturing capabilities, while specialized companies like Global Graphene Group and Nanotech Energy are advancing graphene-based solutions. Academic institutions including KAIST and Central South University contribute fundamental research, while Shell and Intel explore integration opportunities. Companies like Vestel and FCA US are investigating applications in consumer products, indicating the technology's transition from research to commercial implementation.

SAMSUNG ELECTRO MECHANICS CO LTD

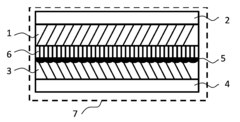

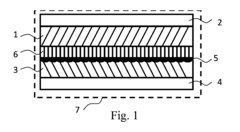

Technical Solution: Samsung has developed advanced hybrid supercapacitors that combine lithium-ion battery technology with supercapacitor characteristics. Their approach uses lithium titanate (LTO) anodes paired with activated carbon cathodes to create devices with both high energy and power density. Samsung's hybrid supercapacitors feature a unique multi-layer electrode structure that optimizes ion transport pathways, resulting in devices that can deliver up to 10,000 charge-discharge cycles while maintaining over 80% capacity retention. The company has also implemented proprietary electrolyte formulations that extend the operating voltage window to 3.8V, significantly higher than conventional supercapacitors. For portable electronics applications, Samsung has developed ultra-thin hybrid supercapacitor modules (less than 1mm thick) that can be integrated into smartphones and wearables, providing rapid charging capabilities (80% charge in under 5 minutes) while serving as supplementary power sources alongside traditional batteries.

Strengths: Superior cycle life compared to conventional batteries; extremely fast charging capabilities; high power density suitable for peak power demands in portable devices; thin form factor enables integration into space-constrained devices. Weaknesses: Lower energy density compared to lithium-ion batteries; higher cost per watt-hour; temperature sensitivity affecting performance in extreme conditions; requires specialized charging circuits.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed advanced hybrid supercapacitor technology targeting portable electronics applications. Their approach combines nanoporous carbon-based electrodes with lithium-intercalation materials to create devices with both high power and energy density. CEA's hybrid supercapacitors utilize a unique asymmetric configuration with activated carbon cathodes and lithium titanate anodes, enabling operation at higher voltages (up to 3.5V) than conventional supercapacitors. The organization has pioneered ionic liquid electrolytes that remain stable at elevated temperatures and voltages, significantly enhancing safety and performance. For portable electronics, CEA has developed thin-film hybrid supercapacitors using microfabrication techniques that can be directly integrated onto silicon substrates, enabling on-chip energy storage with power densities exceeding 1000 W/cm³. Their technology demonstrates exceptional cycle stability, maintaining over 90% capacity after 20,000 charge-discharge cycles, and can operate effectively across a wide temperature range (-30°C to 70°C). CEA has also developed self-healing electrode materials that can recover from microfractures during cycling, significantly extending device lifespan.

Strengths: Exceptional temperature stability; superior safety characteristics with non-flammable electrolytes; excellent integration potential with semiconductor manufacturing; very high cycle life suitable for long-term deployment. Weaknesses: Lower energy density compared to commercial lithium-ion batteries; higher manufacturing complexity; specialized materials requirements increase costs; limited commercial-scale production experience.

Core Patents and Research in Hybrid Supercapacitor Technology

High energy hybrid supercapacitors using lithium metal powders

PatentInactiveUS20120212879A1

Innovation

- A hybrid supercapacitor design featuring a negative electrode with air-stable lithium metal powder coated on the surface, combined with high surface area activated carbon positive electrodes and a non-aqueous lithium salt electrolyte, eliminating the need for lithium pre-doping and simplifying the manufacturing process.

Supercapacitor comprising nanostructure of a metal-chalcogen compound

PatentWO2024209476A1

Innovation

- A hybrid supercapacitor design incorporating a first electrode with a carbon-based material and a nanostructure of a metal-chalcogen compound, such as Cu, V, Ni, Fe, Mn, and Sn, combined with a second electrode featuring a similar carbon-based material and nanostructure, utilizing electrolytes like KOH or NaOH, to enhance energy storage capabilities.

Environmental Impact and Sustainability Considerations

The integration of hybrid supercapacitors in portable electronics presents significant environmental implications that warrant careful consideration. These devices offer promising sustainability advantages compared to traditional energy storage solutions, particularly lithium-ion batteries. The manufacturing process of hybrid supercapacitors typically requires fewer rare earth elements and toxic materials, reducing the environmental footprint associated with resource extraction and processing. This characteristic is particularly valuable as global concerns about resource depletion and mining impacts continue to intensify.

The extended cycle life of hybrid supercapacitors—often exceeding 100,000 charge-discharge cycles compared to 500-1,000 cycles for conventional batteries—substantially reduces electronic waste generation. This longevity translates to fewer replacement units and consequently less manufacturing-related pollution over the product lifecycle. Additionally, the absence or reduced concentration of toxic heavy metals like cadmium and lead in many hybrid supercapacitor designs mitigates end-of-life disposal concerns.

Energy efficiency represents another critical environmental advantage of hybrid supercapacitors. Their rapid charging capabilities and lower internal resistance result in reduced energy losses during operation. Studies indicate that hybrid supercapacitors can achieve energy conversion efficiencies exceeding 95% in optimal conditions, compared to 70-85% for typical lithium-ion batteries. This efficiency improvement, when scaled across millions of portable electronic devices, could yield substantial reductions in global energy consumption.

Carbon footprint analyses of hybrid supercapacitor production reveal mixed results. While certain manufacturing processes may require high energy inputs, the extended operational lifespan often compensates for initial environmental costs. Recent life cycle assessments suggest that hybrid supercapacitors can achieve carbon payback within 1-3 years of operation in portable electronics applications, depending on usage patterns and energy sources.

Water consumption and pollution present ongoing challenges in hybrid supercapacitor production. Electrode manufacturing and electrolyte preparation processes can involve water-intensive steps and potentially hazardous chemicals. Industry leaders are actively developing water recycling systems and less toxic electrolyte formulations to address these concerns. Closed-loop manufacturing initiatives have demonstrated water usage reductions of up to 60% in pilot facilities.

Recycling infrastructure for hybrid supercapacitors remains underdeveloped compared to established battery recycling channels. The composite nature of these devices—often combining carbon materials, metal oxides, and specialized electrolytes—creates separation challenges in conventional recycling processes. However, emerging specialized recycling technologies show promise for recovering valuable materials while minimizing environmental impact, with material recovery rates approaching 85% in advanced facilities.

The extended cycle life of hybrid supercapacitors—often exceeding 100,000 charge-discharge cycles compared to 500-1,000 cycles for conventional batteries—substantially reduces electronic waste generation. This longevity translates to fewer replacement units and consequently less manufacturing-related pollution over the product lifecycle. Additionally, the absence or reduced concentration of toxic heavy metals like cadmium and lead in many hybrid supercapacitor designs mitigates end-of-life disposal concerns.

Energy efficiency represents another critical environmental advantage of hybrid supercapacitors. Their rapid charging capabilities and lower internal resistance result in reduced energy losses during operation. Studies indicate that hybrid supercapacitors can achieve energy conversion efficiencies exceeding 95% in optimal conditions, compared to 70-85% for typical lithium-ion batteries. This efficiency improvement, when scaled across millions of portable electronic devices, could yield substantial reductions in global energy consumption.

Carbon footprint analyses of hybrid supercapacitor production reveal mixed results. While certain manufacturing processes may require high energy inputs, the extended operational lifespan often compensates for initial environmental costs. Recent life cycle assessments suggest that hybrid supercapacitors can achieve carbon payback within 1-3 years of operation in portable electronics applications, depending on usage patterns and energy sources.

Water consumption and pollution present ongoing challenges in hybrid supercapacitor production. Electrode manufacturing and electrolyte preparation processes can involve water-intensive steps and potentially hazardous chemicals. Industry leaders are actively developing water recycling systems and less toxic electrolyte formulations to address these concerns. Closed-loop manufacturing initiatives have demonstrated water usage reductions of up to 60% in pilot facilities.

Recycling infrastructure for hybrid supercapacitors remains underdeveloped compared to established battery recycling channels. The composite nature of these devices—often combining carbon materials, metal oxides, and specialized electrolytes—creates separation challenges in conventional recycling processes. However, emerging specialized recycling technologies show promise for recovering valuable materials while minimizing environmental impact, with material recovery rates approaching 85% in advanced facilities.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of hybrid supercapacitors represents a critical factor in their widespread adoption for portable electronics applications. Current production methods primarily utilize roll-to-roll processing techniques, which have demonstrated reasonable throughput rates but face challenges in maintaining consistent quality across large production volumes. Material sourcing presents another significant consideration, with electrode materials like activated carbon and transition metal oxides requiring specialized processing that impacts overall manufacturing efficiency. The integration of nanomaterials, while beneficial for performance, introduces additional complexity in maintaining uniform dispersion during mass production.

Cost analysis reveals that hybrid supercapacitors currently command a premium of approximately 30-40% over conventional capacitors when normalized by energy storage capacity. Raw material costs constitute 45-55% of the total manufacturing expense, with specialized electrode materials and electrolytes representing the most significant contributors. Labor costs vary substantially by production region, with manufacturing facilities in Southeast Asia offering 30-40% cost advantages compared to Western facilities, though often with trade-offs in automation levels and quality control.

Energy consumption during manufacturing presents another substantial cost factor, particularly in the high-temperature treatment processes required for certain electrode materials. Recent innovations in low-temperature synthesis methods have demonstrated potential to reduce energy requirements by 25-30%, though these approaches remain in early implementation stages. Equipment depreciation and facility overhead typically account for 15-20% of unit costs, with economies of scale becoming evident only at production volumes exceeding 100,000 units monthly.

Yield rates present ongoing challenges, with industry averages hovering between 85-92% for high-quality hybrid supercapacitors suitable for portable electronics. Defect rates increase notably when manufacturing tolerances are tightened to meet the demanding specifications of premium consumer electronics. Quality control processes, particularly those involving electrical performance testing, add approximately 8-12% to the final unit cost but remain essential for ensuring reliability in consumer applications.

Future cost reduction pathways primarily center on materials innovation, with research focusing on abundant, low-cost alternatives to current electrode materials. Manufacturing process optimization through increased automation and improved in-line quality monitoring systems offers potential for both cost reduction and quality improvement. Industry forecasts suggest that with continued investment in manufacturing technology, production costs could decrease by 15-25% over the next three to five years, potentially positioning hybrid supercapacitors as economically competitive alternatives to certain battery technologies in specific portable electronics applications.

Cost analysis reveals that hybrid supercapacitors currently command a premium of approximately 30-40% over conventional capacitors when normalized by energy storage capacity. Raw material costs constitute 45-55% of the total manufacturing expense, with specialized electrode materials and electrolytes representing the most significant contributors. Labor costs vary substantially by production region, with manufacturing facilities in Southeast Asia offering 30-40% cost advantages compared to Western facilities, though often with trade-offs in automation levels and quality control.

Energy consumption during manufacturing presents another substantial cost factor, particularly in the high-temperature treatment processes required for certain electrode materials. Recent innovations in low-temperature synthesis methods have demonstrated potential to reduce energy requirements by 25-30%, though these approaches remain in early implementation stages. Equipment depreciation and facility overhead typically account for 15-20% of unit costs, with economies of scale becoming evident only at production volumes exceeding 100,000 units monthly.

Yield rates present ongoing challenges, with industry averages hovering between 85-92% for high-quality hybrid supercapacitors suitable for portable electronics. Defect rates increase notably when manufacturing tolerances are tightened to meet the demanding specifications of premium consumer electronics. Quality control processes, particularly those involving electrical performance testing, add approximately 8-12% to the final unit cost but remain essential for ensuring reliability in consumer applications.

Future cost reduction pathways primarily center on materials innovation, with research focusing on abundant, low-cost alternatives to current electrode materials. Manufacturing process optimization through increased automation and improved in-line quality monitoring systems offers potential for both cost reduction and quality improvement. Industry forecasts suggest that with continued investment in manufacturing technology, production costs could decrease by 15-25% over the next three to five years, potentially positioning hybrid supercapacitors as economically competitive alternatives to certain battery technologies in specific portable electronics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!