Comparative Study on Hybrid Supercapacitors and Flywheel Storage

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Storage Background and Objectives

Energy storage technologies have evolved significantly over the past decades, driven by the increasing demand for efficient, reliable, and sustainable power management solutions. The global energy landscape is undergoing a profound transformation, shifting from fossil fuel-based systems to renewable energy sources. This transition necessitates advanced energy storage systems capable of addressing the intermittent nature of renewable energy generation, grid stability challenges, and the growing electrification of transportation and industrial sectors.

Hybrid supercapacitors and flywheel storage represent two distinct yet promising approaches to energy storage, each with unique characteristics and applications. Hybrid supercapacitors combine the high energy density of batteries with the superior power density and cycle life of traditional supercapacitors, offering a balanced solution for various applications. Meanwhile, flywheel energy storage systems (FESS) utilize rotational kinetic energy to store and deliver power, providing exceptional cycle life, rapid response times, and minimal environmental impact.

The historical development of these technologies reveals interesting trajectories. Supercapacitors emerged in the mid-20th century, with significant advancements in electrode materials and electrolytes occurring in the 1990s and 2000s. Hybrid variants began gaining traction in the early 2010s as researchers sought to overcome the energy density limitations of conventional supercapacitors. Flywheel technology, though conceptually ancient, saw revolutionary improvements in the late 20th century with the introduction of advanced materials, magnetic bearings, and vacuum enclosures, dramatically enhancing performance and safety.

Current technological trends indicate accelerating development in both fields. For hybrid supercapacitors, research focuses on novel electrode materials, electrolyte formulations, and structural designs to further improve energy density while maintaining the inherent advantages of supercapacitors. Flywheel technology is advancing through innovations in composite materials, bearing systems, and power electronics, enabling higher energy densities and reduced losses.

The primary objective of this comparative study is to comprehensively evaluate the technical characteristics, performance metrics, application suitability, and future potential of hybrid supercapacitors and flywheel storage technologies. This analysis aims to identify the strengths, limitations, and complementary aspects of these technologies across various use cases, including grid stabilization, renewable energy integration, transportation, and industrial applications.

Furthermore, this study seeks to establish a framework for assessing the economic viability, environmental impact, and scalability of these technologies, providing valuable insights for strategic decision-making in technology development, investment prioritization, and market deployment strategies.

Hybrid supercapacitors and flywheel storage represent two distinct yet promising approaches to energy storage, each with unique characteristics and applications. Hybrid supercapacitors combine the high energy density of batteries with the superior power density and cycle life of traditional supercapacitors, offering a balanced solution for various applications. Meanwhile, flywheel energy storage systems (FESS) utilize rotational kinetic energy to store and deliver power, providing exceptional cycle life, rapid response times, and minimal environmental impact.

The historical development of these technologies reveals interesting trajectories. Supercapacitors emerged in the mid-20th century, with significant advancements in electrode materials and electrolytes occurring in the 1990s and 2000s. Hybrid variants began gaining traction in the early 2010s as researchers sought to overcome the energy density limitations of conventional supercapacitors. Flywheel technology, though conceptually ancient, saw revolutionary improvements in the late 20th century with the introduction of advanced materials, magnetic bearings, and vacuum enclosures, dramatically enhancing performance and safety.

Current technological trends indicate accelerating development in both fields. For hybrid supercapacitors, research focuses on novel electrode materials, electrolyte formulations, and structural designs to further improve energy density while maintaining the inherent advantages of supercapacitors. Flywheel technology is advancing through innovations in composite materials, bearing systems, and power electronics, enabling higher energy densities and reduced losses.

The primary objective of this comparative study is to comprehensively evaluate the technical characteristics, performance metrics, application suitability, and future potential of hybrid supercapacitors and flywheel storage technologies. This analysis aims to identify the strengths, limitations, and complementary aspects of these technologies across various use cases, including grid stabilization, renewable energy integration, transportation, and industrial applications.

Furthermore, this study seeks to establish a framework for assessing the economic viability, environmental impact, and scalability of these technologies, providing valuable insights for strategic decision-making in technology development, investment prioritization, and market deployment strategies.

Market Analysis for Hybrid Energy Storage Solutions

The global hybrid energy storage market is experiencing significant growth, driven by increasing demand for reliable and efficient energy storage solutions across various sectors. The market size for hybrid energy storage systems combining supercapacitors and flywheel technologies was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2030, representing a compound annual growth rate of 14.3%.

Renewable energy integration represents the largest application segment, accounting for nearly 40% of the market share. As intermittent renewable sources like solar and wind continue to expand globally, the need for responsive storage solutions capable of managing fluctuations has become critical. Hybrid systems that combine the rapid response capabilities of supercapacitors with the high-capacity attributes of flywheels are particularly valuable in this context.

The transportation sector constitutes the second-largest market segment at 25%, with significant adoption in electric vehicles, railway systems, and maritime applications. The ability of hybrid storage systems to manage peak power demands while extending battery life has made them increasingly attractive to vehicle manufacturers seeking to optimize performance and reduce costs.

Regional analysis reveals that Asia-Pacific currently leads the market with 38% share, driven by China's aggressive renewable energy deployment and manufacturing capabilities. North America follows at 30%, with strong growth in grid stabilization applications and electric vehicle infrastructure. Europe accounts for 25% of the market, with particularly strong adoption in countries with advanced renewable energy policies such as Germany and Denmark.

Key customer segments include utility companies seeking grid stabilization solutions, renewable energy developers requiring storage for intermittent generation, transportation manufacturers, and industrial facilities with high-power applications. Each segment demonstrates distinct requirements regarding power capacity, response time, and cycle life, driving diversification in hybrid storage system designs.

Market barriers include high initial capital costs, with hybrid systems typically commanding a 30-40% premium over single-technology solutions. Technical complexity in system integration and control algorithms also presents challenges for widespread adoption. However, these barriers are gradually diminishing as manufacturing scales up and system integration expertise becomes more widespread.

The competitive landscape features both established energy storage providers expanding their portfolios and specialized startups focusing exclusively on hybrid solutions. Strategic partnerships between technology providers and system integrators have become increasingly common as the market matures.

Renewable energy integration represents the largest application segment, accounting for nearly 40% of the market share. As intermittent renewable sources like solar and wind continue to expand globally, the need for responsive storage solutions capable of managing fluctuations has become critical. Hybrid systems that combine the rapid response capabilities of supercapacitors with the high-capacity attributes of flywheels are particularly valuable in this context.

The transportation sector constitutes the second-largest market segment at 25%, with significant adoption in electric vehicles, railway systems, and maritime applications. The ability of hybrid storage systems to manage peak power demands while extending battery life has made them increasingly attractive to vehicle manufacturers seeking to optimize performance and reduce costs.

Regional analysis reveals that Asia-Pacific currently leads the market with 38% share, driven by China's aggressive renewable energy deployment and manufacturing capabilities. North America follows at 30%, with strong growth in grid stabilization applications and electric vehicle infrastructure. Europe accounts for 25% of the market, with particularly strong adoption in countries with advanced renewable energy policies such as Germany and Denmark.

Key customer segments include utility companies seeking grid stabilization solutions, renewable energy developers requiring storage for intermittent generation, transportation manufacturers, and industrial facilities with high-power applications. Each segment demonstrates distinct requirements regarding power capacity, response time, and cycle life, driving diversification in hybrid storage system designs.

Market barriers include high initial capital costs, with hybrid systems typically commanding a 30-40% premium over single-technology solutions. Technical complexity in system integration and control algorithms also presents challenges for widespread adoption. However, these barriers are gradually diminishing as manufacturing scales up and system integration expertise becomes more widespread.

The competitive landscape features both established energy storage providers expanding their portfolios and specialized startups focusing exclusively on hybrid solutions. Strategic partnerships between technology providers and system integrators have become increasingly common as the market matures.

Technical Challenges in Supercapacitors and Flywheel Systems

Despite significant advancements in energy storage technologies, both supercapacitors and flywheel systems face substantial technical challenges that limit their widespread adoption. Supercapacitors struggle with energy density limitations, typically achieving only 5-10 Wh/kg compared to lithium-ion batteries' 100-265 Wh/kg. This fundamental constraint restricts their application in scenarios requiring sustained power delivery over extended periods.

Material science presents another significant hurdle for supercapacitors. Current electrode materials, predominantly activated carbon, graphene, and metal oxides, exhibit performance trade-offs between power density, energy density, and cycle life. Novel materials like MXenes and metal-organic frameworks show promise but face scalability and stability issues in commercial applications.

Self-discharge rates remain problematic for supercapacitors, with many devices losing 10-20% of their stored energy within 24 hours. This phenomenon, caused by faradaic reactions and ion redistribution within the electrolyte, severely impacts their viability for long-term energy storage applications.

Flywheel energy storage systems encounter distinct technical barriers. Mechanical bearing systems generate friction that causes energy losses of 1-2% per hour in conventional designs. While magnetic bearings reduce these losses, they introduce complexity and cost, requiring sophisticated control systems to maintain stable levitation.

Material strength limitations constrain flywheel energy density, as rotational speed is capped by the tensile strength of rotor materials. Current carbon fiber composites can withstand approximately 2,000-3,000 MPa, but theoretical designs require materials exceeding 5,000 MPa for significant energy density improvements.

Safety concerns present another major challenge for flywheel systems. Catastrophic failure modes can result in explosive fragmentation if containment systems are inadequate. This necessitates robust containment structures that add significant weight and cost to the overall system.

Hybrid supercapacitor-flywheel systems face integration challenges related to power electronics and control systems. Efficiently managing power flow between these technologies with different response characteristics requires sophisticated power conversion systems with minimal losses. Current power electronics typically introduce 3-5% efficiency losses during each conversion step.

Thermal management presents challenges for both technologies. Supercapacitors experience performance degradation at temperature extremes, while flywheels generate heat through air resistance and bearing friction. Effective cooling systems add complexity and parasitic energy losses to both technologies.

Cost remains perhaps the most significant barrier to widespread adoption. Current supercapacitor costs range from $10,000-20,000 per kWh, while flywheel systems typically cost $1,000-5,000 per kW, significantly higher than competing technologies like lithium-ion batteries at $200-300 per kWh.

Material science presents another significant hurdle for supercapacitors. Current electrode materials, predominantly activated carbon, graphene, and metal oxides, exhibit performance trade-offs between power density, energy density, and cycle life. Novel materials like MXenes and metal-organic frameworks show promise but face scalability and stability issues in commercial applications.

Self-discharge rates remain problematic for supercapacitors, with many devices losing 10-20% of their stored energy within 24 hours. This phenomenon, caused by faradaic reactions and ion redistribution within the electrolyte, severely impacts their viability for long-term energy storage applications.

Flywheel energy storage systems encounter distinct technical barriers. Mechanical bearing systems generate friction that causes energy losses of 1-2% per hour in conventional designs. While magnetic bearings reduce these losses, they introduce complexity and cost, requiring sophisticated control systems to maintain stable levitation.

Material strength limitations constrain flywheel energy density, as rotational speed is capped by the tensile strength of rotor materials. Current carbon fiber composites can withstand approximately 2,000-3,000 MPa, but theoretical designs require materials exceeding 5,000 MPa for significant energy density improvements.

Safety concerns present another major challenge for flywheel systems. Catastrophic failure modes can result in explosive fragmentation if containment systems are inadequate. This necessitates robust containment structures that add significant weight and cost to the overall system.

Hybrid supercapacitor-flywheel systems face integration challenges related to power electronics and control systems. Efficiently managing power flow between these technologies with different response characteristics requires sophisticated power conversion systems with minimal losses. Current power electronics typically introduce 3-5% efficiency losses during each conversion step.

Thermal management presents challenges for both technologies. Supercapacitors experience performance degradation at temperature extremes, while flywheels generate heat through air resistance and bearing friction. Effective cooling systems add complexity and parasitic energy losses to both technologies.

Cost remains perhaps the most significant barrier to widespread adoption. Current supercapacitor costs range from $10,000-20,000 per kWh, while flywheel systems typically cost $1,000-5,000 per kW, significantly higher than competing technologies like lithium-ion batteries at $200-300 per kWh.

Current Hybrid Supercapacitor and Flywheel Solutions

01 Integration of hybrid supercapacitors with flywheel energy storage systems

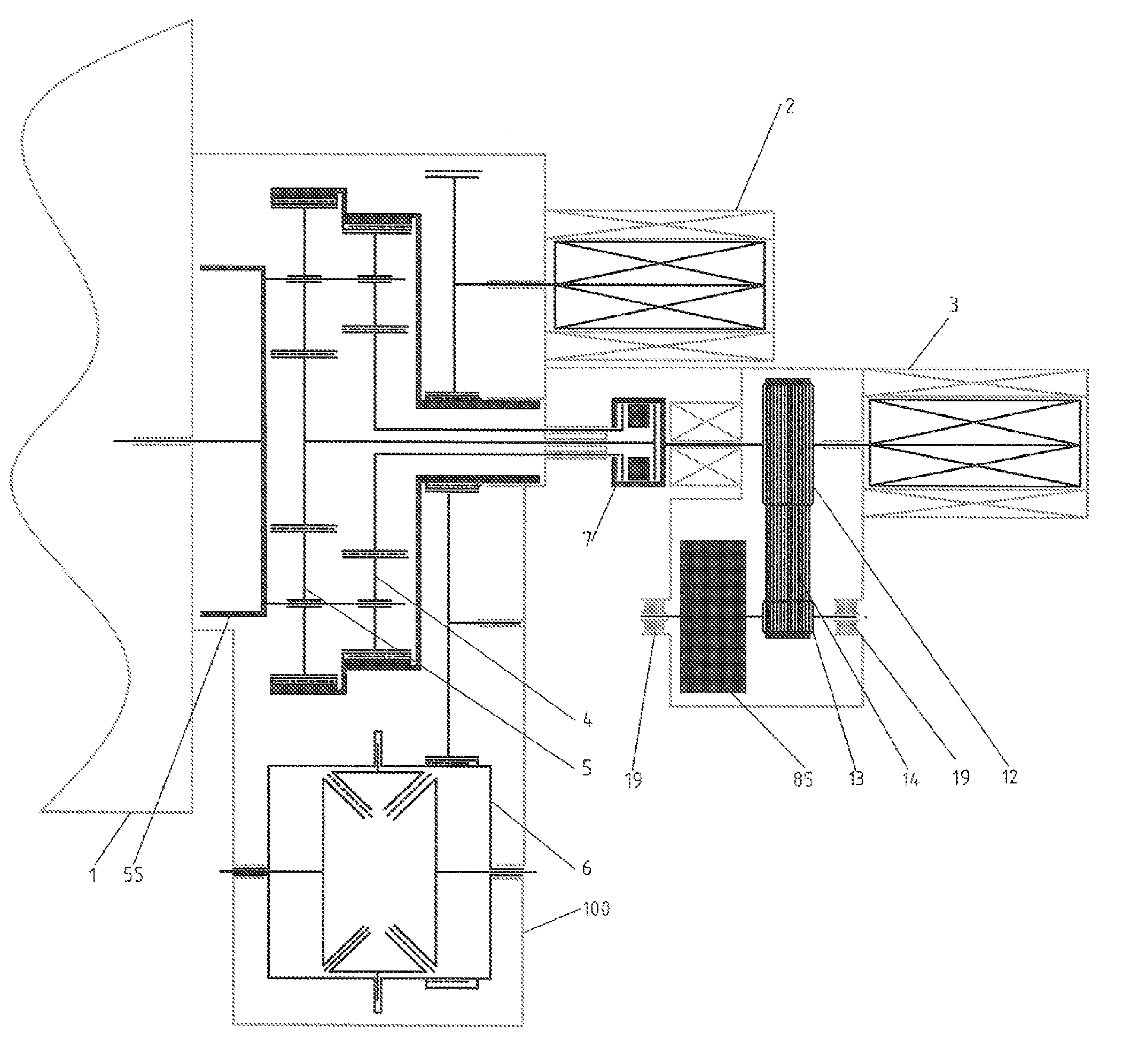

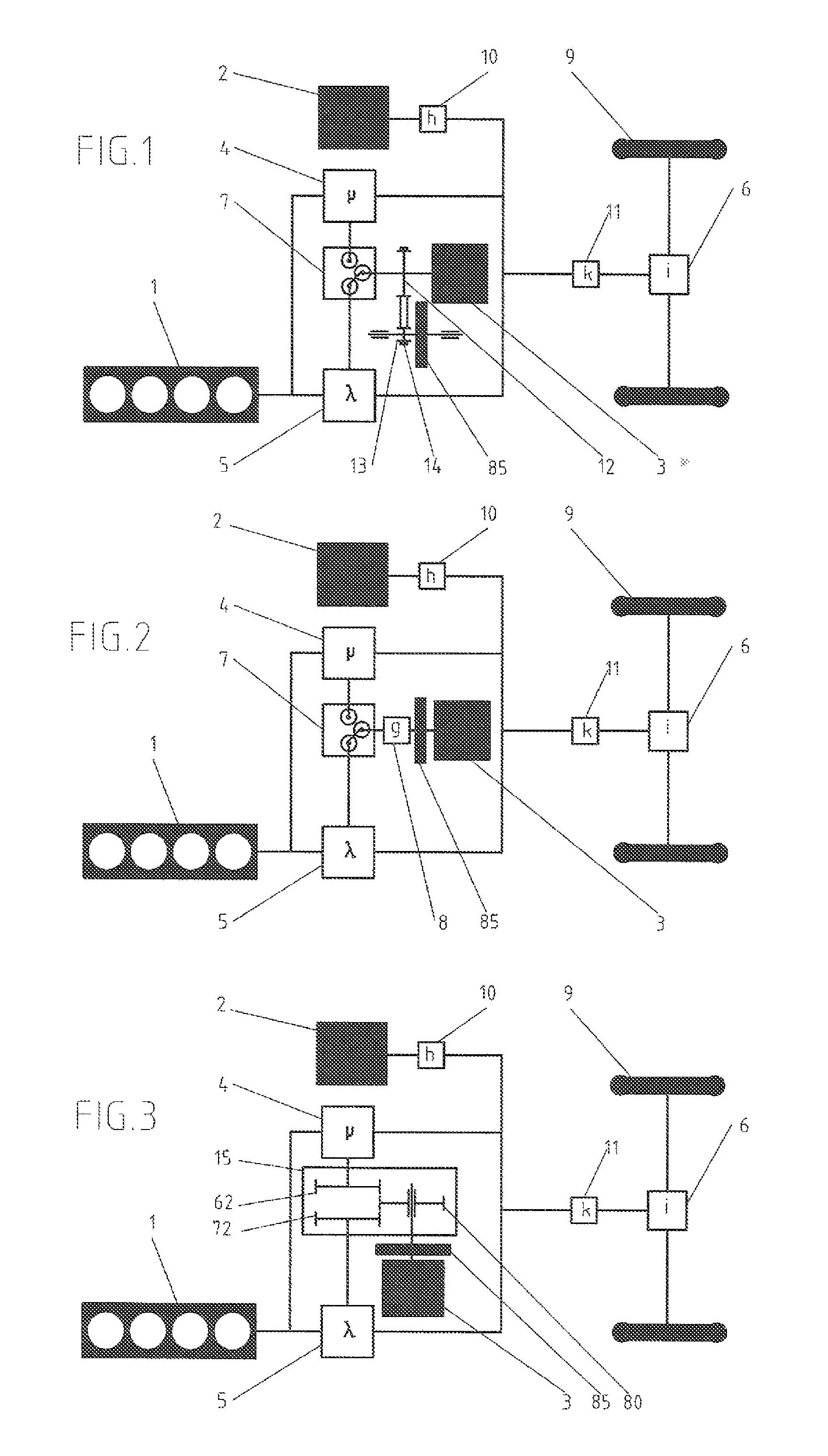

Hybrid energy storage systems that combine supercapacitors with flywheel technology offer complementary benefits. Supercapacitors provide rapid energy discharge and high power density, while flywheels offer high energy density and long-term storage capabilities. This integration creates more efficient and reliable energy storage solutions for applications requiring both quick response times and sustained power delivery. The combined system can better manage peak loads, improve energy recovery, and provide backup power with enhanced overall system efficiency.- Integration of hybrid supercapacitors with flywheel energy storage systems: Hybrid energy storage systems that combine supercapacitors with flywheel technology offer complementary benefits. Supercapacitors provide rapid energy discharge and high power density, while flywheels deliver sustained energy storage with high cycle life. This integration creates more efficient and reliable energy storage solutions for applications requiring both quick response times and extended energy delivery, such as in electric vehicles, renewable energy systems, and grid stabilization.

- Vehicle applications of hybrid supercapacitor-flywheel systems: Hybrid supercapacitor-flywheel systems are particularly valuable in vehicle applications, where they can capture and store braking energy while providing rapid power delivery for acceleration. These systems help improve fuel efficiency, reduce emissions, and enhance overall vehicle performance. The combination allows for better energy management in electric, hybrid, and conventional vehicles by balancing immediate power needs with longer-term energy storage requirements.

- Grid stabilization and renewable energy integration: Hybrid supercapacitor-flywheel systems provide effective solutions for grid stabilization and renewable energy integration. These systems can respond rapidly to fluctuations in power supply and demand, making them ideal for frequency regulation and voltage support. When connected to renewable energy sources like wind and solar, they can store excess energy during peak production periods and release it during low production times, helping to smooth out the intermittent nature of renewable energy generation.

- Advanced control systems for hybrid energy storage: Sophisticated control systems are essential for optimizing the performance of hybrid supercapacitor-flywheel storage systems. These control systems manage energy flow between components, determine optimal charging and discharging cycles, and ensure system stability under varying load conditions. Advanced algorithms can predict energy demands, prioritize power sources based on efficiency parameters, and extend the operational life of the system by preventing excessive cycling of individual components.

- Thermal management and efficiency improvements: Effective thermal management is crucial for maintaining the efficiency and longevity of hybrid supercapacitor-flywheel systems. Heat generation during rapid charge/discharge cycles and mechanical friction in flywheels must be carefully managed. Innovative cooling systems, low-friction bearings, and vacuum enclosures for flywheels can significantly improve system efficiency. Additionally, advanced materials for supercapacitor electrodes and flywheel rotors contribute to higher energy density, reduced losses, and improved overall system performance.

02 Vehicle applications of hybrid supercapacitor-flywheel systems

Hybrid supercapacitor-flywheel energy storage systems are particularly valuable in vehicle applications, including electric and hybrid electric vehicles. These systems can capture and store regenerative braking energy more efficiently, with supercapacitors handling rapid charge/discharge cycles and flywheels providing longer-term energy storage. This combination improves vehicle range, acceleration performance, and overall energy efficiency. The technology is especially beneficial for vehicles with frequent start-stop cycles, such as urban buses, delivery vehicles, and performance automobiles.Expand Specific Solutions03 Grid stabilization and renewable energy integration

Hybrid supercapacitor-flywheel systems play a crucial role in grid stabilization and renewable energy integration. These systems can respond rapidly to fluctuations in power supply and demand, making them ideal for frequency regulation and voltage support in electrical grids. When paired with renewable energy sources like solar and wind, which have inherent intermittency issues, these hybrid storage systems can smooth power output, store excess energy during peak production periods, and release it during high demand or low production periods, thereby enhancing grid reliability and facilitating higher renewable energy penetration.Expand Specific Solutions04 Advanced control systems for hybrid energy storage

Sophisticated control systems are essential for optimizing the performance of hybrid supercapacitor-flywheel energy storage systems. These control systems manage power flow between different storage components, determine optimal charging and discharging strategies, and ensure system stability under various operating conditions. Advanced algorithms can predict energy demands, prioritize storage methods based on current needs, and maximize overall system efficiency. These control systems often incorporate machine learning techniques to adapt to changing conditions and improve performance over time.Expand Specific Solutions05 Thermal management and safety enhancements

Effective thermal management is critical for hybrid supercapacitor-flywheel systems to ensure optimal performance and safety. Heat generation during rapid charge/discharge cycles in supercapacitors and friction in flywheel bearings must be carefully managed. Advanced cooling systems, temperature monitoring, and thermal insulation techniques are employed to maintain operational efficiency and prevent overheating. Safety features include containment systems for flywheels, electrical isolation for supercapacitors, and comprehensive monitoring systems that can detect and respond to potential failure modes, ensuring reliable operation in various applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hybrid supercapacitor and flywheel energy storage market is in a growth phase, with increasing adoption driven by the global shift toward renewable energy integration and grid stability needs. The market size is expanding rapidly, projected to reach significant scale as energy storage becomes critical for sustainable power systems. Technologically, flywheel systems are more mature, with companies like Beacon Power and Helix Power leading commercial deployments, while hybrid supercapacitors are advancing through research efforts at institutions like North China Electric Power University and Huazhong University. Major utilities including Korea Electric Power Corp. and State Grid Corp. of China are investing in both technologies, while automotive players such as Porsche AG and Boeing are exploring high-performance applications. The competitive landscape features established players and innovative startups developing complementary solutions for different market segments.

Helix Power Corp.

Technical Solution: Helix Power has pioneered high-power flywheel energy storage systems focused on grid stabilization and power quality applications. Their proprietary technology utilizes carbon fiber composite flywheels operating at ultra-high speeds (up to 60,000 RPM) in vacuum-sealed containment systems. Helix's flywheels employ advanced magnetic bearings that eliminate mechanical contact, dramatically reducing friction losses and maintenance requirements. The company's modular design approach allows for scalable deployment, with each unit capable of delivering 1MW of power for short durations (15-30 seconds). This makes them particularly suitable for applications requiring high power but relatively low energy, such as voltage sag correction, frequency regulation, and bridging power during switching between power sources. Helix's systems feature sophisticated power electronics that enable precise control of power flow and near-instantaneous response times (under 4 milliseconds), providing critical grid support services that conventional generation cannot match.

Strengths: Extremely rapid response time (milliseconds), very high power density, virtually unlimited cycle life with minimal degradation, and ability to provide both power absorption and delivery. Weaknesses: Limited energy storage duration (seconds to minutes rather than hours), higher upfront capital costs compared to some competing technologies, and specialized installation requirements.

Beacon Power LLC

Technical Solution: Beacon Power has developed advanced flywheel energy storage systems specifically designed for grid frequency regulation and renewable energy integration. Their flagship technology utilizes carbon fiber composite flywheels that spin at speeds of 16,000 RPM in a vacuum environment to minimize friction losses. The company's Smart Energy Matrix system consists of multiple 100kW/25kWh flywheel units arranged in arrays that can provide up to 20MW of frequency regulation capacity. Beacon's flywheels use permanent magnet synchronous machines operating as motor-generators, with advanced magnetic bearings that virtually eliminate mechanical friction. Their systems can respond to grid signals in less than 4 seconds, providing both up and down regulation with round-trip efficiencies exceeding 85%. The technology is particularly valuable for grid stabilization as it can cycle frequently (up to 175,000 full charge-discharge cycles) without degradation, making it ideal for the rapid response needed in frequency regulation markets.

Strengths: Extremely fast response time (milliseconds), long cycle life (15+ years/175,000+ cycles), high round-trip efficiency (85%+), and zero degradation regardless of depth of discharge. Weaknesses: Higher initial capital costs compared to some battery technologies, limited energy density making it less suitable for long-duration storage, and requires sophisticated control systems and specialized manufacturing.

Key Patents and Innovations in Energy Storage

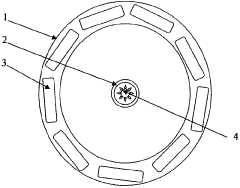

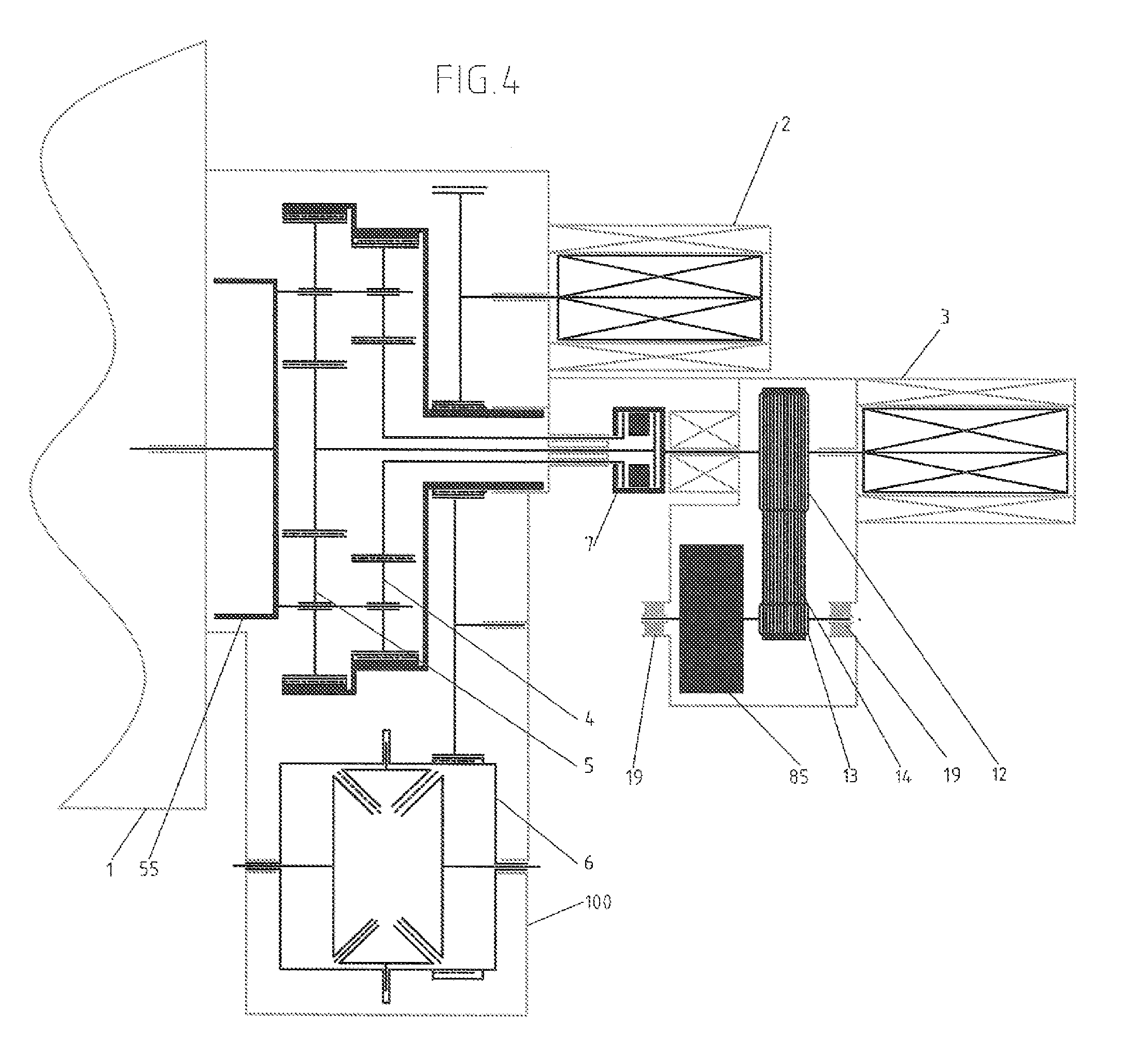

Flywheel hybrid energy storage system

PatentInactiveGB2458532A

Innovation

- A flywheel hybrid energy storage system that integrates a rotating disc rotor for kinetic energy storage and an electrical energy storage system at the rim, allowing for dual energy storage and conversion between kinetic and electrical forms.

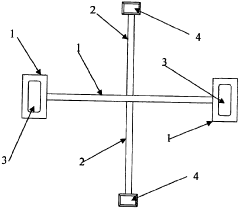

Flywheel to recover kinetic energy for hybrid vehicle which has two planetary gears mechanisms for power derivation

PatentInactiveUS8840499B2

Innovation

- A double planetary gears mechanism is used to improve energy storage by coupling a high-inertia generator or flywheel to the rotor, allowing for efficient energy transfer and storage, with a gear selector to manage vehicle modes and torque protection, and integrating the flywheel into the generator housing to reduce weight and cost.

Environmental Impact Assessment

The environmental impact assessment of hybrid supercapacitors and flywheel storage systems reveals significant differences in their ecological footprints throughout their lifecycle. Hybrid supercapacitors, combining features of traditional capacitors and batteries, generally demonstrate lower environmental impacts during operation due to their non-toxic materials and absence of harmful chemicals. The primary materials used in supercapacitors—activated carbon, metal oxides, and electrolytes—have relatively low extraction impacts compared to traditional battery materials like lithium and cobalt.

Flywheel storage systems, conversely, rely heavily on composite materials, specialized metals, and precision engineering components. Their manufacturing process requires substantial energy input and generates a higher carbon footprint initially. However, flywheels compensate for this during their operational phase, as they can undergo significantly more charge-discharge cycles (often exceeding 100,000 cycles) compared to hybrid supercapacitors (typically 10,000-20,000 cycles), extending their functional lifespan considerably.

Both technologies offer substantial environmental advantages over conventional battery technologies regarding end-of-life management. Hybrid supercapacitors contain fewer toxic substances and hazardous materials, making recycling processes less complex and environmentally damaging. The carbon-based materials can be recovered and repurposed with relatively straightforward processes. Flywheels present even greater advantages in this regard, as their components—primarily metal and composite materials—are highly recyclable with established industrial processes.

Energy efficiency metrics further differentiate these technologies from an environmental perspective. Hybrid supercapacitors typically achieve 90-95% round-trip efficiency, while advanced flywheel systems can reach 85-90%. This slight efficiency advantage for supercapacitors translates to lower energy losses and reduced operational carbon footprints in grid-scale applications.

Land use considerations also favor these technologies compared to pumped hydro or compressed air energy storage. Both hybrid supercapacitors and flywheel systems have compact footprints, with flywheels requiring specialized containment structures but minimal land area. This reduced spatial requirement minimizes habitat disruption and allows for installation in previously developed areas, decreasing the need for natural land conversion.

Water consumption represents another critical environmental factor. Unlike many conventional energy storage technologies that require significant water resources for cooling or operation, both hybrid supercapacitors and flywheels operate with minimal water requirements, reducing pressure on increasingly scarce freshwater resources in many regions globally.

Flywheel storage systems, conversely, rely heavily on composite materials, specialized metals, and precision engineering components. Their manufacturing process requires substantial energy input and generates a higher carbon footprint initially. However, flywheels compensate for this during their operational phase, as they can undergo significantly more charge-discharge cycles (often exceeding 100,000 cycles) compared to hybrid supercapacitors (typically 10,000-20,000 cycles), extending their functional lifespan considerably.

Both technologies offer substantial environmental advantages over conventional battery technologies regarding end-of-life management. Hybrid supercapacitors contain fewer toxic substances and hazardous materials, making recycling processes less complex and environmentally damaging. The carbon-based materials can be recovered and repurposed with relatively straightforward processes. Flywheels present even greater advantages in this regard, as their components—primarily metal and composite materials—are highly recyclable with established industrial processes.

Energy efficiency metrics further differentiate these technologies from an environmental perspective. Hybrid supercapacitors typically achieve 90-95% round-trip efficiency, while advanced flywheel systems can reach 85-90%. This slight efficiency advantage for supercapacitors translates to lower energy losses and reduced operational carbon footprints in grid-scale applications.

Land use considerations also favor these technologies compared to pumped hydro or compressed air energy storage. Both hybrid supercapacitors and flywheel systems have compact footprints, with flywheels requiring specialized containment structures but minimal land area. This reduced spatial requirement minimizes habitat disruption and allows for installation in previously developed areas, decreasing the need for natural land conversion.

Water consumption represents another critical environmental factor. Unlike many conventional energy storage technologies that require significant water resources for cooling or operation, both hybrid supercapacitors and flywheels operate with minimal water requirements, reducing pressure on increasingly scarce freshwater resources in many regions globally.

Grid Integration Strategies

The integration of hybrid supercapacitors and flywheel storage systems into existing power grids requires carefully designed strategies that address technical compatibility, operational efficiency, and economic viability. Grid operators must consider the unique characteristics of each technology when developing integration frameworks that maximize their respective advantages.

For hybrid supercapacitors, grid integration typically involves power electronic interfaces that can manage rapid charge and discharge cycles. These interfaces must be equipped with sophisticated control algorithms that respond to grid frequency fluctuations within milliseconds. The distributed deployment model works particularly well for supercapacitors, allowing them to be positioned at strategic points throughout the distribution network where voltage support is most needed.

Flywheel energy storage systems, conversely, are generally integrated at substation level due to their physical size and operational characteristics. Their integration requires robust mechanical-to-electrical conversion systems and specialized inverters capable of handling the high rotational energy. Grid operators have found success with modular flywheel arrays that can be scaled according to capacity requirements while maintaining system stability.

Both technologies benefit from advanced energy management systems (EMS) that optimize their operation within the broader grid context. These systems employ predictive algorithms to anticipate demand fluctuations and coordinate storage response accordingly. The integration architecture typically follows a hierarchical control structure, with local controllers managing individual storage units while communicating with central coordination systems.

Hybrid approaches that combine both technologies have demonstrated superior performance in field trials. Such configurations typically position flywheels as primary frequency response units, with supercapacitors providing ultra-fast power quality support. This complementary arrangement leverages the millisecond response time of supercapacitors alongside the sustained output capabilities of flywheels.

Regulatory frameworks significantly impact integration strategies, with grid codes increasingly recognizing the value of fast-response storage. Markets that have implemented capacity payments for ancillary services have seen accelerated adoption of these technologies. Forward-thinking utilities have developed specialized interconnection standards that streamline the integration process while ensuring system security and reliability.

Communication protocols represent another critical aspect of integration, with IEC 61850 emerging as the preferred standard for storage system interoperability. Real-time monitoring capabilities are essential for grid operators to maintain visibility of storage system status and performance metrics, enabling dynamic adjustment of control parameters as grid conditions evolve.

For hybrid supercapacitors, grid integration typically involves power electronic interfaces that can manage rapid charge and discharge cycles. These interfaces must be equipped with sophisticated control algorithms that respond to grid frequency fluctuations within milliseconds. The distributed deployment model works particularly well for supercapacitors, allowing them to be positioned at strategic points throughout the distribution network where voltage support is most needed.

Flywheel energy storage systems, conversely, are generally integrated at substation level due to their physical size and operational characteristics. Their integration requires robust mechanical-to-electrical conversion systems and specialized inverters capable of handling the high rotational energy. Grid operators have found success with modular flywheel arrays that can be scaled according to capacity requirements while maintaining system stability.

Both technologies benefit from advanced energy management systems (EMS) that optimize their operation within the broader grid context. These systems employ predictive algorithms to anticipate demand fluctuations and coordinate storage response accordingly. The integration architecture typically follows a hierarchical control structure, with local controllers managing individual storage units while communicating with central coordination systems.

Hybrid approaches that combine both technologies have demonstrated superior performance in field trials. Such configurations typically position flywheels as primary frequency response units, with supercapacitors providing ultra-fast power quality support. This complementary arrangement leverages the millisecond response time of supercapacitors alongside the sustained output capabilities of flywheels.

Regulatory frameworks significantly impact integration strategies, with grid codes increasingly recognizing the value of fast-response storage. Markets that have implemented capacity payments for ancillary services have seen accelerated adoption of these technologies. Forward-thinking utilities have developed specialized interconnection standards that streamline the integration process while ensuring system security and reliability.

Communication protocols represent another critical aspect of integration, with IEC 61850 emerging as the preferred standard for storage system interoperability. Real-time monitoring capabilities are essential for grid operators to maintain visibility of storage system status and performance metrics, enabling dynamic adjustment of control parameters as grid conditions evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!