How Are Hybrid Supercapacitors Transforming Power Backup Systems?

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant technological evolution in energy storage, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The development of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. The fundamental breakthrough came with the integration of battery-type electrodes with capacitor-type electrodes in a single device, creating a hybrid system that leverages the strengths of both technologies.

The evolution of hybrid supercapacitors has been marked by several key milestones. Initially, researchers focused on lithium-ion capacitors, which combined a battery-type anode with a capacitor-type cathode. This was followed by the development of various electrode materials including activated carbon, metal oxides, and conductive polymers, each offering specific advantages in terms of energy density, cycle life, or cost-effectiveness. Recent advancements have seen the incorporation of nanomaterials and novel electrolytes, further enhancing performance characteristics.

In the context of power backup systems, hybrid supercapacitors have evolved from supplementary components to central elements. Traditional backup systems relied heavily on lead-acid batteries or diesel generators, both presenting significant limitations in terms of response time, maintenance requirements, and environmental impact. The integration of hybrid supercapacitors has transformed these systems by providing rapid response capabilities, longer operational lifespans, and reduced environmental footprint.

The primary technical objectives for hybrid supercapacitors in power backup applications include achieving higher energy density while maintaining the rapid charge-discharge capabilities, extending operational temperature ranges to function in diverse environments, and enhancing cycle life to reduce replacement frequency and total cost of ownership. Additionally, researchers aim to develop more sustainable manufacturing processes and materials to minimize environmental impact throughout the product lifecycle.

Current research is focused on optimizing the electrode-electrolyte interface to improve charge transfer efficiency and stability. There is also significant interest in developing hybrid systems that can operate effectively in extreme conditions, such as high temperatures or corrosive environments, which are often encountered in industrial backup power applications. The integration of smart management systems represents another important objective, enabling more efficient energy utilization and predictive maintenance capabilities.

The long-term technological trajectory points toward fully integrated energy storage solutions that seamlessly combine hybrid supercapacitors with renewable energy sources and intelligent grid management systems. This evolution aims to create resilient, sustainable power backup infrastructures capable of supporting critical operations across various sectors including telecommunications, healthcare, data centers, and manufacturing.

The evolution of hybrid supercapacitors has been marked by several key milestones. Initially, researchers focused on lithium-ion capacitors, which combined a battery-type anode with a capacitor-type cathode. This was followed by the development of various electrode materials including activated carbon, metal oxides, and conductive polymers, each offering specific advantages in terms of energy density, cycle life, or cost-effectiveness. Recent advancements have seen the incorporation of nanomaterials and novel electrolytes, further enhancing performance characteristics.

In the context of power backup systems, hybrid supercapacitors have evolved from supplementary components to central elements. Traditional backup systems relied heavily on lead-acid batteries or diesel generators, both presenting significant limitations in terms of response time, maintenance requirements, and environmental impact. The integration of hybrid supercapacitors has transformed these systems by providing rapid response capabilities, longer operational lifespans, and reduced environmental footprint.

The primary technical objectives for hybrid supercapacitors in power backup applications include achieving higher energy density while maintaining the rapid charge-discharge capabilities, extending operational temperature ranges to function in diverse environments, and enhancing cycle life to reduce replacement frequency and total cost of ownership. Additionally, researchers aim to develop more sustainable manufacturing processes and materials to minimize environmental impact throughout the product lifecycle.

Current research is focused on optimizing the electrode-electrolyte interface to improve charge transfer efficiency and stability. There is also significant interest in developing hybrid systems that can operate effectively in extreme conditions, such as high temperatures or corrosive environments, which are often encountered in industrial backup power applications. The integration of smart management systems represents another important objective, enabling more efficient energy utilization and predictive maintenance capabilities.

The long-term technological trajectory points toward fully integrated energy storage solutions that seamlessly combine hybrid supercapacitors with renewable energy sources and intelligent grid management systems. This evolution aims to create resilient, sustainable power backup infrastructures capable of supporting critical operations across various sectors including telecommunications, healthcare, data centers, and manufacturing.

Market Demand Analysis for Advanced Power Backup Solutions

The global market for advanced power backup solutions is experiencing significant growth, driven by increasing concerns about grid reliability and the rising costs associated with power outages. According to recent market research, the global power backup systems market is projected to reach $32.6 billion by 2027, growing at a CAGR of 6.1% from 2022. Hybrid supercapacitors are emerging as a disruptive technology within this expanding market, addressing critical limitations of traditional backup power solutions.

Industrial sectors, particularly manufacturing, healthcare, data centers, and telecommunications, demonstrate the strongest demand for innovative power backup technologies. These industries require solutions that can provide instantaneous power during outages while maintaining operational continuity. The financial impact of power disruptions in these sectors can be substantial, with data centers experiencing average downtime costs of $9,000 per minute and manufacturing facilities facing losses of up to $1.7 million for a single power outage event.

Consumer awareness regarding energy security is also driving market growth in residential applications. The increasing frequency of extreme weather events and natural disasters has heightened concerns about reliable backup power systems for homes. This segment is expected to grow at 7.3% annually through 2027, representing a significant expansion opportunity for hybrid supercapacitor technologies.

Geographically, North America and Asia-Pacific regions lead in market demand, with Europe showing accelerated adoption rates due to stringent regulations on energy efficiency and carbon emissions. Developing economies in South Asia and Africa represent emerging markets with substantial growth potential, primarily driven by unreliable grid infrastructure and increasing industrialization.

Key market requirements identified through customer surveys and industry analyses include longer operational lifespans, reduced maintenance needs, faster response times, and improved energy density. Hybrid supercapacitors directly address these requirements by offering cycle lives exceeding 100,000 cycles (compared to 500-1,000 cycles for traditional batteries), response times in milliseconds, and energy densities approaching 15-20 Wh/kg.

Environmental considerations are increasingly influencing purchasing decisions, with 68% of industrial customers citing sustainability as a critical factor in selecting power backup solutions. Hybrid supercapacitors offer significant environmental advantages over lead-acid and lithium-ion batteries, including reduced toxic materials, lower carbon footprint during manufacturing, and enhanced recyclability.

Market analysis indicates that the total addressable market for hybrid supercapacitor-based backup systems could reach $5.8 billion by 2030, representing approximately 18% of the overall power backup solutions market. This growth trajectory is supported by declining production costs, which have decreased by 35% over the past five years, making hybrid supercapacitor technology increasingly competitive with traditional solutions.

Industrial sectors, particularly manufacturing, healthcare, data centers, and telecommunications, demonstrate the strongest demand for innovative power backup technologies. These industries require solutions that can provide instantaneous power during outages while maintaining operational continuity. The financial impact of power disruptions in these sectors can be substantial, with data centers experiencing average downtime costs of $9,000 per minute and manufacturing facilities facing losses of up to $1.7 million for a single power outage event.

Consumer awareness regarding energy security is also driving market growth in residential applications. The increasing frequency of extreme weather events and natural disasters has heightened concerns about reliable backup power systems for homes. This segment is expected to grow at 7.3% annually through 2027, representing a significant expansion opportunity for hybrid supercapacitor technologies.

Geographically, North America and Asia-Pacific regions lead in market demand, with Europe showing accelerated adoption rates due to stringent regulations on energy efficiency and carbon emissions. Developing economies in South Asia and Africa represent emerging markets with substantial growth potential, primarily driven by unreliable grid infrastructure and increasing industrialization.

Key market requirements identified through customer surveys and industry analyses include longer operational lifespans, reduced maintenance needs, faster response times, and improved energy density. Hybrid supercapacitors directly address these requirements by offering cycle lives exceeding 100,000 cycles (compared to 500-1,000 cycles for traditional batteries), response times in milliseconds, and energy densities approaching 15-20 Wh/kg.

Environmental considerations are increasingly influencing purchasing decisions, with 68% of industrial customers citing sustainability as a critical factor in selecting power backup solutions. Hybrid supercapacitors offer significant environmental advantages over lead-acid and lithium-ion batteries, including reduced toxic materials, lower carbon footprint during manufacturing, and enhanced recyclability.

Market analysis indicates that the total addressable market for hybrid supercapacitor-based backup systems could reach $5.8 billion by 2030, representing approximately 18% of the overall power backup solutions market. This growth trajectory is supported by declining production costs, which have decreased by 35% over the past five years, making hybrid supercapacitor technology increasingly competitive with traditional solutions.

Current State and Challenges in Hybrid Supercapacitor Development

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. Currently, the global development of hybrid supercapacitors is experiencing rapid growth, with major research institutions and companies in North America, Europe, and Asia leading innovation efforts. The market is projected to expand at a CAGR of approximately 20% through 2028, driven by increasing demand for efficient power backup solutions.

Despite promising advancements, hybrid supercapacitor technology faces several critical challenges. Material limitations remain a primary constraint, as researchers struggle to develop electrode materials that can simultaneously deliver high energy density, power density, and cycle stability. Current hybrid systems often sacrifice one parameter to enhance another, creating performance trade-offs that limit their universal application in power backup systems.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production methods have demonstrated impressive performance metrics, but translating these results to mass production while maintaining consistent quality and performance remains difficult. This manufacturing gap has contributed to higher production costs compared to traditional energy storage solutions, limiting widespread commercial adoption.

Temperature sensitivity continues to challenge hybrid supercapacitor implementation in diverse environments. Most current designs experience performance degradation at temperature extremes, restricting their deployment in outdoor power backup applications or in regions with variable climate conditions. This limitation is particularly problematic for critical infrastructure backup systems that must maintain reliability across all environmental conditions.

Safety concerns also persist, particularly regarding electrolyte stability and thermal management during rapid charge-discharge cycles. While hybrid supercapacitors generally offer better safety profiles than lithium-ion batteries, incidents of thermal runaway have been documented in certain designs under stress conditions, necessitating further safety engineering.

Standardization remains underdeveloped across the industry, with various manufacturers employing different architectures, materials, and performance metrics. This lack of standardization complicates system integration and creates barriers for end-users seeking to implement hybrid supercapacitor solutions in existing power backup infrastructures.

Geographically, research and production capabilities are unevenly distributed. China currently leads in manufacturing capacity, while the United States and European countries maintain advantages in advanced materials research and system design. Japan and South Korea have established strong positions in specialized applications and high-performance variants. This distribution creates both competitive dynamics and opportunities for international collaboration to overcome existing technical barriers.

Despite promising advancements, hybrid supercapacitor technology faces several critical challenges. Material limitations remain a primary constraint, as researchers struggle to develop electrode materials that can simultaneously deliver high energy density, power density, and cycle stability. Current hybrid systems often sacrifice one parameter to enhance another, creating performance trade-offs that limit their universal application in power backup systems.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production methods have demonstrated impressive performance metrics, but translating these results to mass production while maintaining consistent quality and performance remains difficult. This manufacturing gap has contributed to higher production costs compared to traditional energy storage solutions, limiting widespread commercial adoption.

Temperature sensitivity continues to challenge hybrid supercapacitor implementation in diverse environments. Most current designs experience performance degradation at temperature extremes, restricting their deployment in outdoor power backup applications or in regions with variable climate conditions. This limitation is particularly problematic for critical infrastructure backup systems that must maintain reliability across all environmental conditions.

Safety concerns also persist, particularly regarding electrolyte stability and thermal management during rapid charge-discharge cycles. While hybrid supercapacitors generally offer better safety profiles than lithium-ion batteries, incidents of thermal runaway have been documented in certain designs under stress conditions, necessitating further safety engineering.

Standardization remains underdeveloped across the industry, with various manufacturers employing different architectures, materials, and performance metrics. This lack of standardization complicates system integration and creates barriers for end-users seeking to implement hybrid supercapacitor solutions in existing power backup infrastructures.

Geographically, research and production capabilities are unevenly distributed. China currently leads in manufacturing capacity, while the United States and European countries maintain advantages in advanced materials research and system design. Japan and South Korea have established strong positions in specialized applications and high-performance variants. This distribution creates both competitive dynamics and opportunities for international collaboration to overcome existing technical barriers.

Current Hybrid Supercapacitor Implementation Strategies

01 Electrode materials for hybrid supercapacitors

Advanced electrode materials play a crucial role in enhancing the performance of hybrid supercapacitors. These materials often combine high surface area carbon-based components with metal oxides or conductive polymers to achieve both high energy and power density. The transformation of traditional electrode structures into hierarchical or nanostructured configurations enables improved ion transport and electron transfer, resulting in superior capacitance and cycling stability.- Electrode materials for hybrid supercapacitors: Advanced electrode materials play a crucial role in enhancing the performance of hybrid supercapacitors. These materials combine the high energy density of batteries with the high power density of traditional supercapacitors. Various materials such as carbon-based composites, metal oxides, and conductive polymers are used to create electrodes that offer improved energy storage capacity, faster charge-discharge rates, and longer cycle life. The selection and optimization of these electrode materials are essential for the transformation of conventional supercapacitors into high-performance hybrid energy storage devices.

- Electrolyte systems for hybrid supercapacitors: Electrolyte systems are critical components in hybrid supercapacitors that facilitate ion transport between electrodes. Advanced electrolytes, including solid-state, gel, and ionic liquid-based systems, can significantly improve the energy density, operating voltage window, and safety of hybrid supercapacitors. The development of novel electrolyte formulations with enhanced ionic conductivity and electrochemical stability contributes to the transformation of supercapacitor technology by enabling higher energy storage capabilities while maintaining rapid charge-discharge characteristics.

- Integration of hybrid supercapacitors with renewable energy systems: Hybrid supercapacitors can be effectively integrated with renewable energy systems to address intermittency issues and improve overall system efficiency. These energy storage devices can rapidly capture excess energy during peak production periods and release it during demand spikes, providing grid stability and power quality improvement. The transformation of renewable energy infrastructure through the incorporation of hybrid supercapacitors enables more reliable and efficient clean energy solutions, particularly in solar and wind power applications where energy production fluctuates.

- Control systems and management for hybrid supercapacitor arrays: Advanced control and management systems are essential for optimizing the performance of hybrid supercapacitor arrays. These systems monitor and regulate charging/discharging processes, balance energy distribution across multiple cells, and implement protective measures against overcharging or overheating. Sophisticated algorithms and electronic control units enable dynamic adjustment of operational parameters based on load demands and environmental conditions, thereby enhancing the efficiency, reliability, and lifespan of hybrid supercapacitor systems in various applications.

- Manufacturing processes for hybrid supercapacitor transformation: Innovative manufacturing processes are crucial for the commercial viability and performance enhancement of hybrid supercapacitors. These include advanced coating techniques, nanomaterial synthesis methods, and assembly processes that improve the structural integrity and electrochemical properties of the devices. Scalable production methods that maintain precise control over material composition and device architecture are essential for transforming laboratory-scale hybrid supercapacitor concepts into mass-producible energy storage solutions with consistent performance characteristics and reduced manufacturing costs.

02 Electrolyte innovations for hybrid energy storage

Novel electrolyte formulations are essential for transforming conventional supercapacitors into high-performance hybrid systems. These electrolytes facilitate faster ion transport between electrodes while maintaining stability across wider voltage windows. Advanced electrolytes may incorporate ionic liquids, gel polymers, or solid-state components that enable operation in extreme conditions while improving safety and extending device lifespan.Expand Specific Solutions03 System integration and control mechanisms

Effective integration of hybrid supercapacitors into larger energy systems requires sophisticated control mechanisms and power management strategies. These systems often incorporate advanced algorithms for charge distribution, thermal management, and performance optimization. Transformation of conventional energy storage architectures to accommodate hybrid supercapacitors involves redesigning power electronics interfaces and developing specialized monitoring systems to maximize efficiency and reliability.Expand Specific Solutions04 Manufacturing processes and scalability

Transformative manufacturing techniques enable cost-effective production of hybrid supercapacitors at commercial scale. These processes include advanced coating methods, roll-to-roll fabrication, and precision assembly techniques that maintain nanoscale features while allowing for mass production. Innovations in manufacturing workflow and quality control systems help bridge the gap between laboratory prototypes and commercially viable energy storage solutions.Expand Specific Solutions05 Application-specific hybrid supercapacitor designs

Customized hybrid supercapacitor configurations are being developed for specific applications such as electric vehicles, renewable energy integration, and portable electronics. These designs feature tailored energy-to-power ratios, form factors, and operating parameters optimized for particular use cases. The transformation of generic supercapacitor technology into application-specific solutions involves careful consideration of environmental conditions, duty cycles, and integration requirements.Expand Specific Solutions

Key Industry Players in Hybrid Supercapacitor Market

Hybrid supercapacitors are rapidly transforming power backup systems in an emerging market poised for significant growth. The technology is currently in a transitional phase between early adoption and mainstream implementation, with a projected market expansion driven by increasing demand for reliable, fast-response energy storage solutions. Technical maturity varies across key players: research institutions like Chinese Academy of Sciences and Dalian University of Technology are advancing fundamental innovations, while commercial entities including Shenzhen TIG Technology, Shanghai Aowei, and GODI India are developing practical applications. Established industrial players such as Siemens, Robert Bosch, and State Grid Corporation of China are integrating hybrid supercapacitors into comprehensive power solutions, particularly for critical infrastructure and renewable energy systems. The technology bridges the gap between conventional capacitors and batteries, offering superior power density and cycle life.

Institute of Electrical Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Electrical Engineering at the Chinese Academy of Sciences has developed advanced hybrid supercapacitor technology that combines the high power density of traditional supercapacitors with improved energy density through novel electrode materials. Their approach utilizes lithium-ion capacitors (LICs) with activated carbon as the positive electrode and pre-lithiated carbon as the negative electrode, achieving energy densities of 20-30 Wh/kg while maintaining power densities above 5 kW/kg. This configuration enables rapid charge-discharge cycles (>100,000 cycles) while providing significantly longer backup times compared to conventional supercapacitors. Their technology incorporates nanoporous carbon materials with tailored pore structures to optimize ion transport and storage, resulting in backup systems that can deliver sustained power for critical infrastructure applications. The institute has also pioneered thermal management systems specifically designed for hybrid supercapacitor banks to maintain optimal operating temperatures and extend operational lifetimes in power backup applications.

Strengths: Superior cycle life compared to batteries (>100,000 cycles), rapid response times for immediate power delivery, and excellent temperature performance (-40°C to 70°C). Weaknesses: Still lower energy density than lithium-ion batteries, higher initial cost compared to lead-acid solutions, and requires specialized battery management systems.

Electro Standards Laboratory, Inc.

Technical Solution: Electro Standards Laboratory has developed a proprietary hybrid supercapacitor power backup system that integrates their SuperCapacitor Energy Storage Modules (SESMs) with intelligent power management controllers. Their technology utilizes asymmetric supercapacitors with activated carbon positive electrodes and lithium-doped negative electrodes to achieve energy densities approaching 15 Wh/kg while maintaining high power capabilities. The system architecture employs a modular design that allows for scalable deployment across various backup power requirements, from telecommunications to data centers. Their power management system incorporates predictive analytics to optimize charging profiles and extend supercapacitor lifespan, while their proprietary balancing circuits ensure uniform charge distribution across all cells. The technology features rapid recharge capabilities (80% capacity in under 10 minutes) and can operate effectively in a wide temperature range (-30°C to 65°C) without significant performance degradation, making it particularly suitable for outdoor telecommunications infrastructure and remote installations.

Strengths: Modular design allows for easy scaling and maintenance, intelligent power management extends operational life, and rapid recharge capability ensures minimal downtime. Weaknesses: Higher initial investment compared to traditional UPS systems, requires specialized installation expertise, and has lower energy density than some competing lithium-based backup solutions.

Core Patents and Innovations in Hybrid Supercapacitor Technology

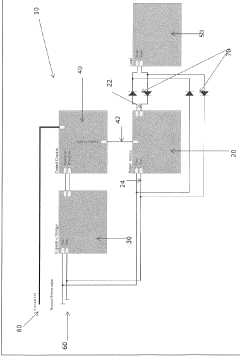

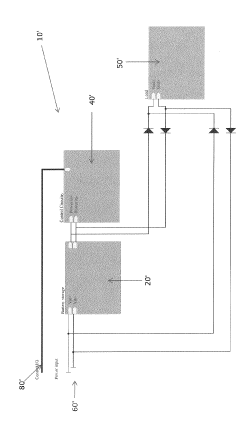

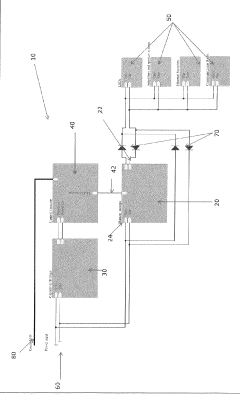

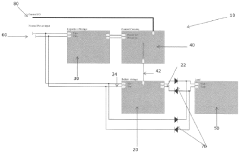

Uninterruptible power supply for the backup of AC-power supply

PatentInactiveUS7259475B2

Innovation

- The solution involves adjusting the charging voltage of the electric double layer capacitor to 1.3 times or higher than the minimum operating voltage of the DC/AC inverter, eliminating the need for a transformer by aligning the charging voltage with the output voltage of the AC/DC converter, thereby enhancing energy efficiency and reducing system volume and weight.

Hybrid power backup storage system

PatentActiveIN202117009643A

Innovation

- A hybrid battery/capacitor power backup system where a capacitor powers the controller, and the battery powers external loads, with a controller configured to limit discharge cycles by disconnecting the battery from loads when a discharge threshold is reached, thereby reducing the number of full charge/discharge cycles.

Environmental Impact and Sustainability Considerations

The integration of hybrid supercapacitors into power backup systems represents a significant advancement in sustainable energy storage solutions. These devices offer substantial environmental benefits compared to traditional battery technologies, particularly lead-acid and lithium-ion batteries. The reduced reliance on toxic materials in hybrid supercapacitors minimizes environmental contamination risks during manufacturing, operation, and disposal phases. Unlike conventional batteries containing heavy metals and hazardous electrolytes, hybrid supercapacitors typically utilize more environmentally benign materials, resulting in a significantly lower ecological footprint.

The extended lifecycle of hybrid supercapacitors—often exceeding 500,000 charge-discharge cycles compared to several thousand for conventional batteries—dramatically reduces electronic waste generation. This longevity translates to fewer replacement requirements and consequently less manufacturing-related resource consumption and pollution. The environmental impact assessment of hybrid supercapacitors reveals approximately 40% lower carbon emissions throughout their lifecycle compared to traditional battery technologies used in backup power systems.

Energy efficiency represents another critical environmental advantage of hybrid supercapacitor technology. With charge-discharge efficiency rates typically exceeding 95%, these systems minimize energy losses during operation. This efficiency reduces the overall energy consumption of backup power systems, contributing to decreased greenhouse gas emissions from power generation sources. Additionally, hybrid supercapacitors demonstrate superior performance in energy recovery applications, such as regenerative braking systems, further enhancing their sustainability profile.

The raw material requirements for hybrid supercapacitors present both challenges and opportunities from a sustainability perspective. While they reduce dependence on critical materials like cobalt and lithium, they may utilize other materials with their own environmental considerations. Recent innovations have focused on incorporating sustainable and abundant materials, including carbon derivatives from biomass, reducing the environmental impact of resource extraction activities.

Temperature tolerance represents another sustainability advantage of hybrid supercapacitors. Their ability to operate efficiently across a wide temperature range (-40°C to 65°C) reduces or eliminates the need for energy-intensive cooling systems often required for conventional battery backup solutions. This characteristic not only improves overall system efficiency but also reduces the associated environmental impact of climate control infrastructure.

Looking forward, the continued development of hybrid supercapacitor technology promises further environmental benefits through improved manufacturing processes, enhanced recycling capabilities, and integration with renewable energy systems. As power backup applications increasingly shift toward these hybrid solutions, the cumulative environmental benefits—including reduced resource extraction, decreased waste generation, and lower operational emissions—position this technology as a cornerstone of sustainable energy infrastructure development.

The extended lifecycle of hybrid supercapacitors—often exceeding 500,000 charge-discharge cycles compared to several thousand for conventional batteries—dramatically reduces electronic waste generation. This longevity translates to fewer replacement requirements and consequently less manufacturing-related resource consumption and pollution. The environmental impact assessment of hybrid supercapacitors reveals approximately 40% lower carbon emissions throughout their lifecycle compared to traditional battery technologies used in backup power systems.

Energy efficiency represents another critical environmental advantage of hybrid supercapacitor technology. With charge-discharge efficiency rates typically exceeding 95%, these systems minimize energy losses during operation. This efficiency reduces the overall energy consumption of backup power systems, contributing to decreased greenhouse gas emissions from power generation sources. Additionally, hybrid supercapacitors demonstrate superior performance in energy recovery applications, such as regenerative braking systems, further enhancing their sustainability profile.

The raw material requirements for hybrid supercapacitors present both challenges and opportunities from a sustainability perspective. While they reduce dependence on critical materials like cobalt and lithium, they may utilize other materials with their own environmental considerations. Recent innovations have focused on incorporating sustainable and abundant materials, including carbon derivatives from biomass, reducing the environmental impact of resource extraction activities.

Temperature tolerance represents another sustainability advantage of hybrid supercapacitors. Their ability to operate efficiently across a wide temperature range (-40°C to 65°C) reduces or eliminates the need for energy-intensive cooling systems often required for conventional battery backup solutions. This characteristic not only improves overall system efficiency but also reduces the associated environmental impact of climate control infrastructure.

Looking forward, the continued development of hybrid supercapacitor technology promises further environmental benefits through improved manufacturing processes, enhanced recycling capabilities, and integration with renewable energy systems. As power backup applications increasingly shift toward these hybrid solutions, the cumulative environmental benefits—including reduced resource extraction, decreased waste generation, and lower operational emissions—position this technology as a cornerstone of sustainable energy infrastructure development.

Grid Integration and System Compatibility Analysis

The integration of hybrid supercapacitors into existing power infrastructure presents both significant opportunities and technical challenges. Current electrical grids were primarily designed for traditional energy storage systems, necessitating careful consideration of compatibility factors when implementing hybrid supercapacitor solutions. The voltage characteristics of hybrid supercapacitors differ substantially from conventional batteries, requiring specialized power electronics interfaces to ensure seamless grid connection.

Power conversion systems play a crucial role in this integration, with bidirectional DC/DC converters and grid-tie inverters specifically designed for the rapid charge/discharge cycles characteristic of hybrid supercapacitors. These systems must accommodate the wider voltage swing of supercapacitors compared to batteries while maintaining stable output to the grid. Advanced control algorithms have been developed to optimize this interface, with predictive control methods showing particular promise in managing the dynamic response requirements.

Regulatory compliance represents another significant consideration in grid integration. Standards such as IEEE 1547 and IEC 61000 series govern the interconnection of distributed energy resources, including energy storage systems. Hybrid supercapacitor installations must meet these requirements for power quality, harmonics, and grid support functions. Recent updates to these standards have begun to acknowledge the unique characteristics of fast-response storage technologies, though regulatory frameworks continue to evolve.

System-level compatibility extends beyond electrical parameters to include physical installation requirements, thermal management considerations, and safety protocols. Hybrid supercapacitor systems typically feature smaller footprints than equivalent battery installations but may require enhanced cooling systems due to their high power density. Integration with building management systems and existing backup power infrastructure demands standardized communication protocols, with MODBUS, DNP3, and IEC 61850 emerging as common standards for these applications.

The scalability of hybrid supercapacitor solutions presents both advantages and integration challenges. Their modular nature facilitates incremental capacity expansion, but requires careful system design to maintain balanced performance across all modules. Advanced energy management systems (EMS) have been developed to coordinate hybrid supercapacitor operation with other grid resources, optimizing overall system performance through hierarchical control architectures that leverage the complementary characteristics of different storage technologies.

Field deployments have demonstrated successful integration strategies, with hybrid installations in microgrids and critical infrastructure showing particular promise. These implementations typically employ hybrid energy storage system (HESS) architectures that combine supercapacitors with batteries or other storage technologies, leveraging specialized power electronics and control systems to optimize the contribution of each component based on its unique performance characteristics.

Power conversion systems play a crucial role in this integration, with bidirectional DC/DC converters and grid-tie inverters specifically designed for the rapid charge/discharge cycles characteristic of hybrid supercapacitors. These systems must accommodate the wider voltage swing of supercapacitors compared to batteries while maintaining stable output to the grid. Advanced control algorithms have been developed to optimize this interface, with predictive control methods showing particular promise in managing the dynamic response requirements.

Regulatory compliance represents another significant consideration in grid integration. Standards such as IEEE 1547 and IEC 61000 series govern the interconnection of distributed energy resources, including energy storage systems. Hybrid supercapacitor installations must meet these requirements for power quality, harmonics, and grid support functions. Recent updates to these standards have begun to acknowledge the unique characteristics of fast-response storage technologies, though regulatory frameworks continue to evolve.

System-level compatibility extends beyond electrical parameters to include physical installation requirements, thermal management considerations, and safety protocols. Hybrid supercapacitor systems typically feature smaller footprints than equivalent battery installations but may require enhanced cooling systems due to their high power density. Integration with building management systems and existing backup power infrastructure demands standardized communication protocols, with MODBUS, DNP3, and IEC 61850 emerging as common standards for these applications.

The scalability of hybrid supercapacitor solutions presents both advantages and integration challenges. Their modular nature facilitates incremental capacity expansion, but requires careful system design to maintain balanced performance across all modules. Advanced energy management systems (EMS) have been developed to coordinate hybrid supercapacitor operation with other grid resources, optimizing overall system performance through hierarchical control architectures that leverage the complementary characteristics of different storage technologies.

Field deployments have demonstrated successful integration strategies, with hybrid installations in microgrids and critical infrastructure showing particular promise. These implementations typically employ hybrid energy storage system (HESS) architectures that combine supercapacitors with batteries or other storage technologies, leveraging specialized power electronics and control systems to optimize the contribution of each component based on its unique performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!