Emerging Regulations Affecting Hybrid Supercapacitor Utilization

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Regulatory Landscape and Development Goals

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high energy density of batteries with the rapid charge-discharge capabilities of traditional supercapacitors. The regulatory landscape surrounding these devices has evolved considerably over the past decade, reflecting growing awareness of both their potential benefits and associated risks. Initially, regulations were primarily focused on basic safety standards for electronic components, with little specific attention to energy storage technologies beyond conventional batteries.

The evolution of hybrid supercapacitor regulation has been driven by several key factors, including environmental concerns, safety considerations, and the need for standardization across global markets. Early regulatory frameworks from 2010-2015 primarily addressed these devices under general electrical equipment guidelines, but recent years have seen the emergence of more specialized regulatory approaches tailored to their unique characteristics.

Current regulatory trends indicate a shift toward more comprehensive oversight, with particular emphasis on lifecycle management, hazardous material restrictions, and performance standardization. The European Union's approach through the WEEE Directive and RoHS regulations has established important precedents for managing electronic waste and restricting hazardous substances in these devices. Similarly, North American regulations through UL standards and transportation safety protocols have created frameworks specifically addressing the unique properties of high-capacity energy storage systems.

The Asia-Pacific region, particularly China and Japan, has developed some of the most advanced regulatory frameworks for hybrid supercapacitor technology, reflecting their significant manufacturing presence in this sector. These regulations often focus on quality control, performance standards, and increasingly, recycling requirements.

The primary technical goals driving regulatory development include establishing standardized testing protocols for energy density, cycle life, and safety performance. Regulatory bodies aim to create frameworks that ensure consumer safety while enabling continued innovation in this rapidly evolving field. Current development targets focus on harmonizing international standards to reduce market fragmentation and compliance costs for manufacturers.

Looking forward, regulatory evolution is expected to address emerging concerns around raw material sourcing, particularly for critical minerals used in hybrid supercapacitor construction. Additionally, regulations are increasingly incorporating sustainability metrics, requiring manufacturers to demonstrate improved environmental performance throughout the product lifecycle.

The technical objectives for future regulatory frameworks include developing more sophisticated testing methodologies that accurately reflect real-world usage conditions, establishing clearer guidelines for integration with renewable energy systems, and creating certification processes that can keep pace with rapid technological advancement in this field.

The evolution of hybrid supercapacitor regulation has been driven by several key factors, including environmental concerns, safety considerations, and the need for standardization across global markets. Early regulatory frameworks from 2010-2015 primarily addressed these devices under general electrical equipment guidelines, but recent years have seen the emergence of more specialized regulatory approaches tailored to their unique characteristics.

Current regulatory trends indicate a shift toward more comprehensive oversight, with particular emphasis on lifecycle management, hazardous material restrictions, and performance standardization. The European Union's approach through the WEEE Directive and RoHS regulations has established important precedents for managing electronic waste and restricting hazardous substances in these devices. Similarly, North American regulations through UL standards and transportation safety protocols have created frameworks specifically addressing the unique properties of high-capacity energy storage systems.

The Asia-Pacific region, particularly China and Japan, has developed some of the most advanced regulatory frameworks for hybrid supercapacitor technology, reflecting their significant manufacturing presence in this sector. These regulations often focus on quality control, performance standards, and increasingly, recycling requirements.

The primary technical goals driving regulatory development include establishing standardized testing protocols for energy density, cycle life, and safety performance. Regulatory bodies aim to create frameworks that ensure consumer safety while enabling continued innovation in this rapidly evolving field. Current development targets focus on harmonizing international standards to reduce market fragmentation and compliance costs for manufacturers.

Looking forward, regulatory evolution is expected to address emerging concerns around raw material sourcing, particularly for critical minerals used in hybrid supercapacitor construction. Additionally, regulations are increasingly incorporating sustainability metrics, requiring manufacturers to demonstrate improved environmental performance throughout the product lifecycle.

The technical objectives for future regulatory frameworks include developing more sophisticated testing methodologies that accurately reflect real-world usage conditions, establishing clearer guidelines for integration with renewable energy systems, and creating certification processes that can keep pace with rapid technological advancement in this field.

Market Demand Analysis for Hybrid Supercapacitor Technologies

The global market for hybrid supercapacitors has been experiencing significant growth, driven by increasing demand for efficient energy storage solutions across multiple sectors. Current market analysis indicates that the energy storage market is projected to reach $546 billion by 2035, with hybrid supercapacitors capturing an expanding share due to their unique performance characteristics that bridge conventional capacitors and batteries.

Industrial applications represent the largest market segment for hybrid supercapacitors, particularly in manufacturing equipment, robotics, and industrial automation systems where rapid charge-discharge cycles and reliability are critical. The automotive sector follows closely, with hybrid and electric vehicles requiring advanced energy storage solutions that can handle regenerative braking and power delivery demands while meeting stringent safety standards.

Consumer electronics constitutes another rapidly growing segment, with demand for faster-charging devices with longer operational lifetimes. The renewable energy sector is emerging as a significant market driver, as grid stabilization and energy storage systems increasingly incorporate hybrid supercapacitors to manage intermittent power generation from solar and wind sources.

Market research indicates that regulatory developments are significantly influencing adoption patterns. Regions with stricter environmental regulations, particularly in Europe and parts of Asia, are seeing accelerated market growth as manufacturers seek compliant energy storage technologies. The European Union's Battery Directive revisions and upcoming regulations on energy storage systems are creating both challenges and opportunities for hybrid supercapacitor technologies.

Customer demand is increasingly focused on three key performance metrics: energy density, cycle life, and safety. Recent surveys of industrial customers indicate willingness to pay premium prices for hybrid supercapacitors that demonstrate superior performance in these areas while meeting regulatory requirements. This trend is particularly pronounced in safety-critical applications such as medical devices, aerospace, and defense systems.

Regional market analysis reveals that Asia-Pacific currently dominates the hybrid supercapacitor market, accounting for approximately 45% of global demand, followed by North America and Europe. However, regulatory divergence between these regions is creating market fragmentation, with manufacturers needing to develop region-specific products to address varying compliance requirements.

The market is also witnessing increased demand for customized solutions, with end-users seeking hybrid supercapacitors tailored to specific application requirements rather than standardized products. This trend is driving manufacturers to develop modular designs and configurable systems that can be adapted to different regulatory environments while maintaining core performance characteristics.

Industrial applications represent the largest market segment for hybrid supercapacitors, particularly in manufacturing equipment, robotics, and industrial automation systems where rapid charge-discharge cycles and reliability are critical. The automotive sector follows closely, with hybrid and electric vehicles requiring advanced energy storage solutions that can handle regenerative braking and power delivery demands while meeting stringent safety standards.

Consumer electronics constitutes another rapidly growing segment, with demand for faster-charging devices with longer operational lifetimes. The renewable energy sector is emerging as a significant market driver, as grid stabilization and energy storage systems increasingly incorporate hybrid supercapacitors to manage intermittent power generation from solar and wind sources.

Market research indicates that regulatory developments are significantly influencing adoption patterns. Regions with stricter environmental regulations, particularly in Europe and parts of Asia, are seeing accelerated market growth as manufacturers seek compliant energy storage technologies. The European Union's Battery Directive revisions and upcoming regulations on energy storage systems are creating both challenges and opportunities for hybrid supercapacitor technologies.

Customer demand is increasingly focused on three key performance metrics: energy density, cycle life, and safety. Recent surveys of industrial customers indicate willingness to pay premium prices for hybrid supercapacitors that demonstrate superior performance in these areas while meeting regulatory requirements. This trend is particularly pronounced in safety-critical applications such as medical devices, aerospace, and defense systems.

Regional market analysis reveals that Asia-Pacific currently dominates the hybrid supercapacitor market, accounting for approximately 45% of global demand, followed by North America and Europe. However, regulatory divergence between these regions is creating market fragmentation, with manufacturers needing to develop region-specific products to address varying compliance requirements.

The market is also witnessing increased demand for customized solutions, with end-users seeking hybrid supercapacitors tailored to specific application requirements rather than standardized products. This trend is driving manufacturers to develop modular designs and configurable systems that can be adapted to different regulatory environments while maintaining core performance characteristics.

Current Regulatory Challenges and Technical Limitations

The regulatory landscape for hybrid supercapacitors is rapidly evolving, creating significant challenges for manufacturers, integrators, and end-users. Currently, there exists a fragmented regulatory framework across different regions, with the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives imposing strict limitations on materials used in supercapacitor manufacturing. These regulations particularly impact electrolyte compositions and electrode materials, forcing manufacturers to reformulate their designs while maintaining performance specifications.

In North America, the Department of Energy (DOE) and Environmental Protection Agency (EPA) have introduced guidelines focusing on energy density requirements and end-of-life disposal protocols for energy storage systems, including hybrid supercapacitors. These regulations, while not as prescriptive as EU directives, create compliance challenges for global manufacturers seeking unified production standards.

Asian markets, particularly China and Japan, have implemented their own regulatory frameworks emphasizing safety standards and performance metrics, further complicating the global regulatory landscape. The lack of harmonized international standards creates significant market entry barriers and increases compliance costs across different jurisdictions.

From a technical perspective, current hybrid supercapacitor technologies face several critical limitations. Energy density remains substantially lower than lithium-ion batteries, typically achieving only 10-15 Wh/kg compared to 150-250 Wh/kg for advanced lithium-ion systems. This fundamental limitation restricts their application in energy-intensive use cases despite their superior power density and cycle life.

Temperature sensitivity presents another significant challenge, with performance degradation occurring at both high (>65°C) and low (<-20°C) temperature extremes. This restricts deployment in automotive and outdoor energy storage applications without additional thermal management systems, increasing system complexity and cost.

Electrolyte stability issues continue to plague long-term reliability, with current organic electrolytes demonstrating degradation over extended cycling, particularly under high voltage conditions. This degradation pathway limits the practical lifespan of devices despite theoretical cycle life advantages.

Manufacturing scalability remains problematic due to precision requirements in electrode preparation and assembly. Current production methods involve complex processes that are difficult to scale while maintaining consistent quality, resulting in higher production costs compared to conventional capacitors and batteries.

Self-discharge rates, while improved in hybrid designs, still exceed those of batteries, limiting energy retention capabilities for long-term storage applications. This characteristic restricts their utility in backup power systems requiring extended standby periods without maintenance charging.

In North America, the Department of Energy (DOE) and Environmental Protection Agency (EPA) have introduced guidelines focusing on energy density requirements and end-of-life disposal protocols for energy storage systems, including hybrid supercapacitors. These regulations, while not as prescriptive as EU directives, create compliance challenges for global manufacturers seeking unified production standards.

Asian markets, particularly China and Japan, have implemented their own regulatory frameworks emphasizing safety standards and performance metrics, further complicating the global regulatory landscape. The lack of harmonized international standards creates significant market entry barriers and increases compliance costs across different jurisdictions.

From a technical perspective, current hybrid supercapacitor technologies face several critical limitations. Energy density remains substantially lower than lithium-ion batteries, typically achieving only 10-15 Wh/kg compared to 150-250 Wh/kg for advanced lithium-ion systems. This fundamental limitation restricts their application in energy-intensive use cases despite their superior power density and cycle life.

Temperature sensitivity presents another significant challenge, with performance degradation occurring at both high (>65°C) and low (<-20°C) temperature extremes. This restricts deployment in automotive and outdoor energy storage applications without additional thermal management systems, increasing system complexity and cost.

Electrolyte stability issues continue to plague long-term reliability, with current organic electrolytes demonstrating degradation over extended cycling, particularly under high voltage conditions. This degradation pathway limits the practical lifespan of devices despite theoretical cycle life advantages.

Manufacturing scalability remains problematic due to precision requirements in electrode preparation and assembly. Current production methods involve complex processes that are difficult to scale while maintaining consistent quality, resulting in higher production costs compared to conventional capacitors and batteries.

Self-discharge rates, while improved in hybrid designs, still exceed those of batteries, limiting energy retention capabilities for long-term storage applications. This characteristic restricts their utility in backup power systems requiring extended standby periods without maintenance charging.

Current Compliance Strategies and Technical Solutions

01 Safety regulations for hybrid supercapacitors

Safety regulations for hybrid supercapacitors focus on preventing thermal runaway, electrical hazards, and ensuring proper containment of electrolytes. These regulations typically include requirements for thermal management systems, electrical isolation, short-circuit protection, and pressure relief mechanisms. Manufacturers must comply with specific testing protocols to demonstrate that their hybrid supercapacitor systems can withstand various failure modes without causing safety incidents.- Safety regulations and standards for hybrid supercapacitors: Safety regulations and standards are crucial for hybrid supercapacitors to ensure their safe operation and prevent hazards such as overheating, short circuits, or explosions. These regulations typically cover aspects like thermal management, electrical safety parameters, and containment measures. Compliance with these safety standards is mandatory for manufacturers before their products can be marketed and used in various applications, particularly in consumer electronics and automotive sectors.

- Environmental compliance and disposal regulations: Hybrid supercapacitors are subject to environmental regulations governing their manufacturing processes, material selection, and end-of-life disposal. These regulations aim to minimize the environmental impact of potentially hazardous materials used in supercapacitors, such as certain electrolytes and electrode materials. Manufacturers must adhere to guidelines for proper disposal and recycling of these components, and may need to implement take-back programs or participate in electronic waste management systems.

- Performance certification and testing protocols: Hybrid supercapacitors must undergo rigorous testing and certification processes to verify their performance claims and ensure reliability. These protocols evaluate parameters such as energy density, power density, cycle life, and operational temperature range. Standardized testing methods allow for consistent comparison between different products and technologies. Certification bodies establish benchmarks that manufacturers must meet to receive approval for specific applications, particularly in critical sectors like transportation, medical devices, and industrial equipment.

- Integration regulations for electrical systems: Regulations governing the integration of hybrid supercapacitors into larger electrical systems address compatibility, interface standards, and operational parameters. These include specifications for electrical connections, control systems, and protection mechanisms when supercapacitors are incorporated into power management systems. Standards also cover communication protocols between supercapacitors and other components in energy storage systems, ensuring safe and efficient operation within complex electrical architectures such as smart grids, renewable energy systems, and electric vehicles.

- Transportation and shipping regulations: Hybrid supercapacitors are subject to specific transportation and shipping regulations due to their energy storage capabilities and potential safety risks. These regulations classify supercapacitors based on their energy content and composition, with different requirements for packaging, labeling, and handling during transport. International shipping standards may require special documentation, testing certificates, and packaging designed to prevent short circuits or damage during transit. Air transport typically has the strictest regulations, with limitations on the quantity and configuration of supercapacitors that can be transported on passenger or cargo aircraft.

02 Environmental compliance standards

Environmental regulations for hybrid supercapacitors address the use of hazardous materials, end-of-life disposal, and recycling requirements. These standards limit the use of toxic substances in manufacturing and mandate proper disposal procedures to prevent environmental contamination. Manufacturers must adhere to restrictions on heavy metals, certain electrolyte chemicals, and provide documentation on the recyclability of components. Some regulations also require life cycle assessments to evaluate the overall environmental impact.Expand Specific Solutions03 Performance certification requirements

Performance certification requirements for hybrid supercapacitors establish standardized testing methodologies to verify energy density, power density, cycle life, and operational temperature range claims. These regulations ensure that manufacturers provide accurate performance specifications and that devices meet minimum performance standards for their intended applications. Certification processes typically include third-party verification of key performance parameters and durability under various operating conditions.Expand Specific Solutions04 Grid integration and electrical standards

Regulations governing the integration of hybrid supercapacitors into electrical grids establish requirements for electrical compatibility, power quality, and grid stability. These standards specify acceptable voltage fluctuations, frequency response characteristics, and fault protection mechanisms. For grid-connected applications, hybrid supercapacitors must comply with interconnection standards that ensure they can operate safely alongside other grid components and respond appropriately during grid disturbances.Expand Specific Solutions05 Transportation and shipping regulations

Transportation regulations for hybrid supercapacitors address the risks associated with shipping these high-energy devices. These regulations specify packaging requirements, labeling standards, and testing protocols to ensure safe transport by air, sea, and land. Manufacturers must demonstrate that their devices can withstand transportation stresses without damage or safety incidents. Special provisions apply to different energy capacities, with higher-energy devices subject to more stringent requirements including specialized packaging and handling procedures.Expand Specific Solutions

Key Industry Players and Regulatory Stakeholders

The hybrid supercapacitor market is currently in a growth phase, with emerging regulations significantly shaping its trajectory. The global market size is projected to expand substantially due to increasing demand for efficient energy storage solutions in automotive, electronics, and renewable energy sectors. Technologically, companies demonstrate varying maturity levels: established players like Robert Bosch GmbH, Samsung Electro-Mechanics, and SAIC Motor are advancing commercial applications, while Nanotech Energy and American Lithium Energy lead in silicon anode innovations. Research institutions including Tsinghua University and University of Washington are developing next-generation technologies. Chinese manufacturers like Shanghai Aowei and Chaowei Power are gaining prominence as production scales. Regulatory frameworks around safety standards, material sustainability, and end-of-life recycling are creating both compliance challenges and innovation opportunities across this competitive landscape.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed a comprehensive regulatory compliance framework for their hybrid supercapacitor technology, particularly focusing on China's evolving energy storage regulations. Their approach includes advanced thermal management systems that meet stringent safety standards required by recent Chinese regulations for public transportation applications. The company has implemented a dual-layer monitoring system that continuously tracks performance parameters to ensure compliance with energy density and cycle life requirements mandated by the latest Chinese national standards for energy storage devices. Additionally, Aowei has pioneered recyclable electrode materials that align with emerging environmental regulations in both domestic and international markets, achieving over 80% recyclability rates while maintaining performance specifications.

Strengths: Strong position in the Chinese market with established regulatory relationships; comprehensive understanding of regional safety standards. Weaknesses: Limited global regulatory experience compared to multinational competitors; potentially higher compliance costs due to rapidly changing domestic regulations.

Robert Bosch GmbH

Technical Solution: Bosch has developed a regulatory-compliant hybrid supercapacitor platform specifically designed to meet the stringent requirements of European automotive and industrial standards. Their technology incorporates a proprietary Battery Management System (BMS) that actively monitors and controls supercapacitor parameters to ensure compliance with UN/ECE R100 (for electric vehicle safety) and IEC 62619 (for industrial applications). The system features adaptive control algorithms that can be updated remotely to accommodate evolving regulatory frameworks across different jurisdictions. Bosch's hybrid supercapacitors utilize non-toxic electrolytes that comply with REACH and RoHS directives, while their manufacturing processes adhere to ISO 14001 environmental management standards. The company has also developed comprehensive end-of-life protocols that align with the EU Battery Directive's recycling requirements.

Strengths: Extensive experience navigating complex European regulatory frameworks; strong integration capabilities with existing automotive systems; established global compliance infrastructure. Weaknesses: Higher production costs associated with meeting multiple regional standards; potentially conservative design approaches that may limit performance optimization.

Critical Patents and Technical Standards Analysis

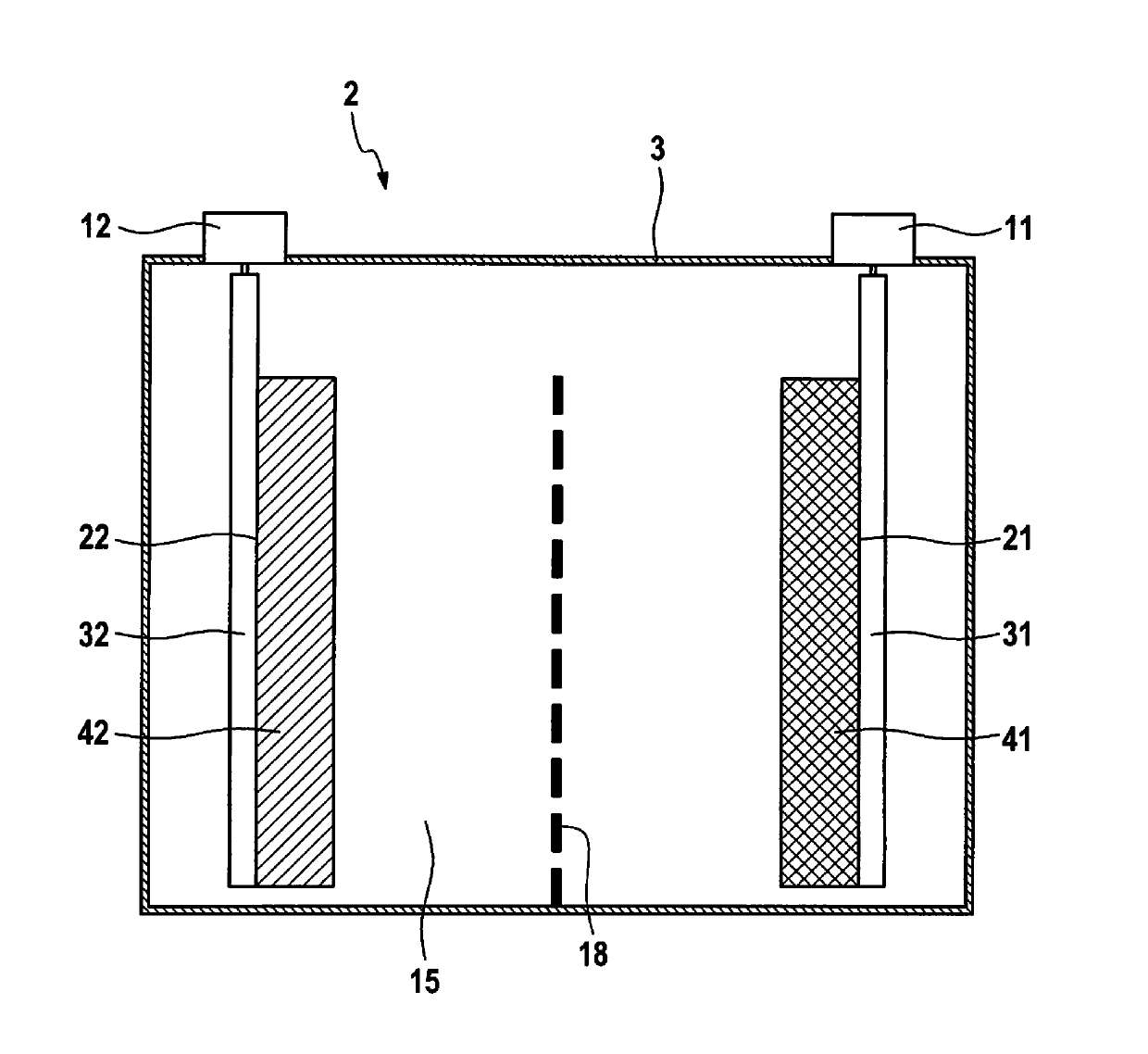

Symmetric hybrid supercapacitor and use of LiMnxFe1-xPO4 as electrode material for a hybrid supercapacitor

PatentActiveUS10020122B2

Innovation

- The use of LiMnxFe1-xPO4 with 0.1<x<0.9 as cathode material, combined with Li4Ti5O12 as anode and carbon-based composite materials, enhances electrical properties and stability by forming synergistic effects and improving electrical contact through carbon coating and addition of graphite/carbon black nanoparticles.

Hybrid supercapacitor, including an electrolyte composition, having improved conductivity

PatentInactiveUS10269507B2

Innovation

- A hybrid supercapacitor design incorporating a liquid electrolyte composition with aprotic organic solvents, conducting salts, and Lewis acid additives that form complex compounds with anions, enhancing ion solvation and reducing charge density to increase conductivity.

Environmental Impact Assessment and Sustainability Requirements

The environmental impact of hybrid supercapacitors has become a critical focus area for regulatory bodies worldwide, with sustainability requirements increasingly shaping the development and deployment of these energy storage technologies. Recent environmental regulations have established stringent standards for the entire lifecycle of hybrid supercapacitors, from raw material extraction to end-of-life disposal and recycling processes.

Material sourcing regulations now mandate detailed documentation of supply chains, particularly for critical materials like rare earth elements and transition metals used in electrode manufacturing. The European Union's Conflict Minerals Regulation and similar frameworks in North America require manufacturers to verify that materials are sourced from environmentally responsible and socially ethical operations, with full traceability requirements being phased in between 2023-2025.

Manufacturing processes for hybrid supercapacitors face intensified scrutiny regarding energy consumption, water usage, and chemical emissions. The Industrial Emissions Directive in Europe and equivalent regulations in Asia-Pacific markets have established progressively lower thresholds for permissible emissions during production. Notably, regulations now require lifecycle carbon footprint assessments that account for embedded carbon in manufacturing processes, with carbon intensity limits becoming increasingly restrictive.

Operational sustainability requirements focus on energy efficiency metrics, with several jurisdictions implementing minimum performance standards for charge-discharge efficiency and self-discharge rates. The International Electrotechnical Commission (IEC) has developed specific testing protocols for hybrid supercapacitor environmental performance verification, which are being adopted into regulatory frameworks globally.

End-of-life management represents perhaps the most rapidly evolving regulatory area. Extended Producer Responsibility (EPR) schemes are expanding to explicitly include hybrid supercapacitors, requiring manufacturers to establish collection and recycling programs. The EU Battery Directive revision specifically addresses supercapacitor technologies, mandating minimum recycled content percentages that will increase incrementally from 2025 to 2035.

Toxicity concerns have prompted restrictions on certain electrolytes and electrode materials, with phase-out timelines established for substances identified as potentially harmful. Manufacturers must now provide comprehensive material safety data and environmental impact statements as part of product certification processes, with particular emphasis on leachate potential and biodegradability characteristics of component materials.

These evolving regulations are driving significant innovation in green chemistry approaches to hybrid supercapacitor design, with bio-based electrolytes and environmentally benign electrode materials gaining regulatory preference through incentive structures and expedited approval pathways.

Material sourcing regulations now mandate detailed documentation of supply chains, particularly for critical materials like rare earth elements and transition metals used in electrode manufacturing. The European Union's Conflict Minerals Regulation and similar frameworks in North America require manufacturers to verify that materials are sourced from environmentally responsible and socially ethical operations, with full traceability requirements being phased in between 2023-2025.

Manufacturing processes for hybrid supercapacitors face intensified scrutiny regarding energy consumption, water usage, and chemical emissions. The Industrial Emissions Directive in Europe and equivalent regulations in Asia-Pacific markets have established progressively lower thresholds for permissible emissions during production. Notably, regulations now require lifecycle carbon footprint assessments that account for embedded carbon in manufacturing processes, with carbon intensity limits becoming increasingly restrictive.

Operational sustainability requirements focus on energy efficiency metrics, with several jurisdictions implementing minimum performance standards for charge-discharge efficiency and self-discharge rates. The International Electrotechnical Commission (IEC) has developed specific testing protocols for hybrid supercapacitor environmental performance verification, which are being adopted into regulatory frameworks globally.

End-of-life management represents perhaps the most rapidly evolving regulatory area. Extended Producer Responsibility (EPR) schemes are expanding to explicitly include hybrid supercapacitors, requiring manufacturers to establish collection and recycling programs. The EU Battery Directive revision specifically addresses supercapacitor technologies, mandating minimum recycled content percentages that will increase incrementally from 2025 to 2035.

Toxicity concerns have prompted restrictions on certain electrolytes and electrode materials, with phase-out timelines established for substances identified as potentially harmful. Manufacturers must now provide comprehensive material safety data and environmental impact statements as part of product certification processes, with particular emphasis on leachate potential and biodegradability characteristics of component materials.

These evolving regulations are driving significant innovation in green chemistry approaches to hybrid supercapacitor design, with bio-based electrolytes and environmentally benign electrode materials gaining regulatory preference through incentive structures and expedited approval pathways.

Cross-Border Regulatory Harmonization Opportunities

The global landscape of hybrid supercapacitor regulations presents significant opportunities for cross-border harmonization that could accelerate technology adoption while ensuring safety and environmental standards. Currently, regulatory frameworks vary substantially across major markets, creating compliance challenges for manufacturers and limiting market access for innovative energy storage solutions.

Efforts toward regulatory harmonization are emerging through several international initiatives. The International Electrotechnical Commission (IEC) has established working groups specifically focused on developing unified standards for hybrid supercapacitor testing, performance metrics, and safety requirements. These efforts aim to create a common technical language that can be referenced by national regulatory bodies.

Regional harmonization efforts are particularly advanced between the European Union and North American markets. The EU-US Trade and Technology Council has identified energy storage technologies, including hybrid supercapacitors, as a priority area for regulatory alignment. This collaboration focuses on establishing equivalent safety certification processes that would allow manufacturers to undergo a single testing protocol acceptable in both markets.

Asia-Pacific economies are also moving toward greater regulatory coherence through the Asia-Pacific Economic Cooperation (APEC) forum. Japan, South Korea, and China—all significant players in supercapacitor manufacturing—have initiated dialogues to standardize technical specifications and environmental compliance requirements, potentially creating a harmonized market of over 2 billion consumers.

Mutual recognition agreements (MRAs) represent another promising avenue for cross-border harmonization. These agreements, which acknowledge the equivalence of different national certification systems, could significantly reduce compliance costs and time-to-market for hybrid supercapacitor technologies. The existing MRA between Australia and New Zealand for electrical equipment provides a successful model that could be expanded to include hybrid energy storage systems.

Emerging economies present both challenges and opportunities for regulatory harmonization. Countries like India and Brazil are developing their regulatory frameworks for advanced energy storage technologies, creating a unique opportunity to implement internationally aligned standards from the outset rather than retrofitting existing regulations.

The financial benefits of harmonization are substantial. Industry analyses suggest that a manufacturer operating across five major markets could reduce compliance costs by up to 45% through harmonized regulations, while accelerating market entry by an average of eight months. These efficiencies would likely translate to faster technology adoption and more competitive pricing for end users.

Efforts toward regulatory harmonization are emerging through several international initiatives. The International Electrotechnical Commission (IEC) has established working groups specifically focused on developing unified standards for hybrid supercapacitor testing, performance metrics, and safety requirements. These efforts aim to create a common technical language that can be referenced by national regulatory bodies.

Regional harmonization efforts are particularly advanced between the European Union and North American markets. The EU-US Trade and Technology Council has identified energy storage technologies, including hybrid supercapacitors, as a priority area for regulatory alignment. This collaboration focuses on establishing equivalent safety certification processes that would allow manufacturers to undergo a single testing protocol acceptable in both markets.

Asia-Pacific economies are also moving toward greater regulatory coherence through the Asia-Pacific Economic Cooperation (APEC) forum. Japan, South Korea, and China—all significant players in supercapacitor manufacturing—have initiated dialogues to standardize technical specifications and environmental compliance requirements, potentially creating a harmonized market of over 2 billion consumers.

Mutual recognition agreements (MRAs) represent another promising avenue for cross-border harmonization. These agreements, which acknowledge the equivalence of different national certification systems, could significantly reduce compliance costs and time-to-market for hybrid supercapacitor technologies. The existing MRA between Australia and New Zealand for electrical equipment provides a successful model that could be expanded to include hybrid energy storage systems.

Emerging economies present both challenges and opportunities for regulatory harmonization. Countries like India and Brazil are developing their regulatory frameworks for advanced energy storage technologies, creating a unique opportunity to implement internationally aligned standards from the outset rather than retrofitting existing regulations.

The financial benefits of harmonization are substantial. Industry analyses suggest that a manufacturer operating across five major markets could reduce compliance costs by up to 45% through harmonized regulations, while accelerating market entry by an average of eight months. These efficiencies would likely translate to faster technology adoption and more competitive pricing for end users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!