Regulatory Frameworks Governing Hybrid Supercapacitors

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Regulatory Background and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high energy density of batteries with the rapid charge-discharge capabilities of traditional supercapacitors. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. The development trajectory has accelerated notably in the past decade, driven by increasing demands for more efficient energy storage solutions across multiple industries.

The regulatory landscape governing hybrid supercapacitors has evolved in parallel with technological advancements. Initially, these devices were regulated under broader frameworks for electronic components, but as their unique characteristics became apparent, more specific regulatory approaches emerged. Key milestones include the introduction of IEC 62391 standards for fixed electric double-layer capacitors and the subsequent adaptations to accommodate hybrid technologies.

Current regulatory frameworks vary significantly across regions, with the European Union implementing the most comprehensive approach through its Battery Directive (2006/66/EC) and subsequent amendments, which now encompass hybrid energy storage technologies. In North America, the regulatory environment is more fragmented, with standards primarily driven by industry associations rather than centralized governmental bodies.

The primary objective of contemporary regulatory efforts is to establish standardized safety protocols, performance metrics, and environmental guidelines specific to hybrid supercapacitors. This includes addressing concerns related to thermal stability, cycle life assessment methodologies, and end-of-life management. The unique electrochemical properties of hybrid supercapacitors present distinct regulatory challenges that conventional battery or capacitor frameworks cannot adequately address.

Looking forward, regulatory evolution is expected to focus on three key areas: harmonization of international standards to facilitate global market access, development of specific testing protocols that accurately reflect real-world performance characteristics of hybrid systems, and integration of sustainability requirements throughout the product lifecycle. The International Electrochemical Commission (IEC) has established a dedicated working group to develop comprehensive standards specifically for hybrid energy storage technologies by 2025.

The technological trajectory suggests that as hybrid supercapacitors continue to advance in energy density and operational stability, regulatory frameworks will need to adapt accordingly. This includes addressing emerging concerns related to new electrode materials, electrolytes, and manufacturing processes. The ultimate goal is to establish a regulatory environment that ensures safety and reliability while enabling continued innovation in this rapidly evolving field.

The regulatory landscape governing hybrid supercapacitors has evolved in parallel with technological advancements. Initially, these devices were regulated under broader frameworks for electronic components, but as their unique characteristics became apparent, more specific regulatory approaches emerged. Key milestones include the introduction of IEC 62391 standards for fixed electric double-layer capacitors and the subsequent adaptations to accommodate hybrid technologies.

Current regulatory frameworks vary significantly across regions, with the European Union implementing the most comprehensive approach through its Battery Directive (2006/66/EC) and subsequent amendments, which now encompass hybrid energy storage technologies. In North America, the regulatory environment is more fragmented, with standards primarily driven by industry associations rather than centralized governmental bodies.

The primary objective of contemporary regulatory efforts is to establish standardized safety protocols, performance metrics, and environmental guidelines specific to hybrid supercapacitors. This includes addressing concerns related to thermal stability, cycle life assessment methodologies, and end-of-life management. The unique electrochemical properties of hybrid supercapacitors present distinct regulatory challenges that conventional battery or capacitor frameworks cannot adequately address.

Looking forward, regulatory evolution is expected to focus on three key areas: harmonization of international standards to facilitate global market access, development of specific testing protocols that accurately reflect real-world performance characteristics of hybrid systems, and integration of sustainability requirements throughout the product lifecycle. The International Electrochemical Commission (IEC) has established a dedicated working group to develop comprehensive standards specifically for hybrid energy storage technologies by 2025.

The technological trajectory suggests that as hybrid supercapacitors continue to advance in energy density and operational stability, regulatory frameworks will need to adapt accordingly. This includes addressing emerging concerns related to new electrode materials, electrolytes, and manufacturing processes. The ultimate goal is to establish a regulatory environment that ensures safety and reliability while enabling continued innovation in this rapidly evolving field.

Market Demand Analysis for Hybrid Supercapacitors

The global market for hybrid supercapacitors has been experiencing significant growth driven by increasing demand for efficient energy storage solutions across multiple sectors. The automotive industry represents one of the primary demand drivers, with electric and hybrid vehicles requiring advanced energy storage systems that can deliver both high power density for acceleration and sufficient energy density for range. Market research indicates that the automotive sector accounts for approximately 35% of the current hybrid supercapacitor market, with projections showing continued expansion as electric vehicle adoption accelerates worldwide.

Industrial applications constitute another substantial market segment, where hybrid supercapacitors are increasingly deployed in manufacturing equipment, heavy machinery, and grid stabilization systems. These applications value the rapid charge-discharge capabilities and extended cycle life that hybrid supercapacitors offer compared to traditional batteries. The industrial sector currently represents about 28% of market demand, with growth rates exceeding general market averages.

Consumer electronics manufacturers have also begun incorporating hybrid supercapacitor technology into portable devices, seeking to address battery life limitations and charging speed concerns. While this segment currently accounts for a smaller portion of the market at roughly 15%, it shows promising growth potential as miniaturization techniques advance and cost factors improve.

Renewable energy integration presents perhaps the most significant long-term growth opportunity for hybrid supercapacitors. As solar and wind power installations continue to expand globally, the need for efficient energy storage solutions to manage intermittency issues becomes increasingly critical. Market analysts project that demand from renewable energy applications could grow at compound annual rates of over 25% in the coming decade.

Geographically, Asia-Pacific currently dominates the market demand landscape, accounting for approximately 45% of global consumption. This regional concentration stems from the strong presence of electronics manufacturing, automotive production, and aggressive renewable energy deployment across countries like China, Japan, and South Korea. North America and Europe follow with roughly 25% and 20% market shares respectively, with both regions showing accelerated adoption rates driven by sustainability initiatives and electrification trends.

Market forecasts suggest that the global hybrid supercapacitor market could reach substantial valuation within the next five years, representing a compound annual growth rate significantly outpacing traditional energy storage technologies. This growth trajectory is supported by increasing regulatory pressure for cleaner energy solutions, technological advancements improving performance metrics, and gradual cost reductions making hybrid supercapacitors more economically viable across a broader range of applications.

Industrial applications constitute another substantial market segment, where hybrid supercapacitors are increasingly deployed in manufacturing equipment, heavy machinery, and grid stabilization systems. These applications value the rapid charge-discharge capabilities and extended cycle life that hybrid supercapacitors offer compared to traditional batteries. The industrial sector currently represents about 28% of market demand, with growth rates exceeding general market averages.

Consumer electronics manufacturers have also begun incorporating hybrid supercapacitor technology into portable devices, seeking to address battery life limitations and charging speed concerns. While this segment currently accounts for a smaller portion of the market at roughly 15%, it shows promising growth potential as miniaturization techniques advance and cost factors improve.

Renewable energy integration presents perhaps the most significant long-term growth opportunity for hybrid supercapacitors. As solar and wind power installations continue to expand globally, the need for efficient energy storage solutions to manage intermittency issues becomes increasingly critical. Market analysts project that demand from renewable energy applications could grow at compound annual rates of over 25% in the coming decade.

Geographically, Asia-Pacific currently dominates the market demand landscape, accounting for approximately 45% of global consumption. This regional concentration stems from the strong presence of electronics manufacturing, automotive production, and aggressive renewable energy deployment across countries like China, Japan, and South Korea. North America and Europe follow with roughly 25% and 20% market shares respectively, with both regions showing accelerated adoption rates driven by sustainability initiatives and electrification trends.

Market forecasts suggest that the global hybrid supercapacitor market could reach substantial valuation within the next five years, representing a compound annual growth rate significantly outpacing traditional energy storage technologies. This growth trajectory is supported by increasing regulatory pressure for cleaner energy solutions, technological advancements improving performance metrics, and gradual cost reductions making hybrid supercapacitors more economically viable across a broader range of applications.

Global Regulatory Landscape and Technical Challenges

The global regulatory landscape for hybrid supercapacitors remains fragmented, with significant variations across regions. In North America, the Department of Energy (DOE) has established performance and safety standards focusing on energy density, cycle life, and thermal stability. The Environmental Protection Agency (EPA) imposes additional requirements regarding the disposal and recycling of materials containing heavy metals and electrolytes commonly found in these devices.

The European Union maintains the most comprehensive regulatory framework through its Battery Directive (2006/66/EC, updated in 2022), which now explicitly includes supercapacitors and hybrid energy storage systems. This framework mandates minimum performance standards, material restrictions (particularly regarding cadmium, lead, and mercury content), and end-of-life management protocols. The EU's REACH regulation further restricts certain chemical compounds used in electrolytes.

In Asia, regulatory approaches vary significantly. Japan's METI (Ministry of Economy, Trade and Industry) has developed specific technical standards for hybrid supercapacitors used in automotive and grid applications, while China's regulatory framework focuses primarily on manufacturing standards through GB/T specifications, with less emphasis on environmental considerations.

A major technical challenge in meeting these diverse regulations is the development of standardized testing protocols. Current testing methodologies vary significantly across jurisdictions, creating barriers to global market access and increasing compliance costs. The lack of harmonized performance metrics makes cross-market comparisons difficult for manufacturers and consumers alike.

Material compliance represents another significant hurdle. Many high-performance hybrid supercapacitors rely on rare earth elements or potentially hazardous materials that face increasing regulatory scrutiny. Manufacturers must navigate complex supply chain documentation requirements to demonstrate compliance with material restrictions in different markets.

Safety certification presents additional challenges, particularly for high-energy density hybrid supercapacitors. Thermal runaway risks, electrolyte leakage, and short-circuit prevention mechanisms must be validated through different testing regimes depending on the target market. The IEC 62576 standard provides some guidance but has not been universally adopted.

Recycling and disposal regulations create further complexity. Extended Producer Responsibility (EPR) schemes in Europe and parts of Asia require manufacturers to establish collection and recycling systems, while the technical challenges of separating and recovering materials from hybrid devices remain significant. The composite nature of these systems, combining battery and capacitor technologies, creates unique end-of-life management challenges not addressed by existing regulatory frameworks.

The European Union maintains the most comprehensive regulatory framework through its Battery Directive (2006/66/EC, updated in 2022), which now explicitly includes supercapacitors and hybrid energy storage systems. This framework mandates minimum performance standards, material restrictions (particularly regarding cadmium, lead, and mercury content), and end-of-life management protocols. The EU's REACH regulation further restricts certain chemical compounds used in electrolytes.

In Asia, regulatory approaches vary significantly. Japan's METI (Ministry of Economy, Trade and Industry) has developed specific technical standards for hybrid supercapacitors used in automotive and grid applications, while China's regulatory framework focuses primarily on manufacturing standards through GB/T specifications, with less emphasis on environmental considerations.

A major technical challenge in meeting these diverse regulations is the development of standardized testing protocols. Current testing methodologies vary significantly across jurisdictions, creating barriers to global market access and increasing compliance costs. The lack of harmonized performance metrics makes cross-market comparisons difficult for manufacturers and consumers alike.

Material compliance represents another significant hurdle. Many high-performance hybrid supercapacitors rely on rare earth elements or potentially hazardous materials that face increasing regulatory scrutiny. Manufacturers must navigate complex supply chain documentation requirements to demonstrate compliance with material restrictions in different markets.

Safety certification presents additional challenges, particularly for high-energy density hybrid supercapacitors. Thermal runaway risks, electrolyte leakage, and short-circuit prevention mechanisms must be validated through different testing regimes depending on the target market. The IEC 62576 standard provides some guidance but has not been universally adopted.

Recycling and disposal regulations create further complexity. Extended Producer Responsibility (EPR) schemes in Europe and parts of Asia require manufacturers to establish collection and recycling systems, while the technical challenges of separating and recovering materials from hybrid devices remain significant. The composite nature of these systems, combining battery and capacitor technologies, creates unique end-of-life management challenges not addressed by existing regulatory frameworks.

Current Compliance Frameworks and Testing Protocols

01 Electrode materials for hybrid supercapacitors

Various electrode materials can be used in hybrid supercapacitors to enhance energy density and power performance. These materials include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for the creation of hybrid systems that leverage both battery-type and capacitive storage mechanisms, resulting in improved energy storage capabilities while maintaining high power density and cycle life.- Electrode materials for hybrid supercapacitors: Various electrode materials can be used in hybrid supercapacitors to enhance energy density and power performance. These materials include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for the creation of hybrid systems that leverage both battery-type and capacitive storage mechanisms, resulting in improved energy storage capabilities and cycle life.

- Electrolyte compositions for hybrid supercapacitors: Specialized electrolyte compositions play a crucial role in hybrid supercapacitor performance. These electrolytes can be aqueous, organic, or ionic liquid-based, each offering different advantages in terms of operating voltage window, ionic conductivity, and temperature stability. Advanced electrolyte formulations help to increase energy density while maintaining high power capabilities and ensuring long-term operational stability.

- Energy management systems for hybrid supercapacitors: Energy management systems are designed to optimize the performance of hybrid supercapacitors in various applications. These systems include control circuits, power converters, and monitoring technologies that regulate charging and discharging processes. Advanced management systems can balance energy distribution, prevent overcharging, and extend the operational lifetime of hybrid supercapacitor systems while maximizing their efficiency.

- Manufacturing processes for hybrid supercapacitors: Innovative manufacturing techniques are employed to produce high-performance hybrid supercapacitors. These processes include advanced coating methods, electrode assembly techniques, and packaging solutions that enhance the electrical and mechanical properties of the devices. Specialized manufacturing approaches help to improve the interface between different components, reduce internal resistance, and ensure consistent performance across production batches.

- Integration of hybrid supercapacitors in energy storage systems: Hybrid supercapacitors can be integrated into larger energy storage systems to provide complementary performance characteristics. These integration approaches include hybrid battery-supercapacitor systems, renewable energy storage solutions, and grid stabilization applications. By combining hybrid supercapacitors with other energy storage technologies, these systems can deliver both high energy density and high power density, addressing the limitations of individual storage technologies.

02 Electrolyte compositions for hybrid supercapacitors

Specialized electrolyte formulations play a crucial role in hybrid supercapacitor performance. These electrolytes can be aqueous, organic, or ionic liquid-based, each offering different advantages in terms of operating voltage window, ionic conductivity, and temperature stability. Advanced electrolyte compositions help to increase energy density by enabling higher operating voltages while maintaining good ionic transport properties and electrochemical stability.Expand Specific Solutions03 Integration of hybrid supercapacitors in energy management systems

Hybrid supercapacitors can be effectively integrated into energy management systems for various applications including renewable energy storage, automotive systems, and grid stabilization. These integration approaches involve specialized control algorithms, power electronics interfaces, and thermal management systems that optimize the performance of hybrid supercapacitors in conjunction with other energy storage technologies, maximizing efficiency and extending operational lifetime.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitors

Advanced manufacturing techniques for hybrid supercapacitors include specialized coating methods, electrode assembly processes, and packaging technologies. These processes focus on optimizing the interface between different materials, ensuring uniform distribution of active components, and creating stable electrode-electrolyte interfaces. Innovations in manufacturing help to reduce costs, improve consistency, and enhance the scalability of hybrid supercapacitor production.Expand Specific Solutions05 Novel hybrid supercapacitor architectures

Innovative architectural designs for hybrid supercapacitors include asymmetric configurations, interdigitated electrode structures, and hierarchical porous frameworks. These novel architectures aim to optimize ion transport pathways, maximize active surface area, and enhance the synergy between different charge storage mechanisms. By engineering the physical structure of the device, these designs achieve improved energy and power densities while maintaining excellent cycling stability.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

The regulatory landscape for hybrid supercapacitors is evolving as the technology matures, currently positioned at the early commercialization phase. The market is experiencing rapid growth, projected to reach $720 million by 2025 with a CAGR of 19.2%. Key players demonstrate varying technological maturity: established corporations like Microsoft Technology Licensing, Toshiba, and Robert Bosch lead with comprehensive patent portfolios, while CRRC subsidiaries and State Grid Corp. of China focus on grid-scale applications. Academic institutions including MIT, Xiamen University, and Indian Institute of Science contribute fundamental research, creating a competitive ecosystem where regulatory frameworks are still developing to address safety standards, performance metrics, and environmental considerations across transportation, energy storage, and consumer electronics applications.

KYOCERA AVX Components Corp.

Technical Solution: KYOCERA AVX has developed a comprehensive regulatory compliance framework for their hybrid supercapacitor technology that addresses multiple international standards. Their approach integrates UL 810A certification for supercapacitors with IEC 62391 standards, while simultaneously ensuring compliance with RoHS and REACH regulations for material composition. The company has pioneered a dual-track regulatory strategy that separates energy storage performance standards from safety and environmental compliance, allowing for more efficient certification processes. Their framework includes detailed documentation systems for material traceability and regular third-party verification of compliance with evolving global regulations. KYOCERA AVX also maintains active participation in international standards committees to help shape future regulatory developments for hybrid supercapacitor technologies.

Strengths: Strong established presence in electronic components market with extensive experience navigating global regulatory environments; comprehensive compliance documentation systems. Weaknesses: Regulatory framework may be overly focused on traditional markets rather than emerging applications; potential challenges adapting to rapidly evolving regulations in developing markets.

State Grid Corp. of China

Technical Solution: State Grid has developed a comprehensive regulatory framework for hybrid supercapacitors deployed in grid-scale energy storage applications. Their approach centers on China's evolving energy storage standards (GB/T 36558) while incorporating international best practices from IEEE and IEC standards. The framework features a three-tier compliance structure addressing safety, performance, and grid integration requirements specifically for large-scale hybrid supercapacitor installations. State Grid has pioneered specialized testing protocols for high-voltage applications that exceed 10kV, addressing unique safety concerns in transmission infrastructure. Their regulatory approach includes detailed requirements for remote monitoring systems that track compliance parameters in real-time, with automated reporting to regulatory authorities. The framework also incorporates China's specific environmental regulations for energy storage systems, including material restrictions and end-of-life management requirements that align with circular economy principles.

Strengths: Unparalleled experience with grid-scale energy storage regulations; strong alignment with China's rapidly evolving regulatory environment; comprehensive safety protocols for high-voltage applications. Weaknesses: Framework may have limited applicability outside Chinese markets; potential challenges with international certification recognition.

Critical Standards and Certification Requirements

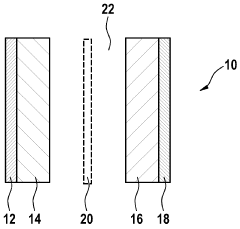

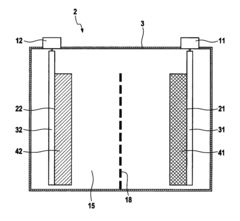

Hybrid supercapacitor with overcharge protection additives

PatentInactiveDE102016217820A1

Innovation

- Incorporation of specific additives such as weakly coordinated perfluoroborane clusters, anisole compounds, S- or N-containing heterocyclic aromatics, phenothiazine compounds, cyclohexylbenzene, biphenyl, 2,2-diphenylpropane, phenyl tert-butyl carbonate, and 3-thiopheneacetonitrile into the electrolyte to provide overcharge protection by forming an insulating layer or acting as redox shuttles.

Electrolyte additive for hybrid supercapacitors to reduce charge transfer resistance, and hybrid supercapacitor including the same

PatentInactiveUS10153097B2

Innovation

- A hybrid supercapacitor design incorporating a negative electrode with statically capacitive and electrochemical redox-active materials, a positive electrode with similar materials, and an electrolyte mixture containing a liquid, aprotic organic solvent, conducting salt, and a partially halogenated aromatic compound, enhancing energy storage efficiency and rate capability.

Environmental Impact and Sustainability Regulations

The regulatory landscape for hybrid supercapacitors increasingly focuses on environmental impact and sustainability requirements. As these energy storage devices gain market share, governments worldwide are implementing stricter regulations regarding their materials, manufacturing processes, and end-of-life management. The European Union leads with its comprehensive framework under the Waste Electrical and Electronic Equipment (WEEE) Directive and the Restriction of Hazardous Substances (RoHS) Directive, which limit the use of harmful substances like lead, mercury, and certain flame retardants in electronic components including supercapacitors.

Carbon footprint regulations are becoming more stringent, with several jurisdictions now requiring manufacturers to disclose the environmental impact of their production processes. The EU's Product Environmental Footprint (PEF) methodology specifically addresses energy storage technologies, requiring lifecycle assessments that account for raw material extraction, manufacturing energy consumption, and transportation emissions. Companies producing hybrid supercapacitors must now document their compliance with these standards to access European markets.

Resource efficiency regulations are evolving rapidly, with particular focus on critical raw materials used in hybrid supercapacitors. The EU's Critical Raw Materials Act and similar legislation in the United States aim to reduce dependency on imported materials and promote sustainable sourcing. These frameworks establish requirements for traceability of materials like cobalt, graphene, and rare earth elements commonly used in advanced supercapacitor designs.

End-of-life management represents another critical regulatory domain. Extended Producer Responsibility (EPR) schemes in over 30 countries now mandate that manufacturers establish collection and recycling programs for their products. For hybrid supercapacitors, which often contain valuable but potentially hazardous materials, these regulations require detailed documentation of material recovery rates and proper disposal procedures for non-recyclable components.

Emerging regulations are increasingly focusing on design for sustainability. The EU's Ecodesign Directive is expanding to cover energy storage systems, potentially mandating minimum requirements for durability, repairability, and recyclability of hybrid supercapacitors. This shift toward circular economy principles is pushing manufacturers to redesign their products for easier disassembly and material recovery.

Certification standards are becoming more prominent regulatory tools, with voluntary schemes like the Electronic Product Environmental Assessment Tool (EPEAT) gaining regulatory recognition. These standards evaluate products across multiple environmental criteria and are increasingly referenced in government procurement policies, effectively creating market access barriers for non-compliant products.

Carbon footprint regulations are becoming more stringent, with several jurisdictions now requiring manufacturers to disclose the environmental impact of their production processes. The EU's Product Environmental Footprint (PEF) methodology specifically addresses energy storage technologies, requiring lifecycle assessments that account for raw material extraction, manufacturing energy consumption, and transportation emissions. Companies producing hybrid supercapacitors must now document their compliance with these standards to access European markets.

Resource efficiency regulations are evolving rapidly, with particular focus on critical raw materials used in hybrid supercapacitors. The EU's Critical Raw Materials Act and similar legislation in the United States aim to reduce dependency on imported materials and promote sustainable sourcing. These frameworks establish requirements for traceability of materials like cobalt, graphene, and rare earth elements commonly used in advanced supercapacitor designs.

End-of-life management represents another critical regulatory domain. Extended Producer Responsibility (EPR) schemes in over 30 countries now mandate that manufacturers establish collection and recycling programs for their products. For hybrid supercapacitors, which often contain valuable but potentially hazardous materials, these regulations require detailed documentation of material recovery rates and proper disposal procedures for non-recyclable components.

Emerging regulations are increasingly focusing on design for sustainability. The EU's Ecodesign Directive is expanding to cover energy storage systems, potentially mandating minimum requirements for durability, repairability, and recyclability of hybrid supercapacitors. This shift toward circular economy principles is pushing manufacturers to redesign their products for easier disassembly and material recovery.

Certification standards are becoming more prominent regulatory tools, with voluntary schemes like the Electronic Product Environmental Assessment Tool (EPEAT) gaining regulatory recognition. These standards evaluate products across multiple environmental criteria and are increasingly referenced in government procurement policies, effectively creating market access barriers for non-compliant products.

Safety Protocols and Risk Management Guidelines

The implementation of comprehensive safety protocols and risk management guidelines is paramount for the responsible development and deployment of hybrid supercapacitor technologies. Current regulatory frameworks mandate specific safety measures that address the unique characteristics of these energy storage devices, particularly their high power density and rapid charge-discharge capabilities.

Primary safety protocols focus on thermal management systems, as hybrid supercapacitors can generate significant heat during operation. These protocols typically require multi-layered temperature monitoring systems with automated shutdown mechanisms that activate when predetermined temperature thresholds are exceeded. Additionally, electrical isolation standards have been established to prevent short circuits and electrical arcing, which represent significant safety hazards in high-power applications.

Risk management guidelines for hybrid supercapacitors emphasize the importance of regular inspection schedules and preventive maintenance procedures. These guidelines typically require documentation of performance parameters over time to identify potential degradation patterns before they manifest as safety issues. The International Electrotechnical Commission (IEC) has developed specific testing protocols (IEC 62576 and IEC 62391) that manufacturers must follow to verify the safety and reliability of their products under various operational conditions.

Transportation regulations present another critical aspect of safety management for hybrid supercapacitors. The UN Model Regulations for the Transport of Dangerous Goods classify these devices based on their energy storage capacity and potential hazards during transit. Manufacturers must adhere to specific packaging requirements and labeling standards to ensure safe handling throughout the supply chain.

Emergency response protocols constitute an essential component of the safety framework. These protocols outline specific procedures for addressing thermal runaway events, electrolyte leakage, or structural failures. Facility operators must maintain detailed emergency response plans and conduct regular drills to ensure preparedness for potential incidents involving hybrid supercapacitor systems.

Environmental considerations are increasingly integrated into safety guidelines, with particular attention to end-of-life management and disposal procedures. Regulatory frameworks in the EU, under the Waste Electrical and Electronic Equipment (WEEE) Directive, mandate specific recycling requirements for components containing potentially hazardous materials, while the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain substances in manufacturing processes.

Industry-specific adaptations of these safety protocols exist for automotive, grid storage, and consumer electronics applications, reflecting the diverse operational environments and risk profiles associated with different use cases of hybrid supercapacitor technology.

Primary safety protocols focus on thermal management systems, as hybrid supercapacitors can generate significant heat during operation. These protocols typically require multi-layered temperature monitoring systems with automated shutdown mechanisms that activate when predetermined temperature thresholds are exceeded. Additionally, electrical isolation standards have been established to prevent short circuits and electrical arcing, which represent significant safety hazards in high-power applications.

Risk management guidelines for hybrid supercapacitors emphasize the importance of regular inspection schedules and preventive maintenance procedures. These guidelines typically require documentation of performance parameters over time to identify potential degradation patterns before they manifest as safety issues. The International Electrotechnical Commission (IEC) has developed specific testing protocols (IEC 62576 and IEC 62391) that manufacturers must follow to verify the safety and reliability of their products under various operational conditions.

Transportation regulations present another critical aspect of safety management for hybrid supercapacitors. The UN Model Regulations for the Transport of Dangerous Goods classify these devices based on their energy storage capacity and potential hazards during transit. Manufacturers must adhere to specific packaging requirements and labeling standards to ensure safe handling throughout the supply chain.

Emergency response protocols constitute an essential component of the safety framework. These protocols outline specific procedures for addressing thermal runaway events, electrolyte leakage, or structural failures. Facility operators must maintain detailed emergency response plans and conduct regular drills to ensure preparedness for potential incidents involving hybrid supercapacitor systems.

Environmental considerations are increasingly integrated into safety guidelines, with particular attention to end-of-life management and disposal procedures. Regulatory frameworks in the EU, under the Waste Electrical and Electronic Equipment (WEEE) Directive, mandate specific recycling requirements for components containing potentially hazardous materials, while the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain substances in manufacturing processes.

Industry-specific adaptations of these safety protocols exist for automotive, grid storage, and consumer electronics applications, reflecting the diverse operational environments and risk profiles associated with different use cases of hybrid supercapacitor technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!