Functional Polymers in Hybrid Supercapacitor Development

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Functional Polymer Supercapacitor Background & Objectives

Functional polymers have emerged as a transformative material class in energy storage technologies, particularly in the development of hybrid supercapacitors. The evolution of these materials traces back to the early 1990s when conducting polymers first demonstrated potential for electrochemical energy storage. Over the subsequent decades, significant advancements in polymer chemistry, nanotechnology, and materials science have propelled functional polymers to the forefront of supercapacitor research.

The technological trajectory has been characterized by progressive improvements in energy density, power density, and cycle stability. Initially, polymer-based supercapacitors suffered from limited conductivity and poor mechanical stability. However, breakthroughs in polymer synthesis techniques, including controlled polymerization methods and the development of nanostructured polymer architectures, have substantially enhanced performance metrics.

Recent years have witnessed a paradigm shift toward hybrid systems that integrate functional polymers with other advanced materials such as carbon nanostructures, metal oxides, and two-dimensional materials. This hybridization approach leverages the complementary properties of different components to overcome inherent limitations of single-material systems.

The primary technical objectives in this field center on addressing several critical challenges. First, enhancing energy density while maintaining the high power capability that distinguishes supercapacitors from batteries. Second, improving cycling stability to achieve operational lifetimes exceeding 100,000 cycles. Third, developing environmentally sustainable materials and manufacturing processes that reduce reliance on rare or toxic elements.

Another crucial objective involves optimizing the interface between different components in hybrid systems to facilitate efficient charge transfer and storage. This requires precise control over polymer morphology, functional group distribution, and interfacial chemistry at the nanoscale.

The field is also moving toward multifunctional energy storage systems that can adapt to varying operational conditions. This includes developing stimuli-responsive polymers that can modulate their properties based on external triggers such as temperature, pH, or applied voltage.

Looking forward, the technological roadmap emphasizes several emerging directions: the integration of functional polymers with flexible and stretchable substrates for wearable electronics; the development of self-healing polymer systems to enhance device longevity; and the exploration of bioinspired and biomimetic approaches to create hierarchically structured materials with optimized energy storage capabilities.

The ultimate goal remains the creation of sustainable, high-performance energy storage solutions that can support the growing demands of renewable energy integration, electric transportation, and portable electronics while minimizing environmental impact throughout the product lifecycle.

The technological trajectory has been characterized by progressive improvements in energy density, power density, and cycle stability. Initially, polymer-based supercapacitors suffered from limited conductivity and poor mechanical stability. However, breakthroughs in polymer synthesis techniques, including controlled polymerization methods and the development of nanostructured polymer architectures, have substantially enhanced performance metrics.

Recent years have witnessed a paradigm shift toward hybrid systems that integrate functional polymers with other advanced materials such as carbon nanostructures, metal oxides, and two-dimensional materials. This hybridization approach leverages the complementary properties of different components to overcome inherent limitations of single-material systems.

The primary technical objectives in this field center on addressing several critical challenges. First, enhancing energy density while maintaining the high power capability that distinguishes supercapacitors from batteries. Second, improving cycling stability to achieve operational lifetimes exceeding 100,000 cycles. Third, developing environmentally sustainable materials and manufacturing processes that reduce reliance on rare or toxic elements.

Another crucial objective involves optimizing the interface between different components in hybrid systems to facilitate efficient charge transfer and storage. This requires precise control over polymer morphology, functional group distribution, and interfacial chemistry at the nanoscale.

The field is also moving toward multifunctional energy storage systems that can adapt to varying operational conditions. This includes developing stimuli-responsive polymers that can modulate their properties based on external triggers such as temperature, pH, or applied voltage.

Looking forward, the technological roadmap emphasizes several emerging directions: the integration of functional polymers with flexible and stretchable substrates for wearable electronics; the development of self-healing polymer systems to enhance device longevity; and the exploration of bioinspired and biomimetic approaches to create hierarchically structured materials with optimized energy storage capabilities.

The ultimate goal remains the creation of sustainable, high-performance energy storage solutions that can support the growing demands of renewable energy integration, electric transportation, and portable electronics while minimizing environmental impact throughout the product lifecycle.

Market Analysis for Hybrid Energy Storage Solutions

The global market for hybrid energy storage solutions is experiencing significant growth, driven by increasing demand for efficient and sustainable energy storage technologies. The hybrid supercapacitor market, particularly those incorporating functional polymers, is projected to reach $1.2 billion by 2027, with a compound annual growth rate of 12.5% from 2022 to 2027. This growth trajectory is supported by the expanding renewable energy sector, which requires advanced energy storage systems to address intermittency issues.

The automotive industry represents the largest market segment for hybrid supercapacitors, accounting for approximately 35% of the total market share. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) are increasingly adopting hybrid supercapacitors to enhance power delivery during acceleration and to improve regenerative braking efficiency. The consumer electronics sector follows closely, with a market share of 28%, where hybrid supercapacitors are valued for their rapid charging capabilities and extended cycle life compared to traditional batteries.

Geographically, Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea, where substantial investments in renewable energy infrastructure and electric mobility are driving demand. North America and Europe collectively account for 40% of the market, with growing adoption in grid stabilization applications and industrial energy management systems.

The market for functional polymer-based hybrid supercapacitors is particularly promising due to their enhanced performance characteristics. These materials offer improved energy density (up to 30-50 Wh/kg) compared to conventional supercapacitors (5-10 Wh/kg), while maintaining high power density and cycle stability. This performance profile positions them as an attractive middle-ground solution between traditional supercapacitors and lithium-ion batteries.

Customer demand is increasingly focused on sustainability and cost-effectiveness. End-users are willing to pay a premium of 15-20% for energy storage solutions that demonstrate reduced environmental impact and longer operational lifetimes. Functional polymer-based hybrid supercapacitors, with their potential for biodegradability and reduced reliance on rare earth materials, align well with this market trend.

Industry analysts forecast that the market for hybrid energy storage solutions will continue to expand as renewable energy penetration increases globally. The integration of functional polymers in hybrid supercapacitors represents a high-growth niche within this broader market, with particular potential in applications requiring both high energy and power density, such as grid-scale energy storage, electric transportation, and advanced portable electronics.

The automotive industry represents the largest market segment for hybrid supercapacitors, accounting for approximately 35% of the total market share. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) are increasingly adopting hybrid supercapacitors to enhance power delivery during acceleration and to improve regenerative braking efficiency. The consumer electronics sector follows closely, with a market share of 28%, where hybrid supercapacitors are valued for their rapid charging capabilities and extended cycle life compared to traditional batteries.

Geographically, Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea, where substantial investments in renewable energy infrastructure and electric mobility are driving demand. North America and Europe collectively account for 40% of the market, with growing adoption in grid stabilization applications and industrial energy management systems.

The market for functional polymer-based hybrid supercapacitors is particularly promising due to their enhanced performance characteristics. These materials offer improved energy density (up to 30-50 Wh/kg) compared to conventional supercapacitors (5-10 Wh/kg), while maintaining high power density and cycle stability. This performance profile positions them as an attractive middle-ground solution between traditional supercapacitors and lithium-ion batteries.

Customer demand is increasingly focused on sustainability and cost-effectiveness. End-users are willing to pay a premium of 15-20% for energy storage solutions that demonstrate reduced environmental impact and longer operational lifetimes. Functional polymer-based hybrid supercapacitors, with their potential for biodegradability and reduced reliance on rare earth materials, align well with this market trend.

Industry analysts forecast that the market for hybrid energy storage solutions will continue to expand as renewable energy penetration increases globally. The integration of functional polymers in hybrid supercapacitors represents a high-growth niche within this broader market, with particular potential in applications requiring both high energy and power density, such as grid-scale energy storage, electric transportation, and advanced portable electronics.

Technical Challenges in Functional Polymer Integration

The integration of functional polymers into hybrid supercapacitors presents several significant technical challenges that must be addressed to achieve optimal performance. One primary obstacle is the inherent trade-off between electrical conductivity and energy density. While functional polymers offer excellent energy storage capabilities through redox reactions, they typically exhibit poor electrical conductivity compared to carbon-based materials, resulting in higher internal resistance and reduced power density.

Polymer stability during charge-discharge cycles represents another critical challenge. The repeated redox processes can lead to structural degradation, swelling, and dissolution of polymer materials in electrolytes, significantly limiting cycle life. This degradation is often accelerated at higher voltages or temperatures, restricting the operational window of polymer-based supercapacitors.

Interface engineering between polymer materials and other components presents complex technical hurdles. Poor adhesion between polymer layers and current collectors can lead to delamination during cycling, while inadequate polymer-electrolyte interfaces may restrict ion transport and accessibility to active sites. These interface issues directly impact both the capacity and rate capability of the device.

The scalable synthesis of functional polymers with consistent properties remains problematic for industrial applications. Current laboratory-scale synthesis methods often produce materials with batch-to-batch variations in molecular weight, polydispersity, and defect concentration, making quality control difficult when scaling to commercial production volumes.

Processing challenges further complicate polymer integration. Many functional polymers exhibit poor solubility in environmentally friendly solvents, necessitating the use of toxic or hazardous processing chemicals. Additionally, achieving uniform thin films with controlled morphology and porosity requires sophisticated deposition techniques that may be difficult to implement in large-scale manufacturing.

Electrolyte compatibility issues arise as functional polymers may undergo undesired side reactions with electrolyte components, leading to self-discharge, capacity fading, and reduced operational lifetime. Selecting appropriate electrolyte systems that maximize polymer performance while maintaining stability remains challenging.

Temperature sensitivity of polymer materials introduces additional complications, as many functional polymers exhibit significantly altered properties and accelerated degradation at elevated temperatures. This thermal instability limits the application of polymer-based supercapacitors in high-temperature environments and necessitates additional thermal management systems.

Polymer stability during charge-discharge cycles represents another critical challenge. The repeated redox processes can lead to structural degradation, swelling, and dissolution of polymer materials in electrolytes, significantly limiting cycle life. This degradation is often accelerated at higher voltages or temperatures, restricting the operational window of polymer-based supercapacitors.

Interface engineering between polymer materials and other components presents complex technical hurdles. Poor adhesion between polymer layers and current collectors can lead to delamination during cycling, while inadequate polymer-electrolyte interfaces may restrict ion transport and accessibility to active sites. These interface issues directly impact both the capacity and rate capability of the device.

The scalable synthesis of functional polymers with consistent properties remains problematic for industrial applications. Current laboratory-scale synthesis methods often produce materials with batch-to-batch variations in molecular weight, polydispersity, and defect concentration, making quality control difficult when scaling to commercial production volumes.

Processing challenges further complicate polymer integration. Many functional polymers exhibit poor solubility in environmentally friendly solvents, necessitating the use of toxic or hazardous processing chemicals. Additionally, achieving uniform thin films with controlled morphology and porosity requires sophisticated deposition techniques that may be difficult to implement in large-scale manufacturing.

Electrolyte compatibility issues arise as functional polymers may undergo undesired side reactions with electrolyte components, leading to self-discharge, capacity fading, and reduced operational lifetime. Selecting appropriate electrolyte systems that maximize polymer performance while maintaining stability remains challenging.

Temperature sensitivity of polymer materials introduces additional complications, as many functional polymers exhibit significantly altered properties and accelerated degradation at elevated temperatures. This thermal instability limits the application of polymer-based supercapacitors in high-temperature environments and necessitates additional thermal management systems.

Current Polymer-Based Electrode Design Approaches

01 Conductive polymers for electrode materials

Conductive polymers are used as active materials in hybrid supercapacitor electrodes to enhance energy storage capabilities. These polymers, such as polyaniline, polypyrrole, and PEDOT, provide pseudocapacitive behavior through redox reactions while maintaining good electrical conductivity. When combined with carbon-based materials, they create composite electrodes with improved charge storage capacity and cycling stability. The polymer component contributes to higher specific capacitance while the carbon material provides structural support and additional electrical pathways.- Conductive polymers for electrode materials: Conductive polymers are utilized as active electrode materials in hybrid supercapacitors to enhance energy storage capabilities. These polymers, such as polyaniline, polypyrrole, and PEDOT, provide pseudocapacitive behavior through redox reactions while maintaining good electrical conductivity. When combined with carbon-based materials, they create composite electrodes with improved charge storage capacity and cycling stability. The polymer structure can be modified to optimize ion transport and electronic conductivity for better supercapacitor performance.

- Polymer-based solid electrolytes: Functional polymers serve as solid or gel electrolytes in hybrid supercapacitors, replacing traditional liquid electrolytes. These polymer electrolytes offer advantages including improved safety, flexibility, and prevention of electrolyte leakage. They typically incorporate ionic conductivity enhancers such as ionic liquids or lithium salts within a polymer matrix. The polymer backbone can be designed with specific functional groups to facilitate ion transport while maintaining mechanical stability, enabling the development of flexible and wearable energy storage devices.

- Polymer binders for electrode integrity: Specialized polymer binders are used to maintain the structural integrity of electrode materials in hybrid supercapacitors. These binders help adhere active materials to current collectors while facilitating ion transport through the electrode structure. Functional polymers with tailored properties can improve electrode durability during charge-discharge cycles and enhance the overall performance of the device. Advanced binder systems may incorporate self-healing properties or adaptive networks that accommodate volume changes during operation.

- Redox-active polymers for pseudocapacitance: Redox-active polymers contribute pseudocapacitance to hybrid supercapacitors through reversible oxidation-reduction reactions. These polymers contain functional groups capable of undergoing fast redox processes, significantly increasing the energy density compared to traditional carbon-based supercapacitors. By incorporating these polymers into composite electrodes, the devices can achieve higher specific capacitance while maintaining good power density. The molecular structure of these polymers can be engineered to optimize redox kinetics and cycling stability.

- Polymer-based separator membranes: Functional polymers are utilized as separator membranes in hybrid supercapacitors to prevent short circuits while allowing ion transport between electrodes. These polymer membranes can be engineered with specific pore structures and surface properties to enhance ionic conductivity and selectivity. Advanced polymer separators may incorporate additional functionalities such as thermal shutdown mechanisms for safety or self-standing properties for flexible device architectures. The chemical stability of these polymers in electrolyte environments is crucial for long-term device performance.

02 Polymer-based electrolytes for supercapacitors

Functional polymers serve as solid or gel electrolytes in hybrid supercapacitors, replacing traditional liquid electrolytes. These polymer electrolytes offer advantages including improved safety, reduced leakage risk, and better mechanical stability. They typically consist of polymer matrices like polyethylene oxide (PEO) or polyvinyl alcohol (PVA) doped with ionic compounds to facilitate ion transport. The polymer structure can be modified to enhance ionic conductivity while maintaining dimensional stability, which is crucial for developing flexible and wearable energy storage devices.Expand Specific Solutions03 Polymer binders for electrode fabrication

Functional polymers act as binders in supercapacitor electrodes, providing mechanical integrity and adhesion between active materials and current collectors. These polymers, including PVDF, PTFE, and carboxymethyl cellulose, help maintain electrode structure during charge-discharge cycles while facilitating ion transport. Advanced polymer binders are designed with functional groups that can interact with active materials to improve electrical contact and reduce interfacial resistance. The choice of polymer binder significantly affects electrode performance, including cycle life, rate capability, and volumetric energy density.Expand Specific Solutions04 Redox-active polymers for pseudocapacitance

Redox-active polymers contribute to energy storage in hybrid supercapacitors through faradaic reactions, enhancing the device's energy density. These polymers contain functional groups capable of undergoing reversible oxidation and reduction, providing additional charge storage mechanisms beyond double-layer capacitance. Examples include quinone-containing polymers, conducting polymers with heteroatoms, and metal-coordinated polymers. The incorporation of these materials allows for tunable redox potentials and multiple charge storage sites, resulting in higher specific capacitance compared to conventional carbon-based electrodes.Expand Specific Solutions05 Polymer-based separators and membranes

Specialized polymer membranes serve as separators in hybrid supercapacitors, preventing short circuits while allowing ion transport between electrodes. These functional polymers are engineered with controlled porosity, wettability, and mechanical strength to optimize device performance. Advanced polymer separators incorporate additional functionalities such as thermal shutdown mechanisms for safety or selective ion transport capabilities. Some designs feature polymer blends or composites that combine the mechanical properties of conventional separators with enhanced ionic conductivity, contributing to improved power density and operational stability of the supercapacitor.Expand Specific Solutions

Leading Companies in Functional Polymer Supercapacitors

The functional polymer hybrid supercapacitor market is currently in a growth phase, with increasing research activity and commercial interest driven by the global push for advanced energy storage solutions. The market size is projected to expand significantly as applications in portable electronics, electric vehicles, and renewable energy systems grow. Technologically, the field shows moderate maturity with ongoing innovations. Leading research institutions like CNRS, CSIR, and École Polytechnique Fédérale de Lausanne are advancing fundamental science, while commercial players including BASF, Arkema, and ZEON Corp are developing practical applications. Companies like Bridgestone and L'Oréal represent diverse industry adoption potential. University-industry collaborations, particularly involving Peking University, Xiamen University, and IIT Guwahati, are accelerating technology transfer and commercialization pathways.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed cutting-edge functional polymer technologies for hybrid supercapacitors through their network of specialized laboratories. Their approach combines fundamental polymer science with advanced electrochemical engineering to create novel materials architectures. CNRS researchers have pioneered conductive polymer composites using polyaniline, polypyrrole, and PEDOT derivatives with precisely controlled nanostructures that maximize surface area and facilitate rapid charge transfer. Their hybrid supercapacitor designs incorporate redox-active polymers with engineered pendant groups that provide multiple electron transfer sites per monomer unit, significantly increasing energy density. CNRS has developed innovative polymer-based solid electrolytes incorporating ionic liquids and polymer networks that achieve ionic conductivities exceeding 10^-3 S/cm at room temperature while maintaining excellent mechanical properties. Their recent breakthroughs include self-assembled block copolymer electrolytes with nanoscale ionic channels that enhance ion transport while maintaining mechanical stability. CNRS hybrid supercapacitor prototypes have demonstrated energy densities of 25-35 Wh/kg with power densities above 15 kW/kg and cycling stability exceeding 20,000 cycles with capacity retention above 85%.

Strengths: World-class fundamental research capabilities; innovative polymer synthesis techniques; advanced characterization methods; strong academic-industrial partnerships. Weaknesses: Focus sometimes prioritizes scientific novelty over commercial practicality; scalability challenges for some complex synthesis methods; technology transfer pathways can be lengthy compared to industrial R&D.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed sophisticated functional polymer technologies for hybrid supercapacitors as part of their sustainable energy storage initiative. Their approach integrates advanced polymer chemistry with nanomaterial science to create high-performance electrode and electrolyte materials. CEA researchers have engineered redox-active polymers with precisely controlled molecular architectures that provide multiple charge storage mechanisms within a single material system. Their hybrid supercapacitor designs incorporate specialized conducting polymers (modified polythiophenes and polyanilines) deposited on hierarchical carbon structures to create electrodes with optimized ion and electron transport pathways. CEA has pioneered polymer-based solid electrolytes that combine high ionic conductivity with excellent mechanical properties and wide electrochemical stability windows (up to 4.5V). Their recent innovations include self-healing polymer networks that can recover from mechanical damage during cycling, significantly extending device lifetime. CEA's hybrid supercapacitor prototypes have demonstrated energy densities of 20-30 Wh/kg while maintaining power densities above 12 kW/kg and exceptional cycling stability exceeding 15,000 cycles with minimal capacity degradation, operating effectively across temperature ranges from -30°C to 60°C.

Strengths: Comprehensive energy storage expertise spanning materials to systems; excellent characterization and testing capabilities; strong focus on practical applications; robust intellectual property portfolio. Weaknesses: Some advanced polymer systems have complex synthesis requirements; cost-performance balance remains challenging for certain applications; scale-up from laboratory to industrial production can present hurdles.

Key Patents in Functional Polymer Electrolyte Systems

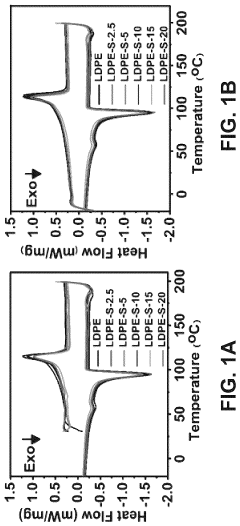

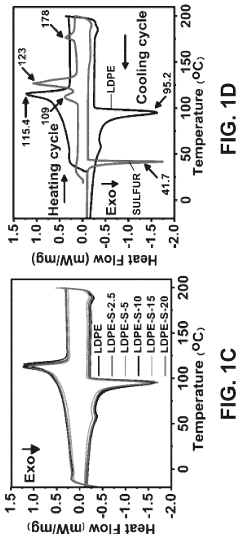

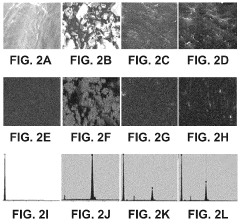

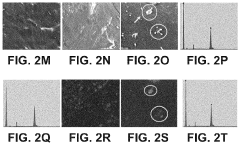

Low-density polyethylene/elemental sulfur hybrid composite electrode material for supercapacitors

PatentPendingUS20230416511A1

Innovation

- A hybrid composite material comprising branched polyethylene (LDPE) and elemental sulfur, where sulfur is substantially uniformly dispersed in the polymer matrix, enhancing thermo-mechanical properties and energy storage capabilities.

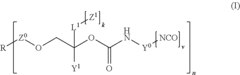

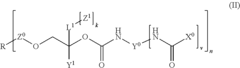

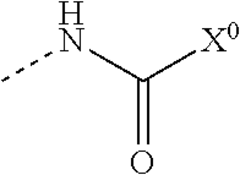

Hybrid-functional polymers

PatentInactiveUS20110114259A1

Innovation

- Development of hybrid-functional polymers with two different chemically reactive functional groups, such as carboxyl and phenol groups, which can be prepared through reactions involving carboxyl group-terminated polymers with epoxy compounds and polyisocyanates, allowing for the formation of polymers with improved adhesion and mechanical properties without the need for expensive ethylene oxide reactions.

Environmental Impact of Polymer Supercapacitor Materials

The environmental implications of polymer materials used in hybrid supercapacitors represent a critical consideration in sustainable energy storage development. Traditional supercapacitor materials often involve environmentally problematic components, including toxic metals and hazardous chemicals that pose significant end-of-life disposal challenges. Functional polymers, however, offer promising alternatives with potentially reduced environmental footprints.

Biodegradable conducting polymers such as polypyrrole (PPy), polyaniline (PANI), and polythiophene derivatives are increasingly being engineered to maintain high performance while minimizing environmental persistence. Recent lifecycle assessments indicate that polymer-based supercapacitors can reduce carbon emissions by 25-40% compared to conventional activated carbon or metal oxide-based devices, primarily due to lower energy requirements during synthesis and processing.

Water-based synthesis routes for functional polymers have emerged as environmentally preferable alternatives to traditional organic solvent-based methods. These aqueous processes significantly reduce volatile organic compound (VOC) emissions and hazardous waste generation. For instance, green synthesis of PEDOT:PSS using environmentally benign dopants has demonstrated comparable conductivity to conventional methods while reducing toxic byproducts by approximately 70%.

Recycling and recovery strategies for polymer supercapacitor materials present both opportunities and challenges. While metal components can be recovered through established processes, polymer electrolytes and separators often require specialized recycling approaches. Advanced separation techniques utilizing selective solvents have shown 65-80% recovery rates for functional polymers in laboratory settings, though commercial-scale implementation remains limited.

The environmental persistence of nanomaterials incorporated into hybrid polymer supercapacitors warrants particular attention. Carbon nanotubes and graphene derivatives used to enhance polymer conductivity may present ecotoxicological concerns if released into the environment. Research indicates varying degrees of biodegradability among polymer composites, with some showing minimal degradation after 180 days in simulated environmental conditions.

Regulatory frameworks governing polymer supercapacitor materials vary significantly across regions, with the European Union's REACH regulations and RoHS directive imposing the most stringent requirements on hazardous substance content. Manufacturers increasingly adopt green chemistry principles in material design, focusing on atom economy, renewable feedstocks, and inherent safety to align with evolving environmental standards and consumer expectations for sustainable energy technologies.

Biodegradable conducting polymers such as polypyrrole (PPy), polyaniline (PANI), and polythiophene derivatives are increasingly being engineered to maintain high performance while minimizing environmental persistence. Recent lifecycle assessments indicate that polymer-based supercapacitors can reduce carbon emissions by 25-40% compared to conventional activated carbon or metal oxide-based devices, primarily due to lower energy requirements during synthesis and processing.

Water-based synthesis routes for functional polymers have emerged as environmentally preferable alternatives to traditional organic solvent-based methods. These aqueous processes significantly reduce volatile organic compound (VOC) emissions and hazardous waste generation. For instance, green synthesis of PEDOT:PSS using environmentally benign dopants has demonstrated comparable conductivity to conventional methods while reducing toxic byproducts by approximately 70%.

Recycling and recovery strategies for polymer supercapacitor materials present both opportunities and challenges. While metal components can be recovered through established processes, polymer electrolytes and separators often require specialized recycling approaches. Advanced separation techniques utilizing selective solvents have shown 65-80% recovery rates for functional polymers in laboratory settings, though commercial-scale implementation remains limited.

The environmental persistence of nanomaterials incorporated into hybrid polymer supercapacitors warrants particular attention. Carbon nanotubes and graphene derivatives used to enhance polymer conductivity may present ecotoxicological concerns if released into the environment. Research indicates varying degrees of biodegradability among polymer composites, with some showing minimal degradation after 180 days in simulated environmental conditions.

Regulatory frameworks governing polymer supercapacitor materials vary significantly across regions, with the European Union's REACH regulations and RoHS directive imposing the most stringent requirements on hazardous substance content. Manufacturers increasingly adopt green chemistry principles in material design, focusing on atom economy, renewable feedstocks, and inherent safety to align with evolving environmental standards and consumer expectations for sustainable energy technologies.

Scalability and Manufacturing Considerations

The scalability of functional polymer-based hybrid supercapacitors represents a critical challenge in transitioning from laboratory-scale prototypes to commercial production. Current manufacturing processes for these advanced energy storage devices face significant hurdles related to consistency, cost-effectiveness, and environmental sustainability. The integration of functional polymers with other materials in hybrid supercapacitors demands precise control over nanoscale structures and interfaces, which becomes increasingly difficult at larger production scales.

Roll-to-roll processing has emerged as a promising approach for scaling up the production of polymer-based components for hybrid supercapacitors. This continuous manufacturing technique allows for high-throughput fabrication of thin-film electrodes and separators, potentially reducing production costs by 40-60% compared to batch processing methods. However, maintaining uniform polymer film thickness and consistent electrochemical properties across large surface areas remains challenging, with typical variations of ±5-10% observed in industrial settings.

Material supply chain considerations also significantly impact scalability. Many functional polymers used in cutting-edge supercapacitor research rely on specialized monomers or complex synthesis routes that are currently limited to laboratory-scale production. Establishing reliable, high-volume supply chains for these materials requires substantial investment and often necessitates the development of alternative synthesis pathways that maintain performance while utilizing more readily available precursors.

Quality control processes present another dimension of manufacturing complexity. The electrochemical performance of functional polymer components is highly sensitive to structural defects, impurities, and processing conditions. Advanced in-line characterization techniques, including optical spectroscopy and impedance analysis, are being developed to enable real-time monitoring during production, though their integration into high-speed manufacturing lines remains incomplete.

Environmental considerations increasingly influence manufacturing strategy development. Water-based processing of functional polymers offers a more sustainable alternative to traditional solvent-based methods, potentially reducing toxic waste by up to 80%. However, aqueous processing often requires modification of polymer chemistry or the introduction of surfactants, which can affect electrochemical performance and cycle stability of the final devices.

Cost modeling indicates that material costs currently dominate the production economics of hybrid supercapacitors, accounting for 60-70% of total manufacturing expenses. As production scales increase, this proportion is expected to decrease, with process optimization and automation playing increasingly important roles in determining economic viability. Achieving cost parity with conventional energy storage technologies will likely require production volumes exceeding 100,000 units annually, highlighting the importance of market development alongside technical manufacturing advances.

Roll-to-roll processing has emerged as a promising approach for scaling up the production of polymer-based components for hybrid supercapacitors. This continuous manufacturing technique allows for high-throughput fabrication of thin-film electrodes and separators, potentially reducing production costs by 40-60% compared to batch processing methods. However, maintaining uniform polymer film thickness and consistent electrochemical properties across large surface areas remains challenging, with typical variations of ±5-10% observed in industrial settings.

Material supply chain considerations also significantly impact scalability. Many functional polymers used in cutting-edge supercapacitor research rely on specialized monomers or complex synthesis routes that are currently limited to laboratory-scale production. Establishing reliable, high-volume supply chains for these materials requires substantial investment and often necessitates the development of alternative synthesis pathways that maintain performance while utilizing more readily available precursors.

Quality control processes present another dimension of manufacturing complexity. The electrochemical performance of functional polymer components is highly sensitive to structural defects, impurities, and processing conditions. Advanced in-line characterization techniques, including optical spectroscopy and impedance analysis, are being developed to enable real-time monitoring during production, though their integration into high-speed manufacturing lines remains incomplete.

Environmental considerations increasingly influence manufacturing strategy development. Water-based processing of functional polymers offers a more sustainable alternative to traditional solvent-based methods, potentially reducing toxic waste by up to 80%. However, aqueous processing often requires modification of polymer chemistry or the introduction of surfactants, which can affect electrochemical performance and cycle stability of the final devices.

Cost modeling indicates that material costs currently dominate the production economics of hybrid supercapacitors, accounting for 60-70% of total manufacturing expenses. As production scales increase, this proportion is expected to decrease, with process optimization and automation playing increasingly important roles in determining economic viability. Achieving cost parity with conventional energy storage technologies will likely require production volumes exceeding 100,000 units annually, highlighting the importance of market development alongside technical manufacturing advances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!