Hybrid Supercapacitors in Military and Defense Applications

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Military Hybrid Supercapacitor Background and Objectives

Hybrid supercapacitors represent a significant technological advancement in energy storage systems, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries for specialized applications requiring both rapid power delivery and sustained energy supply.

In military and defense contexts, energy storage solutions have traditionally faced a critical trade-off between power and energy density. Conventional batteries offer high energy density but suffer from limited power output and cycle life, while traditional supercapacitors provide excellent power density but lack sufficient energy storage capacity for extended operations. The development of hybrid supercapacitors emerged as a response to these limitations, aiming to create a more versatile energy storage solution.

The technological trajectory of hybrid supercapacitors has been characterized by continuous improvements in electrode materials, electrolytes, and system integration. Early iterations utilized activated carbon electrodes combined with battery-type materials, while more recent developments have incorporated advanced nanomaterials such as graphene, carbon nanotubes, and metal oxides to enhance performance characteristics.

Military applications present unique operational demands that conventional energy storage technologies struggle to meet. These include requirements for functioning across extreme temperature ranges (-40°C to +85°C), withstanding high mechanical stress and vibration, maintaining reliability in harsh environmental conditions, and delivering consistent performance over thousands of charge-discharge cycles without significant degradation.

The primary technical objectives for hybrid supercapacitors in military applications include achieving energy densities exceeding 20 Wh/kg while maintaining power densities above 10 kW/kg, extending operational temperature ranges, enhancing cycle life beyond 100,000 cycles, reducing weight and volume constraints, and ensuring compatibility with existing military power management systems.

Recent technological breakthroughs have focused on asymmetric designs that pair a battery-type electrode with a supercapacitor-type electrode, enabling devices that can deliver both high energy and power density. These innovations have positioned hybrid supercapacitors as increasingly viable solutions for applications ranging from soldier-portable equipment to vehicle starting systems, weapons platforms, and unmanned aerial vehicles.

The development trajectory aims to address persistent challenges including self-discharge rates, energy density limitations compared to advanced lithium-ion batteries, manufacturing scalability, and system integration complexities. As military systems increasingly rely on sophisticated electronics and electrification, the demand for advanced energy storage solutions continues to drive innovation in this field.

In military and defense contexts, energy storage solutions have traditionally faced a critical trade-off between power and energy density. Conventional batteries offer high energy density but suffer from limited power output and cycle life, while traditional supercapacitors provide excellent power density but lack sufficient energy storage capacity for extended operations. The development of hybrid supercapacitors emerged as a response to these limitations, aiming to create a more versatile energy storage solution.

The technological trajectory of hybrid supercapacitors has been characterized by continuous improvements in electrode materials, electrolytes, and system integration. Early iterations utilized activated carbon electrodes combined with battery-type materials, while more recent developments have incorporated advanced nanomaterials such as graphene, carbon nanotubes, and metal oxides to enhance performance characteristics.

Military applications present unique operational demands that conventional energy storage technologies struggle to meet. These include requirements for functioning across extreme temperature ranges (-40°C to +85°C), withstanding high mechanical stress and vibration, maintaining reliability in harsh environmental conditions, and delivering consistent performance over thousands of charge-discharge cycles without significant degradation.

The primary technical objectives for hybrid supercapacitors in military applications include achieving energy densities exceeding 20 Wh/kg while maintaining power densities above 10 kW/kg, extending operational temperature ranges, enhancing cycle life beyond 100,000 cycles, reducing weight and volume constraints, and ensuring compatibility with existing military power management systems.

Recent technological breakthroughs have focused on asymmetric designs that pair a battery-type electrode with a supercapacitor-type electrode, enabling devices that can deliver both high energy and power density. These innovations have positioned hybrid supercapacitors as increasingly viable solutions for applications ranging from soldier-portable equipment to vehicle starting systems, weapons platforms, and unmanned aerial vehicles.

The development trajectory aims to address persistent challenges including self-discharge rates, energy density limitations compared to advanced lithium-ion batteries, manufacturing scalability, and system integration complexities. As military systems increasingly rely on sophisticated electronics and electrification, the demand for advanced energy storage solutions continues to drive innovation in this field.

Defense Market Demand Analysis for Energy Storage Solutions

The defense sector's energy storage requirements are undergoing significant transformation, driven by the evolving nature of military operations and technological advancements. Current analysis indicates a robust demand for advanced energy storage solutions across various defense applications, with hybrid supercapacitors emerging as a particularly promising technology.

Military operations increasingly require portable, reliable, and high-performance energy storage systems. The global defense energy storage market was valued at approximately $1.8 billion in 2022 and is projected to grow at a CAGR of 6.7% through 2030. This growth is primarily fueled by the increasing electrification of military platforms, the rise of unmanned systems, and the need for enhanced energy resilience in field operations.

Key demand drivers include the military's shift toward silent watch capabilities, where vehicles must maintain operational readiness with minimal acoustic and thermal signatures. This application alone represents nearly 20% of the defense energy storage market. Additionally, the proliferation of soldier-worn electronics, tactical communication systems, and portable battlefield equipment has created substantial demand for lightweight, high-energy-density storage solutions.

The defense sector's unique requirements significantly differ from civilian applications. Military energy storage systems must function reliably in extreme environmental conditions (-40°C to +70°C), withstand mechanical shock and vibration, offer rapid charging capabilities, and maintain performance integrity after prolonged storage periods. These stringent requirements have historically limited adoption of certain commercial technologies.

Regional analysis reveals that North America dominates the defense energy storage market with 42% share, followed by Europe (27%) and Asia-Pacific (21%). However, the fastest growth is occurring in the Asia-Pacific region, where defense modernization initiatives in countries like India, Japan, and South Korea are driving increased investment in advanced energy technologies.

By application segment, vehicle electrification represents the largest market share (34%), followed by unmanned systems (28%), soldier power systems (22%), and base/installation energy security (16%). The unmanned systems segment is experiencing the highest growth rate at 9.3% annually, reflecting the increasing deployment of autonomous platforms across military domains.

Defense procurement cycles present unique market challenges, with typical development-to-deployment timelines spanning 5-7 years. This extended timeline necessitates energy storage technologies that offer clear technological advantages while demonstrating exceptional reliability and service life to justify integration into military platforms.

Military operations increasingly require portable, reliable, and high-performance energy storage systems. The global defense energy storage market was valued at approximately $1.8 billion in 2022 and is projected to grow at a CAGR of 6.7% through 2030. This growth is primarily fueled by the increasing electrification of military platforms, the rise of unmanned systems, and the need for enhanced energy resilience in field operations.

Key demand drivers include the military's shift toward silent watch capabilities, where vehicles must maintain operational readiness with minimal acoustic and thermal signatures. This application alone represents nearly 20% of the defense energy storage market. Additionally, the proliferation of soldier-worn electronics, tactical communication systems, and portable battlefield equipment has created substantial demand for lightweight, high-energy-density storage solutions.

The defense sector's unique requirements significantly differ from civilian applications. Military energy storage systems must function reliably in extreme environmental conditions (-40°C to +70°C), withstand mechanical shock and vibration, offer rapid charging capabilities, and maintain performance integrity after prolonged storage periods. These stringent requirements have historically limited adoption of certain commercial technologies.

Regional analysis reveals that North America dominates the defense energy storage market with 42% share, followed by Europe (27%) and Asia-Pacific (21%). However, the fastest growth is occurring in the Asia-Pacific region, where defense modernization initiatives in countries like India, Japan, and South Korea are driving increased investment in advanced energy technologies.

By application segment, vehicle electrification represents the largest market share (34%), followed by unmanned systems (28%), soldier power systems (22%), and base/installation energy security (16%). The unmanned systems segment is experiencing the highest growth rate at 9.3% annually, reflecting the increasing deployment of autonomous platforms across military domains.

Defense procurement cycles present unique market challenges, with typical development-to-deployment timelines spanning 5-7 years. This extended timeline necessitates energy storage technologies that offer clear technological advantages while demonstrating exceptional reliability and service life to justify integration into military platforms.

Current State and Challenges in Military Energy Storage

Military energy storage systems are currently undergoing significant transformation, with traditional lead-acid and lithium-ion batteries facing increasing challenges in meeting the demanding requirements of modern defense applications. The current energy storage landscape in military operations predominantly relies on these conventional technologies, which often struggle with energy density limitations, operational temperature constraints, and cycle life issues in extreme environments.

Lithium-ion batteries remain the most widely deployed advanced energy storage solution in military applications, offering reasonable energy density and reliability. However, they present significant safety concerns, particularly vulnerability to thermal runaway in combat situations. Additionally, their performance degrades substantially in extreme temperature conditions frequently encountered in military operations.

The defense sector faces unique energy storage challenges that commercial solutions cannot adequately address. Military equipment requires power sources that can function reliably in temperatures ranging from -40°C to +70°C, withstand severe mechanical shock and vibration, and operate in high-humidity environments while maintaining long shelf life. Furthermore, these systems must be capable of rapid charging and delivering high power bursts when needed for critical operations.

Weight and volume constraints represent another significant challenge, particularly for soldier-carried equipment and unmanned systems. Current battery technologies often contribute up to 20% of a soldier's carried weight, limiting operational mobility and effectiveness. The energy density of existing solutions falls short of meeting the increasing power demands of advanced electronic warfare systems, communications equipment, and weapon platforms.

Supply chain security has emerged as a critical concern, with many raw materials for battery production sourced from geopolitically sensitive regions. The Department of Defense has identified energy storage component manufacturing as a strategic vulnerability, with limited domestic production capacity for military-grade energy storage systems.

Hybrid supercapacitors show promising potential to address these challenges by combining the high energy density of batteries with the superior power density and cycle life of supercapacitors. However, their integration into military systems faces significant hurdles, including limited standardization, insufficient testing protocols for military-specific applications, and the need for specialized battery management systems capable of handling their unique charge-discharge characteristics.

The military's increasing focus on silent watch capabilities, electric propulsion for tactical vehicles, and energy-intensive directed energy weapons is driving demand for next-generation storage solutions that exceed the capabilities of current technologies. This creates both urgent challenges and opportunities for innovation in hybrid supercapacitor development specifically tailored to defense applications.

Lithium-ion batteries remain the most widely deployed advanced energy storage solution in military applications, offering reasonable energy density and reliability. However, they present significant safety concerns, particularly vulnerability to thermal runaway in combat situations. Additionally, their performance degrades substantially in extreme temperature conditions frequently encountered in military operations.

The defense sector faces unique energy storage challenges that commercial solutions cannot adequately address. Military equipment requires power sources that can function reliably in temperatures ranging from -40°C to +70°C, withstand severe mechanical shock and vibration, and operate in high-humidity environments while maintaining long shelf life. Furthermore, these systems must be capable of rapid charging and delivering high power bursts when needed for critical operations.

Weight and volume constraints represent another significant challenge, particularly for soldier-carried equipment and unmanned systems. Current battery technologies often contribute up to 20% of a soldier's carried weight, limiting operational mobility and effectiveness. The energy density of existing solutions falls short of meeting the increasing power demands of advanced electronic warfare systems, communications equipment, and weapon platforms.

Supply chain security has emerged as a critical concern, with many raw materials for battery production sourced from geopolitically sensitive regions. The Department of Defense has identified energy storage component manufacturing as a strategic vulnerability, with limited domestic production capacity for military-grade energy storage systems.

Hybrid supercapacitors show promising potential to address these challenges by combining the high energy density of batteries with the superior power density and cycle life of supercapacitors. However, their integration into military systems faces significant hurdles, including limited standardization, insufficient testing protocols for military-specific applications, and the need for specialized battery management systems capable of handling their unique charge-discharge characteristics.

The military's increasing focus on silent watch capabilities, electric propulsion for tactical vehicles, and energy-intensive directed energy weapons is driving demand for next-generation storage solutions that exceed the capabilities of current technologies. This creates both urgent challenges and opportunities for innovation in hybrid supercapacitor development specifically tailored to defense applications.

Current Hybrid Supercapacitor Solutions for Defense

01 Electrode materials for hybrid supercapacitors

Various materials can be used as electrodes in hybrid supercapacitors to enhance energy density and performance. These include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for both high energy and power density in a single device. The electrode composition significantly impacts the capacitance, cycling stability, and overall performance of hybrid supercapacitors.- Electrode materials for hybrid supercapacitors: Hybrid supercapacitors utilize specialized electrode materials to combine the high energy density of batteries with the high power density of traditional supercapacitors. These materials often include carbon-based structures (like graphene or carbon nanotubes) combined with metal oxides or conductive polymers. The electrode composition significantly impacts the device's performance characteristics, including charge storage capacity, cycling stability, and rate capability. Advanced manufacturing techniques enable precise control over electrode morphology and surface area to optimize electrochemical performance.

- Electrolyte formulations for hybrid supercapacitors: Electrolyte composition plays a crucial role in hybrid supercapacitor performance, affecting operating voltage window, ionic conductivity, and overall device stability. Advanced electrolyte formulations may include organic, aqueous, or ionic liquid-based solutions, each offering different advantages in terms of voltage range, temperature stability, and safety. Some formulations incorporate additives to enhance specific properties such as conductivity or to prevent electrode degradation. The interface between the electrolyte and electrode materials is particularly important for optimizing charge transfer processes and minimizing internal resistance.

- Energy management systems for hybrid supercapacitors: Energy management systems are designed to optimize the performance of hybrid supercapacitors in practical applications. These systems include specialized charging/discharging control algorithms, voltage regulation circuits, and thermal management components. Advanced management systems can balance power distribution between multiple cells, monitor state of charge, and protect against overcharging or deep discharging. Integration with renewable energy sources often requires sophisticated power electronics to handle variable input conditions while maintaining optimal supercapacitor performance.

- Manufacturing processes for hybrid supercapacitors: Manufacturing techniques for hybrid supercapacitors focus on achieving precise control over material properties and device assembly. These processes may include specialized coating methods for electrode preparation, advanced assembly techniques for maintaining consistent internal structure, and quality control measures to ensure performance uniformity. Some manufacturing innovations focus on scalable production methods to reduce costs while maintaining high performance standards. Post-production treatments such as thermal annealing or activation processes can further enhance the electrochemical properties of the finished devices.

- Applications and integration of hybrid supercapacitors: Hybrid supercapacitors find applications across various sectors including automotive, renewable energy, consumer electronics, and industrial systems. Their integration often requires specialized interface circuits and mechanical designs to accommodate their unique electrical characteristics. In electric vehicles, hybrid supercapacitors can complement batteries by handling high-power demands during acceleration and regenerative braking. For renewable energy systems, these devices provide rapid response capabilities for grid stabilization and power quality improvement. Miniaturized versions are being developed for wearable electronics and IoT devices where both energy density and power delivery are critical.

02 Electrolyte compositions for hybrid supercapacitors

The electrolyte plays a crucial role in hybrid supercapacitor performance. Various electrolyte compositions, including aqueous, organic, and ionic liquid-based electrolytes, can be used to optimize the operating voltage window, ionic conductivity, and electrochemical stability. Advanced electrolyte formulations can enhance the energy density and cycle life of hybrid supercapacitors while maintaining their high power capabilities.Expand Specific Solutions03 Energy management systems using hybrid supercapacitors

Hybrid supercapacitors can be integrated into energy management systems for various applications including renewable energy storage, automotive systems, and consumer electronics. These systems often combine supercapacitors with batteries to leverage the high power density of supercapacitors and the high energy density of batteries. Advanced control algorithms and power electronics are used to optimize the energy flow between different storage components.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitors

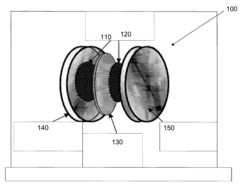

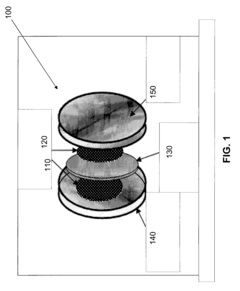

Various manufacturing techniques are employed to produce hybrid supercapacitors with optimized performance. These include methods for electrode preparation, assembly processes, and encapsulation techniques. Advanced manufacturing approaches such as roll-to-roll processing, 3D printing, and nanofabrication can be used to enhance the performance and reduce the production costs of hybrid supercapacitors.Expand Specific Solutions05 Structural designs for hybrid supercapacitors

Innovative structural designs can significantly improve the performance of hybrid supercapacitors. These include interdigitated electrode configurations, sandwich structures, and hierarchical architectures. The structural design affects the ion transport pathways, electrode-electrolyte interface area, and mechanical stability of the device. Novel designs can lead to enhanced energy and power densities while maintaining long cycle life.Expand Specific Solutions

Key Industry Players in Military Hybrid Supercapacitors

The hybrid supercapacitor market in military and defense applications is currently in a growth phase, with increasing adoption driven by demands for high-power energy storage solutions in tactical equipment, vehicles, and portable systems. The global market is expanding at approximately 12-15% CAGR, valued at around $500 million specifically for defense applications. Technology maturity varies across players: established manufacturers like Samsung Electro-Mechanics, Thales, and Robert Bosch lead with commercialized solutions, while research-focused entities such as American Lithium Energy, Nanotech Energy, and Saft Groupe are advancing next-generation technologies with enhanced power density and operational stability. University collaborations (Michigan, California, Delaware) are pushing boundaries in materials science, while defense contractors like FCA US and Shell are integrating these technologies into military platforms, creating a competitive landscape balanced between established industrial players and innovative technology developers.

American Lithium Energy Corp.

Technical Solution: American Lithium Energy Corp. has developed a proprietary hybrid supercapacitor technology specifically engineered for military and defense applications. Their ALECTRION™ system combines lithium-ion battery chemistry with supercapacitor elements to create a power solution that delivers both high energy density and rapid discharge capabilities. The technology features specialized carbon-composite electrodes with nano-structured materials that enhance surface area and charge storage capacity while maintaining structural integrity under battlefield conditions. ALE's hybrid supercapacitors incorporate military-specific safety features including thermal runaway prevention systems, ballistic protection layers, and fail-safe circuitry that prevents catastrophic failure even when damaged in combat. Their systems have been designed to meet MIL-STD-810G requirements for environmental resistance, including operation in extreme temperatures (-40°C to +71°C), high humidity, salt fog, and sand/dust exposure. The company has successfully integrated their hybrid supercapacitor technology into soldier-worn power systems, reducing weight by approximately 30% compared to traditional military batteries while extending operational duration by up to 72 hours for critical communications and electronic warfare equipment.

Strengths: Purpose-built for military applications with comprehensive compliance to military standards and specifications. Significant weight reduction benefits for soldier-carried systems. Enhanced safety features specifically designed for combat environments. Weaknesses: Higher production costs than commercial-grade energy storage solutions. Limited production capacity for meeting large-scale military procurement needs. Requires specialized training for field maintenance and optimal deployment.

Thales SA

Technical Solution: Thales SA has developed advanced hybrid supercapacitor systems specifically designed for military and defense applications. Their technology combines high-energy lithium-ion capacitors with traditional supercapacitors to create power solutions that deliver both high energy density and high power density. These systems feature proprietary electrode materials that enhance charge storage capacity while maintaining rapid discharge capabilities essential for defense applications. Thales' hybrid supercapacitors incorporate military-grade ruggedization techniques, including reinforced casings and specialized thermal management systems that allow operation in extreme environments (-40°C to +85°C). Their systems include advanced Battery Management Systems (BMS) with military-grade encryption for secure operation and monitoring in battlefield conditions. The technology has been successfully deployed in various defense platforms including portable soldier systems, unmanned aerial vehicles (UAVs), and tactical communication equipment, providing up to 100,000 charge-discharge cycles compared to conventional batteries' 1,000-3,000 cycles.

Strengths: Superior performance in extreme military environments with high temperature tolerance and shock resistance. Military-grade security features and encryption protect against cyber threats. Extended operational lifespan reduces field maintenance requirements. Weaknesses: Higher initial acquisition costs compared to conventional battery systems. Requires specialized training for maintenance personnel. More complex integration with legacy military power systems.

Core Patents and Research in Military-Grade Supercapacitors

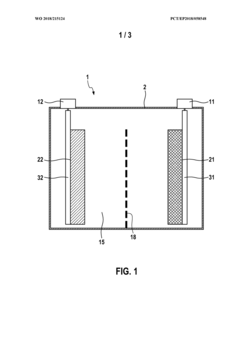

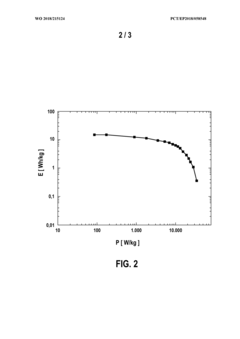

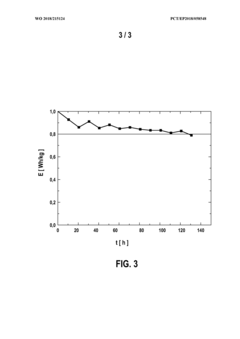

Hybrid supercapacitor for high-temperature applications

PatentWO2018215124A1

Innovation

- A hybrid supercapacitor design featuring a negative electrode with static capacitive active material, a positive electrode with electrochemical redox active material, and an electrolyte composition including an ionic liquid and lithium-containing conductive additive, allowing for high power and energy density along with extended lifespan at elevated temperatures.

Single-wall carbon nanotube supercapacitor

PatentInactiveUS8213157B2

Innovation

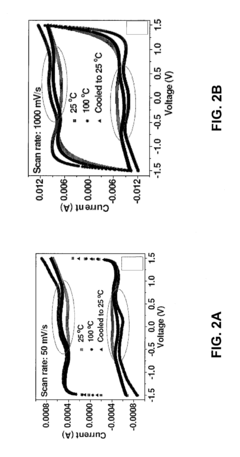

- The use of single-walled carbon nanotube film electrodes and an organic electrolyte, such as TEABF4/PC, in a coin cell supercapacitor design, where the electrodes are synthesized through chemical vapor deposition and purified without filtration, allowing for direct use as mechanically stable electrodes without current collectors, and the electrolyte is soaked in a separator made of glass microfiber or polypropylene, enabling operation from 25°C to 100°C.

Battlefield Resilience and Operational Requirements

Military operations demand power systems that can withstand extreme conditions while maintaining optimal performance. Hybrid supercapacitors represent a critical advancement in meeting these battlefield resilience requirements, offering superior performance in temperature ranges from -40°C to +65°C compared to traditional lithium-ion batteries that struggle below -20°C or above +55°C. This temperature tolerance ensures functionality across diverse deployment environments from arctic to desert conditions without performance degradation.

Combat situations impose severe mechanical stress on equipment through shock, vibration, and impact. Hybrid supercapacitors demonstrate exceptional mechanical resilience with no moving parts or liquid electrolytes that could leak when damaged. Testing shows these systems can withstand acceleration forces exceeding 10,000g, making them suitable for artillery-launched electronics and other high-impact applications where conventional batteries would fail.

Operational continuity represents another critical battlefield requirement addressed by hybrid supercapacitors. Their rapid charge capability—achieving 80% capacity in under 5 minutes versus hours for conventional batteries—enables quick redeployment of systems during mission-critical operations. This characteristic proves invaluable during brief operational pauses where equipment must quickly return to full functionality.

The extended cycle life of hybrid supercapacitors (100,000+ cycles compared to 500-1,000 for lithium-ion batteries) significantly reduces maintenance requirements and logistics burdens in field operations. Military units can operate for extended periods without replacement power components, enhancing operational independence and reducing vulnerability associated with supply chain dependencies.

Electromagnetic pulse (EMP) resilience represents a growing concern in modern warfare scenarios. Hybrid supercapacitors demonstrate superior resistance to EMP effects compared to conventional battery systems with complex electronic management systems. This characteristic ensures power availability during electronic warfare situations where other systems might be compromised.

Weight reduction remains a persistent operational requirement for military applications. Hybrid supercapacitors offer power density advantages that translate to weight savings of 30-40% compared to equivalent capacity battery systems. For infantry carrying personal electronic equipment or unmanned aerial vehicles with strict weight limitations, these savings directly enhance operational capabilities and endurance.

The operational requirement for silent operation is addressed through hybrid supercapacitors' solid-state design, eliminating the noise signature associated with generators or other mechanical power systems. This characteristic proves essential for covert operations where acoustic stealth determines mission success or failure.

Combat situations impose severe mechanical stress on equipment through shock, vibration, and impact. Hybrid supercapacitors demonstrate exceptional mechanical resilience with no moving parts or liquid electrolytes that could leak when damaged. Testing shows these systems can withstand acceleration forces exceeding 10,000g, making them suitable for artillery-launched electronics and other high-impact applications where conventional batteries would fail.

Operational continuity represents another critical battlefield requirement addressed by hybrid supercapacitors. Their rapid charge capability—achieving 80% capacity in under 5 minutes versus hours for conventional batteries—enables quick redeployment of systems during mission-critical operations. This characteristic proves invaluable during brief operational pauses where equipment must quickly return to full functionality.

The extended cycle life of hybrid supercapacitors (100,000+ cycles compared to 500-1,000 for lithium-ion batteries) significantly reduces maintenance requirements and logistics burdens in field operations. Military units can operate for extended periods without replacement power components, enhancing operational independence and reducing vulnerability associated with supply chain dependencies.

Electromagnetic pulse (EMP) resilience represents a growing concern in modern warfare scenarios. Hybrid supercapacitors demonstrate superior resistance to EMP effects compared to conventional battery systems with complex electronic management systems. This characteristic ensures power availability during electronic warfare situations where other systems might be compromised.

Weight reduction remains a persistent operational requirement for military applications. Hybrid supercapacitors offer power density advantages that translate to weight savings of 30-40% compared to equivalent capacity battery systems. For infantry carrying personal electronic equipment or unmanned aerial vehicles with strict weight limitations, these savings directly enhance operational capabilities and endurance.

The operational requirement for silent operation is addressed through hybrid supercapacitors' solid-state design, eliminating the noise signature associated with generators or other mechanical power systems. This characteristic proves essential for covert operations where acoustic stealth determines mission success or failure.

Security and Supply Chain Considerations

The security implications of hybrid supercapacitors in military and defense applications extend far beyond performance considerations. Military-grade energy storage systems require stringent protection against unauthorized access, tampering, and potential cyber threats. Hybrid supercapacitors, with their integrated electronic control systems, present potential vulnerabilities that must be addressed through comprehensive security protocols, including encrypted communication channels and secure firmware update mechanisms. Additionally, these systems must incorporate fail-safe mechanisms to prevent exploitation during combat situations or in the event of capture by hostile forces.

Supply chain security represents a critical concern for defense applications of hybrid supercapacitor technology. The global nature of component sourcing introduces significant vulnerabilities, particularly regarding rare earth materials and specialized electronic components. Many critical materials for advanced electrode development originate from geopolitically sensitive regions, creating potential supply disruptions during international conflicts. Defense departments increasingly implement rigorous supply chain risk management frameworks that require complete component traceability and verification of manufacturing origins.

Domestic manufacturing capabilities for hybrid supercapacitors remain limited in many Western nations, creating strategic vulnerabilities. The concentration of production expertise in specific geographic regions presents risks of supply disruption during global crises. Military planners increasingly advocate for reshoring critical component manufacturing and developing redundant supply networks to ensure operational resilience. Recent defense procurement policies have emphasized the importance of establishing secure domestic production capabilities for energy storage technologies deemed essential for national security.

Material authentication and counterfeit prevention represent additional challenges in the hybrid supercapacitor supply chain. The sophisticated nature of these components makes verification of authenticity particularly challenging, requiring advanced testing protocols and secure chain-of-custody documentation. Military contractors must implement rigorous quality control measures, including destructive testing of sample components and advanced spectroscopic analysis to verify material composition and performance characteristics.

Long-term sustainability of hybrid supercapacitor supply chains requires strategic planning regarding critical materials. Several key components, particularly those utilizing rare earth elements, face potential supply constraints as global demand increases. Defense agencies are actively funding research into alternative materials that can provide similar performance while reducing dependence on geopolitically vulnerable supply sources. This includes exploration of synthetic substitutes and recovery processes for reclaiming critical materials from decommissioned systems.

Supply chain security represents a critical concern for defense applications of hybrid supercapacitor technology. The global nature of component sourcing introduces significant vulnerabilities, particularly regarding rare earth materials and specialized electronic components. Many critical materials for advanced electrode development originate from geopolitically sensitive regions, creating potential supply disruptions during international conflicts. Defense departments increasingly implement rigorous supply chain risk management frameworks that require complete component traceability and verification of manufacturing origins.

Domestic manufacturing capabilities for hybrid supercapacitors remain limited in many Western nations, creating strategic vulnerabilities. The concentration of production expertise in specific geographic regions presents risks of supply disruption during global crises. Military planners increasingly advocate for reshoring critical component manufacturing and developing redundant supply networks to ensure operational resilience. Recent defense procurement policies have emphasized the importance of establishing secure domestic production capabilities for energy storage technologies deemed essential for national security.

Material authentication and counterfeit prevention represent additional challenges in the hybrid supercapacitor supply chain. The sophisticated nature of these components makes verification of authenticity particularly challenging, requiring advanced testing protocols and secure chain-of-custody documentation. Military contractors must implement rigorous quality control measures, including destructive testing of sample components and advanced spectroscopic analysis to verify material composition and performance characteristics.

Long-term sustainability of hybrid supercapacitor supply chains requires strategic planning regarding critical materials. Several key components, particularly those utilizing rare earth elements, face potential supply constraints as global demand increases. Defense agencies are actively funding research into alternative materials that can provide similar performance while reducing dependence on geopolitically vulnerable supply sources. This includes exploration of synthetic substitutes and recovery processes for reclaiming critical materials from decommissioned systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!