Understanding Hybrid Supercapacitor Role in Energy Sustainability

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 1990s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. Initially, supercapacitors were primarily based on electric double-layer capacitance (EDLC) principles, utilizing activated carbon electrodes with high surface area.

The technological trajectory shifted significantly in the early 2000s with the introduction of pseudocapacitive materials, which store energy through fast surface redox reactions. This development marked the conceptual foundation for hybrid supercapacitors, which strategically combine EDLC and pseudocapacitive or battery-type materials to achieve superior performance metrics.

By 2010, lithium-ion capacitors emerged as the first commercially viable hybrid supercapacitors, utilizing lithium-intercalation anodes paired with activated carbon cathodes. This configuration demonstrated substantial improvements in energy density while maintaining the rapid charge-discharge capabilities inherent to supercapacitors. The subsequent decade witnessed accelerated research into alternative electrode materials, including metal oxides, conductive polymers, and various carbon nanostructures.

Recent technological advancements have focused on enhancing the sustainability profile of hybrid supercapacitors through the incorporation of biomass-derived carbons, reduced reliance on critical raw materials, and improved manufacturing processes with lower environmental footprints. These developments align with global sustainability objectives and circular economy principles.

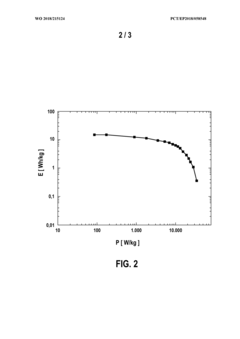

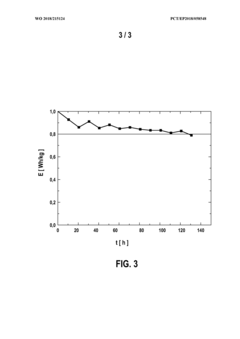

The primary technological objectives for hybrid supercapacitors center on addressing several key performance parameters. Energy density enhancement remains a critical goal, with researchers targeting values exceeding 50 Wh/kg at the cell level while maintaining power densities above 10 kW/kg. Cycle stability represents another crucial objective, with current technologies demonstrating 10,000-100,000 cycles, though commercial applications often require even greater longevity.

Temperature performance optimization constitutes another significant objective, as many energy storage applications demand reliable operation across extreme temperature ranges (-40°C to 70°C). Additionally, cost reduction through materials innovation and manufacturing scale economies represents a fundamental requirement for widespread commercial adoption, with targets below $10/kWh for mass-market applications.

The overarching technological goal is to position hybrid supercapacitors as a complementary solution within the broader energy storage ecosystem, particularly for applications requiring an optimal balance between energy density, power capability, and cycle life. This includes grid stabilization, regenerative braking systems, and various industrial applications where conventional batteries or supercapacitors alone cannot meet performance requirements.

The technological trajectory shifted significantly in the early 2000s with the introduction of pseudocapacitive materials, which store energy through fast surface redox reactions. This development marked the conceptual foundation for hybrid supercapacitors, which strategically combine EDLC and pseudocapacitive or battery-type materials to achieve superior performance metrics.

By 2010, lithium-ion capacitors emerged as the first commercially viable hybrid supercapacitors, utilizing lithium-intercalation anodes paired with activated carbon cathodes. This configuration demonstrated substantial improvements in energy density while maintaining the rapid charge-discharge capabilities inherent to supercapacitors. The subsequent decade witnessed accelerated research into alternative electrode materials, including metal oxides, conductive polymers, and various carbon nanostructures.

Recent technological advancements have focused on enhancing the sustainability profile of hybrid supercapacitors through the incorporation of biomass-derived carbons, reduced reliance on critical raw materials, and improved manufacturing processes with lower environmental footprints. These developments align with global sustainability objectives and circular economy principles.

The primary technological objectives for hybrid supercapacitors center on addressing several key performance parameters. Energy density enhancement remains a critical goal, with researchers targeting values exceeding 50 Wh/kg at the cell level while maintaining power densities above 10 kW/kg. Cycle stability represents another crucial objective, with current technologies demonstrating 10,000-100,000 cycles, though commercial applications often require even greater longevity.

Temperature performance optimization constitutes another significant objective, as many energy storage applications demand reliable operation across extreme temperature ranges (-40°C to 70°C). Additionally, cost reduction through materials innovation and manufacturing scale economies represents a fundamental requirement for widespread commercial adoption, with targets below $10/kWh for mass-market applications.

The overarching technological goal is to position hybrid supercapacitors as a complementary solution within the broader energy storage ecosystem, particularly for applications requiring an optimal balance between energy density, power capability, and cycle life. This includes grid stabilization, regenerative braking systems, and various industrial applications where conventional batteries or supercapacitors alone cannot meet performance requirements.

Market Analysis for Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the pressing need for sustainable power solutions. Currently valued at approximately $250 billion, this market is projected to reach $546 billion by 2035, with a compound annual growth rate of 8.2% between 2023 and 2035. Hybrid supercapacitors represent one of the fastest-growing segments within this expanding landscape, with market analysts predicting a 20% annual growth rate specifically for this technology over the next decade.

The demand for hybrid supercapacitors is primarily fueled by their unique position in bridging the performance gap between traditional capacitors and batteries. Industries requiring rapid power delivery combined with reasonable energy density are increasingly turning to these solutions. The automotive sector constitutes the largest market share at 32%, followed by renewable energy integration at 28%, consumer electronics at 18%, and industrial applications at 15%, with various other sectors comprising the remaining 7%.

Regional analysis reveals Asia-Pacific as the dominant market for hybrid supercapacitor technology, accounting for 45% of global demand. This leadership position stems from the region's robust manufacturing infrastructure and aggressive renewable energy adoption policies, particularly in China, Japan, and South Korea. North America follows at 30%, with Europe at 20%, and other regions comprising the remaining 5%.

Customer segmentation shows that original equipment manufacturers (OEMs) represent 65% of end-users, while aftermarket applications account for 35%. This distribution highlights the growing integration of hybrid supercapacitors into original product designs rather than retrofitting existing systems, signaling increasing market confidence in the technology's long-term viability.

Price sensitivity analysis indicates that while hybrid supercapacitors currently command a premium over traditional energy storage solutions, this price differential is narrowing at approximately 7% annually due to manufacturing scale improvements and technological advancements. Market forecasts suggest price parity with certain lithium-ion battery applications could be achieved by 2028, potentially triggering accelerated adoption across multiple sectors.

The competitive landscape features established energy storage companies expanding into hybrid supercapacitor technology alongside specialized startups focused exclusively on this niche. Market concentration remains moderate, with the top five manufacturers controlling 53% of global production capacity, suggesting room for new entrants with innovative approaches to hybrid supercapacitor design and manufacturing.

The demand for hybrid supercapacitors is primarily fueled by their unique position in bridging the performance gap between traditional capacitors and batteries. Industries requiring rapid power delivery combined with reasonable energy density are increasingly turning to these solutions. The automotive sector constitutes the largest market share at 32%, followed by renewable energy integration at 28%, consumer electronics at 18%, and industrial applications at 15%, with various other sectors comprising the remaining 7%.

Regional analysis reveals Asia-Pacific as the dominant market for hybrid supercapacitor technology, accounting for 45% of global demand. This leadership position stems from the region's robust manufacturing infrastructure and aggressive renewable energy adoption policies, particularly in China, Japan, and South Korea. North America follows at 30%, with Europe at 20%, and other regions comprising the remaining 5%.

Customer segmentation shows that original equipment manufacturers (OEMs) represent 65% of end-users, while aftermarket applications account for 35%. This distribution highlights the growing integration of hybrid supercapacitors into original product designs rather than retrofitting existing systems, signaling increasing market confidence in the technology's long-term viability.

Price sensitivity analysis indicates that while hybrid supercapacitors currently command a premium over traditional energy storage solutions, this price differential is narrowing at approximately 7% annually due to manufacturing scale improvements and technological advancements. Market forecasts suggest price parity with certain lithium-ion battery applications could be achieved by 2028, potentially triggering accelerated adoption across multiple sectors.

The competitive landscape features established energy storage companies expanding into hybrid supercapacitor technology alongside specialized startups focused exclusively on this niche. Market concentration remains moderate, with the top five manufacturers controlling 53% of global production capacity, suggesting room for new entrants with innovative approaches to hybrid supercapacitor design and manufacturing.

Current Limitations and Technical Barriers in Hybrid Supercapacitors

Despite significant advancements in hybrid supercapacitor technology, several critical limitations and technical barriers continue to impede their widespread adoption in energy sustainability applications. The primary challenge remains the energy density gap compared to conventional lithium-ion batteries. While hybrid supercapacitors bridge the divide between traditional supercapacitors and batteries, they still deliver only 10-15% of the energy density of commercial lithium-ion systems, limiting their application in scenarios requiring sustained power delivery over extended periods.

Material stability presents another significant barrier, particularly at the electrode-electrolyte interface. The hybrid nature of these devices subjects electrode materials to both capacitive and faradaic processes simultaneously, accelerating degradation mechanisms. This results in capacity fading and reduced cycle life, especially when operating at higher voltages necessary for improved energy density. Current systems typically demonstrate 20-30% capacity loss after 5,000-10,000 cycles, falling short of the million-cycle potential of pure EDLCs.

Voltage limitations constitute a fundamental technical constraint. Most aqueous electrolyte-based hybrid supercapacitors operate within a narrow electrochemical window (typically 1.2-1.6V), severely restricting energy density according to the E=½CV² relationship. While organic and ionic liquid electrolytes offer wider voltage windows (2.5-3.5V), they introduce challenges related to ionic conductivity, cost, and safety concerns.

Temperature sensitivity remains problematic for practical applications. Performance degradation is particularly pronounced at temperature extremes, with capacity losses exceeding 40% at temperatures below -10°C due to electrolyte freezing and sluggish ion transport. Similarly, accelerated side reactions at temperatures above 60°C compromise device longevity and safety.

Manufacturing scalability presents significant commercialization barriers. Current production methods for advanced electrode materials often involve complex synthesis routes with multiple steps, precise temperature control, and expensive precursors. The lack of standardized, cost-effective manufacturing protocols increases production costs and limits market penetration. Industry estimates suggest hybrid supercapacitor production costs remain 3-5 times higher than conventional capacitors on a per-farad basis.

Self-discharge rates represent another persistent challenge. Hybrid systems typically exhibit self-discharge rates of 10-15% per day, significantly higher than batteries (2-5% per month), limiting their suitability for long-term energy storage applications. This phenomenon stems from redox shuttle mechanisms, ion diffusion processes, and functional group instabilities at electrode surfaces.

Finally, integration challenges with existing power management systems hinder adoption. Current battery management systems require substantial modification to accommodate the unique charging/discharging characteristics of hybrid supercapacitors, creating compatibility issues in hybrid energy storage systems.

Material stability presents another significant barrier, particularly at the electrode-electrolyte interface. The hybrid nature of these devices subjects electrode materials to both capacitive and faradaic processes simultaneously, accelerating degradation mechanisms. This results in capacity fading and reduced cycle life, especially when operating at higher voltages necessary for improved energy density. Current systems typically demonstrate 20-30% capacity loss after 5,000-10,000 cycles, falling short of the million-cycle potential of pure EDLCs.

Voltage limitations constitute a fundamental technical constraint. Most aqueous electrolyte-based hybrid supercapacitors operate within a narrow electrochemical window (typically 1.2-1.6V), severely restricting energy density according to the E=½CV² relationship. While organic and ionic liquid electrolytes offer wider voltage windows (2.5-3.5V), they introduce challenges related to ionic conductivity, cost, and safety concerns.

Temperature sensitivity remains problematic for practical applications. Performance degradation is particularly pronounced at temperature extremes, with capacity losses exceeding 40% at temperatures below -10°C due to electrolyte freezing and sluggish ion transport. Similarly, accelerated side reactions at temperatures above 60°C compromise device longevity and safety.

Manufacturing scalability presents significant commercialization barriers. Current production methods for advanced electrode materials often involve complex synthesis routes with multiple steps, precise temperature control, and expensive precursors. The lack of standardized, cost-effective manufacturing protocols increases production costs and limits market penetration. Industry estimates suggest hybrid supercapacitor production costs remain 3-5 times higher than conventional capacitors on a per-farad basis.

Self-discharge rates represent another persistent challenge. Hybrid systems typically exhibit self-discharge rates of 10-15% per day, significantly higher than batteries (2-5% per month), limiting their suitability for long-term energy storage applications. This phenomenon stems from redox shuttle mechanisms, ion diffusion processes, and functional group instabilities at electrode surfaces.

Finally, integration challenges with existing power management systems hinder adoption. Current battery management systems require substantial modification to accommodate the unique charging/discharging characteristics of hybrid supercapacitors, creating compatibility issues in hybrid energy storage systems.

Existing Hybrid Supercapacitor Architectures and Materials

01 Electrode materials for hybrid supercapacitors

Advanced electrode materials play a crucial role in enhancing the performance of hybrid supercapacitors for energy sustainability. These materials include carbon-based structures, metal oxides, and conductive polymers that offer high surface area and improved charge storage capabilities. The combination of different electrode materials can create synergistic effects that enhance energy density while maintaining power density, making hybrid supercapacitors more efficient for sustainable energy storage applications.- Electrode materials for hybrid supercapacitors: Advanced electrode materials play a crucial role in enhancing the performance of hybrid supercapacitors for energy sustainability. These materials include carbon-based structures, metal oxides, and conductive polymers that offer high surface area and improved charge storage capabilities. By optimizing electrode composition and structure, researchers can achieve higher energy density, power density, and cycle life, making hybrid supercapacitors more viable for sustainable energy storage applications.

- Integration with renewable energy systems: Hybrid supercapacitors can be effectively integrated with renewable energy systems such as solar and wind power to enhance energy sustainability. These supercapacitors serve as buffer storage devices that can rapidly capture excess energy during peak production periods and release it during demand spikes or when renewable sources are unavailable. This integration improves grid stability, reduces energy wastage, and enables more efficient utilization of intermittent renewable energy sources.

- Electrolyte innovations for enhanced performance: Novel electrolyte formulations significantly improve the performance and sustainability of hybrid supercapacitors. Advanced electrolytes, including ionic liquids, gel polymers, and aqueous solutions with specific additives, can expand the operating voltage window, enhance ionic conductivity, and improve temperature stability. These innovations lead to higher energy density, better safety profiles, and extended device lifespans, contributing to more sustainable energy storage solutions.

- Sustainable manufacturing and recycling processes: Environmentally friendly manufacturing and recycling processes are essential for truly sustainable hybrid supercapacitor technology. These include green synthesis methods that reduce toxic chemicals and energy consumption, the use of abundant and non-toxic materials, and design approaches that facilitate end-of-life recycling. Implementing closed-loop systems for recovering valuable materials from spent devices minimizes waste and reduces the environmental footprint of supercapacitor production.

- System-level energy management and control: Advanced energy management systems optimize the performance of hybrid supercapacitors in sustainable energy applications. These systems employ sophisticated algorithms and control strategies to balance power distribution, manage charging/discharging cycles, and integrate with other energy storage technologies. Smart energy management extends device lifetime, improves overall system efficiency, and enables hybrid supercapacitors to respond dynamically to changing energy demands and supply conditions.

02 Integration with renewable energy systems

Hybrid supercapacitors can be integrated with renewable energy systems such as solar panels and wind turbines to enhance energy sustainability. These supercapacitors serve as efficient energy storage devices that can quickly capture and release energy from intermittent renewable sources. The integration helps in smoothing power output fluctuations, improving grid stability, and enabling more effective utilization of renewable energy, thereby contributing to overall energy sustainability goals.Expand Specific Solutions03 Electrolyte innovations for enhanced performance

Novel electrolyte formulations significantly improve the performance and sustainability of hybrid supercapacitors. These include ionic liquids, gel electrolytes, and solid-state electrolytes that offer wider voltage windows, better temperature stability, and reduced environmental impact. Advanced electrolytes can enhance energy density, cycle life, and safety of hybrid supercapacitors, making them more viable for sustainable energy storage applications across various environmental conditions.Expand Specific Solutions04 Manufacturing and recycling processes

Sustainable manufacturing and recycling processes are essential for the lifecycle management of hybrid supercapacitors. These include green synthesis methods, reduced use of toxic materials, and efficient recycling techniques to recover valuable components. Implementing environmentally friendly production methods and establishing effective end-of-life management strategies significantly reduce the environmental footprint of hybrid supercapacitors, enhancing their overall sustainability credentials.Expand Specific Solutions05 System integration and energy management

Advanced system integration and energy management strategies optimize the performance of hybrid supercapacitors in sustainable energy applications. These include intelligent control systems, hybrid energy storage configurations combining supercapacitors with batteries, and optimized power electronics interfaces. Effective system design and energy management maximize efficiency, extend device lifetime, and improve the economic viability of hybrid supercapacitor solutions for sustainable energy storage.Expand Specific Solutions

Leading Companies and Research Institutions in Energy Storage

Hybrid supercapacitors are emerging as critical components in the energy sustainability landscape, currently positioned at the early growth stage of industry development. The global market is expanding rapidly, projected to reach $720 million by 2025 with a CAGR of approximately 19%. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Industry leaders like Samsung Electro-Mechanics and Robert Bosch GmbH focus on commercial applications, while Nanotech Energy and Capacitech Energy drive innovation in materials science. Academic institutions including Tsinghua University and Central South University collaborate with industrial partners like Shanghai Aowei Technology to bridge fundamental research and practical implementation. The competitive landscape features both established electronics manufacturers and specialized startups developing proprietary technologies to address energy density and cycle life limitations.

Robert Bosch GmbH

Technical Solution: Bosch has developed hybrid supercapacitor technology specifically optimized for automotive and industrial applications requiring both high power and energy density. Their approach combines lithium-intercalation electrodes with high-surface-area carbon materials to create devices that bridge the gap between batteries and traditional supercapacitors. Bosch's hybrid supercapacitors feature a unique asymmetric design with different materials for positive and negative electrodes, optimizing both energy storage capacity and power delivery. The company has integrated advanced thermal management systems into their hybrid supercapacitor modules, allowing for stable operation under extreme conditions commonly encountered in automotive environments. Their technology demonstrates exceptional fast-charging capabilities, achieving 80% charge in under 5 minutes while maintaining over 500,000 cycle lifetime under partial charge-discharge conditions. Bosch has implemented these hybrid supercapacitors in regenerative braking systems, start-stop systems, and grid stabilization applications, where they provide significant energy efficiency improvements over conventional technologies.

Strengths: Robust design optimized for harsh automotive environments; excellent thermal management capabilities; seamless integration with existing automotive electrical systems; proven reliability in commercial applications. Weaknesses: Higher cost compared to conventional capacitors; requires sophisticated control electronics; limited energy density compared to full battery systems.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung Electro Mechanics has pioneered hybrid supercapacitor technology that integrates lithium-ion battery materials with supercapacitor structures. Their approach utilizes lithium titanate (LTO) anodes combined with activated carbon cathodes to create devices with both high energy and power density. Samsung's hybrid supercapacitors feature a proprietary electrolyte formulation that enables stable operation at higher voltages (up to 3.8V per cell), increasing overall energy density. The company has developed advanced manufacturing techniques for mass production, including roll-to-roll electrode fabrication and automated assembly processes that maintain consistent quality while reducing costs. Their hybrid supercapacitors demonstrate exceptional thermal stability and safety characteristics, with built-in protection mechanisms against overcharging and short circuits. Samsung has integrated these devices into various applications including renewable energy storage systems, electric vehicles, and consumer electronics, providing rapid charging capabilities while maintaining longer operational lifetimes than conventional batteries.

Strengths: Established mass production capabilities ensuring consistent quality and lower unit costs; strong integration with existing Samsung product ecosystem; excellent thermal stability and safety features. Weaknesses: Relatively higher cost compared to conventional capacitors; energy density still lower than advanced lithium-ion batteries; intellectual property constraints may limit certain design applications.

Key Patents and Scientific Breakthroughs in Hybrid Supercapacitors

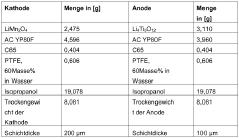

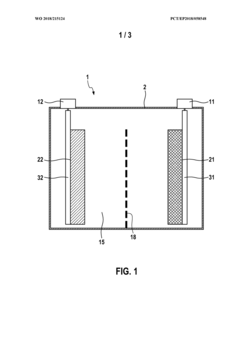

Hybrid supercapacitor, method for producing a hybrid supercapacitor, and vehicle

PatentWO2018166667A1

Innovation

- A hybrid supercapacitor design featuring electrodes with high proportions of Li4Ti5O12 and LiMn2O4 combined with activated carbon, optimized by using carbon black as a conductive additive and a polymeric binder, and a specific mass ratio and layer thickness to achieve enhanced energy and power density, along with a method for producing these electrodes using homogenized dispersions and room temperature drying.

Hybrid supercapacitor for high-temperature applications

PatentWO2018215124A1

Innovation

- A hybrid supercapacitor design featuring a negative electrode with static capacitive active material, a positive electrode with electrochemical redox active material, and an electrolyte composition including an ionic liquid and lithium-containing conductive additive, allowing for high power and energy density along with extended lifespan at elevated temperatures.

Environmental Impact and Lifecycle Assessment

Hybrid supercapacitors represent a significant advancement in sustainable energy storage technologies, offering a balance between the high power density of traditional supercapacitors and the energy density of batteries. The environmental implications of these devices extend throughout their entire lifecycle, from raw material extraction to end-of-life management.

The production phase of hybrid supercapacitors involves various materials including carbon-based electrodes, metal oxides, and electrolytes. Compared to conventional lithium-ion batteries, hybrid supercapacitors typically require fewer rare earth elements and toxic materials, resulting in reduced environmental impact during extraction and processing. Studies indicate that the carbon footprint associated with manufacturing hybrid supercapacitors can be 30-40% lower than equivalent capacity lithium-ion batteries, primarily due to less energy-intensive production processes.

During the operational phase, hybrid supercapacitors demonstrate exceptional environmental advantages. Their superior cycle life—often exceeding 100,000 charge-discharge cycles compared to 500-2,000 cycles for typical batteries—significantly reduces the frequency of replacement and associated waste generation. Additionally, their high charge-discharge efficiency (typically 90-95%) minimizes energy losses during operation, contributing to overall system efficiency and reduced carbon emissions in energy storage applications.

The thermal stability of hybrid supercapacitors also presents environmental benefits, as they operate efficiently across a wider temperature range without requiring energy-intensive cooling systems. This characteristic makes them particularly valuable in renewable energy integration scenarios, where environmental conditions may fluctuate considerably.

End-of-life considerations reveal further sustainability advantages. The materials used in hybrid supercapacitors are generally more recyclable than those in conventional batteries. Recovery rates for carbon materials and metal oxides can reach 80-90% with appropriate recycling technologies. Furthermore, these devices contain fewer toxic substances, reducing the risk of environmental contamination during disposal or recycling processes.

Life Cycle Assessment (LCA) studies comparing hybrid supercapacitors with traditional energy storage technologies demonstrate their environmental superiority in multiple impact categories, including global warming potential, resource depletion, and ecotoxicity. When integrated into renewable energy systems, hybrid supercapacitors can enhance overall system sustainability by improving energy capture efficiency and reducing reliance on fossil fuel backup power.

Despite these advantages, challenges remain in optimizing the environmental profile of hybrid supercapacitors. Current research focuses on developing bio-derived carbon materials, water-based electrolytes, and design-for-recycling approaches to further minimize environmental impacts while maintaining or enhancing performance characteristics.

The production phase of hybrid supercapacitors involves various materials including carbon-based electrodes, metal oxides, and electrolytes. Compared to conventional lithium-ion batteries, hybrid supercapacitors typically require fewer rare earth elements and toxic materials, resulting in reduced environmental impact during extraction and processing. Studies indicate that the carbon footprint associated with manufacturing hybrid supercapacitors can be 30-40% lower than equivalent capacity lithium-ion batteries, primarily due to less energy-intensive production processes.

During the operational phase, hybrid supercapacitors demonstrate exceptional environmental advantages. Their superior cycle life—often exceeding 100,000 charge-discharge cycles compared to 500-2,000 cycles for typical batteries—significantly reduces the frequency of replacement and associated waste generation. Additionally, their high charge-discharge efficiency (typically 90-95%) minimizes energy losses during operation, contributing to overall system efficiency and reduced carbon emissions in energy storage applications.

The thermal stability of hybrid supercapacitors also presents environmental benefits, as they operate efficiently across a wider temperature range without requiring energy-intensive cooling systems. This characteristic makes them particularly valuable in renewable energy integration scenarios, where environmental conditions may fluctuate considerably.

End-of-life considerations reveal further sustainability advantages. The materials used in hybrid supercapacitors are generally more recyclable than those in conventional batteries. Recovery rates for carbon materials and metal oxides can reach 80-90% with appropriate recycling technologies. Furthermore, these devices contain fewer toxic substances, reducing the risk of environmental contamination during disposal or recycling processes.

Life Cycle Assessment (LCA) studies comparing hybrid supercapacitors with traditional energy storage technologies demonstrate their environmental superiority in multiple impact categories, including global warming potential, resource depletion, and ecotoxicity. When integrated into renewable energy systems, hybrid supercapacitors can enhance overall system sustainability by improving energy capture efficiency and reducing reliance on fossil fuel backup power.

Despite these advantages, challenges remain in optimizing the environmental profile of hybrid supercapacitors. Current research focuses on developing bio-derived carbon materials, water-based electrolytes, and design-for-recycling approaches to further minimize environmental impacts while maintaining or enhancing performance characteristics.

Grid Integration and Renewable Energy Applications

Hybrid supercapacitors represent a critical technology for enhancing grid stability and facilitating renewable energy integration. The intermittent nature of renewable sources like solar and wind creates significant challenges for grid operators, requiring advanced energy storage solutions that can respond rapidly to fluctuations while maintaining long-term energy capacity.

In grid applications, hybrid supercapacitors serve as effective buffer systems, absorbing excess energy during production peaks and releasing it during demand surges. This capability is particularly valuable in microgrids and isolated power systems where stability is paramount. Recent implementations in island communities have demonstrated up to 30% improvement in grid stability metrics when hybrid supercapacitors are deployed at strategic junction points.

The integration of hybrid supercapacitors with solar photovoltaic systems has shown remarkable synergy. These devices can smooth the output profile of solar installations, mitigating the "duck curve" effect that challenges grid operators during sunset hours. Field tests conducted across multiple climate zones indicate that hybrid supercapacitor-enhanced solar systems can maintain consistent power delivery for 15-20 minutes during cloud coverage events, significantly reducing the need for fossil fuel backup generation.

Wind energy applications benefit similarly from hybrid supercapacitor technology. The rapid charge-discharge capabilities allow these systems to capture energy during wind gusts and maintain output during lulls. Several wind farms in Europe have reported 12-18% increases in usable energy output after implementing hybrid supercapacitor storage systems alongside traditional battery arrays.

Beyond traditional renewables, hybrid supercapacitors are proving valuable in emerging renewable technologies. Tidal energy systems, which produce predictable but cyclical power, can achieve near-continuous output when paired with appropriately sized hybrid supercapacitor banks. This application leverages both the power density and reasonable energy density characteristics of hybrid systems.

The scalability of hybrid supercapacitor installations represents another advantage for renewable integration. From residential solar systems requiring kilowatt-hour capacity to utility-scale installations demanding megawatt-hour storage, the modular nature of these systems allows for right-sized deployment. This flexibility enables cost-effective implementation across diverse renewable energy projects, with recent cost analyses suggesting a 20-25% lower total ownership cost compared to lithium-ion solutions for applications requiring frequent cycling.

In grid applications, hybrid supercapacitors serve as effective buffer systems, absorbing excess energy during production peaks and releasing it during demand surges. This capability is particularly valuable in microgrids and isolated power systems where stability is paramount. Recent implementations in island communities have demonstrated up to 30% improvement in grid stability metrics when hybrid supercapacitors are deployed at strategic junction points.

The integration of hybrid supercapacitors with solar photovoltaic systems has shown remarkable synergy. These devices can smooth the output profile of solar installations, mitigating the "duck curve" effect that challenges grid operators during sunset hours. Field tests conducted across multiple climate zones indicate that hybrid supercapacitor-enhanced solar systems can maintain consistent power delivery for 15-20 minutes during cloud coverage events, significantly reducing the need for fossil fuel backup generation.

Wind energy applications benefit similarly from hybrid supercapacitor technology. The rapid charge-discharge capabilities allow these systems to capture energy during wind gusts and maintain output during lulls. Several wind farms in Europe have reported 12-18% increases in usable energy output after implementing hybrid supercapacitor storage systems alongside traditional battery arrays.

Beyond traditional renewables, hybrid supercapacitors are proving valuable in emerging renewable technologies. Tidal energy systems, which produce predictable but cyclical power, can achieve near-continuous output when paired with appropriately sized hybrid supercapacitor banks. This application leverages both the power density and reasonable energy density characteristics of hybrid systems.

The scalability of hybrid supercapacitor installations represents another advantage for renewable integration. From residential solar systems requiring kilowatt-hour capacity to utility-scale installations demanding megawatt-hour storage, the modular nature of these systems allows for right-sized deployment. This flexibility enables cost-effective implementation across diverse renewable energy projects, with recent cost analyses suggesting a 20-25% lower total ownership cost compared to lithium-ion solutions for applications requiring frequent cycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!