The Role of Hybrid Supercapacitors in Next-Gen Energy Solutions

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant evolution in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The development of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. Initially, these hybrid systems utilized activated carbon electrodes combined with battery-type electrodes, but significant advancements have occurred in materials science and engineering over the past two decades.

The technological trajectory has been marked by several key innovations, including the development of novel electrode materials such as metal oxides, conducting polymers, and more recently, graphene and carbon nanotubes. These materials have dramatically improved the performance parameters of hybrid supercapacitors, enabling higher energy densities while maintaining the rapid charge-discharge capabilities that make supercapacitors valuable for specific applications.

Current research trends indicate a growing focus on sustainable and abundant materials, moving away from rare earth elements and toward environmentally friendly alternatives. This shift aligns with global sustainability goals and addresses supply chain vulnerabilities that have plagued traditional battery technologies. Additionally, there is increasing emphasis on scalable manufacturing processes to reduce production costs and facilitate widespread commercial adoption.

The primary technical objectives for hybrid supercapacitor development center around achieving optimal balance between energy density, power density, cycle life, and cost-effectiveness. Researchers aim to develop systems that can deliver energy densities approaching those of lithium-ion batteries (>200 Wh/kg) while maintaining the high power capabilities (>10 kW/kg) and exceptional cycle life (>100,000 cycles) characteristic of supercapacitors.

Another critical objective involves improving temperature performance, as current systems often experience significant capacity degradation at extreme temperatures. Enhancing operational stability across a wider temperature range (-40°C to 70°C) would significantly expand application possibilities, particularly in automotive and aerospace sectors.

Looking forward, the technology evolution is expected to accelerate with the integration of artificial intelligence for materials discovery and optimization. Computational methods are increasingly being employed to predict novel material combinations and architectures that could lead to breakthrough performance improvements. The convergence of nanotechnology, advanced manufacturing techniques, and computational design is creating unprecedented opportunities for innovation in this field.

The ultimate goal for hybrid supercapacitor technology is to establish itself as a complementary or alternative solution to conventional batteries in next-generation energy systems, particularly in applications requiring rapid energy delivery, frequent cycling, and long operational lifetimes. This includes grid stabilization, electric vehicles, consumer electronics, and renewable energy integration systems.

The technological trajectory has been marked by several key innovations, including the development of novel electrode materials such as metal oxides, conducting polymers, and more recently, graphene and carbon nanotubes. These materials have dramatically improved the performance parameters of hybrid supercapacitors, enabling higher energy densities while maintaining the rapid charge-discharge capabilities that make supercapacitors valuable for specific applications.

Current research trends indicate a growing focus on sustainable and abundant materials, moving away from rare earth elements and toward environmentally friendly alternatives. This shift aligns with global sustainability goals and addresses supply chain vulnerabilities that have plagued traditional battery technologies. Additionally, there is increasing emphasis on scalable manufacturing processes to reduce production costs and facilitate widespread commercial adoption.

The primary technical objectives for hybrid supercapacitor development center around achieving optimal balance between energy density, power density, cycle life, and cost-effectiveness. Researchers aim to develop systems that can deliver energy densities approaching those of lithium-ion batteries (>200 Wh/kg) while maintaining the high power capabilities (>10 kW/kg) and exceptional cycle life (>100,000 cycles) characteristic of supercapacitors.

Another critical objective involves improving temperature performance, as current systems often experience significant capacity degradation at extreme temperatures. Enhancing operational stability across a wider temperature range (-40°C to 70°C) would significantly expand application possibilities, particularly in automotive and aerospace sectors.

Looking forward, the technology evolution is expected to accelerate with the integration of artificial intelligence for materials discovery and optimization. Computational methods are increasingly being employed to predict novel material combinations and architectures that could lead to breakthrough performance improvements. The convergence of nanotechnology, advanced manufacturing techniques, and computational design is creating unprecedented opportunities for innovation in this field.

The ultimate goal for hybrid supercapacitor technology is to establish itself as a complementary or alternative solution to conventional batteries in next-generation energy systems, particularly in applications requiring rapid energy delivery, frequent cycling, and long operational lifetimes. This includes grid stabilization, electric vehicles, consumer electronics, and renewable energy integration systems.

Market Demand Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the electrification of transportation. According to recent market analyses, the advanced energy storage market is projected to reach $546 billion by 2035, with a compound annual growth rate of 19.7% from 2023 to 2035. This remarkable expansion reflects the urgent need for efficient, reliable, and sustainable energy storage solutions that can address the intermittency challenges of renewable energy generation.

Hybrid supercapacitors are emerging as a critical technology in this landscape, positioned at the intersection of traditional batteries and conventional supercapacitors. The market demand for these hybrid systems stems from several converging factors. First, the rapid adoption of electric vehicles (EVs) requires energy storage solutions that can deliver both high power density for acceleration and sufficient energy density for range. Hybrid supercapacitors, with their ability to provide up to 10 times the power density of lithium-ion batteries while offering greater energy storage than traditional supercapacitors, are increasingly viewed as an optimal solution for this application.

The renewable energy sector represents another significant market driver. As solar and wind power installations continue to grow globally, reaching over 1,400 GW of combined installed capacity in 2022, the need for efficient energy storage to manage intermittency has become paramount. Hybrid supercapacitors offer rapid charge-discharge capabilities that make them ideal for grid stabilization and frequency regulation applications, where response times measured in milliseconds can be critical.

Consumer electronics manufacturers are also showing increased interest in hybrid supercapacitor technology. The demand for faster-charging devices with longer operational lifetimes has created a market opportunity estimated at $12.3 billion by 2028. Hybrid supercapacitors' ability to withstand hundreds of thousands of charge-discharge cycles without significant degradation makes them particularly attractive for this sector.

Industrial applications represent another growing market segment. The need for reliable backup power systems and peak-shaving capabilities in manufacturing facilities has created demand for energy storage solutions that can respond rapidly to load fluctuations while maintaining long service lives. Market research indicates that industrial energy storage applications are growing at 22.3% annually, with hybrid supercapacitors poised to capture a significant portion of this growth.

Regional analysis reveals varying adoption rates and market potentials. Asia-Pacific currently leads in hybrid supercapacitor development and implementation, with China, Japan, and South Korea hosting major manufacturers and research centers. North America and Europe are rapidly expanding their investments in this technology, driven by stringent emissions regulations and renewable energy targets. Emerging economies in South America and Africa represent future growth markets as they develop their renewable energy infrastructure.

Hybrid supercapacitors are emerging as a critical technology in this landscape, positioned at the intersection of traditional batteries and conventional supercapacitors. The market demand for these hybrid systems stems from several converging factors. First, the rapid adoption of electric vehicles (EVs) requires energy storage solutions that can deliver both high power density for acceleration and sufficient energy density for range. Hybrid supercapacitors, with their ability to provide up to 10 times the power density of lithium-ion batteries while offering greater energy storage than traditional supercapacitors, are increasingly viewed as an optimal solution for this application.

The renewable energy sector represents another significant market driver. As solar and wind power installations continue to grow globally, reaching over 1,400 GW of combined installed capacity in 2022, the need for efficient energy storage to manage intermittency has become paramount. Hybrid supercapacitors offer rapid charge-discharge capabilities that make them ideal for grid stabilization and frequency regulation applications, where response times measured in milliseconds can be critical.

Consumer electronics manufacturers are also showing increased interest in hybrid supercapacitor technology. The demand for faster-charging devices with longer operational lifetimes has created a market opportunity estimated at $12.3 billion by 2028. Hybrid supercapacitors' ability to withstand hundreds of thousands of charge-discharge cycles without significant degradation makes them particularly attractive for this sector.

Industrial applications represent another growing market segment. The need for reliable backup power systems and peak-shaving capabilities in manufacturing facilities has created demand for energy storage solutions that can respond rapidly to load fluctuations while maintaining long service lives. Market research indicates that industrial energy storage applications are growing at 22.3% annually, with hybrid supercapacitors poised to capture a significant portion of this growth.

Regional analysis reveals varying adoption rates and market potentials. Asia-Pacific currently leads in hybrid supercapacitor development and implementation, with China, Japan, and South Korea hosting major manufacturers and research centers. North America and Europe are rapidly expanding their investments in this technology, driven by stringent emissions regulations and renewable energy targets. Emerging economies in South America and Africa represent future growth markets as they develop their renewable energy infrastructure.

Current State and Technical Challenges in Hybrid Supercapacitors

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. Currently, these devices occupy a critical middle ground in the energy storage spectrum, offering faster charging capabilities than batteries while storing more energy than conventional supercapacitors. The global market for hybrid supercapacitors has been growing steadily, with a compound annual growth rate exceeding 20% since 2018, driven primarily by applications in electric vehicles, renewable energy integration, and consumer electronics.

Despite their promising attributes, hybrid supercapacitors face several technical challenges that limit their widespread adoption. The most significant hurdle remains the energy density gap compared to lithium-ion batteries, with current commercial hybrid supercapacitors achieving only 10-15 Wh/kg versus 150-250 Wh/kg for advanced lithium-ion systems. This limitation restricts their application in scenarios requiring extended energy delivery, such as long-range electric vehicles.

Material science constraints present another major challenge. The electrode materials, typically comprising carbon-based anodes and metal oxide or conducting polymer cathodes, suffer from stability issues during extended cycling. Research data indicates that performance degradation of 20-30% can occur after 10,000 charge-discharge cycles, particularly in high-temperature environments above 60°C. This degradation manifests as increased internal resistance and reduced capacitance retention.

Manufacturing scalability remains problematic, with current production methods involving complex processes that result in high unit costs. The average production cost for hybrid supercapacitors stands at approximately $20-30 per kWh, significantly higher than the $7-10 per kWh for mass-produced lithium-ion batteries. This cost differential creates a substantial barrier to market penetration, particularly in price-sensitive consumer applications.

Geographically, research and development in hybrid supercapacitor technology shows distinct patterns. Japan and South Korea lead in commercial production, with companies like Panasonic and Samsung investing heavily in manufacturing infrastructure. China has emerged as a significant player in materials research, particularly in graphene-based electrode development. The United States and European Union focus primarily on fundamental research, with substantial government funding directed toward university and national laboratory initiatives.

Temperature sensitivity presents another technical limitation, with performance metrics showing significant deterioration at temperature extremes. Below -20°C, capacitance can decrease by up to 50%, while operating above 70°C accelerates electrolyte degradation, leading to shortened device lifespan. This temperature dependence restricts application in harsh environmental conditions, such as aerospace or certain industrial settings.

Electrolyte optimization remains an active research area, as current formulations struggle to provide the ideal balance of ionic conductivity, electrochemical stability, and safety. Organic electrolytes offer wider voltage windows but present flammability concerns, while aqueous systems provide better safety at the cost of reduced energy density. This fundamental trade-off continues to challenge researchers seeking to develop next-generation hybrid supercapacitor systems.

Despite their promising attributes, hybrid supercapacitors face several technical challenges that limit their widespread adoption. The most significant hurdle remains the energy density gap compared to lithium-ion batteries, with current commercial hybrid supercapacitors achieving only 10-15 Wh/kg versus 150-250 Wh/kg for advanced lithium-ion systems. This limitation restricts their application in scenarios requiring extended energy delivery, such as long-range electric vehicles.

Material science constraints present another major challenge. The electrode materials, typically comprising carbon-based anodes and metal oxide or conducting polymer cathodes, suffer from stability issues during extended cycling. Research data indicates that performance degradation of 20-30% can occur after 10,000 charge-discharge cycles, particularly in high-temperature environments above 60°C. This degradation manifests as increased internal resistance and reduced capacitance retention.

Manufacturing scalability remains problematic, with current production methods involving complex processes that result in high unit costs. The average production cost for hybrid supercapacitors stands at approximately $20-30 per kWh, significantly higher than the $7-10 per kWh for mass-produced lithium-ion batteries. This cost differential creates a substantial barrier to market penetration, particularly in price-sensitive consumer applications.

Geographically, research and development in hybrid supercapacitor technology shows distinct patterns. Japan and South Korea lead in commercial production, with companies like Panasonic and Samsung investing heavily in manufacturing infrastructure. China has emerged as a significant player in materials research, particularly in graphene-based electrode development. The United States and European Union focus primarily on fundamental research, with substantial government funding directed toward university and national laboratory initiatives.

Temperature sensitivity presents another technical limitation, with performance metrics showing significant deterioration at temperature extremes. Below -20°C, capacitance can decrease by up to 50%, while operating above 70°C accelerates electrolyte degradation, leading to shortened device lifespan. This temperature dependence restricts application in harsh environmental conditions, such as aerospace or certain industrial settings.

Electrolyte optimization remains an active research area, as current formulations struggle to provide the ideal balance of ionic conductivity, electrochemical stability, and safety. Organic electrolytes offer wider voltage windows but present flammability concerns, while aqueous systems provide better safety at the cost of reduced energy density. This fundamental trade-off continues to challenge researchers seeking to develop next-generation hybrid supercapacitor systems.

Current Technical Solutions for Hybrid Supercapacitor Implementation

01 Electrode materials for hybrid supercapacitors

Various electrode materials can be used in hybrid supercapacitors to enhance energy density and performance. These materials include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for the optimization of both energy and power density in hybrid supercapacitors, making them more efficient for energy storage applications.- Electrode materials for hybrid supercapacitors: Various electrode materials can be used in hybrid supercapacitors to enhance energy density and power performance. These materials include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for the optimization of both capacitive and battery-like storage mechanisms, resulting in improved energy density while maintaining high power capability. Advanced electrode architectures and nanostructured materials further enhance the electrochemical performance of hybrid supercapacitors.

- Electrolyte compositions for hybrid supercapacitors: Electrolyte compositions play a crucial role in determining the performance of hybrid supercapacitors. Various electrolyte systems, including aqueous, organic, and ionic liquid-based electrolytes, can be used to optimize the operating voltage window, ionic conductivity, and electrochemical stability. Tailored electrolyte formulations can enhance the energy density by expanding the voltage window while ensuring long cycle life. Additives in the electrolyte can also improve the interface between the electrode and electrolyte, reducing internal resistance and enhancing overall performance.

- Integration of hybrid supercapacitors in energy storage systems: Hybrid supercapacitors can be integrated into various energy storage systems to provide both high energy and power density. These systems can be used in applications such as renewable energy storage, grid stabilization, and electric vehicles. The integration often involves combining hybrid supercapacitors with batteries or other energy storage devices to create a complementary system that leverages the advantages of each component. Advanced control systems and power management strategies are employed to optimize the performance and lifespan of these integrated energy storage solutions.

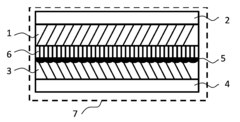

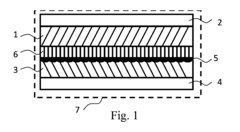

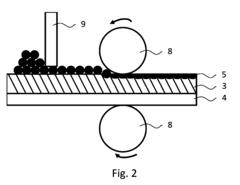

- Manufacturing processes for hybrid supercapacitors: Various manufacturing processes are employed to produce hybrid supercapacitors with optimized performance characteristics. These processes include techniques for electrode preparation, assembly methods, and packaging technologies. Advanced fabrication methods such as roll-to-roll processing, 3D printing, and spray coating can be used to create high-performance electrodes with controlled porosity and surface area. Post-processing treatments like thermal annealing and surface modification can further enhance the electrochemical properties of the components, resulting in improved device performance.

- Performance enhancement techniques for hybrid supercapacitors: Various techniques can be employed to enhance the performance of hybrid supercapacitors. These include surface modification of electrode materials, doping strategies, and hierarchical structuring to improve charge storage and transport properties. Composite materials combining different active components can synergistically enhance both energy and power density. Additionally, novel cell designs and architectures, such as interdigitated electrodes and asymmetric configurations, can optimize the utilization of active materials and improve overall device performance. Temperature management and self-healing mechanisms can also extend the operational lifetime of hybrid supercapacitors.

02 Integration of hybrid supercapacitors with renewable energy systems

Hybrid supercapacitors can be integrated with renewable energy systems such as solar and wind power to provide efficient energy storage solutions. These systems help in managing the intermittent nature of renewable energy sources by storing excess energy during peak production periods and releasing it during low production periods, thereby ensuring a continuous and reliable power supply.Expand Specific Solutions03 Electrolyte compositions for hybrid supercapacitors

The performance of hybrid supercapacitors can be significantly improved by optimizing the electrolyte composition. Various electrolytes, including aqueous, organic, and ionic liquids, can be used to enhance the operating voltage, energy density, and cycle life of hybrid supercapacitors. The choice of electrolyte also affects the temperature range and safety of the device.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitors

Advanced manufacturing techniques are employed to produce high-performance hybrid supercapacitors. These processes include coating, printing, and assembly methods that ensure uniform distribution of active materials and good contact between components. Innovations in manufacturing processes help to reduce costs, improve scalability, and enhance the overall performance of hybrid supercapacitors.Expand Specific Solutions05 Energy management systems for hybrid supercapacitors

Energy management systems are crucial for optimizing the performance of hybrid supercapacitors in various applications. These systems include control algorithms, power electronics, and monitoring devices that regulate charging and discharging processes, prevent overcharging, and ensure efficient energy utilization. Advanced energy management systems can extend the lifespan of hybrid supercapacitors and improve their overall efficiency.Expand Specific Solutions

Key Industry Players and Competitive Landscape Analysis

Hybrid supercapacitors represent a rapidly evolving technology in the energy storage landscape, currently transitioning from early development to commercial application phases. The market is projected to grow significantly, driven by increasing demand for high-performance energy storage solutions in automotive, electronics, and renewable energy sectors. Leading players include established electronics manufacturers like Samsung Electro-Mechanics and Robert Bosch GmbH, alongside specialized energy storage innovators such as Nanotech Energy and Shanghai Aowei Technology. Academic institutions including University of California and Tyndall National Institute are advancing fundamental research, while automotive companies like SAIC Motor and Peugeot SA are exploring integration opportunities. The technology is approaching commercial maturity with improvements in energy density, charging capabilities, and cost-effectiveness positioning hybrid supercapacitors as crucial components in next-generation energy solutions.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed a proprietary hybrid supercapacitor technology that combines the high power density of traditional supercapacitors with improved energy density approaching that of batteries. Their solution utilizes advanced carbon-based electrodes with lithium-doped materials to create a hybrid energy storage system. The company has successfully implemented these hybrid supercapacitors in urban transit applications, particularly in rapid charging electric buses that can be charged in 30 seconds at bus stops and operate for 5-10 kilometers between charges. Their technology employs a unique asymmetric design with activated carbon as the positive electrode and lithium titanate as the negative electrode, enabling operation at higher voltages (up to 3.8V per cell) compared to conventional supercapacitors (2.7V), resulting in significantly higher energy density while maintaining fast charge-discharge capabilities.

Strengths: Extremely fast charging capability (seconds rather than hours), long cycle life (>100,000 cycles), and proven commercial deployment in public transportation. Weaknesses: Still has lower energy density compared to lithium-ion batteries, higher cost per kWh than conventional batteries, and requires specialized charging infrastructure for optimal performance.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung Electro Mechanics has developed advanced hybrid supercapacitors that integrate graphene-based materials with metal oxide nanostructures to create high-performance energy storage solutions. Their technology utilizes a proprietary electrode fabrication process that creates hierarchical porous structures, maximizing surface area while maintaining excellent electrical conductivity. Samsung's hybrid supercapacitors employ manganese oxide and nickel hydroxide as pseudocapacitive materials combined with graphene sheets, achieving energy densities of 30-40 Wh/kg while maintaining power densities above 10 kW/kg. The company has also pioneered solid-state hybrid supercapacitors using gel polymer electrolytes that enhance safety and allow for flexible form factors. These devices feature operating voltages up to 4.0V per cell and demonstrate temperature stability from -40°C to 70°C, making them suitable for automotive and consumer electronics applications where both power and energy requirements are demanding.

Strengths: Excellent balance of energy and power density, superior temperature performance compared to conventional batteries, and compatibility with existing manufacturing processes. Weaknesses: Higher production costs than conventional supercapacitors, more complex manufacturing process requiring precise control of nanomaterials, and intellectual property constraints limiting widespread adoption.

Core Patents and Innovations in Hybrid Supercapacitor Technology

High energy hybrid supercapacitors using lithium metal powders

PatentInactiveUS20120212879A1

Innovation

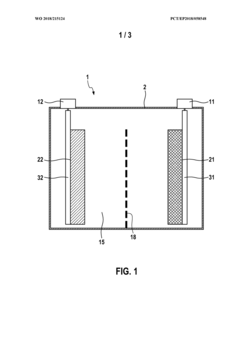

- A hybrid supercapacitor design featuring a negative electrode with air-stable lithium metal powder coated on the surface, combined with high surface area activated carbon positive electrodes and a non-aqueous lithium salt electrolyte, eliminating the need for lithium pre-doping and simplifying the manufacturing process.

Hybrid supercapacitor for high-temperature applications

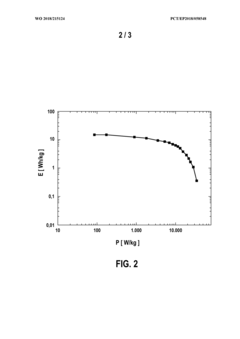

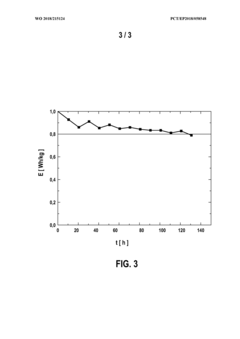

PatentWO2018215124A1

Innovation

- A hybrid supercapacitor design featuring a negative electrode with static capacitive active material, a positive electrode with electrochemical redox active material, and an electrolyte composition including an ionic liquid and lithium-containing conductive additive, allowing for high power and energy density along with extended lifespan at elevated temperatures.

Environmental Impact and Sustainability Considerations

The environmental impact of hybrid supercapacitors represents a critical consideration in their adoption for next-generation energy solutions. Unlike traditional energy storage technologies that rely heavily on environmentally harmful materials, hybrid supercapacitors offer significant sustainability advantages. Their reduced dependence on rare earth elements and toxic heavy metals compared to conventional batteries translates to lower environmental extraction costs and diminished ecosystem disruption during material sourcing.

Manufacturing processes for hybrid supercapacitors generally require less energy input than lithium-ion battery production, resulting in a smaller carbon footprint during the manufacturing phase. The absence of highly toxic electrolytes in many hybrid supercapacitor designs further reduces environmental risks associated with production, usage, and disposal. This characteristic makes them inherently safer for both human health and ecological systems.

The extended cycle life of hybrid supercapacitors—often exceeding 100,000 charge-discharge cycles compared to 500-2,000 cycles for typical lithium-ion batteries—significantly reduces electronic waste generation. This longevity translates to fewer replacement units and consequently less material consumption over time. Additionally, the materials used in hybrid supercapacitors are generally more amenable to recycling processes, with higher recovery rates for carbon-based materials and metal oxides.

When integrated into renewable energy systems, hybrid supercapacitors enhance overall system efficiency by providing rapid charge-discharge capabilities that complement the intermittent nature of renewable sources. This synergy enables more effective utilization of clean energy, potentially displacing fossil fuel consumption and reducing associated greenhouse gas emissions. Their application in grid stabilization further supports higher penetration of renewable energy sources into existing power infrastructure.

End-of-life considerations also favor hybrid supercapacitors from a sustainability perspective. Their simpler material composition facilitates more straightforward recycling processes compared to complex battery chemistries. Research indicates that up to 80% of materials in hybrid supercapacitors can be recovered and repurposed, creating potential for circular economy applications that minimize waste and resource depletion.

Despite these advantages, challenges remain in optimizing the environmental profile of hybrid supercapacitors. Current production methods still involve energy-intensive processes for nanomaterial synthesis, and some designs incorporate materials with moderate environmental impacts. Ongoing research focuses on developing bio-derived carbon sources, environmentally benign electrolytes, and energy-efficient manufacturing techniques to further enhance the sustainability credentials of this promising technology.

Manufacturing processes for hybrid supercapacitors generally require less energy input than lithium-ion battery production, resulting in a smaller carbon footprint during the manufacturing phase. The absence of highly toxic electrolytes in many hybrid supercapacitor designs further reduces environmental risks associated with production, usage, and disposal. This characteristic makes them inherently safer for both human health and ecological systems.

The extended cycle life of hybrid supercapacitors—often exceeding 100,000 charge-discharge cycles compared to 500-2,000 cycles for typical lithium-ion batteries—significantly reduces electronic waste generation. This longevity translates to fewer replacement units and consequently less material consumption over time. Additionally, the materials used in hybrid supercapacitors are generally more amenable to recycling processes, with higher recovery rates for carbon-based materials and metal oxides.

When integrated into renewable energy systems, hybrid supercapacitors enhance overall system efficiency by providing rapid charge-discharge capabilities that complement the intermittent nature of renewable sources. This synergy enables more effective utilization of clean energy, potentially displacing fossil fuel consumption and reducing associated greenhouse gas emissions. Their application in grid stabilization further supports higher penetration of renewable energy sources into existing power infrastructure.

End-of-life considerations also favor hybrid supercapacitors from a sustainability perspective. Their simpler material composition facilitates more straightforward recycling processes compared to complex battery chemistries. Research indicates that up to 80% of materials in hybrid supercapacitors can be recovered and repurposed, creating potential for circular economy applications that minimize waste and resource depletion.

Despite these advantages, challenges remain in optimizing the environmental profile of hybrid supercapacitors. Current production methods still involve energy-intensive processes for nanomaterial synthesis, and some designs incorporate materials with moderate environmental impacts. Ongoing research focuses on developing bio-derived carbon sources, environmentally benign electrolytes, and energy-efficient manufacturing techniques to further enhance the sustainability credentials of this promising technology.

Integration Challenges with Existing Energy Infrastructure

The integration of hybrid supercapacitors into existing energy infrastructure presents significant technical and operational challenges that must be addressed for successful implementation. Current power grids and energy storage systems were primarily designed for conventional technologies, creating compatibility issues when introducing hybrid supercapacitors. These advanced energy storage devices operate with different voltage profiles, charge-discharge characteristics, and control requirements compared to traditional batteries or standard capacitors.

Physical integration challenges include space constraints and thermal management considerations. Many existing facilities lack the appropriate housing or cooling systems necessary for optimal hybrid supercapacitor performance. The power electronics interface between hybrid supercapacitors and the grid requires specialized converters and control systems capable of managing their unique charge-discharge profiles, which often necessitates substantial retrofitting of existing infrastructure.

Regulatory frameworks and industry standards present another significant barrier. Current electrical codes and safety standards were developed before the emergence of hybrid supercapacitor technology, creating compliance uncertainties. Grid operators and utilities often require extensive testing and certification before allowing new technologies to connect to their networks, extending implementation timelines and increasing costs.

The economic dimension cannot be overlooked, as integration typically demands significant capital investment. Existing business models and cost structures in the energy sector may not adequately account for the unique value proposition of hybrid supercapacitors, particularly their high cycle life and rapid response capabilities. This creates financial barriers to adoption despite potential long-term benefits.

Technical expertise represents another challenge, as maintenance personnel and system operators require specialized training to effectively manage hybrid supercapacitor systems. The knowledge gap extends to system designers and engineers who may lack experience with this relatively new technology, potentially leading to suboptimal integration solutions.

Software and control system compatibility issues further complicate integration efforts. Energy management systems must be updated or replaced to effectively monitor and control hybrid supercapacitor performance characteristics. The algorithms governing energy dispatch and storage optimization need significant modification to leverage the unique capabilities of these devices, particularly their ability to provide both power-intensive and energy-intensive services.

Physical integration challenges include space constraints and thermal management considerations. Many existing facilities lack the appropriate housing or cooling systems necessary for optimal hybrid supercapacitor performance. The power electronics interface between hybrid supercapacitors and the grid requires specialized converters and control systems capable of managing their unique charge-discharge profiles, which often necessitates substantial retrofitting of existing infrastructure.

Regulatory frameworks and industry standards present another significant barrier. Current electrical codes and safety standards were developed before the emergence of hybrid supercapacitor technology, creating compliance uncertainties. Grid operators and utilities often require extensive testing and certification before allowing new technologies to connect to their networks, extending implementation timelines and increasing costs.

The economic dimension cannot be overlooked, as integration typically demands significant capital investment. Existing business models and cost structures in the energy sector may not adequately account for the unique value proposition of hybrid supercapacitors, particularly their high cycle life and rapid response capabilities. This creates financial barriers to adoption despite potential long-term benefits.

Technical expertise represents another challenge, as maintenance personnel and system operators require specialized training to effectively manage hybrid supercapacitor systems. The knowledge gap extends to system designers and engineers who may lack experience with this relatively new technology, potentially leading to suboptimal integration solutions.

Software and control system compatibility issues further complicate integration efforts. Energy management systems must be updated or replaced to effectively monitor and control hybrid supercapacitor performance characteristics. The algorithms governing energy dispatch and storage optimization need significant modification to leverage the unique capabilities of these devices, particularly their ability to provide both power-intensive and energy-intensive services.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!