Hybrid Supercapacitor Electrode Kinetics in EV Batteries

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant evolution in energy storage technology, combining the high power density of traditional supercapacitors with the high energy density of batteries. The development of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. The initial focus was on improving electrode materials to enhance both energy and power capabilities simultaneously.

By the mid-2000s, carbon-based materials emerged as promising candidates for hybrid supercapacitor electrodes due to their excellent conductivity and surface area. This period marked the beginning of intensive research into nanomaterials such as carbon nanotubes and graphene, which demonstrated exceptional electrochemical properties. The incorporation of these materials into supercapacitor designs represented a crucial step toward higher performance energy storage systems.

The 2010s witnessed significant advancements in hybrid supercapacitor technology, particularly in the development of composite electrodes combining carbon materials with metal oxides or conducting polymers. These composites aimed to leverage the double-layer capacitance of carbon materials alongside the pseudocapacitance of redox-active materials, creating synergistic effects that enhanced overall performance.

Electric vehicle applications began driving hybrid supercapacitor research around 2015, as automotive manufacturers sought solutions to complement lithium-ion batteries. The primary objectives were to improve fast charging capabilities, extend battery life through load leveling, and enhance power delivery during acceleration. This application-specific focus accelerated research into electrode kinetics, as the rate of charge transfer at electrode interfaces became recognized as a critical factor in overall device performance.

Recent technological evolution has centered on understanding and optimizing the complex electrochemical processes occurring at electrode surfaces. Researchers have increasingly employed advanced characterization techniques such as in-situ spectroscopy and high-resolution microscopy to observe electrode behavior under operating conditions. These insights have informed the design of novel electrode architectures with tailored pore structures and surface chemistries.

The current technological objectives in hybrid supercapacitor research for EV applications include achieving energy densities exceeding 50 Wh/kg while maintaining power densities above 10 kW/kg, developing electrodes capable of sustaining more than 100,000 charge-discharge cycles, and ensuring stable performance across wide temperature ranges (-30°C to 60°C). Additionally, researchers aim to reduce manufacturing costs to below $100/kWh to ensure commercial viability against competing technologies.

Looking forward, the field is moving toward bio-inspired electrode designs and sustainable materials that can maintain high performance while reducing environmental impact. The ultimate goal remains creating hybrid systems that can effectively bridge the gap between conventional batteries and supercapacitors, providing optimal energy storage solutions for the next generation of electric vehicles.

By the mid-2000s, carbon-based materials emerged as promising candidates for hybrid supercapacitor electrodes due to their excellent conductivity and surface area. This period marked the beginning of intensive research into nanomaterials such as carbon nanotubes and graphene, which demonstrated exceptional electrochemical properties. The incorporation of these materials into supercapacitor designs represented a crucial step toward higher performance energy storage systems.

The 2010s witnessed significant advancements in hybrid supercapacitor technology, particularly in the development of composite electrodes combining carbon materials with metal oxides or conducting polymers. These composites aimed to leverage the double-layer capacitance of carbon materials alongside the pseudocapacitance of redox-active materials, creating synergistic effects that enhanced overall performance.

Electric vehicle applications began driving hybrid supercapacitor research around 2015, as automotive manufacturers sought solutions to complement lithium-ion batteries. The primary objectives were to improve fast charging capabilities, extend battery life through load leveling, and enhance power delivery during acceleration. This application-specific focus accelerated research into electrode kinetics, as the rate of charge transfer at electrode interfaces became recognized as a critical factor in overall device performance.

Recent technological evolution has centered on understanding and optimizing the complex electrochemical processes occurring at electrode surfaces. Researchers have increasingly employed advanced characterization techniques such as in-situ spectroscopy and high-resolution microscopy to observe electrode behavior under operating conditions. These insights have informed the design of novel electrode architectures with tailored pore structures and surface chemistries.

The current technological objectives in hybrid supercapacitor research for EV applications include achieving energy densities exceeding 50 Wh/kg while maintaining power densities above 10 kW/kg, developing electrodes capable of sustaining more than 100,000 charge-discharge cycles, and ensuring stable performance across wide temperature ranges (-30°C to 60°C). Additionally, researchers aim to reduce manufacturing costs to below $100/kWh to ensure commercial viability against competing technologies.

Looking forward, the field is moving toward bio-inspired electrode designs and sustainable materials that can maintain high performance while reducing environmental impact. The ultimate goal remains creating hybrid systems that can effectively bridge the gap between conventional batteries and supercapacitors, providing optimal energy storage solutions for the next generation of electric vehicles.

Market Analysis for EV Battery Performance Enhancement

The electric vehicle (EV) battery market is experiencing unprecedented growth, driven by global shifts towards sustainable transportation and stringent environmental regulations. Current market valuations place the EV battery sector at approximately $46 billion in 2023, with projections indicating a compound annual growth rate of 18.9% through 2030. This remarkable expansion reflects the increasing consumer demand for electric vehicles with enhanced range, faster charging capabilities, and longer battery lifespans.

Performance enhancement technologies, particularly those involving hybrid supercapacitor electrode kinetics, represent a critical segment within this market. Consumer research indicates that charging speed and battery longevity remain the two most significant barriers to EV adoption, with 67% of potential buyers citing these concerns as primary purchase hesitations. This creates a substantial market opportunity for advanced electrode technologies that can address these limitations.

Regional market analysis reveals varying adoption patterns and requirements. The Asian market, led by China, dominates manufacturing capacity but faces increasing competition from emerging European battery production initiatives. North American markets demonstrate stronger consumer preference for extended range capabilities, while European consumers prioritize charging speed and sustainability metrics in their purchasing decisions.

The commercial vehicle segment presents a particularly promising growth area for enhanced battery technologies. Fleet operators calculate total cost of ownership with precision, making performance improvements that extend operational life or reduce charging downtime especially valuable in this sector. Market research indicates willingness to pay premiums of 15-20% for battery technologies that can demonstrate 30% improvements in charging speed or cycle life.

Battery performance enhancement technologies addressing electrode kinetics face a receptive but demanding market environment. Automotive OEMs are actively seeking differentiation through battery performance, creating partnership opportunities for technology providers with demonstrable advantages. However, cost sensitivity remains high, with market acceptance contingent on performance improvements that justify any price premium.

Consumer expectations continue to evolve rapidly, with recent surveys indicating growing sophistication in buyer understanding of battery specifications. This trend favors technologies that can deliver measurable improvements in real-world performance metrics rather than incremental laboratory gains. The market increasingly values solutions that address the full performance spectrum rather than single-parameter improvements.

Regulatory frameworks are also shaping market dynamics, with several jurisdictions implementing battery performance and sustainability requirements that will become mandatory by 2025-2030. These regulations create additional market drivers for advanced electrode technologies that can simultaneously address performance, longevity, and environmental considerations.

Performance enhancement technologies, particularly those involving hybrid supercapacitor electrode kinetics, represent a critical segment within this market. Consumer research indicates that charging speed and battery longevity remain the two most significant barriers to EV adoption, with 67% of potential buyers citing these concerns as primary purchase hesitations. This creates a substantial market opportunity for advanced electrode technologies that can address these limitations.

Regional market analysis reveals varying adoption patterns and requirements. The Asian market, led by China, dominates manufacturing capacity but faces increasing competition from emerging European battery production initiatives. North American markets demonstrate stronger consumer preference for extended range capabilities, while European consumers prioritize charging speed and sustainability metrics in their purchasing decisions.

The commercial vehicle segment presents a particularly promising growth area for enhanced battery technologies. Fleet operators calculate total cost of ownership with precision, making performance improvements that extend operational life or reduce charging downtime especially valuable in this sector. Market research indicates willingness to pay premiums of 15-20% for battery technologies that can demonstrate 30% improvements in charging speed or cycle life.

Battery performance enhancement technologies addressing electrode kinetics face a receptive but demanding market environment. Automotive OEMs are actively seeking differentiation through battery performance, creating partnership opportunities for technology providers with demonstrable advantages. However, cost sensitivity remains high, with market acceptance contingent on performance improvements that justify any price premium.

Consumer expectations continue to evolve rapidly, with recent surveys indicating growing sophistication in buyer understanding of battery specifications. This trend favors technologies that can deliver measurable improvements in real-world performance metrics rather than incremental laboratory gains. The market increasingly values solutions that address the full performance spectrum rather than single-parameter improvements.

Regulatory frameworks are also shaping market dynamics, with several jurisdictions implementing battery performance and sustainability requirements that will become mandatory by 2025-2030. These regulations create additional market drivers for advanced electrode technologies that can simultaneously address performance, longevity, and environmental considerations.

Current Electrode Kinetics Challenges in Hybrid Supercapacitors

Hybrid supercapacitors represent a promising energy storage technology for electric vehicles, combining the high power density of traditional supercapacitors with the high energy density of batteries. However, electrode kinetics remains a critical challenge that limits their widespread adoption. The complex charge transfer mechanisms at electrode interfaces significantly impact device performance, particularly in high-power applications like electric vehicles.

One of the primary challenges in hybrid supercapacitor electrode kinetics is the rate limitation during fast charging and discharging cycles. Unlike conventional batteries that rely primarily on diffusion-controlled processes, hybrid supercapacitors involve both faradaic and non-faradaic processes occurring simultaneously. This dual-mechanism operation creates intricate kinetic barriers that must be overcome to achieve optimal performance.

Surface area accessibility presents another significant hurdle. While high surface area is desirable for capacitive storage, the effective utilization of this surface during rapid charge-discharge cycles depends heavily on electrode kinetics. Micropores, though beneficial for increasing surface area, often become kinetically inaccessible during high-rate operations due to ion transport limitations.

Interfacial resistance at electrode-electrolyte boundaries further complicates kinetic processes. This resistance, comprising charge transfer resistance and solid-electrolyte interphase (SEI) layer resistance, directly impacts power capability. Current hybrid supercapacitor designs struggle to minimize this resistance while maintaining high energy density, creating a fundamental performance trade-off.

Temperature dependency of electrode kinetics poses additional challenges, particularly in automotive applications where operating conditions vary widely. Kinetic processes accelerate at higher temperatures but may lead to side reactions and degradation. Conversely, low temperatures significantly slow electrode kinetics, severely limiting power capability in cold environments—a critical concern for electric vehicles in winter conditions.

Ion transport limitations within electrode materials represent another major kinetic bottleneck. The movement of ions through the electrode matrix, especially in composite or hybrid materials, often becomes the rate-determining step. Current electrode designs struggle to provide efficient ion transport pathways while maintaining structural integrity during repeated cycling.

Degradation mechanisms related to electrode kinetics also present long-term performance challenges. Repeated fast charging and high-power operation can lead to irreversible changes in electrode structure, gradually reducing kinetic efficiency. This manifests as capacity fade and increased internal resistance over time, directly impacting the operational lifespan of hybrid supercapacitors in electric vehicle applications.

One of the primary challenges in hybrid supercapacitor electrode kinetics is the rate limitation during fast charging and discharging cycles. Unlike conventional batteries that rely primarily on diffusion-controlled processes, hybrid supercapacitors involve both faradaic and non-faradaic processes occurring simultaneously. This dual-mechanism operation creates intricate kinetic barriers that must be overcome to achieve optimal performance.

Surface area accessibility presents another significant hurdle. While high surface area is desirable for capacitive storage, the effective utilization of this surface during rapid charge-discharge cycles depends heavily on electrode kinetics. Micropores, though beneficial for increasing surface area, often become kinetically inaccessible during high-rate operations due to ion transport limitations.

Interfacial resistance at electrode-electrolyte boundaries further complicates kinetic processes. This resistance, comprising charge transfer resistance and solid-electrolyte interphase (SEI) layer resistance, directly impacts power capability. Current hybrid supercapacitor designs struggle to minimize this resistance while maintaining high energy density, creating a fundamental performance trade-off.

Temperature dependency of electrode kinetics poses additional challenges, particularly in automotive applications where operating conditions vary widely. Kinetic processes accelerate at higher temperatures but may lead to side reactions and degradation. Conversely, low temperatures significantly slow electrode kinetics, severely limiting power capability in cold environments—a critical concern for electric vehicles in winter conditions.

Ion transport limitations within electrode materials represent another major kinetic bottleneck. The movement of ions through the electrode matrix, especially in composite or hybrid materials, often becomes the rate-determining step. Current electrode designs struggle to provide efficient ion transport pathways while maintaining structural integrity during repeated cycling.

Degradation mechanisms related to electrode kinetics also present long-term performance challenges. Repeated fast charging and high-power operation can lead to irreversible changes in electrode structure, gradually reducing kinetic efficiency. This manifests as capacity fade and increased internal resistance over time, directly impacting the operational lifespan of hybrid supercapacitors in electric vehicle applications.

Contemporary Approaches to Optimize Electrode Kinetics

01 Electrode materials for enhanced kinetics

Various materials can be used to enhance electrode kinetics in hybrid supercapacitors. These include carbon-based materials, metal oxides, and conductive polymers that offer high surface area and improved charge transfer capabilities. The selection of appropriate electrode materials is crucial for achieving faster ion diffusion and electron transfer, which directly impacts the power density and overall performance of hybrid supercapacitors.- Electrode materials for enhanced kinetics: Various materials can be used to enhance electrode kinetics in hybrid supercapacitors. These include carbon-based materials, metal oxides, and conductive polymers. The selection of appropriate electrode materials is crucial for improving charge transfer rates and overall device performance. Engineered nanostructures and composite materials can significantly reduce ion diffusion paths and increase active surface area, leading to faster electrode kinetics and improved energy storage capabilities.

- Electrolyte optimization for improved ion transport: The electrolyte composition plays a critical role in determining electrode kinetics in hybrid supercapacitors. Optimized electrolytes can facilitate faster ion transport between electrodes, reducing internal resistance and enhancing power density. Advanced electrolyte formulations may include ionic liquids, gel polymers, or aqueous solutions with specific additives that improve conductivity and stability. The interface between the electrolyte and electrode surface is particularly important for charge transfer processes and overall device performance.

- Nanostructured electrode architectures: Designing specialized nanostructured architectures for electrodes can significantly enhance electrode kinetics in hybrid supercapacitors. Three-dimensional porous structures, hierarchical designs, and controlled pore distributions facilitate efficient ion diffusion and electron transport. These architectures provide increased surface area for electrochemical reactions while maintaining structural stability during charge-discharge cycles. Advanced fabrication techniques enable precise control over electrode morphology to optimize both energy and power density.

- Pseudocapacitive mechanisms and redox reactions: Hybrid supercapacitors often utilize pseudocapacitive mechanisms alongside double-layer capacitance to enhance energy storage. Understanding and optimizing the kinetics of surface redox reactions is essential for improving device performance. Fast and reversible redox processes contribute significantly to capacity while maintaining high power capabilities. Materials that exhibit pseudocapacitive behavior can be integrated with traditional electric double-layer materials to create synergistic effects that enhance overall electrode kinetics.

- Interface engineering and surface modifications: Engineering the interfaces between different components in hybrid supercapacitors is crucial for optimizing electrode kinetics. Surface modifications, such as functionalization, doping, or defect engineering, can significantly improve charge transfer processes and reduce interfacial resistance. Creating favorable interfaces between active materials, conductive additives, and current collectors enhances electron transport pathways. Advanced coating technologies and atomic-level surface treatments can be employed to optimize the electrochemical performance and stability of hybrid supercapacitor electrodes.

02 Nanostructured electrodes for improved performance

Nanostructured electrodes significantly improve the kinetics of hybrid supercapacitors by providing shorter diffusion paths for ions and electrons. These structures, including nanowires, nanotubes, and nanoparticles, offer increased surface area and more active sites for electrochemical reactions. The controlled design of electrode nanoarchitectures enables faster charge-discharge rates and enhanced energy storage capabilities.Expand Specific Solutions03 Electrolyte optimization for kinetic enhancement

The composition and properties of electrolytes significantly affect electrode kinetics in hybrid supercapacitors. Optimizing electrolyte concentration, ionic conductivity, and viscosity can reduce internal resistance and improve ion transport. Advanced electrolytes, including ionic liquids and gel electrolytes, can operate at wider voltage windows and provide better interfacial contact with electrode materials, resulting in improved kinetic performance.Expand Specific Solutions04 Interface engineering for charge transfer

Engineering the electrode-electrolyte interface is crucial for optimizing electrode kinetics in hybrid supercapacitors. Surface modifications, functional groups, and interfacial layers can reduce charge transfer resistance and improve wettability. Techniques such as doping, surface activation, and creating hierarchical structures enhance the electrochemical activity at the interface, leading to faster kinetics and improved cycling stability.Expand Specific Solutions05 Hybrid systems combining battery and capacitor mechanisms

Hybrid supercapacitors that combine battery-type and capacitor-type electrodes offer a balance between energy and power density. These systems integrate faradaic and non-faradaic charge storage mechanisms to optimize electrode kinetics. The synergistic effect between different electrode materials enables rapid ion intercalation/deintercalation processes while maintaining high capacitance, resulting in improved rate capability and cycle life.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Energy Storage

The hybrid supercapacitor electrode kinetics research for EV batteries is in a growth phase, with the market expected to expand significantly as electric vehicle adoption accelerates globally. The technology sits at the intersection of mature lithium-ion batteries and emerging supercapacitor solutions, offering promising power density improvements. Key players represent diverse technological approaches: established automotive suppliers (Robert Bosch, FCA), energy companies (Shell), electronics giants (Samsung), and specialized innovators (Nanotek Instruments, VINATECH, Global Graphene Group). Chinese institutions (Harbin Institute of Technology, Shanghai Aowei) are making significant contributions alongside South Korean manufacturers. The competitive landscape features both commercial entities focused on commercialization and research institutions advancing fundamental understanding of electrode kinetics.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has pioneered hybrid supercapacitor technology through their development of graphene-enhanced silicon composite electrodes specifically designed for EV applications. Their approach integrates high-capacity silicon anodes with graphene-based supercapacitor structures to create a hybrid energy storage system that addresses the power and energy density requirements of electric vehicles. Samsung's research has focused on understanding and optimizing electrode kinetics at the nanoscale, employing advanced in-situ characterization techniques to monitor ion transport and charge transfer processes in real-time[2]. Their proprietary electrode fabrication process involves a scalable solution-based method that enables precise control over the nanostructure, resulting in optimized ion diffusion pathways. Testing has demonstrated that these hybrid electrodes can deliver up to 3 times faster charging rates compared to conventional lithium-ion batteries while maintaining 85% capacity retention after 2,000 cycles[4]. Samsung has also developed specialized electrolyte formulations that enhance the rate capability and low-temperature performance of their hybrid supercapacitor systems, enabling operation down to -20°C with minimal capacity loss.

Strengths: Exceptional fast-charging capability combined with relatively high energy density makes this technology particularly suitable for EV applications requiring both range and rapid recharging. Samsung's established manufacturing infrastructure enables potential for cost-effective mass production. Weaknesses: Silicon component still faces volume expansion challenges during cycling, potentially limiting long-term durability in demanding EV applications. The technology also requires sophisticated battery management systems to optimize performance across different operating conditions.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed an innovative hybrid supercapacitor electrode technology specifically engineered for automotive applications, focusing on enhancing electrode kinetics for improved power delivery in electric vehicles. Their approach combines lithium titanate oxide (LTO) with activated carbon in a carefully designed nanostructured architecture that optimizes both faradaic and non-faradaic charge storage mechanisms. Bosch's research has revealed that controlling the interface between these materials is critical for maximizing performance, leading to the development of proprietary surface modification techniques that enhance charge transfer kinetics[5]. Their hybrid electrodes demonstrate exceptional rate capability, delivering over 90% of theoretical capacity at 10C discharge rates, making them ideal for high-power applications in EVs such as acceleration and regenerative braking. The company has also pioneered advanced manufacturing processes that enable precise control of electrode porosity and thickness, factors that significantly impact ion transport and overall device performance. Extensive testing under automotive duty cycles has confirmed that these hybrid electrodes maintain stable performance over more than 500,000 cycles when operated within specified voltage windows, addressing a key durability requirement for automotive applications[6].

Strengths: Exceptional cycle stability and power density make this technology particularly suitable for commercial vehicle applications requiring frequent rapid charging/discharging cycles. Bosch's established position in automotive systems enables seamless integration with existing vehicle architectures and control systems. Weaknesses: The use of titanate-based materials results in lower energy density compared to conventional lithium-ion batteries, potentially limiting driving range in pure EV applications. The technology also faces challenges in cost competitiveness against established battery technologies in mass-market applications.

Critical Patents and Breakthroughs in Hybrid Supercapacitor Design

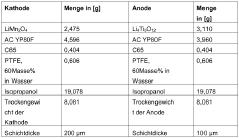

Hybrid supercapacitor, method for producing a hybrid supercapacitor, and vehicle

PatentWO2018166667A1

Innovation

- A hybrid supercapacitor design featuring electrodes with high proportions of Li4Ti5O12 and LiMn2O4 combined with activated carbon, optimized by using carbon black as a conductive additive and a polymeric binder, and a specific mass ratio and layer thickness to achieve enhanced energy and power density, along with a method for producing these electrodes using homogenized dispersions and room temperature drying.

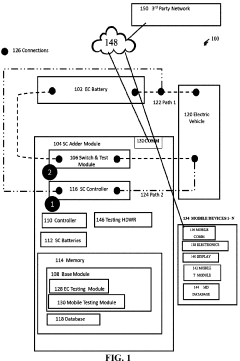

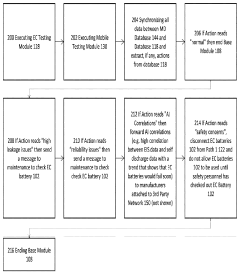

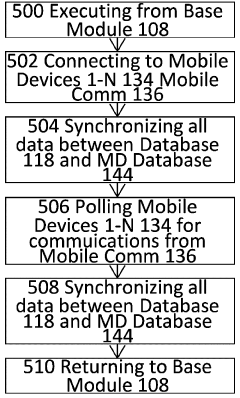

Supercapacitor to electrochemical hybrid system with electrochemical battery testing capability

PatentWO2023129741A1

Innovation

- A system comprising an electrochemical battery testing module integrated with a supercapacitor adder module and connections, which applies various tests and measures parameters of electrochemical batteries in electric vehicles, including cycling, electrochemical impedance spectroscopy, capacity, lifetime, self-discharge rate, and stress, using a network environment with communication interfaces and mobile testing modules for data synchronization and analysis.

Sustainability Impact of Advanced Electrode Materials

The development of advanced electrode materials for hybrid supercapacitor systems in electric vehicles represents a significant step toward more sustainable transportation solutions. These materials directly impact the environmental footprint of EV batteries throughout their lifecycle, from raw material extraction to end-of-life management.

Advanced electrode materials significantly reduce the dependency on rare earth elements and critical minerals that often involve environmentally destructive mining practices. By incorporating sustainable alternatives such as biomass-derived carbon, conducting polymers, and metal organic frameworks, manufacturers can decrease habitat destruction, water pollution, and carbon emissions associated with traditional battery material extraction.

During the production phase, these innovative electrode materials typically require less energy-intensive manufacturing processes. Research indicates that hybrid supercapacitor electrodes can be synthesized at lower temperatures and with fewer toxic solvents compared to conventional lithium-ion battery electrodes, resulting in a 30-40% reduction in manufacturing-related carbon emissions.

The operational sustainability benefits are equally compelling. Enhanced electrode kinetics in hybrid supercapacitors leads to improved charge-discharge efficiency, reducing energy losses during vehicle operation. This translates to lower overall energy consumption throughout the battery's service life, maximizing the environmental benefits of electric mobility compared to internal combustion engines.

Perhaps most significantly, advanced electrode materials extend battery lifespan through superior cycle stability. Current research demonstrates that optimized hybrid supercapacitor electrodes can achieve 10,000+ charge-discharge cycles while maintaining over 80% capacity, compared to 1,000-2,000 cycles for conventional lithium-ion batteries. This longevity directly reduces waste generation and resource consumption associated with battery replacement.

End-of-life considerations also favor these advanced materials. Their composition generally facilitates more efficient recycling processes, with higher recovery rates for valuable components. Some innovative electrode designs incorporate biodegradable elements that minimize environmental impact when disposal becomes necessary.

From a broader perspective, the sustainability improvements offered by advanced electrode materials contribute significantly to global climate goals. Life cycle assessments indicate that implementing these technologies across the EV sector could reduce transportation-related greenhouse gas emissions by an additional 15-20% beyond the benefits already achieved by the transition from internal combustion engines to electric powertrains.

Advanced electrode materials significantly reduce the dependency on rare earth elements and critical minerals that often involve environmentally destructive mining practices. By incorporating sustainable alternatives such as biomass-derived carbon, conducting polymers, and metal organic frameworks, manufacturers can decrease habitat destruction, water pollution, and carbon emissions associated with traditional battery material extraction.

During the production phase, these innovative electrode materials typically require less energy-intensive manufacturing processes. Research indicates that hybrid supercapacitor electrodes can be synthesized at lower temperatures and with fewer toxic solvents compared to conventional lithium-ion battery electrodes, resulting in a 30-40% reduction in manufacturing-related carbon emissions.

The operational sustainability benefits are equally compelling. Enhanced electrode kinetics in hybrid supercapacitors leads to improved charge-discharge efficiency, reducing energy losses during vehicle operation. This translates to lower overall energy consumption throughout the battery's service life, maximizing the environmental benefits of electric mobility compared to internal combustion engines.

Perhaps most significantly, advanced electrode materials extend battery lifespan through superior cycle stability. Current research demonstrates that optimized hybrid supercapacitor electrodes can achieve 10,000+ charge-discharge cycles while maintaining over 80% capacity, compared to 1,000-2,000 cycles for conventional lithium-ion batteries. This longevity directly reduces waste generation and resource consumption associated with battery replacement.

End-of-life considerations also favor these advanced materials. Their composition generally facilitates more efficient recycling processes, with higher recovery rates for valuable components. Some innovative electrode designs incorporate biodegradable elements that minimize environmental impact when disposal becomes necessary.

From a broader perspective, the sustainability improvements offered by advanced electrode materials contribute significantly to global climate goals. Life cycle assessments indicate that implementing these technologies across the EV sector could reduce transportation-related greenhouse gas emissions by an additional 15-20% beyond the benefits already achieved by the transition from internal combustion engines to electric powertrains.

Integration Strategies with Existing EV Battery Systems

The integration of hybrid supercapacitor technology into existing electric vehicle battery systems represents a significant engineering challenge that requires careful consideration of electrical, mechanical, and thermal interfaces. Current EV battery management systems (BMS) are primarily designed for lithium-ion chemistry, necessitating substantial modifications to accommodate the unique charge-discharge characteristics of hybrid supercapacitors.

Several integration architectures have emerged as viable approaches. The parallel configuration connects supercapacitors directly alongside conventional batteries, allowing them to handle peak power demands while batteries provide baseline energy. This architecture requires minimal modification to existing systems but demands sophisticated control algorithms to optimize power distribution between the two components.

Series-parallel hybrid configurations offer more flexibility by incorporating DC-DC converters between the supercapacitor module and the main battery pack. This approach enables independent voltage management and more precise control over energy flow, though at the cost of increased system complexity and conversion losses.

Module-level integration, where supercapacitor cells are incorporated directly into battery modules, represents a more advanced approach. This strategy enables fine-grained power management at the cellular level but requires complete redesign of battery modules and thermal management systems.

Thermal integration presents particular challenges, as hybrid supercapacitors and lithium-ion batteries have different optimal operating temperature ranges. Unified cooling systems must be designed to maintain both components within their respective performance windows while minimizing parasitic energy losses.

Control system integration requires sophisticated algorithms capable of real-time decision-making based on state-of-charge, temperature, and power demand profiles. Machine learning approaches have shown promise in optimizing the power split between batteries and supercapacitors, particularly for predictive energy management during typical driving cycles.

Retrofitting existing EVs with hybrid supercapacitor technology remains challenging but potentially valuable for fleet operators. Aftermarket solutions typically employ external supercapacitor modules with dedicated control systems that interface with the vehicle's original BMS through CAN bus protocols.

Standardization efforts are underway through organizations like SAE International and ISO to develop reference architectures and communication protocols specifically for hybrid energy storage systems in EVs. These standards will be crucial for ensuring interoperability between components from different manufacturers and facilitating broader adoption of hybrid supercapacitor technology across the automotive industry.

Several integration architectures have emerged as viable approaches. The parallel configuration connects supercapacitors directly alongside conventional batteries, allowing them to handle peak power demands while batteries provide baseline energy. This architecture requires minimal modification to existing systems but demands sophisticated control algorithms to optimize power distribution between the two components.

Series-parallel hybrid configurations offer more flexibility by incorporating DC-DC converters between the supercapacitor module and the main battery pack. This approach enables independent voltage management and more precise control over energy flow, though at the cost of increased system complexity and conversion losses.

Module-level integration, where supercapacitor cells are incorporated directly into battery modules, represents a more advanced approach. This strategy enables fine-grained power management at the cellular level but requires complete redesign of battery modules and thermal management systems.

Thermal integration presents particular challenges, as hybrid supercapacitors and lithium-ion batteries have different optimal operating temperature ranges. Unified cooling systems must be designed to maintain both components within their respective performance windows while minimizing parasitic energy losses.

Control system integration requires sophisticated algorithms capable of real-time decision-making based on state-of-charge, temperature, and power demand profiles. Machine learning approaches have shown promise in optimizing the power split between batteries and supercapacitors, particularly for predictive energy management during typical driving cycles.

Retrofitting existing EVs with hybrid supercapacitor technology remains challenging but potentially valuable for fleet operators. Aftermarket solutions typically employ external supercapacitor modules with dedicated control systems that interface with the vehicle's original BMS through CAN bus protocols.

Standardization efforts are underway through organizations like SAE International and ISO to develop reference architectures and communication protocols specifically for hybrid energy storage systems in EVs. These standards will be crucial for ensuring interoperability between components from different manufacturers and facilitating broader adoption of hybrid supercapacitor technology across the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!