What Applications Are Leveraging Hybrid Supercapacitor Technology?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Background and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional supercapacitors, particularly their relatively low energy density compared to batteries.

The development trajectory has been marked by continuous improvements in electrode materials, electrolytes, and cell designs. Initially, carbon-based materials dominated the electrode landscape, but recent years have witnessed the integration of battery-type materials such as metal oxides, conducting polymers, and lithium-intercalation compounds, which has substantially enhanced energy storage capabilities while maintaining rapid charge-discharge rates.

A pivotal milestone in hybrid supercapacitor technology was the introduction of lithium-ion capacitors (LICs) around 2008, which combined a battery-type anode with a supercapacitor-type cathode. This innovation significantly increased energy density while preserving much of the power performance and cycle life inherent to supercapacitors.

The global research community has subsequently expanded the hybrid concept to include various other ion systems, such as sodium-ion and potassium-ion hybrid capacitors, addressing sustainability concerns and raw material availability issues associated with lithium-based systems.

Current technological objectives for hybrid supercapacitors focus on several key areas. Researchers aim to further increase energy density while maintaining the exceptional power characteristics and cycle stability. There is also significant emphasis on developing environmentally friendly and sustainable materials to replace rare or toxic components currently used in some hybrid systems.

Another critical objective is cost reduction through simplified manufacturing processes and the use of abundant materials, which would facilitate broader market adoption. Improving temperature performance is equally important, as many applications require reliable operation in extreme conditions, from sub-zero environments to high-temperature settings.

Integration capabilities represent another frontier, with efforts directed toward designing hybrid supercapacitors that can be seamlessly incorporated into existing energy systems or combined with other energy storage technologies in hybrid configurations. This includes developing standardized form factors and interfaces that facilitate adoption across various industries.

The overarching goal remains to position hybrid supercapacitors as a versatile energy storage solution that bridges the gap between conventional capacitors and batteries, offering an optimal balance of power, energy, longevity, and cost for applications ranging from consumer electronics to grid-scale energy storage systems.

The development trajectory has been marked by continuous improvements in electrode materials, electrolytes, and cell designs. Initially, carbon-based materials dominated the electrode landscape, but recent years have witnessed the integration of battery-type materials such as metal oxides, conducting polymers, and lithium-intercalation compounds, which has substantially enhanced energy storage capabilities while maintaining rapid charge-discharge rates.

A pivotal milestone in hybrid supercapacitor technology was the introduction of lithium-ion capacitors (LICs) around 2008, which combined a battery-type anode with a supercapacitor-type cathode. This innovation significantly increased energy density while preserving much of the power performance and cycle life inherent to supercapacitors.

The global research community has subsequently expanded the hybrid concept to include various other ion systems, such as sodium-ion and potassium-ion hybrid capacitors, addressing sustainability concerns and raw material availability issues associated with lithium-based systems.

Current technological objectives for hybrid supercapacitors focus on several key areas. Researchers aim to further increase energy density while maintaining the exceptional power characteristics and cycle stability. There is also significant emphasis on developing environmentally friendly and sustainable materials to replace rare or toxic components currently used in some hybrid systems.

Another critical objective is cost reduction through simplified manufacturing processes and the use of abundant materials, which would facilitate broader market adoption. Improving temperature performance is equally important, as many applications require reliable operation in extreme conditions, from sub-zero environments to high-temperature settings.

Integration capabilities represent another frontier, with efforts directed toward designing hybrid supercapacitors that can be seamlessly incorporated into existing energy systems or combined with other energy storage technologies in hybrid configurations. This includes developing standardized form factors and interfaces that facilitate adoption across various industries.

The overarching goal remains to position hybrid supercapacitors as a versatile energy storage solution that bridges the gap between conventional capacitors and batteries, offering an optimal balance of power, energy, longevity, and cost for applications ranging from consumer electronics to grid-scale energy storage systems.

Market Demand Analysis for Hybrid Supercapacitor Applications

The global market for hybrid supercapacitors is experiencing robust growth, driven by increasing demand for efficient energy storage solutions across multiple sectors. Current market analysis indicates that the hybrid supercapacitor market is projected to grow at a compound annual growth rate of 20% through 2030, significantly outpacing traditional energy storage technologies.

Transportation and automotive applications represent the largest market segment for hybrid supercapacitors. The rapid expansion of electric and hybrid vehicles has created substantial demand for energy storage systems that can deliver high power density for acceleration while maintaining reasonable energy density for range. Hybrid supercapacitors are particularly valuable in regenerative braking systems, where they can capture and store energy more efficiently than conventional batteries.

Consumer electronics constitutes another significant market segment. Manufacturers are increasingly incorporating hybrid supercapacitors into smartphones, laptops, and wearable devices to complement traditional lithium-ion batteries. This integration allows for faster charging capabilities and extended device lifespans, addressing key consumer pain points in the electronics market.

The renewable energy sector presents perhaps the most promising growth opportunity. As solar and wind power generation continues to expand globally, the need for efficient energy storage solutions to manage intermittency issues becomes critical. Hybrid supercapacitors offer advantages in grid stabilization applications, providing rapid response capabilities for frequency regulation and peak shaving services.

Industrial applications are also driving market demand, particularly in sectors requiring uninterruptible power supplies (UPS) and backup power systems. Data centers, telecommunications infrastructure, and manufacturing facilities increasingly rely on hybrid supercapacitors to ensure operational continuity during power fluctuations or outages.

Market analysis reveals regional variations in adoption patterns. Asia-Pacific currently leads the market, with significant manufacturing capacity and implementation across multiple sectors. North America and Europe follow, with growing adoption rates particularly in renewable energy integration and transportation applications.

Consumer demand trends indicate increasing preference for sustainable and long-lasting energy storage solutions, creating favorable market conditions for hybrid supercapacitors. The technology's reduced environmental impact compared to conventional batteries resonates with environmentally conscious consumers and aligns with corporate sustainability initiatives.

Market forecasts suggest that as manufacturing scales up and costs decrease, hybrid supercapacitors will continue to penetrate new application areas, potentially disrupting traditional battery markets in specific use cases where their performance characteristics provide distinct advantages.

Transportation and automotive applications represent the largest market segment for hybrid supercapacitors. The rapid expansion of electric and hybrid vehicles has created substantial demand for energy storage systems that can deliver high power density for acceleration while maintaining reasonable energy density for range. Hybrid supercapacitors are particularly valuable in regenerative braking systems, where they can capture and store energy more efficiently than conventional batteries.

Consumer electronics constitutes another significant market segment. Manufacturers are increasingly incorporating hybrid supercapacitors into smartphones, laptops, and wearable devices to complement traditional lithium-ion batteries. This integration allows for faster charging capabilities and extended device lifespans, addressing key consumer pain points in the electronics market.

The renewable energy sector presents perhaps the most promising growth opportunity. As solar and wind power generation continues to expand globally, the need for efficient energy storage solutions to manage intermittency issues becomes critical. Hybrid supercapacitors offer advantages in grid stabilization applications, providing rapid response capabilities for frequency regulation and peak shaving services.

Industrial applications are also driving market demand, particularly in sectors requiring uninterruptible power supplies (UPS) and backup power systems. Data centers, telecommunications infrastructure, and manufacturing facilities increasingly rely on hybrid supercapacitors to ensure operational continuity during power fluctuations or outages.

Market analysis reveals regional variations in adoption patterns. Asia-Pacific currently leads the market, with significant manufacturing capacity and implementation across multiple sectors. North America and Europe follow, with growing adoption rates particularly in renewable energy integration and transportation applications.

Consumer demand trends indicate increasing preference for sustainable and long-lasting energy storage solutions, creating favorable market conditions for hybrid supercapacitors. The technology's reduced environmental impact compared to conventional batteries resonates with environmentally conscious consumers and aligns with corporate sustainability initiatives.

Market forecasts suggest that as manufacturing scales up and costs decrease, hybrid supercapacitors will continue to penetrate new application areas, potentially disrupting traditional battery markets in specific use cases where their performance characteristics provide distinct advantages.

Current Status and Technical Challenges in Hybrid Supercapacitors

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining features of both traditional supercapacitors and batteries. Currently, these devices are positioned at a critical juncture in their development trajectory, with substantial progress made in laboratory settings but facing challenges in widespread commercial implementation.

Global research institutions and major energy storage companies have achieved notable breakthroughs in hybrid supercapacitor technology. Recent advancements include the development of novel electrode materials such as lithium titanate, activated carbon with metal oxide composites, and graphene-based structures that significantly enhance energy density while maintaining the high power capabilities characteristic of supercapacitors.

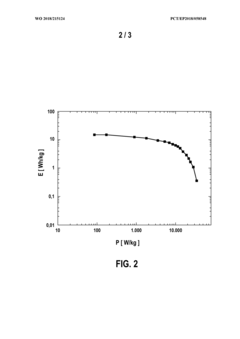

Despite these achievements, several technical challenges persist. The primary limitation remains the energy density gap compared to lithium-ion batteries. While hybrid supercapacitors offer improvements over traditional supercapacitors, they typically achieve only 20-30 Wh/kg compared to 150-250 Wh/kg for commercial lithium-ion batteries. This energy density limitation restricts their application in scenarios requiring extended operation periods.

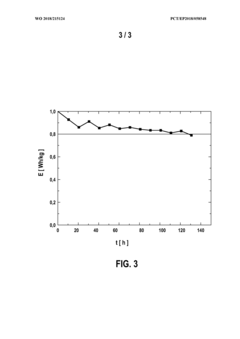

Cycle stability presents another significant challenge. Although hybrid supercapacitors demonstrate better cycling performance than conventional batteries, they still experience capacity degradation over extended cycling, particularly at higher temperatures or when subjected to deep discharge cycles. Current systems typically maintain 80% capacity after 5,000-10,000 cycles, which falls short of the theoretical potential.

Cost factors also impede widespread adoption. Manufacturing expenses remain high due to specialized materials and production processes. The use of rare or precious metals in certain electrode formulations contributes significantly to this cost barrier, making hybrid supercapacitors less economically competitive for mass-market applications.

Geographically, research and development efforts are concentrated in East Asia (particularly Japan, South Korea, and China), North America, and Europe. China has emerged as a leader in production capacity, while Japan maintains an edge in patent filings for advanced materials. European research institutions focus heavily on sustainable materials and manufacturing processes.

Temperature performance limitations constitute another technical hurdle. Current hybrid supercapacitor technologies experience significant performance degradation at temperature extremes, limiting their application in automotive, aerospace, and outdoor energy storage systems that must operate across wide temperature ranges.

Self-discharge rates, though improved compared to traditional supercapacitors, remain higher than in battery systems. This characteristic restricts the use of hybrid supercapacitors in applications requiring long-term energy storage without frequent recharging.

Global research institutions and major energy storage companies have achieved notable breakthroughs in hybrid supercapacitor technology. Recent advancements include the development of novel electrode materials such as lithium titanate, activated carbon with metal oxide composites, and graphene-based structures that significantly enhance energy density while maintaining the high power capabilities characteristic of supercapacitors.

Despite these achievements, several technical challenges persist. The primary limitation remains the energy density gap compared to lithium-ion batteries. While hybrid supercapacitors offer improvements over traditional supercapacitors, they typically achieve only 20-30 Wh/kg compared to 150-250 Wh/kg for commercial lithium-ion batteries. This energy density limitation restricts their application in scenarios requiring extended operation periods.

Cycle stability presents another significant challenge. Although hybrid supercapacitors demonstrate better cycling performance than conventional batteries, they still experience capacity degradation over extended cycling, particularly at higher temperatures or when subjected to deep discharge cycles. Current systems typically maintain 80% capacity after 5,000-10,000 cycles, which falls short of the theoretical potential.

Cost factors also impede widespread adoption. Manufacturing expenses remain high due to specialized materials and production processes. The use of rare or precious metals in certain electrode formulations contributes significantly to this cost barrier, making hybrid supercapacitors less economically competitive for mass-market applications.

Geographically, research and development efforts are concentrated in East Asia (particularly Japan, South Korea, and China), North America, and Europe. China has emerged as a leader in production capacity, while Japan maintains an edge in patent filings for advanced materials. European research institutions focus heavily on sustainable materials and manufacturing processes.

Temperature performance limitations constitute another technical hurdle. Current hybrid supercapacitor technologies experience significant performance degradation at temperature extremes, limiting their application in automotive, aerospace, and outdoor energy storage systems that must operate across wide temperature ranges.

Self-discharge rates, though improved compared to traditional supercapacitors, remain higher than in battery systems. This characteristic restricts the use of hybrid supercapacitors in applications requiring long-term energy storage without frequent recharging.

Current Application Solutions Using Hybrid Supercapacitors

01 Electrode materials for hybrid supercapacitors

Hybrid supercapacitors utilize specialized electrode materials to combine the high energy density of batteries with the high power density of traditional supercapacitors. These materials often include carbon-based structures (like graphene or carbon nanotubes) combined with metal oxides or conductive polymers. The hybrid electrode configuration allows for both electric double-layer capacitance and pseudocapacitive charge storage mechanisms, resulting in improved energy storage capabilities while maintaining fast charge-discharge rates.- Electrode materials for hybrid supercapacitors: Hybrid supercapacitors utilize specialized electrode materials to combine the high energy density of batteries with the high power density of traditional supercapacitors. These materials often include carbon-based structures with metal oxides or conductive polymers. The electrode composition significantly impacts the performance characteristics, including charge storage capacity, cycle life, and charge/discharge rates. Advanced materials engineering at the nanoscale level enables enhanced surface area and improved ion transport mechanisms.

- Electrolyte systems for hybrid supercapacitors: The electrolyte composition plays a crucial role in hybrid supercapacitor performance, affecting operating voltage, temperature range, and overall energy density. Advanced electrolyte systems may incorporate ionic liquids, gel polymers, or solid-state electrolytes to enhance safety and performance. These specialized formulations enable wider voltage windows and improved ion mobility between electrodes, resulting in higher energy storage capabilities while maintaining the rapid charge/discharge characteristics essential for supercapacitor applications.

- Integration of hybrid supercapacitors in energy systems: Hybrid supercapacitors can be effectively integrated into various energy systems to provide peak power support, energy recovery, and grid stabilization. These applications include renewable energy storage, electric vehicles, and smart grid technologies. The integration often involves sophisticated power management systems that optimize the complementary characteristics of supercapacitors and batteries. This approach enables more efficient energy utilization, extended system lifetime, and improved performance in applications requiring both high energy and high power capabilities.

- Manufacturing processes for hybrid supercapacitors: Advanced manufacturing techniques are essential for producing high-performance hybrid supercapacitors. These processes include specialized coating methods, controlled deposition of active materials, and precise assembly procedures. Innovations in manufacturing focus on achieving uniform electrode structures, optimizing interfaces between components, and ensuring consistent quality. Novel approaches such as roll-to-roll processing, 3D printing of electrodes, and precision assembly techniques enable cost-effective production while maintaining the high performance characteristics required for commercial applications.

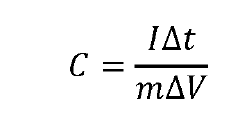

- Circuit design and control systems for hybrid supercapacitors: Specialized circuit designs and control systems are developed to optimize the performance of hybrid supercapacitors in various applications. These systems manage charge/discharge cycles, balance multiple cells, and protect against overcharging or over-discharging. Advanced control algorithms can dynamically adjust operating parameters based on load conditions, temperature, and state of charge. Integrated monitoring systems provide real-time data on performance metrics, enabling predictive maintenance and optimized operation throughout the device lifecycle.

02 Energy management systems for hybrid supercapacitors

Energy management systems are crucial for optimizing the performance of hybrid supercapacitors in various applications. These systems include specialized circuits and control algorithms that manage charge-discharge cycles, monitor voltage levels, and regulate temperature. Advanced energy management solutions enable efficient power distribution, extend the operational lifetime of supercapacitors, and ensure safe operation under varying load conditions, particularly in automotive and renewable energy applications.Expand Specific Solutions03 Integration of hybrid supercapacitors in electronic devices

Hybrid supercapacitors can be integrated into various electronic devices to provide rapid power delivery capabilities alongside conventional batteries. This integration involves specialized circuit designs that accommodate the different electrical characteristics of supercapacitors, including voltage management and charge balancing. The implementation enables improved performance in applications requiring burst power delivery, such as mobile devices, wearable technology, and IoT sensors, while extending battery life and enabling faster charging capabilities.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitor components

Advanced manufacturing techniques are essential for producing high-performance hybrid supercapacitor components. These processes include specialized methods for electrode fabrication, electrolyte formulation, and assembly of the complete energy storage device. Innovations in manufacturing focus on improving material uniformity, increasing surface area of active materials, enhancing interface characteristics between components, and developing scalable production methods that maintain performance while reducing costs.Expand Specific Solutions05 Applications of hybrid supercapacitors in renewable energy systems

Hybrid supercapacitors play a crucial role in renewable energy systems by providing rapid energy storage and release capabilities. They can be used to stabilize power output from intermittent renewable sources like solar and wind, provide frequency regulation for grid stability, and enable efficient energy harvesting in various conditions. The combination of high power density and improved energy density makes hybrid supercapacitors particularly valuable for bridging short-term power fluctuations and supporting peak power demands in renewable energy installations.Expand Specific Solutions

Key Industry Players in Hybrid Supercapacitor Development

Hybrid supercapacitor technology is currently in an early growth phase, with the market expected to expand significantly due to increasing demand for high-performance energy storage solutions. The global market size is projected to reach several billion dollars by 2030, driven by applications in electric vehicles, renewable energy systems, and consumer electronics. From a technical maturity perspective, companies like Samsung Electro Mechanics, Robert Bosch GmbH, and Nanotech Energy are leading commercial development with advanced prototypes and early market products. Shanghai Aowei Technology and Chaowei Power Group are making significant progress in industrial applications, while research institutions such as Dalian University of Technology and Texas A&M University are advancing fundamental technologies. The competitive landscape features both established electronics manufacturers and specialized startups focusing on specific performance improvements in power density, cycle life, and temperature stability.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed a comprehensive hybrid supercapacitor technology platform specifically targeting public transportation and grid-scale energy storage applications. Their approach combines lithium titanate (LTO) anodes with activated carbon cathodes to create hybrid devices that deliver exceptional cycle life (>100,000 cycles) while maintaining high power density. The company has pioneered large-format hybrid supercapacitor modules that can be rapidly charged at bus terminals, enabling electric buses to operate continuously without long charging breaks. Their proprietary thermal management system allows for safe operation under high-current charging conditions, addressing a key limitation of conventional energy storage technologies. Shanghai Aowei has deployed their hybrid supercapacitor systems in over 10,000 buses across major Chinese cities, demonstrating the technology's reliability in real-world conditions. The company has also developed grid-stabilization systems using their hybrid supercapacitors, which provide millisecond response times for frequency regulation while maintaining sufficient energy capacity for longer-duration support.

Strengths: Proven track record in large-scale transportation applications demonstrates technology reliability and durability. Specialized thermal management systems enable safe high-current operation. Weaknesses: Large-format design optimization may limit applicability in smaller-scale applications without significant redesign. Higher initial cost compared to conventional lead-acid batteries used in transportation.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung Electro Mechanics has developed a sophisticated hybrid supercapacitor technology that bridges the gap between conventional supercapacitors and lithium-ion batteries. Their approach utilizes nanoscale engineering of electrode materials, combining high-surface-area carbon structures with lithium-intercalation compounds to create devices with both high power and energy density. Samsung's hybrid supercapacitors employ a proprietary electrolyte formulation that enables stable operation across a wide temperature range (-40°C to 70°C) while maintaining safety. The company has successfully miniaturized this technology for consumer electronics applications, creating ultra-thin hybrid supercapacitors that can be integrated into smartphones, wearables, and IoT devices. These components provide rapid charging capabilities (80% charge in under 5 minutes) while offering energy densities approaching 50 Wh/kg. Samsung has also developed manufacturing techniques that allow these hybrid supercapacitors to be produced using modified versions of existing battery production lines, facilitating cost-effective scaling.

Strengths: Exceptional miniaturization capabilities enable integration into space-constrained consumer electronics. Compatible with existing manufacturing infrastructure, reducing production costs and barriers to scale. Weaknesses: Optimization for consumer electronics may limit immediate applicability in high-power industrial applications. Proprietary electrolyte formulations may face regulatory challenges in certain markets.

Core Patents and Technical Literature in Hybrid Supercapacitor Field

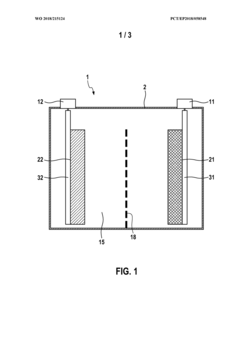

Hybrid supercapacitor for high-temperature applications

PatentWO2018215124A1

Innovation

- A hybrid supercapacitor design featuring a negative electrode with static capacitive active material, a positive electrode with electrochemical redox active material, and an electrolyte composition including an ionic liquid and lithium-containing conductive additive, allowing for high power and energy density along with extended lifespan at elevated temperatures.

Oxide anode materials

PatentWO2022112370A2

Innovation

- The development of V-Nb-Mo oxide composite materials synthesized via continuous hydrothermal flow synthesis, with specific compositions and incorporation of carbon to enhance stability and conductivity, forming graphitic composite materials for improved electrochemical performance.

Environmental Impact and Sustainability Considerations

Hybrid supercapacitor technology represents a significant advancement in sustainable energy storage solutions, offering environmental benefits that extend beyond traditional battery technologies. The integration of these devices into various applications contributes substantially to reducing environmental footprints across multiple sectors. Their extended lifecycle—typically 10-15 years compared to 2-5 years for conventional batteries—directly translates to reduced waste generation and resource consumption over time.

The manufacturing process of hybrid supercapacitors generally requires fewer toxic materials than traditional lithium-ion batteries. The absence or reduced use of heavy metals and harmful chemicals minimizes environmental contamination risks during production, use, and disposal phases. This characteristic is particularly valuable in applications where environmental exposure is a concern, such as in agricultural or marine settings.

Energy efficiency represents another critical environmental advantage of hybrid supercapacitor technology. With charge-discharge efficiency rates often exceeding 95%, these systems minimize energy losses during operation. This high efficiency, combined with their rapid charging capabilities, makes them ideal components in renewable energy systems, where they can effectively capture and store intermittent energy from solar or wind sources with minimal wastage.

From a lifecycle assessment perspective, hybrid supercapacitors demonstrate favorable environmental metrics. Their carbon footprint during manufacturing is generally lower than comparable energy storage technologies, particularly when considering the extended operational lifespan. Additionally, the materials used in many hybrid supercapacitor designs show promising recyclability characteristics, with research indicating recovery rates of up to 80% for certain components.

The integration of hybrid supercapacitors into electric vehicles and public transportation systems contributes significantly to urban sustainability goals. By enabling more efficient regenerative braking systems and providing power for start-stop operations, these devices help reduce fuel consumption and emissions in transportation applications. Studies indicate that hybrid supercapacitor-equipped vehicles can achieve emission reductions of 15-30% in urban driving conditions.

Looking forward, the environmental profile of hybrid supercapacitor technology continues to improve as manufacturers explore bio-based materials and environmentally benign electrolytes. Research into sustainable production methods and end-of-life recycling processes is advancing rapidly, promising to further enhance the technology's contribution to circular economy principles and sustainable development goals.

The manufacturing process of hybrid supercapacitors generally requires fewer toxic materials than traditional lithium-ion batteries. The absence or reduced use of heavy metals and harmful chemicals minimizes environmental contamination risks during production, use, and disposal phases. This characteristic is particularly valuable in applications where environmental exposure is a concern, such as in agricultural or marine settings.

Energy efficiency represents another critical environmental advantage of hybrid supercapacitor technology. With charge-discharge efficiency rates often exceeding 95%, these systems minimize energy losses during operation. This high efficiency, combined with their rapid charging capabilities, makes them ideal components in renewable energy systems, where they can effectively capture and store intermittent energy from solar or wind sources with minimal wastage.

From a lifecycle assessment perspective, hybrid supercapacitors demonstrate favorable environmental metrics. Their carbon footprint during manufacturing is generally lower than comparable energy storage technologies, particularly when considering the extended operational lifespan. Additionally, the materials used in many hybrid supercapacitor designs show promising recyclability characteristics, with research indicating recovery rates of up to 80% for certain components.

The integration of hybrid supercapacitors into electric vehicles and public transportation systems contributes significantly to urban sustainability goals. By enabling more efficient regenerative braking systems and providing power for start-stop operations, these devices help reduce fuel consumption and emissions in transportation applications. Studies indicate that hybrid supercapacitor-equipped vehicles can achieve emission reductions of 15-30% in urban driving conditions.

Looking forward, the environmental profile of hybrid supercapacitor technology continues to improve as manufacturers explore bio-based materials and environmentally benign electrolytes. Research into sustainable production methods and end-of-life recycling processes is advancing rapidly, promising to further enhance the technology's contribution to circular economy principles and sustainable development goals.

Integration Strategies with Existing Energy Storage Systems

The integration of hybrid supercapacitor technology with existing energy storage systems represents a critical advancement in optimizing overall energy management solutions. Current integration approaches primarily focus on creating complementary systems that leverage the strengths of both hybrid supercapacitors and conventional energy storage technologies such as lithium-ion batteries, lead-acid batteries, and fuel cells.

One prominent integration strategy involves the development of hybrid energy storage systems (HESS) that combine hybrid supercapacitors with traditional batteries. This configuration allows the supercapacitors to handle high-power, short-duration demands while batteries manage long-duration, energy-intensive requirements. The integration typically employs sophisticated power management systems that dynamically allocate power demands between the two components based on real-time operational conditions.

Advanced energy management algorithms play a crucial role in these integrated systems. These algorithms optimize the charge-discharge cycles, extending the lifespan of both components while maximizing overall system efficiency. Recent developments in machine learning-based predictive algorithms have further enhanced the intelligent distribution of power loads between hybrid supercapacitors and conventional batteries.

Physical integration architectures vary widely depending on application requirements. Parallel configurations remain the most common, where supercapacitors and batteries connect directly to the load through power converters. However, semi-active and fully active topologies utilizing DC-DC converters are gaining popularity for their superior control capabilities and efficiency benefits, despite higher complexity and cost.

Thermal management represents another critical aspect of integration strategies. Hybrid supercapacitors typically operate efficiently across broader temperature ranges than many battery technologies. Integrated cooling systems that prioritize temperature regulation for the more sensitive components while leveraging the thermal resilience of hybrid supercapacitors are becoming standard in advanced implementations.

From a commercial perspective, modular design approaches are emerging as the preferred integration methodology. These designs allow for scalable solutions where the ratio of hybrid supercapacitor capacity to conventional battery capacity can be adjusted based on specific application requirements. This modularity facilitates easier maintenance, component replacement, and system upgrades without complete redesigns.

The integration landscape continues to evolve with increasing focus on standardization of interfaces between hybrid supercapacitors and existing energy storage technologies. Industry consortiums are working toward establishing common electrical and mechanical connection standards to accelerate adoption and reduce integration complexity across various applications.

One prominent integration strategy involves the development of hybrid energy storage systems (HESS) that combine hybrid supercapacitors with traditional batteries. This configuration allows the supercapacitors to handle high-power, short-duration demands while batteries manage long-duration, energy-intensive requirements. The integration typically employs sophisticated power management systems that dynamically allocate power demands between the two components based on real-time operational conditions.

Advanced energy management algorithms play a crucial role in these integrated systems. These algorithms optimize the charge-discharge cycles, extending the lifespan of both components while maximizing overall system efficiency. Recent developments in machine learning-based predictive algorithms have further enhanced the intelligent distribution of power loads between hybrid supercapacitors and conventional batteries.

Physical integration architectures vary widely depending on application requirements. Parallel configurations remain the most common, where supercapacitors and batteries connect directly to the load through power converters. However, semi-active and fully active topologies utilizing DC-DC converters are gaining popularity for their superior control capabilities and efficiency benefits, despite higher complexity and cost.

Thermal management represents another critical aspect of integration strategies. Hybrid supercapacitors typically operate efficiently across broader temperature ranges than many battery technologies. Integrated cooling systems that prioritize temperature regulation for the more sensitive components while leveraging the thermal resilience of hybrid supercapacitors are becoming standard in advanced implementations.

From a commercial perspective, modular design approaches are emerging as the preferred integration methodology. These designs allow for scalable solutions where the ratio of hybrid supercapacitor capacity to conventional battery capacity can be adjusted based on specific application requirements. This modularity facilitates easier maintenance, component replacement, and system upgrades without complete redesigns.

The integration landscape continues to evolve with increasing focus on standardization of interfaces between hybrid supercapacitors and existing energy storage technologies. Industry consortiums are working toward establishing common electrical and mechanical connection standards to accelerate adoption and reduce integration complexity across various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!