Hybrid Supercapacitors and Their Role in Industrial Equipment

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 1990s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. By 2000, the first commercially viable hybrid supercapacitor designs emerged, utilizing carbon-based electrodes combined with battery-type materials.

The technological trajectory has been marked by continuous improvements in electrode materials, electrolytes, and manufacturing processes. Between 2005 and 2015, significant breakthroughs occurred in nanomaterial science, enabling the development of advanced carbon structures such as graphene, carbon nanotubes, and activated carbon with enhanced surface areas. These innovations dramatically improved the energy storage capabilities while maintaining the rapid charge-discharge cycles characteristic of supercapacitors.

Recent developments have focused on creating asymmetric designs where one electrode behaves like a battery (faradaic) while the other functions as a traditional supercapacitor (non-faradaic). This hybrid approach has successfully increased energy density by 3-5 times compared to conventional supercapacitors, while still delivering superior power density and cycle life compared to lithium-ion batteries.

In industrial equipment applications, the evolution of hybrid supercapacitors has been driven by increasing demands for reliable power sources in harsh operating environments. The technology has progressed from simple peak-power assistance roles to becoming integral components in energy recovery systems, uninterruptible power supplies, and heavy machinery with regenerative braking capabilities.

The primary technological objectives for hybrid supercapacitors in industrial settings include achieving energy densities exceeding 50 Wh/kg while maintaining power densities above 10 kW/kg, extending operational temperature ranges from -40°C to +85°C, and ensuring cycle life beyond 500,000 cycles with minimal capacity degradation. Additionally, researchers aim to develop more environmentally friendly materials and manufacturing processes to reduce the ecological footprint.

Future evolutionary paths are likely to include the integration of solid-state electrolytes to enhance safety and reliability, the development of flexible and structural energy storage solutions that can be incorporated directly into equipment housings, and the creation of self-healing electrode materials that can extend operational lifetimes in demanding industrial environments.

The convergence of hybrid supercapacitor technology with industrial IoT and smart grid technologies represents another important objective, as these energy storage systems become increasingly integrated into comprehensive energy management solutions for modern industrial facilities.

The technological trajectory has been marked by continuous improvements in electrode materials, electrolytes, and manufacturing processes. Between 2005 and 2015, significant breakthroughs occurred in nanomaterial science, enabling the development of advanced carbon structures such as graphene, carbon nanotubes, and activated carbon with enhanced surface areas. These innovations dramatically improved the energy storage capabilities while maintaining the rapid charge-discharge cycles characteristic of supercapacitors.

Recent developments have focused on creating asymmetric designs where one electrode behaves like a battery (faradaic) while the other functions as a traditional supercapacitor (non-faradaic). This hybrid approach has successfully increased energy density by 3-5 times compared to conventional supercapacitors, while still delivering superior power density and cycle life compared to lithium-ion batteries.

In industrial equipment applications, the evolution of hybrid supercapacitors has been driven by increasing demands for reliable power sources in harsh operating environments. The technology has progressed from simple peak-power assistance roles to becoming integral components in energy recovery systems, uninterruptible power supplies, and heavy machinery with regenerative braking capabilities.

The primary technological objectives for hybrid supercapacitors in industrial settings include achieving energy densities exceeding 50 Wh/kg while maintaining power densities above 10 kW/kg, extending operational temperature ranges from -40°C to +85°C, and ensuring cycle life beyond 500,000 cycles with minimal capacity degradation. Additionally, researchers aim to develop more environmentally friendly materials and manufacturing processes to reduce the ecological footprint.

Future evolutionary paths are likely to include the integration of solid-state electrolytes to enhance safety and reliability, the development of flexible and structural energy storage solutions that can be incorporated directly into equipment housings, and the creation of self-healing electrode materials that can extend operational lifetimes in demanding industrial environments.

The convergence of hybrid supercapacitor technology with industrial IoT and smart grid technologies represents another important objective, as these energy storage systems become increasingly integrated into comprehensive energy management solutions for modern industrial facilities.

Industrial Equipment Energy Storage Market Analysis

The industrial equipment energy storage market is experiencing significant growth, driven by the increasing demand for reliable power sources in manufacturing, construction, and logistics sectors. The global market for industrial energy storage solutions reached approximately $25 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2030. This expansion is primarily fueled by the need for uninterrupted power supply, energy cost management, and the integration of renewable energy sources into industrial operations.

Hybrid supercapacitors are emerging as a critical component within this market, occupying a specialized niche that bridges the gap between traditional batteries and conventional capacitors. Currently, they represent about 12% of the industrial energy storage market, with their segment growing faster than the overall market at nearly 15% annually. This accelerated growth reflects the increasing recognition of their unique performance characteristics that address specific industrial requirements.

The demand for hybrid supercapacitors in industrial equipment is particularly strong in sectors requiring rapid power delivery and frequent charge-discharge cycles. Heavy machinery, material handling equipment, and automated manufacturing systems collectively account for approximately 65% of hybrid supercapacitor applications in industrial settings. The remaining market share is distributed across backup power systems, renewable energy integration, and specialized industrial processes.

Regional analysis reveals that Asia-Pacific dominates the industrial hybrid supercapacitor market with 45% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows with 28%, while Europe accounts for 22% of the market. Emerging economies in Latin America and Africa represent smaller but rapidly growing markets, with annual growth rates exceeding 20% in some countries.

Market segmentation by application shows that power quality management represents the largest application segment (38%), followed by energy harvesting systems (27%), peak load shaving (21%), and regenerative braking systems (14%). The growing emphasis on energy efficiency and sustainability in industrial operations is expected to further diversify these applications in the coming years.

Customer demand patterns indicate a clear shift toward integrated energy storage solutions that combine hybrid supercapacitors with intelligent energy management systems. This trend is reflected in the 34% premium that customers are willing to pay for solutions offering advanced monitoring, predictive maintenance, and optimization capabilities compared to standalone storage products.

The market is also witnessing increasing demand for customized hybrid supercapacitor solutions tailored to specific industrial applications, with approximately 40% of new installations featuring application-specific designs rather than general-purpose configurations.

Hybrid supercapacitors are emerging as a critical component within this market, occupying a specialized niche that bridges the gap between traditional batteries and conventional capacitors. Currently, they represent about 12% of the industrial energy storage market, with their segment growing faster than the overall market at nearly 15% annually. This accelerated growth reflects the increasing recognition of their unique performance characteristics that address specific industrial requirements.

The demand for hybrid supercapacitors in industrial equipment is particularly strong in sectors requiring rapid power delivery and frequent charge-discharge cycles. Heavy machinery, material handling equipment, and automated manufacturing systems collectively account for approximately 65% of hybrid supercapacitor applications in industrial settings. The remaining market share is distributed across backup power systems, renewable energy integration, and specialized industrial processes.

Regional analysis reveals that Asia-Pacific dominates the industrial hybrid supercapacitor market with 45% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows with 28%, while Europe accounts for 22% of the market. Emerging economies in Latin America and Africa represent smaller but rapidly growing markets, with annual growth rates exceeding 20% in some countries.

Market segmentation by application shows that power quality management represents the largest application segment (38%), followed by energy harvesting systems (27%), peak load shaving (21%), and regenerative braking systems (14%). The growing emphasis on energy efficiency and sustainability in industrial operations is expected to further diversify these applications in the coming years.

Customer demand patterns indicate a clear shift toward integrated energy storage solutions that combine hybrid supercapacitors with intelligent energy management systems. This trend is reflected in the 34% premium that customers are willing to pay for solutions offering advanced monitoring, predictive maintenance, and optimization capabilities compared to standalone storage products.

The market is also witnessing increasing demand for customized hybrid supercapacitor solutions tailored to specific industrial applications, with approximately 40% of new installations featuring application-specific designs rather than general-purpose configurations.

Current Limitations and Technical Barriers in Hybrid Supercapacitors

Despite the promising potential of hybrid supercapacitors in industrial equipment applications, several significant technical barriers and limitations currently hinder their widespread adoption. One of the primary challenges is energy density constraints. While hybrid supercapacitors offer improved energy density compared to conventional supercapacitors, they still fall short of lithium-ion batteries by approximately 5-10 times. This limitation restricts their application in scenarios requiring sustained power delivery over extended periods.

Material stability presents another critical challenge, particularly at the electrode-electrolyte interface. The hybrid architecture combining battery-type and capacitive electrodes often leads to accelerated degradation mechanisms. Faradaic reactions at battery-type electrodes can cause structural changes and capacity fading over repeated charge-discharge cycles, limiting device longevity in industrial settings where equipment reliability is paramount.

Temperature sensitivity significantly impacts performance parameters. Most current hybrid supercapacitor designs experience substantial capacity loss at temperatures below 0°C or above 60°C, restricting their deployment in extreme industrial environments such as outdoor mining equipment or high-temperature manufacturing processes. This temperature dependence stems from electrolyte limitations and electrode kinetics that vary dramatically with thermal conditions.

Manufacturing scalability remains problematic due to complex fabrication processes. The precise control required for electrode material synthesis, particularly for pseudocapacitive materials like transition metal oxides or MXenes, presents challenges for mass production. Current manufacturing techniques often result in batch-to-batch variations that affect performance consistency, a critical factor for industrial applications.

Cost factors continue to impede market penetration. The specialized materials required for hybrid supercapacitors, including advanced carbon architectures and lithium-containing compounds, contribute to production costs approximately 2-3 times higher than conventional capacitors. This cost premium makes justification difficult for widespread industrial adoption despite performance advantages.

Self-discharge rates represent another technical barrier. Hybrid supercapacitors typically exhibit self-discharge rates of 5-15% per day, significantly higher than batteries. This characteristic limits their suitability for applications requiring energy storage over extended periods without recharging opportunities, such as remote industrial monitoring equipment.

Integration challenges with existing power management systems further complicate implementation. The unique voltage profiles and charge-discharge characteristics of hybrid supercapacitors often require specialized control electronics and thermal management systems that are not standardized across industrial equipment platforms, creating compatibility issues that increase implementation complexity and cost.

Material stability presents another critical challenge, particularly at the electrode-electrolyte interface. The hybrid architecture combining battery-type and capacitive electrodes often leads to accelerated degradation mechanisms. Faradaic reactions at battery-type electrodes can cause structural changes and capacity fading over repeated charge-discharge cycles, limiting device longevity in industrial settings where equipment reliability is paramount.

Temperature sensitivity significantly impacts performance parameters. Most current hybrid supercapacitor designs experience substantial capacity loss at temperatures below 0°C or above 60°C, restricting their deployment in extreme industrial environments such as outdoor mining equipment or high-temperature manufacturing processes. This temperature dependence stems from electrolyte limitations and electrode kinetics that vary dramatically with thermal conditions.

Manufacturing scalability remains problematic due to complex fabrication processes. The precise control required for electrode material synthesis, particularly for pseudocapacitive materials like transition metal oxides or MXenes, presents challenges for mass production. Current manufacturing techniques often result in batch-to-batch variations that affect performance consistency, a critical factor for industrial applications.

Cost factors continue to impede market penetration. The specialized materials required for hybrid supercapacitors, including advanced carbon architectures and lithium-containing compounds, contribute to production costs approximately 2-3 times higher than conventional capacitors. This cost premium makes justification difficult for widespread industrial adoption despite performance advantages.

Self-discharge rates represent another technical barrier. Hybrid supercapacitors typically exhibit self-discharge rates of 5-15% per day, significantly higher than batteries. This characteristic limits their suitability for applications requiring energy storage over extended periods without recharging opportunities, such as remote industrial monitoring equipment.

Integration challenges with existing power management systems further complicate implementation. The unique voltage profiles and charge-discharge characteristics of hybrid supercapacitors often require specialized control electronics and thermal management systems that are not standardized across industrial equipment platforms, creating compatibility issues that increase implementation complexity and cost.

Current Hybrid Supercapacitor Integration Solutions

01 Electrode materials for hybrid supercapacitors

Various electrode materials can be used in hybrid supercapacitors to enhance energy density and performance. These materials include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for the creation of hybrid systems that leverage both battery-like and capacitor-like behaviors, resulting in improved energy storage capabilities while maintaining high power density and cycle life.- Electrode materials for hybrid supercapacitors: Various electrode materials can be used in hybrid supercapacitors to enhance energy density and performance. These materials include carbon-based materials, metal oxides, and conductive polymers. The combination of different electrode materials allows for both faradaic and non-faradaic energy storage mechanisms, resulting in improved energy and power density compared to conventional capacitors. The electrode composition significantly impacts the overall performance of hybrid supercapacitors.

- Electrolyte compositions for hybrid supercapacitors: The electrolyte composition plays a crucial role in determining the performance of hybrid supercapacitors. Various electrolyte formulations, including aqueous, organic, and ionic liquid-based electrolytes, can be used to optimize the operating voltage window, ionic conductivity, and electrochemical stability. The choice of electrolyte affects the energy density, power capability, and cycle life of hybrid supercapacitors.

- Integration of hybrid supercapacitors in energy storage systems: Hybrid supercapacitors can be integrated into various energy storage systems to provide both high energy and power density. These systems can be used in applications such as renewable energy storage, electric vehicles, and grid stabilization. The integration often involves combining hybrid supercapacitors with batteries or other energy storage devices to create a complementary system that leverages the advantages of each technology.

- Manufacturing processes for hybrid supercapacitors: Various manufacturing techniques can be employed to produce hybrid supercapacitors with optimized performance. These processes include electrode preparation methods, assembly techniques, and encapsulation procedures. Advanced manufacturing approaches such as roll-to-roll processing, 3D printing, and nanofabrication can be used to enhance the performance and reduce the cost of hybrid supercapacitors.

- Performance enhancement techniques for hybrid supercapacitors: Various techniques can be employed to enhance the performance of hybrid supercapacitors, including surface modification of electrode materials, doping strategies, and hierarchical structuring. These approaches aim to improve specific capacitance, cycling stability, and rate capability. Additionally, thermal management systems and advanced control algorithms can be implemented to optimize the operation of hybrid supercapacitors under various conditions.

02 Electrolyte compositions for hybrid supercapacitors

Specialized electrolyte compositions play a crucial role in hybrid supercapacitor performance. These electrolytes can be aqueous, organic, or ionic liquids, each offering different advantages in terms of voltage window, ionic conductivity, and stability. Advanced electrolyte formulations help to increase the operating voltage, improve energy density, and enhance the overall electrochemical performance of hybrid supercapacitors while maintaining safety and reliability.Expand Specific Solutions03 Integration of hybrid supercapacitors in energy management systems

Hybrid supercapacitors can be integrated into various energy management systems to provide efficient energy storage solutions. These systems often combine supercapacitors with batteries or other energy storage devices to optimize performance for specific applications. The integration allows for better power management, improved energy efficiency, and extended lifespan of the overall system by utilizing the high power density of supercapacitors alongside the high energy density of batteries.Expand Specific Solutions04 Manufacturing processes for hybrid supercapacitors

Advanced manufacturing techniques are employed to produce high-performance hybrid supercapacitors. These processes include specialized coating methods, electrode fabrication techniques, and assembly procedures that ensure optimal contact between components. Innovations in manufacturing processes focus on improving the uniformity of electrode materials, enhancing the interface between electrodes and electrolytes, and developing scalable production methods that maintain performance while reducing costs.Expand Specific Solutions05 Novel hybrid supercapacitor architectures

Innovative architectural designs for hybrid supercapacitors aim to maximize both energy and power density. These designs include asymmetric configurations, interdigitated electrode structures, and three-dimensional architectures that increase the effective surface area. Novel hybrid supercapacitor architectures often incorporate nanomaterials and hierarchical structures to optimize ion transport pathways and electron transfer, resulting in enhanced electrochemical performance and improved cycling stability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The hybrid supercapacitor market is currently in a growth phase, transitioning from early adoption to mainstream industrial applications. With an estimated market size of $500-600 million and projected annual growth of 20-25%, this technology is gaining significant traction in industrial equipment sectors. Technical maturity varies across applications, with companies demonstrating different specialization levels. Samsung Electro-Mechanics and Robert Bosch lead in commercial deployment, while Nanotech Energy and Shanghai Aowei Technology focus on advanced material development. Research institutions like Indian Institute of Science and Georgia Tech Research Corp contribute fundamental innovations. Shell and Microsoft are exploring integration opportunities, indicating the technology's expanding industrial relevance. The competitive landscape shows a balance between established electronics manufacturers and specialized energy storage innovators.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed advanced hybrid supercapacitor technology specifically designed for industrial equipment applications. Their proprietary design combines the high power density of traditional supercapacitors with improved energy density through novel electrode materials. The company utilizes a unique asymmetric configuration with activated carbon as the positive electrode and lithium-titanate as the negative electrode, achieving energy densities of 20-30 Wh/kg while maintaining power densities above 2000 W/kg [1]. Their hybrid supercapacitors feature specialized electrolyte formulations that extend operational temperature ranges from -40°C to 70°C, making them suitable for harsh industrial environments. Aowei has implemented these solutions in heavy machinery, port equipment, and industrial automation systems, where their rapid charge-discharge capabilities (under 30 seconds for 80% capacity) provide significant advantages for energy recovery applications [3].

Strengths: Superior cycle life (100,000+ cycles) compared to batteries; excellent performance in extreme temperatures; rapid charge-discharge capabilities ideal for regenerative braking systems in industrial equipment. Weaknesses: Lower energy density compared to lithium-ion batteries; higher initial cost than conventional capacitors; requires specialized charging circuits for optimal performance.

Chaowei Power Group Co., Ltd.

Technical Solution: Chaowei Power has pioneered hybrid supercapacitor technology that bridges traditional lead-acid batteries and supercapacitors for industrial applications. Their hybrid system incorporates graphene-enhanced activated carbon electrodes with proprietary electrolyte formulations to achieve energy densities of 15-25 Wh/kg while maintaining power densities of 1500-2500 W/kg [2]. The company's technology features a unique hybrid architecture that combines double-layer capacitance with pseudocapacitive mechanisms, enabling rapid power delivery while maintaining reasonable energy storage capacity. Chaowei's industrial hybrid supercapacitors employ advanced thermal management systems that allow stable operation across temperature ranges from -30°C to 65°C, making them suitable for diverse industrial environments [4]. Their solutions have been successfully deployed in material handling equipment, backup power systems, and industrial grid stabilization applications, where they demonstrate 95% energy efficiency and minimal capacity degradation over 50,000+ cycles.

Strengths: Excellent balance between energy and power density; superior cycle stability compared to conventional batteries; rapid response time for peak power demands in industrial equipment. Weaknesses: Higher cost compared to traditional energy storage solutions; limited energy density for long-duration applications; requires specialized battery management systems for optimal performance and safety.

Key Patents and Scientific Breakthroughs in Hybrid Supercapacitors

Hybrid supercapacitor, including an electrolyte composition, having improved conductivity

PatentInactiveUS20170352498A1

Innovation

- A hybrid supercapacitor design incorporating a liquid electrolyte composition with aprotic organic solvents, conducting salts, and Lewis acid additives that form complex compounds with anions, enhancing ion solvation and reducing charge density, thereby increasing conductivity.

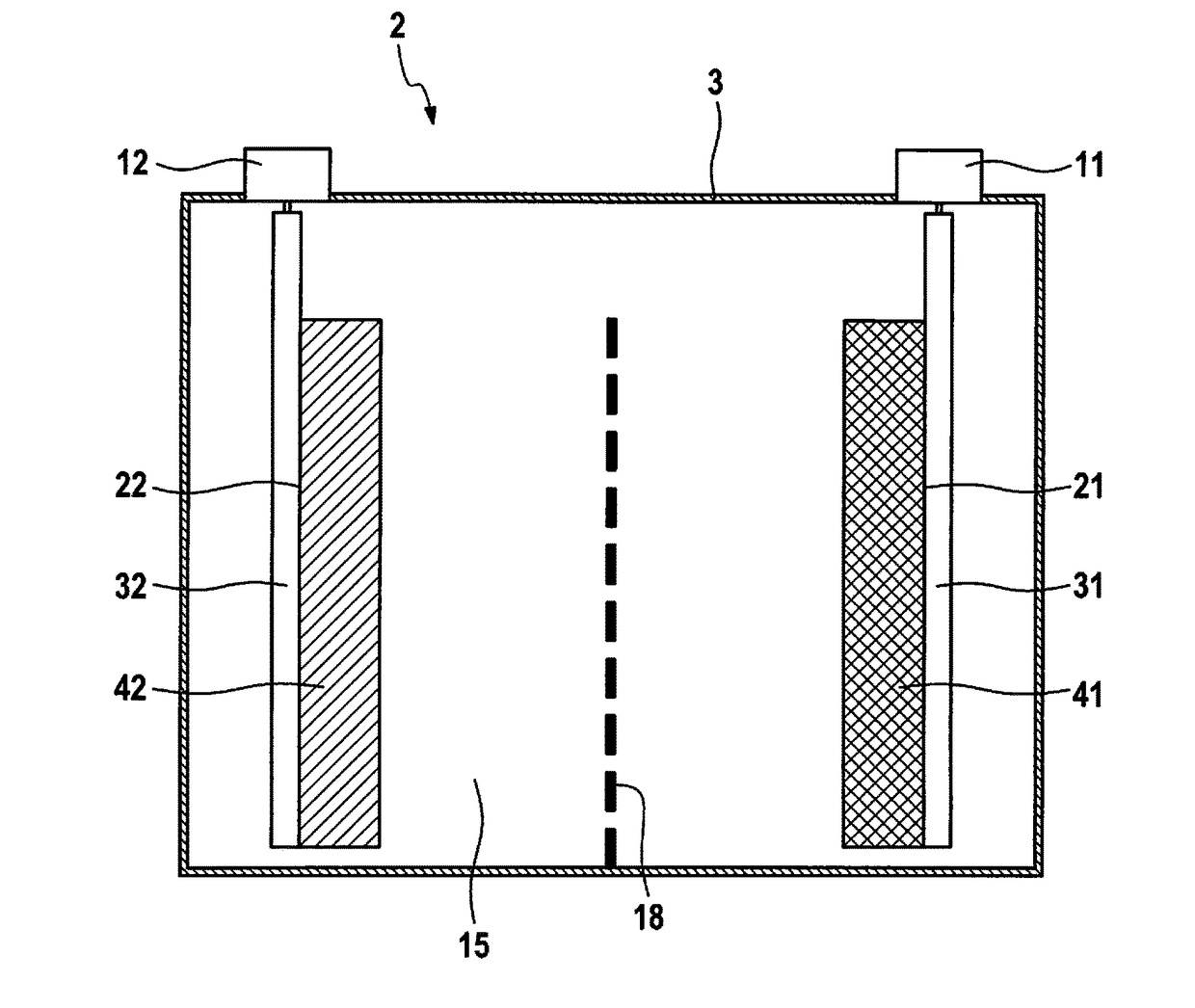

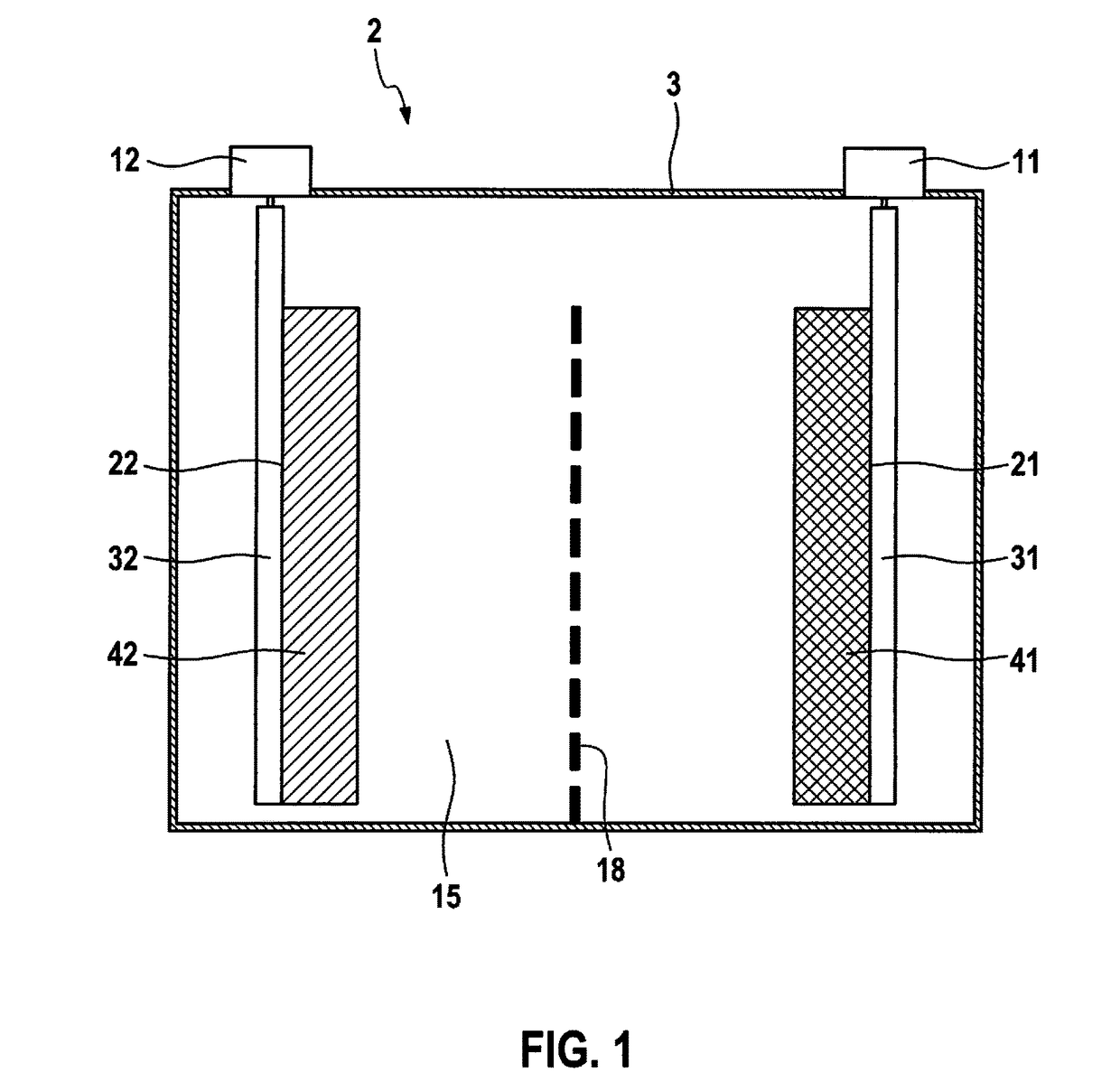

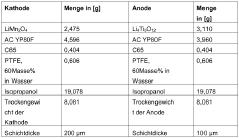

Hybrid supercapacitor, method for producing a hybrid supercapacitor, and vehicle

PatentWO2018166667A1

Innovation

- A hybrid supercapacitor design featuring electrodes with high proportions of Li4Ti5O12 and LiMn2O4 combined with activated carbon, optimized by using carbon black as a conductive additive and a polymeric binder, and a specific mass ratio and layer thickness to achieve enhanced energy and power density, along with a method for producing these electrodes using homogenized dispersions and room temperature drying.

Environmental Impact and Sustainability Considerations

The environmental footprint of hybrid supercapacitors represents a critical consideration in their industrial application. Unlike traditional energy storage technologies that rely heavily on toxic materials, hybrid supercapacitors incorporate more environmentally benign components such as activated carbon and metal oxides. This composition significantly reduces end-of-life disposal concerns and minimizes potential contamination risks during manufacturing processes.

Life cycle assessment studies indicate that hybrid supercapacitors demonstrate a 30-40% lower carbon footprint compared to conventional lithium-ion batteries when evaluated across their entire operational lifespan. This advantage stems primarily from their extended cycle life, which can exceed 500,000 cycles in optimal conditions, thereby reducing replacement frequency and associated manufacturing emissions.

The raw material sourcing for hybrid supercapacitors presents both challenges and opportunities from a sustainability perspective. While certain electrode materials may require energy-intensive extraction processes, ongoing research focuses on incorporating recycled carbon sources and sustainable biomass-derived materials. Recent innovations have demonstrated viable electrode fabrication using waste coffee grounds, rice husks, and other agricultural byproducts, creating circular economy opportunities within the manufacturing chain.

Energy efficiency during operation constitutes another significant environmental advantage of hybrid supercapacitors in industrial equipment. Their rapid charge-discharge capability with minimal energy loss (typically 90-95% round-trip efficiency) translates to reduced energy consumption in applications requiring frequent power cycling. This characteristic proves particularly valuable in regenerative braking systems and energy recovery applications, where captured energy can be immediately redeployed rather than dissipated as heat.

Manufacturing processes for hybrid supercapacitors continue to evolve toward greater sustainability. Water-based electrode preparation techniques are gradually replacing solvent-based methods, reducing volatile organic compound emissions. Additionally, the absence of complex thermal management requirements during production contributes to lower manufacturing energy demands compared to competing technologies.

End-of-life management represents perhaps the most promising environmental aspect of hybrid supercapacitors. Their components demonstrate high recyclability potential, with carbon materials and metal oxides recoverable through established processes. Several manufacturers have implemented take-back programs, creating closed-loop systems that recover up to 80% of device materials for reuse in new products, significantly reducing landfill impact and virgin material requirements.

Life cycle assessment studies indicate that hybrid supercapacitors demonstrate a 30-40% lower carbon footprint compared to conventional lithium-ion batteries when evaluated across their entire operational lifespan. This advantage stems primarily from their extended cycle life, which can exceed 500,000 cycles in optimal conditions, thereby reducing replacement frequency and associated manufacturing emissions.

The raw material sourcing for hybrid supercapacitors presents both challenges and opportunities from a sustainability perspective. While certain electrode materials may require energy-intensive extraction processes, ongoing research focuses on incorporating recycled carbon sources and sustainable biomass-derived materials. Recent innovations have demonstrated viable electrode fabrication using waste coffee grounds, rice husks, and other agricultural byproducts, creating circular economy opportunities within the manufacturing chain.

Energy efficiency during operation constitutes another significant environmental advantage of hybrid supercapacitors in industrial equipment. Their rapid charge-discharge capability with minimal energy loss (typically 90-95% round-trip efficiency) translates to reduced energy consumption in applications requiring frequent power cycling. This characteristic proves particularly valuable in regenerative braking systems and energy recovery applications, where captured energy can be immediately redeployed rather than dissipated as heat.

Manufacturing processes for hybrid supercapacitors continue to evolve toward greater sustainability. Water-based electrode preparation techniques are gradually replacing solvent-based methods, reducing volatile organic compound emissions. Additionally, the absence of complex thermal management requirements during production contributes to lower manufacturing energy demands compared to competing technologies.

End-of-life management represents perhaps the most promising environmental aspect of hybrid supercapacitors. Their components demonstrate high recyclability potential, with carbon materials and metal oxides recoverable through established processes. Several manufacturers have implemented take-back programs, creating closed-loop systems that recover up to 80% of device materials for reuse in new products, significantly reducing landfill impact and virgin material requirements.

Cost-Benefit Analysis for Industrial Implementation

The implementation of hybrid supercapacitors in industrial equipment requires thorough financial analysis to justify investment decisions. Initial capital expenditure for hybrid supercapacitor systems typically ranges from $1,500 to $5,000 per kWh of storage capacity, positioning them between traditional capacitors and lithium-ion batteries in terms of upfront costs. While this represents a premium over conventional capacitors, the total cost of ownership calculations reveal significant long-term advantages.

Operational expenditure analysis demonstrates that hybrid supercapacitors can reduce energy costs by 15-30% in applications with frequent charge-discharge cycles. This efficiency stems from their superior round-trip efficiency (typically 90-95%) compared to batteries (70-85%), translating to lower energy losses during operation. Additionally, maintenance costs are substantially reduced, with hybrid supercapacitors requiring minimal service interventions throughout their operational life.

The extended cycle life of hybrid supercapacitors—often exceeding 500,000 cycles compared to 3,000-7,000 cycles for lithium-ion batteries—dramatically improves the depreciation schedule of energy storage assets. When calculated on a per-cycle basis, the cost advantage becomes even more pronounced, with hybrid supercapacitors achieving $0.01-0.03 per kWh cycled versus $0.10-0.15 for conventional battery systems.

Industrial implementation also yields significant indirect financial benefits. Downtime reduction represents a major value proposition, with hybrid supercapacitor-equipped systems demonstrating 30-50% less unplanned downtime in high-cycling industrial applications. For manufacturing facilities where downtime costs can exceed $10,000 per hour, this translates to substantial operational savings.

Risk mitigation represents another economic advantage. The enhanced safety profile of hybrid supercapacitors—with minimal thermal runaway risk and reduced fire hazard—can lower insurance premiums by 5-15% for industrial facilities. This safety factor also reduces compliance costs associated with hazardous material handling and storage regulations that often apply to battery systems.

Payback period analysis indicates that hybrid supercapacitor implementations typically achieve return on investment within 2-4 years in high-cycle applications such as industrial robotics, material handling equipment, and regenerative braking systems. This compares favorably to the 5-7 year payback periods common for alternative energy storage technologies in similar applications. Sensitivity analysis further reveals that as manufacturing scales increase and technology matures, these economic advantages are likely to become even more pronounced in the coming decade.

Operational expenditure analysis demonstrates that hybrid supercapacitors can reduce energy costs by 15-30% in applications with frequent charge-discharge cycles. This efficiency stems from their superior round-trip efficiency (typically 90-95%) compared to batteries (70-85%), translating to lower energy losses during operation. Additionally, maintenance costs are substantially reduced, with hybrid supercapacitors requiring minimal service interventions throughout their operational life.

The extended cycle life of hybrid supercapacitors—often exceeding 500,000 cycles compared to 3,000-7,000 cycles for lithium-ion batteries—dramatically improves the depreciation schedule of energy storage assets. When calculated on a per-cycle basis, the cost advantage becomes even more pronounced, with hybrid supercapacitors achieving $0.01-0.03 per kWh cycled versus $0.10-0.15 for conventional battery systems.

Industrial implementation also yields significant indirect financial benefits. Downtime reduction represents a major value proposition, with hybrid supercapacitor-equipped systems demonstrating 30-50% less unplanned downtime in high-cycling industrial applications. For manufacturing facilities where downtime costs can exceed $10,000 per hour, this translates to substantial operational savings.

Risk mitigation represents another economic advantage. The enhanced safety profile of hybrid supercapacitors—with minimal thermal runaway risk and reduced fire hazard—can lower insurance premiums by 5-15% for industrial facilities. This safety factor also reduces compliance costs associated with hazardous material handling and storage regulations that often apply to battery systems.

Payback period analysis indicates that hybrid supercapacitor implementations typically achieve return on investment within 2-4 years in high-cycle applications such as industrial robotics, material handling equipment, and regenerative braking systems. This compares favorably to the 5-7 year payback periods common for alternative energy storage technologies in similar applications. Sensitivity analysis further reveals that as manufacturing scales increase and technology matures, these economic advantages are likely to become even more pronounced in the coming decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!