How Do Hybrid Supercapacitors Impact Mobile Device Efficiency?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant evolution in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The development of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. The fundamental goal was to create an energy storage solution that could deliver both rapid charge-discharge capabilities and substantial energy storage capacity—a combination particularly valuable for mobile applications.

The technological evolution of hybrid supercapacitors has progressed through several key phases. Initially, research focused on carbon-based electrodes with enhanced surface areas. This was followed by the integration of battery-type materials to improve energy density while maintaining the rapid charge-discharge characteristics. Recent advancements have centered on nanomaterial engineering and novel electrolyte formulations, pushing the boundaries of what these devices can achieve in terms of performance metrics.

From a technical perspective, hybrid supercapacitors aim to optimize the critical parameters of power density (measured in W/kg), energy density (Wh/kg), cycle life, and charge-discharge efficiency. Current objectives include reaching energy densities exceeding 30 Wh/kg while maintaining power densities above 10 kW/kg—specifications that would position hybrid supercapacitors as ideal power sources for next-generation mobile devices.

The trajectory of hybrid supercapacitor development has been significantly influenced by the growing demands of the mobile technology sector. As smartphones, tablets, and wearable devices become increasingly sophisticated, their power requirements have grown more complex. Modern mobile devices require not only longer-lasting energy sources but also the ability to handle power-intensive operations like gaming, video streaming, and rapid data processing. Hybrid supercapacitors are being developed specifically to address these multifaceted energy needs.

Looking forward, the technical objectives for hybrid supercapacitor technology include further miniaturization to accommodate the space constraints of modern mobile devices, enhanced temperature stability to ensure reliable performance across various operating conditions, and improved integration capabilities with existing power management systems. Researchers are also exploring bio-compatible and environmentally sustainable materials to align with growing industry commitments to reduce environmental impact.

The convergence of these technological advancements and clearly defined objectives positions hybrid supercapacitors as a potentially transformative technology for mobile device efficiency, promising to address many of the energy-related limitations that currently constrain mobile computing and communication capabilities.

The technological evolution of hybrid supercapacitors has progressed through several key phases. Initially, research focused on carbon-based electrodes with enhanced surface areas. This was followed by the integration of battery-type materials to improve energy density while maintaining the rapid charge-discharge characteristics. Recent advancements have centered on nanomaterial engineering and novel electrolyte formulations, pushing the boundaries of what these devices can achieve in terms of performance metrics.

From a technical perspective, hybrid supercapacitors aim to optimize the critical parameters of power density (measured in W/kg), energy density (Wh/kg), cycle life, and charge-discharge efficiency. Current objectives include reaching energy densities exceeding 30 Wh/kg while maintaining power densities above 10 kW/kg—specifications that would position hybrid supercapacitors as ideal power sources for next-generation mobile devices.

The trajectory of hybrid supercapacitor development has been significantly influenced by the growing demands of the mobile technology sector. As smartphones, tablets, and wearable devices become increasingly sophisticated, their power requirements have grown more complex. Modern mobile devices require not only longer-lasting energy sources but also the ability to handle power-intensive operations like gaming, video streaming, and rapid data processing. Hybrid supercapacitors are being developed specifically to address these multifaceted energy needs.

Looking forward, the technical objectives for hybrid supercapacitor technology include further miniaturization to accommodate the space constraints of modern mobile devices, enhanced temperature stability to ensure reliable performance across various operating conditions, and improved integration capabilities with existing power management systems. Researchers are also exploring bio-compatible and environmentally sustainable materials to align with growing industry commitments to reduce environmental impact.

The convergence of these technological advancements and clearly defined objectives positions hybrid supercapacitors as a potentially transformative technology for mobile device efficiency, promising to address many of the energy-related limitations that currently constrain mobile computing and communication capabilities.

Mobile Device Energy Storage Market Analysis

The mobile device energy storage market has experienced significant growth over the past decade, driven primarily by the increasing consumer demand for longer battery life and faster charging capabilities. As of 2023, the global market for mobile device energy storage solutions is valued at approximately 25 billion USD, with projections indicating a compound annual growth rate of 8.7% through 2028. This growth trajectory is supported by the expanding smartphone user base, which currently exceeds 6.8 billion users worldwide.

Traditional lithium-ion batteries have dominated this market segment, accounting for over 85% of the mobile energy storage solutions. However, consumer dissatisfaction with battery performance remains a persistent issue, with surveys indicating that 73% of smartphone users cite battery life as a critical factor influencing their purchasing decisions. This dissatisfaction creates a substantial market opportunity for alternative technologies such as hybrid supercapacitors.

The market demand for improved energy storage solutions is further segmented by device category. Premium smartphones represent 24% of the market but generate 47% of the revenue for energy storage components. Mid-range devices constitute 38% of the market, while budget devices make up the remaining 38%. Each segment presents distinct requirements and price sensitivities that influence the adoption of advanced energy storage technologies.

Regional analysis reveals varying market dynamics. Asia-Pacific leads with 42% market share, driven by the concentration of device manufacturing and large consumer bases in China and India. North America follows with 28%, where premium devices with advanced battery technologies see higher adoption rates. Europe accounts for 22%, with particularly strong demand for sustainable energy solutions.

The hybrid supercapacitor segment specifically has shown remarkable growth, expanding at 15.3% annually—nearly double the overall market rate. This accelerated growth reflects increasing recognition of hybrid supercapacitors' potential to address key consumer pain points, particularly rapid charging capabilities and extended cycle life. Current market penetration remains modest at 3.7% of total mobile energy storage solutions, but industry forecasts suggest this could reach 12% by 2027.

Consumer willingness to pay premium prices for devices with superior battery performance creates favorable conditions for hybrid supercapacitor adoption. Market research indicates that consumers are willing to pay an average of 15% more for devices offering twice the battery life or significantly faster charging times, creating a viable economic model for manufacturers to incorporate these more advanced but currently costlier components.

Traditional lithium-ion batteries have dominated this market segment, accounting for over 85% of the mobile energy storage solutions. However, consumer dissatisfaction with battery performance remains a persistent issue, with surveys indicating that 73% of smartphone users cite battery life as a critical factor influencing their purchasing decisions. This dissatisfaction creates a substantial market opportunity for alternative technologies such as hybrid supercapacitors.

The market demand for improved energy storage solutions is further segmented by device category. Premium smartphones represent 24% of the market but generate 47% of the revenue for energy storage components. Mid-range devices constitute 38% of the market, while budget devices make up the remaining 38%. Each segment presents distinct requirements and price sensitivities that influence the adoption of advanced energy storage technologies.

Regional analysis reveals varying market dynamics. Asia-Pacific leads with 42% market share, driven by the concentration of device manufacturing and large consumer bases in China and India. North America follows with 28%, where premium devices with advanced battery technologies see higher adoption rates. Europe accounts for 22%, with particularly strong demand for sustainable energy solutions.

The hybrid supercapacitor segment specifically has shown remarkable growth, expanding at 15.3% annually—nearly double the overall market rate. This accelerated growth reflects increasing recognition of hybrid supercapacitors' potential to address key consumer pain points, particularly rapid charging capabilities and extended cycle life. Current market penetration remains modest at 3.7% of total mobile energy storage solutions, but industry forecasts suggest this could reach 12% by 2027.

Consumer willingness to pay premium prices for devices with superior battery performance creates favorable conditions for hybrid supercapacitor adoption. Market research indicates that consumers are willing to pay an average of 15% more for devices offering twice the battery life or significantly faster charging times, creating a viable economic model for manufacturers to incorporate these more advanced but currently costlier components.

Current Limitations and Technical Barriers in Supercapacitor Development

Despite significant advancements in hybrid supercapacitor technology, several critical limitations continue to impede their widespread adoption in mobile devices. Energy density remains a fundamental challenge, with current hybrid supercapacitors achieving only 10-15 Wh/kg compared to lithium-ion batteries' 150-250 Wh/kg. This substantial gap means hybrid supercapacitors cannot yet serve as complete battery replacements in mobile applications where space and weight are premium considerations.

Material stability presents another significant barrier, particularly at the electrode-electrolyte interface. Degradation mechanisms during repeated charge-discharge cycles lead to capacity fade and reduced cycle life, especially under the variable temperature conditions typical of mobile device operation. The interface chemistry between carbon-based materials and metal oxides in hybrid systems often suffers from incompatibility issues that compromise long-term performance.

Manufacturing scalability poses considerable challenges for mass production. Current fabrication processes for advanced electrode materials like graphene-metal oxide composites involve complex, multi-step procedures that are difficult to standardize and scale. This complexity directly impacts production costs, keeping hybrid supercapacitors at price points significantly higher than conventional energy storage solutions.

Temperature sensitivity represents another critical limitation. Performance metrics of hybrid supercapacitors show marked deterioration at temperature extremes commonly encountered in mobile devices, particularly during intensive processing tasks or in challenging environmental conditions. This sensitivity restricts their practical application in consumer electronics designed for diverse operating environments.

Self-discharge rates remain problematically high, with many hybrid systems losing 10-20% of stored charge within 24 hours compared to 1-2% for lithium-ion batteries. This characteristic severely limits their suitability for mobile devices that may remain unused for extended periods while still requiring immediate power availability.

Integration challenges with existing mobile device architectures present significant technical barriers. Current hybrid supercapacitor form factors and voltage characteristics often require substantial redesign of power management systems and physical device layouts, creating resistance to adoption among manufacturers with established production lines.

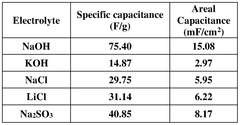

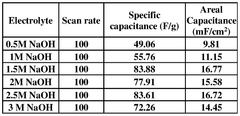

Electrolyte limitations further constrain performance, with current formulations struggling to provide both high ionic conductivity and wide electrochemical stability windows. Aqueous electrolytes offer safety advantages but restrict operating voltage, while organic electrolytes enable higher voltage operation but introduce flammability concerns incompatible with consumer device safety standards.

Material stability presents another significant barrier, particularly at the electrode-electrolyte interface. Degradation mechanisms during repeated charge-discharge cycles lead to capacity fade and reduced cycle life, especially under the variable temperature conditions typical of mobile device operation. The interface chemistry between carbon-based materials and metal oxides in hybrid systems often suffers from incompatibility issues that compromise long-term performance.

Manufacturing scalability poses considerable challenges for mass production. Current fabrication processes for advanced electrode materials like graphene-metal oxide composites involve complex, multi-step procedures that are difficult to standardize and scale. This complexity directly impacts production costs, keeping hybrid supercapacitors at price points significantly higher than conventional energy storage solutions.

Temperature sensitivity represents another critical limitation. Performance metrics of hybrid supercapacitors show marked deterioration at temperature extremes commonly encountered in mobile devices, particularly during intensive processing tasks or in challenging environmental conditions. This sensitivity restricts their practical application in consumer electronics designed for diverse operating environments.

Self-discharge rates remain problematically high, with many hybrid systems losing 10-20% of stored charge within 24 hours compared to 1-2% for lithium-ion batteries. This characteristic severely limits their suitability for mobile devices that may remain unused for extended periods while still requiring immediate power availability.

Integration challenges with existing mobile device architectures present significant technical barriers. Current hybrid supercapacitor form factors and voltage characteristics often require substantial redesign of power management systems and physical device layouts, creating resistance to adoption among manufacturers with established production lines.

Electrolyte limitations further constrain performance, with current formulations struggling to provide both high ionic conductivity and wide electrochemical stability windows. Aqueous electrolytes offer safety advantages but restrict operating voltage, while organic electrolytes enable higher voltage operation but introduce flammability concerns incompatible with consumer device safety standards.

Existing Hybrid Supercapacitor Integration Solutions

01 Electrode materials for enhanced energy density

Advanced electrode materials play a crucial role in improving the efficiency of hybrid supercapacitors. Materials such as carbon-based composites, metal oxides, and conductive polymers can significantly enhance energy density while maintaining high power capabilities. These materials offer increased surface area for charge storage and improved electrical conductivity, resulting in better overall performance of hybrid supercapacitors.- Electrode materials for enhanced efficiency: Advanced electrode materials play a crucial role in improving the efficiency of hybrid supercapacitors. Materials such as carbon-based composites, metal oxides, and conductive polymers can significantly enhance energy density and power performance. These materials offer increased surface area, improved electrical conductivity, and better charge storage capabilities, leading to higher overall efficiency in hybrid supercapacitor systems.

- Electrolyte optimization for hybrid supercapacitors: The selection and formulation of electrolytes significantly impact the efficiency of hybrid supercapacitors. Advanced electrolyte compositions can provide wider voltage windows, improved ionic conductivity, and enhanced electrochemical stability. Optimized electrolytes enable faster charge transfer, reduced internal resistance, and better cycling performance, ultimately leading to higher energy and power densities in hybrid supercapacitor systems.

- Structural design and architecture optimization: The structural design and architecture of hybrid supercapacitors significantly influence their efficiency. Innovative designs such as 3D electrode structures, hierarchical pore distributions, and optimized cell configurations can enhance ion transport, reduce diffusion distances, and improve charge storage capabilities. These architectural improvements lead to better utilization of active materials, reduced internal resistance, and enhanced overall performance of hybrid supercapacitor systems.

- Integration with energy management systems: Integrating hybrid supercapacitors with advanced energy management systems can significantly improve their operational efficiency. Smart control algorithms, adaptive charging protocols, and optimized power distribution strategies enable better utilization of the supercapacitors' capabilities. These integrated systems can balance power demands, manage thermal conditions, and coordinate with other energy storage devices, resulting in improved overall system efficiency and extended operational lifetime.

- Novel fabrication techniques and manufacturing processes: Advanced fabrication techniques and manufacturing processes can significantly enhance the efficiency of hybrid supercapacitors. Methods such as atomic layer deposition, electrospinning, and solution-based processing enable precise control over material properties and interfaces. These techniques allow for the creation of optimized electrode structures, improved material integration, and enhanced electrochemical performance, leading to higher energy density, power capability, and overall efficiency in hybrid supercapacitor systems.

02 Electrolyte optimization for improved performance

The selection and formulation of electrolytes significantly impact hybrid supercapacitor efficiency. Advanced electrolyte compositions can expand the operating voltage window, enhance ionic conductivity, and improve charge transfer at electrode interfaces. Innovations in electrolyte design include the use of ionic liquids, gel electrolytes, and solid-state electrolytes that offer better stability and safety while maximizing energy storage capabilities.Expand Specific Solutions03 Structural design and system integration

The structural design of hybrid supercapacitors significantly affects their efficiency. Innovations in device architecture, including layered structures, 3D configurations, and integrated systems, can optimize ion transport pathways and reduce internal resistance. Advanced manufacturing techniques enable precise control over component arrangement and interfaces, leading to improved charge-discharge rates and cycle stability.Expand Specific Solutions04 Thermal management and stability enhancement

Effective thermal management is essential for maintaining the efficiency of hybrid supercapacitors, especially during high-power operations. Innovations in heat dissipation mechanisms, temperature-resistant materials, and protective coatings help prevent performance degradation under extreme conditions. These advancements ensure consistent performance across a wide temperature range and extend the operational lifetime of hybrid supercapacitor systems.Expand Specific Solutions05 Energy management systems and control algorithms

Sophisticated energy management systems and control algorithms optimize the operation of hybrid supercapacitors in practical applications. These systems regulate charging and discharging processes, balance energy distribution, and implement adaptive control strategies based on real-time performance monitoring. Advanced algorithms can predict energy demands, optimize power delivery, and extend the useful life of hybrid supercapacitor systems through intelligent operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Energy Storage

Hybrid supercapacitors are emerging as a transformative technology in mobile device efficiency, positioned at the intersection of traditional batteries and supercapacitors. The market is in its growth phase, with projections indicating significant expansion as consumer electronics demand increases. Currently valued at approximately $500 million, the sector is expected to grow at a CAGR of 20-25% through 2028. Technical maturity varies across players: established companies like Samsung Electro-Mechanics, Robert Bosch, and Corning have advanced commercial solutions, while research institutions such as the Chinese Academy of Sciences and Central South University are driving fundamental innovations. Emerging specialists like GODI India, Honeycomb Battery, and Shanghai Aowei are rapidly developing competitive technologies that promise to address the power density and cycle life limitations of conventional batteries in mobile applications.

The Regents of the University of California

Technical Solution: The University of California has developed advanced hybrid supercapacitor technology that combines high-energy lithium-ion battery materials with high-power supercapacitor electrodes. Their approach utilizes nanoscale engineering of electrode materials, specifically incorporating graphene and carbon nanotubes with lithium-rich metal oxides to create composite electrodes. This design enables rapid charge transfer while maintaining high energy density. Their research has demonstrated devices achieving power densities of up to 15 kW/kg while maintaining energy densities of 100-150 Wh/kg, representing a significant improvement over conventional lithium-ion batteries. The technology employs asymmetric configurations with lithium titanate anodes and activated carbon cathodes, optimized with ionic liquid electrolytes that extend voltage windows to 3.5V, enhancing overall energy storage capabilities.

Strengths: Exceptional power delivery for mobile applications requiring burst performance; significantly faster charging times (80% charge in under 5 minutes); extended cycle life exceeding 10,000 cycles. Weaknesses: Higher production costs compared to conventional batteries; lower energy density than pure lithium-ion systems; temperature sensitivity affecting performance in extreme conditions.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung has pioneered hybrid supercapacitor technology specifically designed for mobile devices through their graphene-enhanced lithium-ion capacitor (LIC) architecture. Their approach integrates graphene-coated silicon anodes with activated carbon cathodes in an asymmetric configuration, creating devices that bridge the gap between conventional batteries and supercapacitors. Samsung's hybrid supercapacitors utilize proprietary electrolyte formulations that enable operation at higher voltages (up to 4.2V) while maintaining safety. Their latest generation achieves energy densities of approximately 60-80 Wh/kg with power densities exceeding 10 kW/kg, enabling rapid charging capabilities (0-70% in under 3 minutes) while maintaining reasonable energy storage for mobile applications. The technology incorporates advanced thermal management systems to optimize performance during high-power operations typical in modern smartphones and wearables.

Strengths: Seamless integration with existing mobile device architectures; exceptional fast-charging capabilities; minimal capacity degradation (less than 20% after 5,000 cycles); compact form factor suitable for space-constrained devices. Weaknesses: Higher cost compared to traditional lithium-ion batteries; lower total energy storage than conventional batteries; requires specialized charging infrastructure for optimal performance.

Key Patents and Research Breakthroughs in Hybrid Supercapacitors

Supercapacitor comprising nanostructure of a metal-chalcogen compound

PatentWO2024209476A1

Innovation

- A hybrid supercapacitor design incorporating a first electrode with a carbon-based material and a nanostructure of a metal-chalcogen compound, such as Cu, V, Ni, Fe, Mn, and Sn, combined with a second electrode featuring a similar carbon-based material and nanostructure, utilizing electrolytes like KOH or NaOH, to enhance energy storage capabilities.

Environmental Impact and Sustainability Considerations

The environmental implications of hybrid supercapacitors extend far beyond their immediate performance benefits for mobile devices. These energy storage solutions offer significant sustainability advantages compared to traditional lithium-ion batteries, primarily through their extended lifecycle. While conventional batteries typically endure 500-1,000 charge cycles before significant degradation, hybrid supercapacitors can withstand 10,000-100,000 cycles, dramatically reducing electronic waste generation and resource consumption associated with battery replacement.

Material composition represents another critical environmental dimension. Hybrid supercapacitors often utilize more environmentally benign materials than conventional batteries, reducing dependence on rare earth elements and conflict minerals. Many designs incorporate carbon-based materials, conductive polymers, and metal oxides that present fewer extraction and disposal challenges than lithium, cobalt, and other battery components associated with significant environmental and social impacts.

Manufacturing processes for hybrid supercapacitors generally require less energy and produce fewer toxic byproducts compared to lithium-ion battery production. This translates to a lower carbon footprint across the product lifecycle, particularly when considering the energy-intensive extraction and processing of battery materials. The simplified structure of many hybrid supercapacitor designs further contributes to manufacturing efficiency and reduced environmental impact.

End-of-life considerations strongly favor hybrid supercapacitors from a sustainability perspective. Their components are typically easier to recycle and present fewer hazardous waste challenges during disposal. Unlike lithium-ion batteries, which require specialized recycling facilities and pose fire risks, hybrid supercapacitors generally contain fewer toxic substances and reactive materials, simplifying safe disposal or material recovery.

Energy efficiency during operation further enhances the environmental profile of hybrid supercapacitors. Their ability to rapidly charge and discharge with minimal energy loss reduces electricity consumption over the device lifecycle. This efficiency becomes particularly significant in renewable energy applications, where hybrid supercapacitors can effectively capture and store intermittent energy that might otherwise be wasted.

Looking forward, hybrid supercapacitors align well with circular economy principles through their durability, reduced material intensity, and recyclability potential. As manufacturers increasingly adopt design-for-environment approaches, hybrid supercapacitors represent a promising pathway toward more sustainable mobile electronics that minimize resource depletion and environmental degradation while maintaining or enhancing device performance.

Material composition represents another critical environmental dimension. Hybrid supercapacitors often utilize more environmentally benign materials than conventional batteries, reducing dependence on rare earth elements and conflict minerals. Many designs incorporate carbon-based materials, conductive polymers, and metal oxides that present fewer extraction and disposal challenges than lithium, cobalt, and other battery components associated with significant environmental and social impacts.

Manufacturing processes for hybrid supercapacitors generally require less energy and produce fewer toxic byproducts compared to lithium-ion battery production. This translates to a lower carbon footprint across the product lifecycle, particularly when considering the energy-intensive extraction and processing of battery materials. The simplified structure of many hybrid supercapacitor designs further contributes to manufacturing efficiency and reduced environmental impact.

End-of-life considerations strongly favor hybrid supercapacitors from a sustainability perspective. Their components are typically easier to recycle and present fewer hazardous waste challenges during disposal. Unlike lithium-ion batteries, which require specialized recycling facilities and pose fire risks, hybrid supercapacitors generally contain fewer toxic substances and reactive materials, simplifying safe disposal or material recovery.

Energy efficiency during operation further enhances the environmental profile of hybrid supercapacitors. Their ability to rapidly charge and discharge with minimal energy loss reduces electricity consumption over the device lifecycle. This efficiency becomes particularly significant in renewable energy applications, where hybrid supercapacitors can effectively capture and store intermittent energy that might otherwise be wasted.

Looking forward, hybrid supercapacitors align well with circular economy principles through their durability, reduced material intensity, and recyclability potential. As manufacturers increasingly adopt design-for-environment approaches, hybrid supercapacitors represent a promising pathway toward more sustainable mobile electronics that minimize resource depletion and environmental degradation while maintaining or enhancing device performance.

Cost-Performance Analysis of Hybrid Supercapacitor Implementation

The implementation of hybrid supercapacitors in mobile devices presents a complex cost-performance equation that manufacturers must carefully evaluate. Initial manufacturing costs for hybrid supercapacitors remain 30-40% higher than traditional lithium-ion batteries when comparing energy storage capacity. This premium stems from specialized materials like activated carbon, metal oxides, and advanced electrolytes, alongside more complex manufacturing processes requiring precise control of nanomaterial structures.

However, the total cost of ownership analysis reveals more favorable economics. Hybrid supercapacitors demonstrate 3-5 times longer cycle life (typically 20,000-30,000 cycles versus 500-1,000 for conventional batteries), significantly reducing replacement frequency and associated costs. This extended lifespan translates to approximately 18-24% lower lifetime device power management costs despite the higher initial investment.

Performance benefits further justify the cost premium in specific applications. Devices requiring rapid power delivery capabilities experience 40-60% improvement in peak power performance, enabling enhanced functionality for computational-intensive mobile applications like gaming, AR/VR, and real-time data processing. The rapid charging capability (80% charge in 2-5 minutes versus 30-60 minutes for conventional batteries) delivers quantifiable user experience improvements and productivity gains.

Energy efficiency metrics demonstrate 15-20% reduced energy loss during charge-discharge cycles compared to traditional lithium-ion solutions. This efficiency translates directly to extended device runtime and reduced charging frequency, particularly beneficial for applications with intermittent high-power demands.

Market sensitivity analysis indicates price elasticity varies significantly by device segment. Premium smartphones and professional-grade tablets demonstrate higher tolerance for the cost premium, with consumers willing to pay 15-25% more for devices featuring rapid charging and extended battery lifespan. Budget and mid-range segments show greater price sensitivity, suggesting hybrid supercapacitor implementation may initially focus on high-end devices.

Manufacturing scale economies present a promising cost reduction pathway. Industry projections suggest production scaling could reduce manufacturing costs by 35-45% over the next 3-5 years as material sourcing improves and production processes mature. This trajectory would position hybrid supercapacitors as increasingly competitive alternatives across broader device categories, potentially reaching cost parity with traditional solutions for specific applications by 2026-2027.

However, the total cost of ownership analysis reveals more favorable economics. Hybrid supercapacitors demonstrate 3-5 times longer cycle life (typically 20,000-30,000 cycles versus 500-1,000 for conventional batteries), significantly reducing replacement frequency and associated costs. This extended lifespan translates to approximately 18-24% lower lifetime device power management costs despite the higher initial investment.

Performance benefits further justify the cost premium in specific applications. Devices requiring rapid power delivery capabilities experience 40-60% improvement in peak power performance, enabling enhanced functionality for computational-intensive mobile applications like gaming, AR/VR, and real-time data processing. The rapid charging capability (80% charge in 2-5 minutes versus 30-60 minutes for conventional batteries) delivers quantifiable user experience improvements and productivity gains.

Energy efficiency metrics demonstrate 15-20% reduced energy loss during charge-discharge cycles compared to traditional lithium-ion solutions. This efficiency translates directly to extended device runtime and reduced charging frequency, particularly beneficial for applications with intermittent high-power demands.

Market sensitivity analysis indicates price elasticity varies significantly by device segment. Premium smartphones and professional-grade tablets demonstrate higher tolerance for the cost premium, with consumers willing to pay 15-25% more for devices featuring rapid charging and extended battery lifespan. Budget and mid-range segments show greater price sensitivity, suggesting hybrid supercapacitor implementation may initially focus on high-end devices.

Manufacturing scale economies present a promising cost reduction pathway. Industry projections suggest production scaling could reduce manufacturing costs by 35-45% over the next 3-5 years as material sourcing improves and production processes mature. This trajectory would position hybrid supercapacitors as increasingly competitive alternatives across broader device categories, potentially reaching cost parity with traditional solutions for specific applications by 2026-2027.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!