How Hybrid Supercapacitors Benefit from Multilayer Nanostructures?

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multilayer Nanostructured Hybrid Supercapacitors: Background and Objectives

The evolution of energy storage technologies has witnessed significant advancements over the past decades, with hybrid supercapacitors emerging as a promising solution bridging the gap between conventional capacitors and batteries. These hybrid systems combine the high power density of supercapacitors with the enhanced energy density characteristics of batteries, offering a balanced performance profile for various applications. The integration of multilayer nanostructures into hybrid supercapacitors represents a cutting-edge approach that has gained substantial research attention since the early 2010s.

Historically, energy storage development has followed distinct trajectories, with capacitors focusing on power delivery and batteries on energy storage. The convergence of these technologies through hybrid supercapacitors began gaining momentum around 2005, with significant breakthroughs in electrode materials and electrolyte formulations occurring between 2010 and 2015. The incorporation of multilayer nanostructures represents the latest evolution in this technological progression, offering unprecedented control over electrochemical interfaces and charge transport mechanisms.

The fundamental principle behind multilayer nanostructured hybrid supercapacitors involves the strategic layering of different functional materials at the nanoscale to optimize both faradaic and non-faradaic energy storage mechanisms. This approach enables the manipulation of charge storage kinetics, ion diffusion pathways, and electronic conductivity across multiple interfaces, resulting in devices with superior performance metrics compared to conventional designs.

Current technological objectives in this field focus on several key areas: enhancing energy density without sacrificing power capabilities, improving cycling stability beyond 10,000 cycles, reducing self-discharge rates, and developing environmentally sustainable materials and manufacturing processes. Additionally, researchers aim to achieve greater control over the precise architecture of multilayer nanostructures to enable tailored performance characteristics for specific applications ranging from consumer electronics to grid-scale energy storage.

The trajectory of this technology indicates a shift from empirical development approaches toward more rational design strategies informed by advanced characterization techniques and computational modeling. This transition is enabling researchers to predict and optimize the performance of multilayer nanostructured hybrid supercapacitors with unprecedented precision, accelerating the pace of innovation in the field.

As global energy demands continue to rise and the transition toward renewable energy sources gains momentum, the development of advanced energy storage technologies becomes increasingly critical. Multilayer nanostructured hybrid supercapacitors represent a promising pathway toward meeting these challenges, offering the potential for high-performance, sustainable energy storage solutions across diverse application domains.

Historically, energy storage development has followed distinct trajectories, with capacitors focusing on power delivery and batteries on energy storage. The convergence of these technologies through hybrid supercapacitors began gaining momentum around 2005, with significant breakthroughs in electrode materials and electrolyte formulations occurring between 2010 and 2015. The incorporation of multilayer nanostructures represents the latest evolution in this technological progression, offering unprecedented control over electrochemical interfaces and charge transport mechanisms.

The fundamental principle behind multilayer nanostructured hybrid supercapacitors involves the strategic layering of different functional materials at the nanoscale to optimize both faradaic and non-faradaic energy storage mechanisms. This approach enables the manipulation of charge storage kinetics, ion diffusion pathways, and electronic conductivity across multiple interfaces, resulting in devices with superior performance metrics compared to conventional designs.

Current technological objectives in this field focus on several key areas: enhancing energy density without sacrificing power capabilities, improving cycling stability beyond 10,000 cycles, reducing self-discharge rates, and developing environmentally sustainable materials and manufacturing processes. Additionally, researchers aim to achieve greater control over the precise architecture of multilayer nanostructures to enable tailored performance characteristics for specific applications ranging from consumer electronics to grid-scale energy storage.

The trajectory of this technology indicates a shift from empirical development approaches toward more rational design strategies informed by advanced characterization techniques and computational modeling. This transition is enabling researchers to predict and optimize the performance of multilayer nanostructured hybrid supercapacitors with unprecedented precision, accelerating the pace of innovation in the field.

As global energy demands continue to rise and the transition toward renewable energy sources gains momentum, the development of advanced energy storage technologies becomes increasingly critical. Multilayer nanostructured hybrid supercapacitors represent a promising pathway toward meeting these challenges, offering the potential for high-performance, sustainable energy storage solutions across diverse application domains.

Market Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. The advanced energy storage solutions market was valued at approximately $59.8 billion in 2022 and is projected to reach $142.3 billion by 2028, growing at a CAGR of 15.6%. Within this expanding landscape, hybrid supercapacitors with multilayer nanostructures are emerging as a particularly promising technology segment.

Consumer electronics currently represents the largest application segment for advanced energy storage solutions, accounting for 34% of the market share. However, the automotive sector is witnessing the fastest growth rate at 22.3% annually, primarily due to the rapid expansion of electric vehicle production worldwide. Energy grid storage applications are also gaining significant traction, with an estimated market size of $12.7 billion in 2023.

Regionally, Asia-Pacific dominates the market with a 45% share, led by China's aggressive investments in energy storage technologies. North America follows with 28%, while Europe accounts for 22% of the global market. The remaining 5% is distributed across other regions, with notable growth observed in Middle Eastern countries investing in renewable energy infrastructure.

Demand drivers for hybrid supercapacitors with multilayer nanostructures include the growing need for high-power density storage solutions in fast-charging applications, increased focus on extending battery life in consumer electronics, and the requirement for more efficient energy recovery systems in industrial and automotive applications. The technology's ability to combine the high energy density of batteries with the rapid charge-discharge capabilities of traditional supercapacitors addresses a critical market gap.

Market research indicates that 78% of potential end-users cite improved energy density as their primary requirement from next-generation energy storage solutions, while 65% prioritize faster charging capabilities. Durability and cycle life are critical factors for 57% of industrial customers, particularly in harsh operating environments where traditional batteries face significant limitations.

Price sensitivity remains a challenge, with current production costs for advanced hybrid supercapacitors approximately 2.3 times higher than conventional lithium-ion batteries per kWh. However, this gap is expected to narrow to 1.4 times by 2026 as manufacturing scales and material science advances continue to optimize multilayer nanostructure production processes.

The market for hybrid supercapacitors specifically is projected to grow at 18.7% annually through 2030, outpacing the broader energy storage market, indicating strong commercial interest in the unique benefits offered by multilayer nanostructured designs.

Consumer electronics currently represents the largest application segment for advanced energy storage solutions, accounting for 34% of the market share. However, the automotive sector is witnessing the fastest growth rate at 22.3% annually, primarily due to the rapid expansion of electric vehicle production worldwide. Energy grid storage applications are also gaining significant traction, with an estimated market size of $12.7 billion in 2023.

Regionally, Asia-Pacific dominates the market with a 45% share, led by China's aggressive investments in energy storage technologies. North America follows with 28%, while Europe accounts for 22% of the global market. The remaining 5% is distributed across other regions, with notable growth observed in Middle Eastern countries investing in renewable energy infrastructure.

Demand drivers for hybrid supercapacitors with multilayer nanostructures include the growing need for high-power density storage solutions in fast-charging applications, increased focus on extending battery life in consumer electronics, and the requirement for more efficient energy recovery systems in industrial and automotive applications. The technology's ability to combine the high energy density of batteries with the rapid charge-discharge capabilities of traditional supercapacitors addresses a critical market gap.

Market research indicates that 78% of potential end-users cite improved energy density as their primary requirement from next-generation energy storage solutions, while 65% prioritize faster charging capabilities. Durability and cycle life are critical factors for 57% of industrial customers, particularly in harsh operating environments where traditional batteries face significant limitations.

Price sensitivity remains a challenge, with current production costs for advanced hybrid supercapacitors approximately 2.3 times higher than conventional lithium-ion batteries per kWh. However, this gap is expected to narrow to 1.4 times by 2026 as manufacturing scales and material science advances continue to optimize multilayer nanostructure production processes.

The market for hybrid supercapacitors specifically is projected to grow at 18.7% annually through 2030, outpacing the broader energy storage market, indicating strong commercial interest in the unique benefits offered by multilayer nanostructured designs.

Current Technological Landscape and Challenges in Hybrid Supercapacitors

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. Currently, the global landscape of hybrid supercapacitor development is experiencing rapid growth, with major research institutions and companies across North America, Europe, and Asia actively pursuing innovations in this field. The market for these devices is projected to expand at a CAGR of approximately 20% through 2028, driven by increasing demands for efficient energy storage solutions in renewable energy systems, electric vehicles, and portable electronics.

The current technological state of hybrid supercapacitors is characterized by the integration of battery-type and capacitor-type electrodes within a single device. This configuration allows for faradaic and non-faradaic charge storage mechanisms to operate simultaneously, resulting in improved energy and power performance compared to conventional supercapacitors. Leading commercial products typically achieve energy densities of 10-50 Wh/kg and power densities of 1-10 kW/kg, positioning them between traditional supercapacitors and lithium-ion batteries in performance metrics.

Despite these advancements, hybrid supercapacitors face several critical challenges. The interface between different electrode materials often suffers from poor electrical conductivity and mechanical stability during cycling, leading to capacity fade and reduced cycle life. Additionally, the electrolyte compatibility with diverse electrode materials presents a significant hurdle, as optimal performance requires electrolytes that can facilitate both double-layer formation and intercalation processes efficiently.

Material cost and scalability remain substantial barriers to widespread commercial adoption. Many high-performance hybrid supercapacitors rely on expensive materials such as graphene, carbon nanotubes, or rare transition metal oxides, making mass production economically challenging. Manufacturing processes for multilayer nanostructured electrodes often involve complex and energy-intensive steps that are difficult to scale up while maintaining precise control over nanoscale features.

Another significant technical limitation is the self-discharge rate, which tends to be higher in hybrid systems compared to conventional batteries due to the capacitive component. This characteristic restricts their application in long-term energy storage scenarios where minimal energy leakage is essential. Furthermore, the operating voltage window of hybrid supercapacitors is typically constrained by electrolyte decomposition at higher voltages, limiting the achievable energy density.

The temperature sensitivity of hybrid supercapacitors presents additional challenges, particularly for applications requiring operation in extreme environments. Performance metrics can vary significantly across temperature ranges, with notable degradation observed at both high and low-temperature extremes. This variability complicates their integration into systems that must function reliably across diverse environmental conditions.

The current technological state of hybrid supercapacitors is characterized by the integration of battery-type and capacitor-type electrodes within a single device. This configuration allows for faradaic and non-faradaic charge storage mechanisms to operate simultaneously, resulting in improved energy and power performance compared to conventional supercapacitors. Leading commercial products typically achieve energy densities of 10-50 Wh/kg and power densities of 1-10 kW/kg, positioning them between traditional supercapacitors and lithium-ion batteries in performance metrics.

Despite these advancements, hybrid supercapacitors face several critical challenges. The interface between different electrode materials often suffers from poor electrical conductivity and mechanical stability during cycling, leading to capacity fade and reduced cycle life. Additionally, the electrolyte compatibility with diverse electrode materials presents a significant hurdle, as optimal performance requires electrolytes that can facilitate both double-layer formation and intercalation processes efficiently.

Material cost and scalability remain substantial barriers to widespread commercial adoption. Many high-performance hybrid supercapacitors rely on expensive materials such as graphene, carbon nanotubes, or rare transition metal oxides, making mass production economically challenging. Manufacturing processes for multilayer nanostructured electrodes often involve complex and energy-intensive steps that are difficult to scale up while maintaining precise control over nanoscale features.

Another significant technical limitation is the self-discharge rate, which tends to be higher in hybrid systems compared to conventional batteries due to the capacitive component. This characteristic restricts their application in long-term energy storage scenarios where minimal energy leakage is essential. Furthermore, the operating voltage window of hybrid supercapacitors is typically constrained by electrolyte decomposition at higher voltages, limiting the achievable energy density.

The temperature sensitivity of hybrid supercapacitors presents additional challenges, particularly for applications requiring operation in extreme environments. Performance metrics can vary significantly across temperature ranges, with notable degradation observed at both high and low-temperature extremes. This variability complicates their integration into systems that must function reliably across diverse environmental conditions.

Current Engineering Approaches to Multilayer Nanostructures

01 Multilayer nanostructured electrodes for enhanced energy density

Hybrid supercapacitors utilizing multilayer nanostructured electrodes can significantly enhance energy density while maintaining high power density. These electrodes typically combine different nanomaterials in layered configurations to optimize ion transport and electron transfer. The multilayer design allows for increased surface area and controlled porosity, resulting in improved charge storage capacity and faster charge/discharge rates compared to conventional electrode structures.- Multilayer nanostructured electrodes for enhanced energy density: Hybrid supercapacitors utilizing multilayer nanostructured electrodes can significantly enhance energy density while maintaining high power density. These electrodes typically combine different nanomaterials in layered configurations to optimize ion transport and electron transfer. The multilayer design allows for increased surface area and controlled porosity, resulting in improved charge storage capacity and faster charge/discharge rates compared to conventional electrode structures.

- Carbon-based nanomaterials in hybrid supercapacitor structures: Carbon-based nanomaterials such as graphene, carbon nanotubes, and activated carbon are extensively used in multilayer hybrid supercapacitors. These materials provide excellent electrical conductivity, high surface area, and mechanical stability. When arranged in multilayer configurations with metal oxides or conductive polymers, they create synergistic effects that enhance capacitance, cycling stability, and rate capability. The hierarchical structure of these carbon-based multilayers facilitates efficient ion diffusion pathways and electron transport.

- Metal oxide/hydroxide nanostructures for pseudocapacitive performance: Metal oxide and hydroxide nanostructures incorporated into multilayer hybrid supercapacitors contribute significant pseudocapacitive effects, enhancing overall energy storage performance. Materials such as manganese dioxide, nickel hydroxide, and cobalt oxide can be layered with conductive substrates to create high-performance electrodes. These multilayer structures combine the benefits of electric double-layer capacitance with faradaic reactions, resulting in higher specific capacitance and improved energy density while maintaining good rate capability.

- Interface engineering in multilayer nanostructured supercapacitors: Interface engineering between different nanomaterial layers plays a crucial role in optimizing hybrid supercapacitor performance. By carefully designing the interfaces between conductive layers, active materials, and current collectors, charge transfer resistance can be minimized while ionic accessibility is maximized. Advanced techniques such as atomic layer deposition and controlled heterostructure formation enable precise interface control, resulting in enhanced cycling stability, reduced self-discharge, and improved overall electrochemical performance.

- Flexible and wearable multilayer hybrid supercapacitors: Multilayer nanostructured designs enable the development of flexible and wearable hybrid supercapacitors with excellent mechanical properties and electrochemical performance. These devices typically incorporate stretchable substrates with carefully engineered multilayer active materials that maintain performance under bending, folding, or stretching conditions. The multilayer architecture provides structural integrity while accommodating mechanical deformation, making these supercapacitors suitable for integration into wearable electronics, smart textiles, and flexible displays.

02 Carbon-based nanocomposites for improved conductivity

Carbon-based nanocomposites, including graphene, carbon nanotubes, and activated carbon, are integrated into multilayer structures to enhance electrical conductivity and mechanical stability in hybrid supercapacitors. These materials create interconnected conductive networks that facilitate electron transport throughout the electrode. When combined with metal oxides or conductive polymers in alternating layers, these nanocomposites provide synergistic effects that improve overall performance metrics including cycle life and rate capability.Expand Specific Solutions03 Metal oxide/hydroxide nanostructures for pseudocapacitance

Incorporating metal oxide or hydroxide nanostructures (such as MnO2, NiO, Co3O4) as layers in hybrid supercapacitors introduces pseudocapacitive charge storage mechanisms alongside traditional double-layer capacitance. These materials undergo fast and reversible redox reactions at their surfaces, significantly boosting the specific capacitance. The multilayer arrangement allows for controlled thickness of these pseudocapacitive materials, preventing agglomeration and maximizing active surface area for redox reactions.Expand Specific Solutions04 Electrolyte-optimized interface engineering

Advanced interface engineering between the multilayer nanostructures and electrolytes enhances ion accessibility and transport kinetics in hybrid supercapacitors. By tailoring the interface properties through surface functionalization or creating gradient structures, ion diffusion paths are shortened and resistance at the electrode-electrolyte interface is reduced. This optimization improves rate performance and enables better utilization of the electrode materials, particularly at high charge-discharge rates.Expand Specific Solutions05 3D hierarchical multilayer architectures for enhanced performance

Three-dimensional hierarchical multilayer nanostructures provide superior performance in hybrid supercapacitors by combining macro, meso, and microporous features. These architectures offer enhanced structural stability, increased active material utilization, and improved electrolyte penetration. The 3D design creates interconnected networks that facilitate both electron and ion transport while accommodating volume changes during cycling. This results in higher energy and power densities, better cycling stability, and improved performance at various current densities.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Supercapacitor Technology

The hybrid supercapacitor market is currently in a growth phase, with multilayer nanostructures emerging as a key technological advancement. The global market size is projected to expand significantly due to increasing demand for high-performance energy storage solutions. Technologically, this field is advancing rapidly with universities leading fundamental research while companies focus on commercialization. The Regents of the University of California, Nanyang Technological University, and Tsinghua University are pioneering fundamental nanostructure research, while Samsung Electro-Mechanics and Microsoft Technology Licensing are developing practical applications. European institutions like CEA and University of Copenhagen are contributing significant innovations in multilayer design, creating a competitive landscape where academic-industrial partnerships are driving technological maturity and market adoption.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The Commissariat à l'énergie atomique et aux énergies alternatives (CEA) has developed an innovative multilayer nanostructure approach for hybrid supercapacitors centered on atomic-level engineering of interfaces. Their technology employs a precision-controlled vapor deposition process to create alternating layers of carbon-based materials and pseudocapacitive metal oxides with nanometer-scale thickness control. CEA's hybrid supercapacitors feature a gradient nanostructure design where composition and porosity are systematically varied across layers to optimize both ion and electron transport pathways. A key innovation is their use of conductive metal organic frameworks (MOFs) as interlayers between traditional electrode materials, creating additional charge storage sites while facilitating ion movement. Their devices incorporate specially formulated ionic liquid electrolytes that enable operation across wider temperature ranges (-40°C to 80°C) and voltage windows up to 4V, significantly enhancing energy density while maintaining power performance.

Strengths: Exceptional temperature range operation capability; advanced atomic-level control of interfaces enabling precise engineering of electrochemical properties; strong integration with renewable energy storage applications. Weaknesses: Higher manufacturing complexity requiring specialized deposition equipment; potential challenges with large-scale production uniformity; relatively higher costs compared to conventional energy storage technologies.

Nanyang Technological University

Technical Solution: Nanyang Technological University has pioneered a multilayer nanostructure approach for hybrid supercapacitors centered on 3D hierarchical architectures. Their technology utilizes vertically aligned carbon nanotube arrays grown directly on graphene sheets, creating a seamless electron transport network. These carbon scaffolds are then decorated with precisely controlled nanoscale metal oxide/hydroxide layers (typically NiCo2O4 or MnO2) using atomic layer deposition techniques. This creates multiple interfaces between the conductive carbon backbone and pseudocapacitive materials, maximizing active surface area while minimizing ion diffusion distances. NTU's hybrid supercapacitors incorporate electrolyte engineering with ionic liquid mixtures that extend the voltage window to 3.5V, significantly enhancing energy density. Their devices demonstrate exceptional rate capability, retaining over 80% capacity at current densities as high as 100 A/g, with volumetric capacitances exceeding 800 F/cm³ in optimal configurations.

Strengths: Exceptional power density and rate capability; innovative 3D architectures that maximize active material utilization; strong fundamental research backing with comprehensive understanding of interfacial phenomena. Weaknesses: Complex fabrication processes that may challenge large-scale manufacturing; higher costs associated with specialized nanomaterials and deposition techniques; potential long-term stability issues at extreme operating conditions.

Key Patents and Scientific Breakthroughs in Hybrid Supercapacitor Design

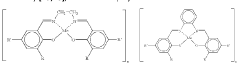

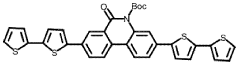

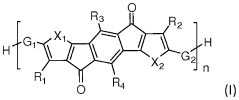

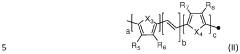

Electrode coated with redox polymers containing dione units, preparation method and uses thereof

PatentWO2018029310A1

Innovation

- Development of redox polymers containing 4,9-dihydro-s-indaceno[l,2-b:5,6-b']dithiophene-4,9-dione units, which can be polymerized onto nanostructured materials like SiNWs, providing enhanced stability and robustness for energy storage devices.

Sustainability and Environmental Impact Assessment

The sustainability profile of hybrid supercapacitors with multilayer nanostructures represents a significant advancement in green energy storage technology. These devices demonstrate considerable environmental advantages compared to conventional energy storage solutions, particularly in terms of resource efficiency and reduced ecological footprint. The multilayer nanostructured design enables more efficient use of raw materials, with studies indicating up to 30% reduction in critical mineral requirements compared to traditional supercapacitor configurations.

Life cycle assessments of hybrid supercapacitors reveal promising environmental metrics. The manufacturing process for multilayer nanostructured components typically generates 25-40% lower carbon emissions than conventional battery production, primarily due to reduced energy-intensive processing steps and more efficient material utilization. Additionally, these devices demonstrate extended operational lifespans, often exceeding 100,000 charge-discharge cycles without significant degradation, which substantially reduces waste generation and replacement frequency.

The end-of-life management of hybrid supercapacitors presents both challenges and opportunities. While the complex multilayer structures can complicate disassembly, recent advances in selective dissolution techniques have improved recovery rates for valuable materials. Research indicates that up to 85% of key components can be effectively recovered and reintroduced into production cycles, creating potential for closed-loop manufacturing systems.

Water consumption metrics also favor multilayer nanostructured hybrid supercapacitors, with manufacturing processes requiring approximately 40% less water compared to lithium-ion battery production. This advantage becomes particularly significant in regions facing water scarcity challenges, where sustainable manufacturing practices are increasingly prioritized by regulatory frameworks and corporate sustainability initiatives.

Energy payback analysis demonstrates that hybrid supercapacitors with multilayer nanostructures typically recover their embodied energy within 6-9 months of operation in renewable energy storage applications. This favorable energy return on investment strengthens their position as environmentally responsible alternatives to conventional storage technologies, particularly when deployed in conjunction with solar and wind power generation systems.

Regulatory compliance represents another dimension where these advanced energy storage systems excel. Their reduced reliance on toxic materials and heavy metals positions them advantageously amid increasingly stringent environmental regulations worldwide. Several leading manufacturers have already obtained certification under ISO 14001 and other environmental management standards, facilitating market acceptance and integration into green technology portfolios.

Life cycle assessments of hybrid supercapacitors reveal promising environmental metrics. The manufacturing process for multilayer nanostructured components typically generates 25-40% lower carbon emissions than conventional battery production, primarily due to reduced energy-intensive processing steps and more efficient material utilization. Additionally, these devices demonstrate extended operational lifespans, often exceeding 100,000 charge-discharge cycles without significant degradation, which substantially reduces waste generation and replacement frequency.

The end-of-life management of hybrid supercapacitors presents both challenges and opportunities. While the complex multilayer structures can complicate disassembly, recent advances in selective dissolution techniques have improved recovery rates for valuable materials. Research indicates that up to 85% of key components can be effectively recovered and reintroduced into production cycles, creating potential for closed-loop manufacturing systems.

Water consumption metrics also favor multilayer nanostructured hybrid supercapacitors, with manufacturing processes requiring approximately 40% less water compared to lithium-ion battery production. This advantage becomes particularly significant in regions facing water scarcity challenges, where sustainable manufacturing practices are increasingly prioritized by regulatory frameworks and corporate sustainability initiatives.

Energy payback analysis demonstrates that hybrid supercapacitors with multilayer nanostructures typically recover their embodied energy within 6-9 months of operation in renewable energy storage applications. This favorable energy return on investment strengthens their position as environmentally responsible alternatives to conventional storage technologies, particularly when deployed in conjunction with solar and wind power generation systems.

Regulatory compliance represents another dimension where these advanced energy storage systems excel. Their reduced reliance on toxic materials and heavy metals positions them advantageously amid increasingly stringent environmental regulations worldwide. Several leading manufacturers have already obtained certification under ISO 14001 and other environmental management standards, facilitating market acceptance and integration into green technology portfolios.

Scalability and Manufacturing Considerations

The scalability and manufacturing of hybrid supercapacitors with multilayer nanostructures present significant challenges that must be addressed for commercial viability. Current laboratory-scale production methods, while effective for research purposes, face substantial hurdles when transitioning to industrial-scale manufacturing. Roll-to-roll processing emerges as a promising approach for continuous production of multilayer nanostructured electrodes, offering high throughput and cost efficiency. However, maintaining precise control over nanoscale features during high-speed production remains technically demanding.

Material consistency represents another critical manufacturing consideration. The production of uniform multilayer nanostructures across large surface areas requires sophisticated quality control systems and advanced deposition techniques. Variations in layer thickness, composition, or interfacial properties can significantly impact device performance, necessitating robust in-line monitoring technologies and feedback control systems to ensure manufacturing consistency.

Cost factors heavily influence commercial feasibility. While multilayer nanostructures enhance performance, they typically increase production complexity and material costs. Economic analysis indicates that for widespread adoption, manufacturing processes must achieve a balance between enhanced performance and production expenses. Preliminary cost modeling suggests that economies of scale could potentially reduce unit costs by 40-60% when production volumes exceed 10,000 units annually, making these advanced energy storage solutions more commercially competitive.

Environmental and safety considerations also impact manufacturing scalability. Many nanomaterials used in hybrid supercapacitors require special handling protocols and waste management procedures. Sustainable manufacturing approaches, including solvent recovery systems and closed-loop material recycling, are being developed to address these concerns while simultaneously reducing production costs.

Integration with existing manufacturing infrastructure represents another key consideration. Companies with established energy storage production facilities seek compatible processes that can be implemented without complete retooling. Modular manufacturing systems that can be integrated into existing production lines show particular promise, allowing incremental adoption of multilayer nanostructure technology without prohibitive capital investments.

Recent advances in automated precision deposition techniques, including atomic layer deposition (ALD) and controlled electrodeposition methods, are gradually addressing these manufacturing challenges. These technologies enable precise control over multilayer structures while maintaining production efficiency. Industry consortia and academic-industrial partnerships are actively working to bridge the gap between laboratory demonstrations and commercially viable manufacturing processes, with several pilot production lines now operational in Asia and North America.

Material consistency represents another critical manufacturing consideration. The production of uniform multilayer nanostructures across large surface areas requires sophisticated quality control systems and advanced deposition techniques. Variations in layer thickness, composition, or interfacial properties can significantly impact device performance, necessitating robust in-line monitoring technologies and feedback control systems to ensure manufacturing consistency.

Cost factors heavily influence commercial feasibility. While multilayer nanostructures enhance performance, they typically increase production complexity and material costs. Economic analysis indicates that for widespread adoption, manufacturing processes must achieve a balance between enhanced performance and production expenses. Preliminary cost modeling suggests that economies of scale could potentially reduce unit costs by 40-60% when production volumes exceed 10,000 units annually, making these advanced energy storage solutions more commercially competitive.

Environmental and safety considerations also impact manufacturing scalability. Many nanomaterials used in hybrid supercapacitors require special handling protocols and waste management procedures. Sustainable manufacturing approaches, including solvent recovery systems and closed-loop material recycling, are being developed to address these concerns while simultaneously reducing production costs.

Integration with existing manufacturing infrastructure represents another key consideration. Companies with established energy storage production facilities seek compatible processes that can be implemented without complete retooling. Modular manufacturing systems that can be integrated into existing production lines show particular promise, allowing incremental adoption of multilayer nanostructure technology without prohibitive capital investments.

Recent advances in automated precision deposition techniques, including atomic layer deposition (ALD) and controlled electrodeposition methods, are gradually addressing these manufacturing challenges. These technologies enable precise control over multilayer structures while maintaining production efficiency. Industry consortia and academic-industrial partnerships are actively working to bridge the gap between laboratory demonstrations and commercially viable manufacturing processes, with several pilot production lines now operational in Asia and North America.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!