Research on the Mechanical Properties of Hybrid Supercapacitors

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Background and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to overcome the limitations of conventional supercapacitors, particularly their relatively low energy density compared to batteries.

The technological trajectory has been marked by continuous improvements in electrode materials, electrolytes, and structural designs. Initially, carbon-based materials dominated the field, but recent years have witnessed the integration of pseudocapacitive materials and battery-type materials to create hybrid systems with enhanced performance characteristics. This hybridization approach has enabled a synergistic combination of double-layer capacitance and faradaic reactions, resulting in devices with improved energy and power metrics.

A critical aspect of hybrid supercapacitor development has been the focus on mechanical properties, which directly impact device durability, flexibility, and overall performance under various operational conditions. The mechanical integrity of these devices becomes particularly important as applications expand into wearable electronics, flexible displays, and structural energy storage components where mechanical stress is inevitable.

Current research objectives in this field are multifaceted. Primary goals include enhancing the mechanical stability of electrode materials under repeated charge-discharge cycles, improving the adhesion between active materials and current collectors, and developing flexible substrates that maintain electrical conductivity under deformation. Additionally, researchers aim to understand the relationship between mechanical properties and electrochemical performance, as mechanical degradation often leads to capacity fading and reduced cycle life.

The industry is also moving toward standardizing testing protocols for mechanical properties, as current methodologies vary significantly across research groups. This standardization would facilitate more meaningful comparisons between different hybrid supercapacitor technologies and accelerate commercialization efforts.

Looking forward, the field is trending toward biomimetic approaches, drawing inspiration from natural structures that exhibit exceptional mechanical resilience. There is also growing interest in self-healing materials that can autonomously repair mechanical damage, potentially extending device lifetimes significantly. The integration of computational modeling with experimental techniques is expected to accelerate material discovery and optimization processes.

The ultimate technological objective remains the development of hybrid supercapacitors that combine high energy density, high power density, excellent mechanical properties, and long cycle life—all at a competitive cost point that enables widespread commercial adoption across multiple sectors including transportation, renewable energy storage, and consumer electronics.

The technological trajectory has been marked by continuous improvements in electrode materials, electrolytes, and structural designs. Initially, carbon-based materials dominated the field, but recent years have witnessed the integration of pseudocapacitive materials and battery-type materials to create hybrid systems with enhanced performance characteristics. This hybridization approach has enabled a synergistic combination of double-layer capacitance and faradaic reactions, resulting in devices with improved energy and power metrics.

A critical aspect of hybrid supercapacitor development has been the focus on mechanical properties, which directly impact device durability, flexibility, and overall performance under various operational conditions. The mechanical integrity of these devices becomes particularly important as applications expand into wearable electronics, flexible displays, and structural energy storage components where mechanical stress is inevitable.

Current research objectives in this field are multifaceted. Primary goals include enhancing the mechanical stability of electrode materials under repeated charge-discharge cycles, improving the adhesion between active materials and current collectors, and developing flexible substrates that maintain electrical conductivity under deformation. Additionally, researchers aim to understand the relationship between mechanical properties and electrochemical performance, as mechanical degradation often leads to capacity fading and reduced cycle life.

The industry is also moving toward standardizing testing protocols for mechanical properties, as current methodologies vary significantly across research groups. This standardization would facilitate more meaningful comparisons between different hybrid supercapacitor technologies and accelerate commercialization efforts.

Looking forward, the field is trending toward biomimetic approaches, drawing inspiration from natural structures that exhibit exceptional mechanical resilience. There is also growing interest in self-healing materials that can autonomously repair mechanical damage, potentially extending device lifetimes significantly. The integration of computational modeling with experimental techniques is expected to accelerate material discovery and optimization processes.

The ultimate technological objective remains the development of hybrid supercapacitors that combine high energy density, high power density, excellent mechanical properties, and long cycle life—all at a competitive cost point that enables widespread commercial adoption across multiple sectors including transportation, renewable energy storage, and consumer electronics.

Market Analysis for Hybrid Supercapacitor Applications

The hybrid supercapacitor market is experiencing significant growth driven by increasing demand for high-performance energy storage solutions across multiple industries. Current market valuations indicate the global hybrid supercapacitor sector reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 19-21% through 2030. This accelerated growth reflects the expanding applications of these devices in automotive, renewable energy, consumer electronics, and industrial sectors.

The automotive industry represents the largest market segment, accounting for roughly 35% of hybrid supercapacitor demand. This is primarily fueled by the rapid expansion of electric and hybrid vehicles, where these devices serve critical functions in regenerative braking systems, start-stop applications, and power management. The mechanical robustness of hybrid supercapacitors makes them particularly valuable in vehicular applications where vibration resistance and structural integrity under varying temperatures are essential performance parameters.

Renewable energy integration constitutes the fastest-growing application segment, with an estimated growth rate of 25% annually. Grid stabilization systems, particularly in wind and solar installations, increasingly incorporate hybrid supercapacitors to manage power fluctuations and provide rapid-response energy storage. The mechanical durability of these devices under cycling conditions is a key factor driving their adoption in these demanding environments.

Consumer electronics manufacturers are increasingly incorporating hybrid supercapacitors in portable devices, wearable technology, and smart home systems. This market segment values the combination of high power density, rapid charging capabilities, and mechanical flexibility that advanced hybrid supercapacitors offer. The segment currently represents approximately 20% of the total market but is expected to expand as miniaturization and flexible form factors improve.

Industrial applications, including heavy machinery, backup power systems, and manufacturing equipment, constitute about 25% of current market demand. These applications particularly value the mechanical stability of hybrid supercapacitors under extreme operating conditions, including high vibration environments, temperature fluctuations, and pressure variations.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 45% of global consumption, followed by North America (28%) and Europe (22%). China, Japan, and South Korea lead in both production capacity and consumption, driven by their robust electronics manufacturing sectors and aggressive electric vehicle adoption policies.

Market challenges include price sensitivity compared to traditional energy storage solutions, with hybrid supercapacitors typically commanding a 30-40% premium over conventional alternatives. However, this price differential is narrowing as production scales increase and manufacturing processes become more efficient, suggesting improved market penetration in cost-sensitive applications over the next 3-5 years.

The automotive industry represents the largest market segment, accounting for roughly 35% of hybrid supercapacitor demand. This is primarily fueled by the rapid expansion of electric and hybrid vehicles, where these devices serve critical functions in regenerative braking systems, start-stop applications, and power management. The mechanical robustness of hybrid supercapacitors makes them particularly valuable in vehicular applications where vibration resistance and structural integrity under varying temperatures are essential performance parameters.

Renewable energy integration constitutes the fastest-growing application segment, with an estimated growth rate of 25% annually. Grid stabilization systems, particularly in wind and solar installations, increasingly incorporate hybrid supercapacitors to manage power fluctuations and provide rapid-response energy storage. The mechanical durability of these devices under cycling conditions is a key factor driving their adoption in these demanding environments.

Consumer electronics manufacturers are increasingly incorporating hybrid supercapacitors in portable devices, wearable technology, and smart home systems. This market segment values the combination of high power density, rapid charging capabilities, and mechanical flexibility that advanced hybrid supercapacitors offer. The segment currently represents approximately 20% of the total market but is expected to expand as miniaturization and flexible form factors improve.

Industrial applications, including heavy machinery, backup power systems, and manufacturing equipment, constitute about 25% of current market demand. These applications particularly value the mechanical stability of hybrid supercapacitors under extreme operating conditions, including high vibration environments, temperature fluctuations, and pressure variations.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 45% of global consumption, followed by North America (28%) and Europe (22%). China, Japan, and South Korea lead in both production capacity and consumption, driven by their robust electronics manufacturing sectors and aggressive electric vehicle adoption policies.

Market challenges include price sensitivity compared to traditional energy storage solutions, with hybrid supercapacitors typically commanding a 30-40% premium over conventional alternatives. However, this price differential is narrowing as production scales increase and manufacturing processes become more efficient, suggesting improved market penetration in cost-sensitive applications over the next 3-5 years.

Current Mechanical Challenges in Hybrid Supercapacitor Development

Hybrid supercapacitors face significant mechanical challenges that impede their widespread adoption and optimal performance. The integration of different materials with varying mechanical properties creates interface stability issues during charge-discharge cycles. These interfaces experience mechanical stress due to volume changes, particularly in electrode materials that undergo expansion and contraction during ion insertion and extraction processes.

Structural integrity represents a critical challenge, as hybrid supercapacitors must withstand thousands of charge-discharge cycles without mechanical degradation. Current designs struggle with delamination between active materials and current collectors, cracking of electrode materials, and deterioration of the electrode-electrolyte interface. These mechanical failures directly translate to capacity fade and increased internal resistance over time.

Flexibility requirements present another significant hurdle, especially for applications in wearable electronics and flexible devices. Traditional rigid structures limit the bending radius and mechanical durability of hybrid supercapacitors under repeated flexing conditions. The development of mechanically robust yet flexible components remains technically challenging, particularly when maintaining electrical connectivity during deformation.

Thermal expansion mismatch between different materials in hybrid supercapacitors creates additional mechanical stress during temperature fluctuations. This thermal-mechanical coupling effect accelerates degradation, especially in applications with wide operating temperature ranges. Current packaging solutions inadequately address these thermal-mechanical stresses, leading to premature device failure.

Manufacturing scalability presents mechanical challenges related to maintaining consistent mechanical properties across large-area electrodes. Roll-to-roll and other high-throughput manufacturing processes introduce mechanical stresses that can compromise structural integrity before the device even reaches the end-user. Ensuring uniform mechanical properties throughout the manufacturing process remains difficult.

Pressure distribution within packaged devices represents another significant challenge. Non-uniform pressure leads to inconsistent electrical contact between components, creating performance variations across the device area. Current compression mechanisms fail to maintain optimal pressure distribution throughout the device lifetime, particularly as materials age and deform.

Mechanical robustness against external forces presents challenges for applications in harsh environments. Vibration, shock, and impact resistance requirements necessitate advanced mechanical design considerations that often conflict with electrochemical performance optimization. The trade-off between mechanical durability and energy/power density remains a significant barrier to widespread adoption in automotive and industrial applications.

Structural integrity represents a critical challenge, as hybrid supercapacitors must withstand thousands of charge-discharge cycles without mechanical degradation. Current designs struggle with delamination between active materials and current collectors, cracking of electrode materials, and deterioration of the electrode-electrolyte interface. These mechanical failures directly translate to capacity fade and increased internal resistance over time.

Flexibility requirements present another significant hurdle, especially for applications in wearable electronics and flexible devices. Traditional rigid structures limit the bending radius and mechanical durability of hybrid supercapacitors under repeated flexing conditions. The development of mechanically robust yet flexible components remains technically challenging, particularly when maintaining electrical connectivity during deformation.

Thermal expansion mismatch between different materials in hybrid supercapacitors creates additional mechanical stress during temperature fluctuations. This thermal-mechanical coupling effect accelerates degradation, especially in applications with wide operating temperature ranges. Current packaging solutions inadequately address these thermal-mechanical stresses, leading to premature device failure.

Manufacturing scalability presents mechanical challenges related to maintaining consistent mechanical properties across large-area electrodes. Roll-to-roll and other high-throughput manufacturing processes introduce mechanical stresses that can compromise structural integrity before the device even reaches the end-user. Ensuring uniform mechanical properties throughout the manufacturing process remains difficult.

Pressure distribution within packaged devices represents another significant challenge. Non-uniform pressure leads to inconsistent electrical contact between components, creating performance variations across the device area. Current compression mechanisms fail to maintain optimal pressure distribution throughout the device lifetime, particularly as materials age and deform.

Mechanical robustness against external forces presents challenges for applications in harsh environments. Vibration, shock, and impact resistance requirements necessitate advanced mechanical design considerations that often conflict with electrochemical performance optimization. The trade-off between mechanical durability and energy/power density remains a significant barrier to widespread adoption in automotive and industrial applications.

Current Solutions for Enhancing Mechanical Stability

01 Flexible and stretchable hybrid supercapacitors

Development of hybrid supercapacitors with enhanced mechanical flexibility and stretchability for wearable electronics and flexible devices. These supercapacitors incorporate elastic substrates, stretchable electrodes, and specialized electrolytes to maintain performance under bending, folding, and stretching conditions. The mechanical properties are optimized through structural design and material selection to ensure durability during repeated deformation cycles while maintaining electrochemical performance.- Carbon-based materials for mechanical stability: Carbon-based materials such as graphene, carbon nanotubes, and carbon fibers are incorporated into hybrid supercapacitors to enhance mechanical properties. These materials provide excellent tensile strength, flexibility, and structural integrity while maintaining high electrical conductivity. The carbon structures create a robust framework that can withstand mechanical stress during charging and discharging cycles, improving the overall durability and lifespan of the supercapacitor.

- Polymer-based composites for flexibility: Polymer-based composites are utilized in hybrid supercapacitors to improve flexibility and mechanical resilience. These composites typically combine conductive polymers with other materials to create electrodes that can bend and stretch without compromising electrical performance. The integration of polymers enhances the supercapacitor's ability to withstand physical deformation, making them suitable for wearable electronics and flexible devices where mechanical adaptability is crucial.

- Metal oxide frameworks for structural enhancement: Metal oxide frameworks are incorporated into hybrid supercapacitors to enhance structural integrity while maintaining high energy storage capabilities. These frameworks provide a rigid structure that improves mechanical stability under various operating conditions. The combination of metal oxides with other materials creates a synergistic effect that enhances both the mechanical properties and electrochemical performance of the supercapacitor, resulting in devices that can withstand mechanical stress while delivering consistent power output.

- Layered composite structures for impact resistance: Layered composite structures are designed for hybrid supercapacitors to improve impact resistance and mechanical durability. These multi-layered configurations distribute mechanical stress across different materials, preventing catastrophic failure under impact or vibration. The strategic arrangement of layers with varying mechanical properties creates a robust structure that can absorb and dissipate energy from external forces, making these supercapacitors suitable for applications in harsh environments or where physical impacts are common.

- Nanostructured materials for mechanical flexibility and strength: Nanostructured materials are employed in hybrid supercapacitors to simultaneously achieve mechanical flexibility and strength. These materials, engineered at the nanoscale, provide unique mechanical advantages such as high surface area, controlled porosity, and customizable mechanical properties. The nanostructuring allows for the development of supercapacitors that can maintain structural integrity during bending, twisting, or stretching while preserving their energy storage capabilities, making them ideal for applications requiring both mechanical resilience and high performance.

02 Carbon-based composite materials for mechanical stability

Utilization of carbon-based materials such as graphene, carbon nanotubes, and activated carbon in hybrid supercapacitor electrodes to enhance mechanical stability and durability. These carbon composites provide structural integrity while maintaining high surface area for energy storage. The integration of carbon materials with metal oxides or conductive polymers creates mechanically robust electrodes that can withstand charge-discharge cycles without significant degradation of physical properties.Expand Specific Solutions03 Polymer-based hybrid supercapacitors with enhanced mechanical properties

Integration of conductive polymers and polymer electrolytes in hybrid supercapacitors to improve mechanical flexibility and impact resistance. These polymer-based components provide elasticity and mechanical strength while maintaining ionic conductivity. The polymer matrices can be engineered to absorb mechanical stress and prevent electrode delamination during operation, resulting in devices with improved durability and longer operational lifetimes under mechanical stress conditions.Expand Specific Solutions04 Structural design for improved mechanical performance

Novel structural designs and architectures for hybrid supercapacitors that enhance mechanical properties while maintaining electrochemical performance. These designs include sandwich structures, 3D interconnected networks, hierarchical porous frameworks, and specialized current collector configurations. The structural engineering approaches focus on distributing mechanical stress, preventing crack propagation, and maintaining electrical connectivity during deformation, resulting in mechanically robust energy storage devices.Expand Specific Solutions05 Nanocomposite materials for enhanced mechanical and electrochemical properties

Development of nanocomposite materials that combine different components at the nanoscale to simultaneously enhance mechanical properties and electrochemical performance of hybrid supercapacitors. These nanocomposites often incorporate metal oxide nanoparticles, conductive nanomaterials, and polymer binders in optimized ratios. The nanoscale integration enables synergistic effects that improve tensile strength, flexibility, and resistance to mechanical degradation while maintaining high energy and power density.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The hybrid supercapacitor market is currently in a growth phase, with increasing demand driven by energy storage needs across multiple sectors. Market size is projected to expand significantly due to applications in electric vehicles, renewable energy systems, and consumer electronics. Technologically, the field shows moderate maturity with ongoing innovations in mechanical properties. Leading players include Samsung Electronics and Samsung Electro Mechanics, who leverage their electronics expertise; Nanotech Energy and Nanotek Instruments, focusing on graphene-based solutions; and Robert Bosch GmbH, applying automotive industry knowledge. Academic institutions like University of California and Dalian University of Technology contribute fundamental research, while companies like Shanghai Aowei and State Grid Corp. of China are developing practical applications for grid-scale implementation.

SAMSUNG ELECTRO MECHANICS CO LTD

Technical Solution: Samsung Electro Mechanics has focused on developing hybrid supercapacitors with superior mechanical properties for applications in flexible electronics and wearable devices. Their research centers on creating mechanically robust electrode materials through innovative composite structures combining carbon-based materials with metal oxides and conductive polymers. The company has developed a proprietary "multi-layer composite electrode" technology that distributes mechanical stress throughout the device structure, preventing localized damage during deformation. Their hybrid supercapacitors demonstrate exceptional flexibility, maintaining over 95% capacitance after 20,000 bending cycles at a 3mm radius. Samsung Electro Mechanics has pioneered specialized binder systems that create strong adhesion between active materials while maintaining flexibility and ionic pathways. Their devices show remarkable tensile strength (>35 MPa) and can withstand compressive forces up to 25 MPa without significant performance degradation. The company has also developed specialized solid-state electrolytes that enhance mechanical stability while providing good ionic conductivity across various operating conditions.

Strengths: Exceptional mechanical durability and flexibility; strong material interfaces preventing delamination; advanced manufacturing capabilities for mass production; comprehensive testing protocols. Weaknesses: Trade-off between mechanical properties and energy density; higher production costs compared to conventional supercapacitors; challenges in maintaining consistent performance across large production batches.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has pioneered research on hybrid supercapacitors with enhanced mechanical properties through their patented nano-structured electrode materials. Their approach focuses on creating mechanically robust electrodes using a combination of graphene, carbon nanotubes, and pseudocapacitive materials. The company has developed a unique "sandwich structure" electrode design that distributes mechanical stress evenly throughout the device, preventing localized damage during deformation. Their hybrid supercapacitors demonstrate exceptional tensile strength (>40 MPa) and can withstand compressive forces up to 20 MPa without performance degradation. Nanotek's proprietary binding agents create strong interfaces between active materials and current collectors, addressing a common failure point in conventional supercapacitors. Mechanical testing reveals their devices maintain over 90% capacitance after 5,000 mechanical compression-decompression cycles. The company has also developed specialized electrolytes that maintain stability under mechanical stress while providing high ionic conductivity across a wide temperature range (-40°C to 70°C).

Strengths: Exceptional mechanical durability under various stress conditions; innovative electrode structure that distributes mechanical forces; strong material interfaces that prevent delamination. Weaknesses: Complex manufacturing process requiring precise control of nanomaterials; higher initial cost compared to conventional supercapacitors; challenges in scaling production while maintaining quality control.

Key Patents and Innovations in Mechanical Design

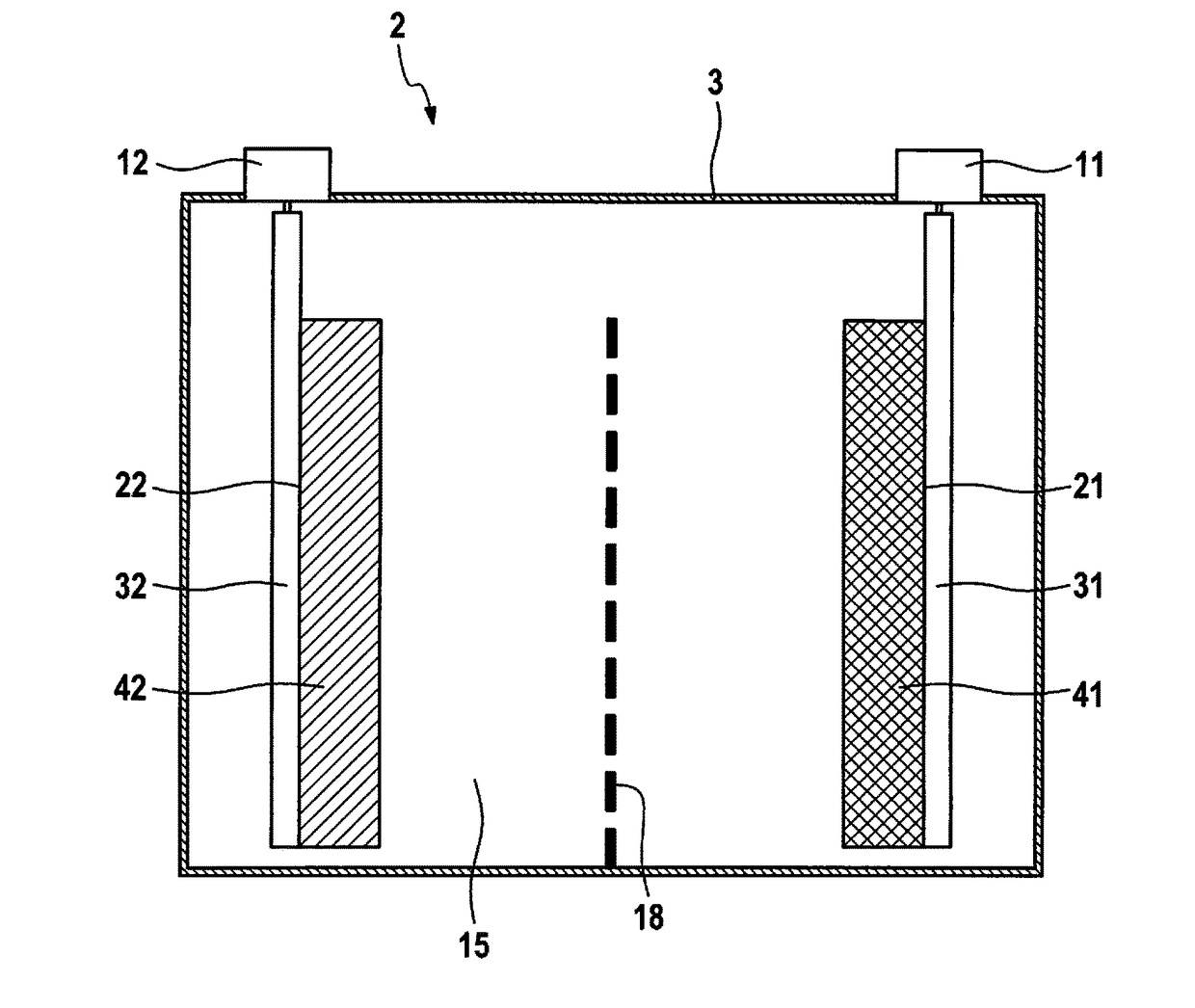

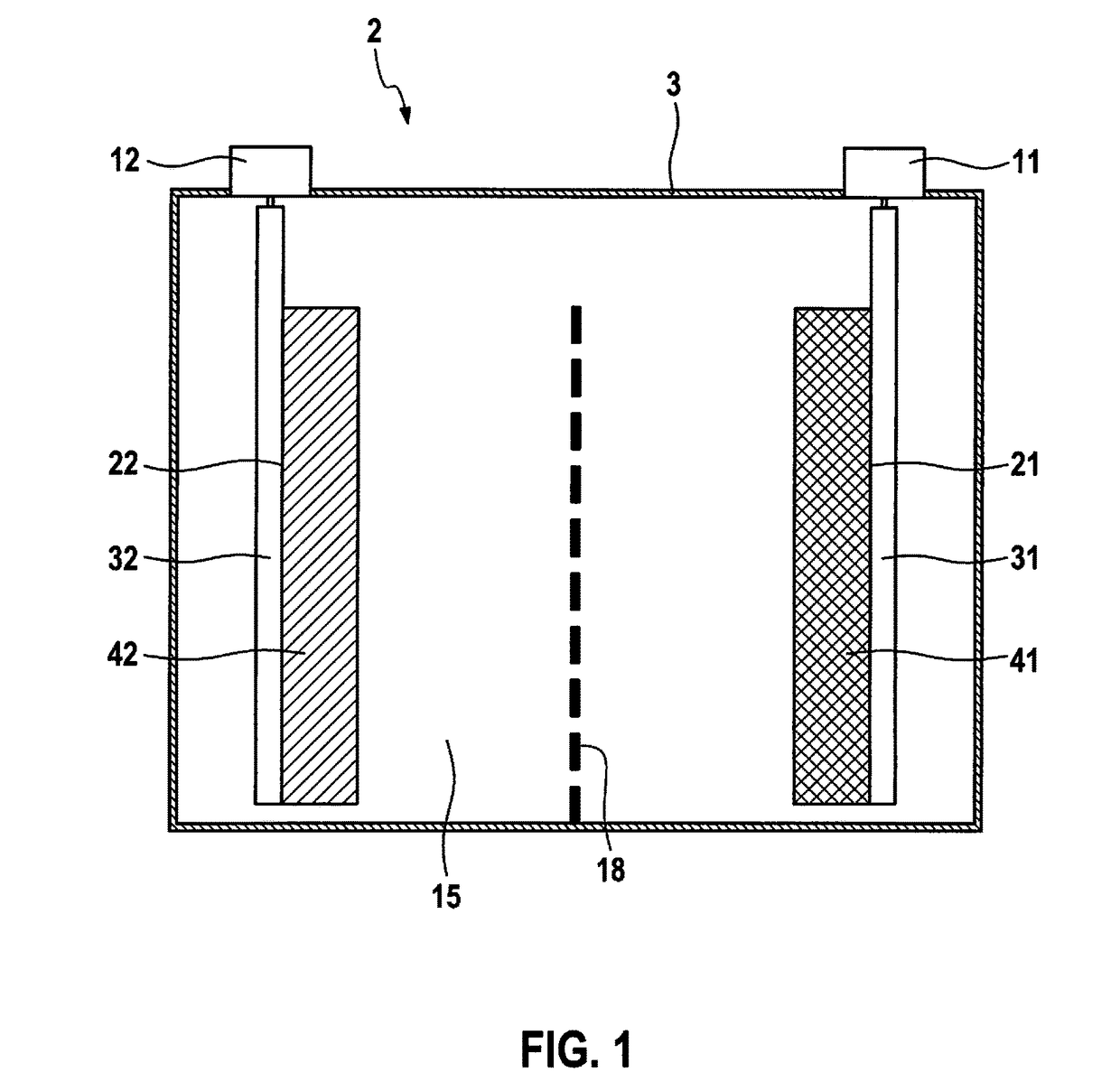

Hybrid supercapacitor, including an electrolyte composition, having improved conductivity

PatentInactiveUS20170352498A1

Innovation

- A hybrid supercapacitor design incorporating a liquid electrolyte composition with aprotic organic solvents, conducting salts, and Lewis acid additives that form complex compounds with anions, enhancing ion solvation and reducing charge density, thereby increasing conductivity.

Hybrid supercapacitor and method of making a hybrid supercapacitor

PatentInactiveDE102018202929A1

Innovation

- A hybrid supercapacitor design using a gel electrolyte formed by mixing a solvent with a polymer to increase viscosity, eliminating the need for liquid solvents and preventing gas formation, while maintaining high energy and power densities.

Materials Science Advancements for Hybrid Supercapacitors

Recent advancements in materials science have significantly propelled the development of hybrid supercapacitors, addressing key challenges in energy storage technology. The integration of novel nanomaterials has revolutionized electrode design, with carbon-based materials like graphene and carbon nanotubes offering exceptional surface area and conductivity properties. These materials demonstrate remarkable mechanical stability under repeated charge-discharge cycles, maintaining structural integrity even after thousands of cycles.

Metal oxide nanostructures, particularly transition metal oxides such as MnO2, NiO, and Co3O4, have emerged as promising pseudocapacitive materials that enhance energy density while maintaining good mechanical resilience. Their incorporation into hybrid systems has led to devices that can withstand mechanical stresses without significant performance degradation.

Polymer-based materials represent another frontier, with conducting polymers like polyaniline and polypyrrole offering flexibility and elasticity that traditional materials lack. These properties are crucial for developing flexible and wearable energy storage devices that can endure bending, twisting, and stretching while maintaining electrochemical performance.

Composite materials combining different material classes have shown synergistic effects, where the mechanical limitations of one component are compensated by the strengths of another. For instance, graphene-metal oxide composites demonstrate improved mechanical durability compared to pure metal oxides, while maintaining high capacitance values.

Advanced characterization techniques have been instrumental in understanding the mechanical behavior of these materials. In-situ TEM, nanoindentation, and atomic force microscopy provide real-time visualization of structural changes during electrochemical cycling, offering insights into failure mechanisms and guiding material optimization strategies.

Hierarchical structures with multi-scale porosity have emerged as a design principle for enhancing both mechanical and electrochemical properties. These structures provide efficient ion transport pathways while distributing mechanical stress more evenly throughout the electrode material, preventing localized damage and extending device lifetime.

Surface modification techniques, including functionalization and coating, have proven effective in improving the interface between different materials, enhancing adhesion and reducing mechanical degradation during cycling. These approaches have been particularly valuable for improving the stability of hybrid systems where materials with different expansion coefficients are combined.

Looking forward, biomimetic approaches inspired by natural structures with exceptional mechanical properties offer promising directions for next-generation supercapacitor materials. Self-healing materials capable of autonomously repairing mechanical damage represent another frontier that could significantly extend device lifetimes in practical applications.

Metal oxide nanostructures, particularly transition metal oxides such as MnO2, NiO, and Co3O4, have emerged as promising pseudocapacitive materials that enhance energy density while maintaining good mechanical resilience. Their incorporation into hybrid systems has led to devices that can withstand mechanical stresses without significant performance degradation.

Polymer-based materials represent another frontier, with conducting polymers like polyaniline and polypyrrole offering flexibility and elasticity that traditional materials lack. These properties are crucial for developing flexible and wearable energy storage devices that can endure bending, twisting, and stretching while maintaining electrochemical performance.

Composite materials combining different material classes have shown synergistic effects, where the mechanical limitations of one component are compensated by the strengths of another. For instance, graphene-metal oxide composites demonstrate improved mechanical durability compared to pure metal oxides, while maintaining high capacitance values.

Advanced characterization techniques have been instrumental in understanding the mechanical behavior of these materials. In-situ TEM, nanoindentation, and atomic force microscopy provide real-time visualization of structural changes during electrochemical cycling, offering insights into failure mechanisms and guiding material optimization strategies.

Hierarchical structures with multi-scale porosity have emerged as a design principle for enhancing both mechanical and electrochemical properties. These structures provide efficient ion transport pathways while distributing mechanical stress more evenly throughout the electrode material, preventing localized damage and extending device lifetime.

Surface modification techniques, including functionalization and coating, have proven effective in improving the interface between different materials, enhancing adhesion and reducing mechanical degradation during cycling. These approaches have been particularly valuable for improving the stability of hybrid systems where materials with different expansion coefficients are combined.

Looking forward, biomimetic approaches inspired by natural structures with exceptional mechanical properties offer promising directions for next-generation supercapacitor materials. Self-healing materials capable of autonomously repairing mechanical damage represent another frontier that could significantly extend device lifetimes in practical applications.

Durability and Lifecycle Assessment Methodologies

The assessment of durability and lifecycle for hybrid supercapacitors requires systematic methodologies that account for their unique mechanical properties. Current industry standards employ accelerated aging tests under controlled temperature and humidity conditions, typically ranging from -40°C to 70°C and 10% to 95% relative humidity respectively. These tests simulate years of operational wear within weeks, providing critical data on performance degradation patterns.

Cycle life testing represents another fundamental methodology, where supercapacitors undergo thousands to millions of charge-discharge cycles at varying current densities. Advanced protocols now incorporate mechanical stress factors during cycling, such as vibration (10-2000 Hz frequency range) and shock resistance (up to 1500g), which are particularly relevant for automotive and aerospace applications where hybrid supercapacitors experience significant mechanical strain.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a non-destructive technique for monitoring internal resistance changes and electrode degradation over time. This method provides valuable insights into the correlation between mechanical integrity and electrochemical performance, enabling researchers to identify failure mechanisms before catastrophic breakdown occurs.

Computational modeling approaches have significantly advanced lifecycle prediction capabilities. Finite Element Analysis (FEA) models now incorporate multi-physics simulations that account for electrochemical, thermal, and mechanical stresses simultaneously. These models can predict stress distribution, potential delamination points, and structural weaknesses under various operational scenarios with increasing accuracy.

Environmental impact assessment methodologies have also evolved to include comprehensive cradle-to-grave analysis. Current best practices evaluate resource consumption, manufacturing energy requirements, operational efficiency, and end-of-life recycling potential. The emerging ISO 14040/14044 framework adaptation specifically for energy storage systems provides standardized metrics for comparing environmental footprints across different supercapacitor technologies.

Recent innovations in in-situ monitoring techniques allow for real-time assessment of mechanical properties during operation. Acoustic emission detection systems can identify microscopic structural changes before they manifest as performance degradation. Similarly, optical strain measurement techniques using specialized coatings provide valuable data on expansion and contraction dynamics during cycling, particularly important for flexible and stretchable hybrid supercapacitor variants.

Standardization efforts by organizations such as IEC, IEEE, and JEDEC have begun addressing the specific requirements of hybrid supercapacitors, though significant gaps remain in harmonizing test protocols across different application domains and ensuring their relevance to emerging material combinations and structural designs.

Cycle life testing represents another fundamental methodology, where supercapacitors undergo thousands to millions of charge-discharge cycles at varying current densities. Advanced protocols now incorporate mechanical stress factors during cycling, such as vibration (10-2000 Hz frequency range) and shock resistance (up to 1500g), which are particularly relevant for automotive and aerospace applications where hybrid supercapacitors experience significant mechanical strain.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a non-destructive technique for monitoring internal resistance changes and electrode degradation over time. This method provides valuable insights into the correlation between mechanical integrity and electrochemical performance, enabling researchers to identify failure mechanisms before catastrophic breakdown occurs.

Computational modeling approaches have significantly advanced lifecycle prediction capabilities. Finite Element Analysis (FEA) models now incorporate multi-physics simulations that account for electrochemical, thermal, and mechanical stresses simultaneously. These models can predict stress distribution, potential delamination points, and structural weaknesses under various operational scenarios with increasing accuracy.

Environmental impact assessment methodologies have also evolved to include comprehensive cradle-to-grave analysis. Current best practices evaluate resource consumption, manufacturing energy requirements, operational efficiency, and end-of-life recycling potential. The emerging ISO 14040/14044 framework adaptation specifically for energy storage systems provides standardized metrics for comparing environmental footprints across different supercapacitor technologies.

Recent innovations in in-situ monitoring techniques allow for real-time assessment of mechanical properties during operation. Acoustic emission detection systems can identify microscopic structural changes before they manifest as performance degradation. Similarly, optical strain measurement techniques using specialized coatings provide valuable data on expansion and contraction dynamics during cycling, particularly important for flexible and stretchable hybrid supercapacitor variants.

Standardization efforts by organizations such as IEC, IEEE, and JEDEC have begun addressing the specific requirements of hybrid supercapacitors, though significant gaps remain in harmonizing test protocols across different application domains and ensuring their relevance to emerging material combinations and structural designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!