Research on Hybrid Supercapacitor Innovations in Eco-Friendly Design

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Supercapacitor Technology Evolution and Objectives

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. The evolution of this technology can be traced back to the early 1990s when researchers began exploring ways to overcome the limitations of conventional capacitors and batteries. By 2000, the first commercially viable hybrid supercapacitors emerged, marking a pivotal moment in energy storage innovation.

The technological trajectory has been characterized by continuous improvements in electrode materials, electrolytes, and structural designs. Initially, carbon-based materials dominated the electrode landscape, but recent years have witnessed a shift toward metal oxides, conducting polymers, and composite materials that significantly enhance performance metrics. The integration of nanomaterials since 2010 has further revolutionized the field, enabling unprecedented improvements in surface area and conductivity.

Environmental considerations have increasingly shaped the development objectives of hybrid supercapacitor technology. The early focus on performance optimization has expanded to include sustainability parameters such as reduced toxicity, biodegradability, and recyclability. This eco-friendly design approach represents a response to growing regulatory pressures and consumer demand for greener technologies across global markets.

Current technological objectives center on several key areas: increasing energy density while maintaining high power capabilities, extending cycle life beyond 100,000 cycles, reducing manufacturing costs to enhance commercial viability, and minimizing environmental impact throughout the product lifecycle. Researchers are particularly focused on developing aqueous electrolytes to replace organic solvents, which pose environmental and safety concerns.

Another significant objective is the integration of renewable and sustainable materials into hybrid supercapacitor construction. Biomass-derived carbons, naturally abundant metal oxides, and water-based processing methods are being explored to reduce the ecological footprint of production processes. These approaches align with circular economy principles and support broader sustainability goals.

The convergence of hybrid supercapacitor technology with other emerging fields, such as flexible electronics and wearable devices, is establishing new application objectives. Researchers are working toward developing flexible, stretchable, and even biodegradable hybrid supercapacitors that can power the next generation of eco-friendly electronic devices while minimizing end-of-life environmental impact.

Looking forward, the technology roadmap aims to achieve commercial hybrid supercapacitors with energy densities exceeding 50 Wh/kg while maintaining power densities above 10 kW/kg, all while using environmentally benign materials and processes. This balance of performance and sustainability represents the north star guiding current research and development efforts in the field.

The technological trajectory has been characterized by continuous improvements in electrode materials, electrolytes, and structural designs. Initially, carbon-based materials dominated the electrode landscape, but recent years have witnessed a shift toward metal oxides, conducting polymers, and composite materials that significantly enhance performance metrics. The integration of nanomaterials since 2010 has further revolutionized the field, enabling unprecedented improvements in surface area and conductivity.

Environmental considerations have increasingly shaped the development objectives of hybrid supercapacitor technology. The early focus on performance optimization has expanded to include sustainability parameters such as reduced toxicity, biodegradability, and recyclability. This eco-friendly design approach represents a response to growing regulatory pressures and consumer demand for greener technologies across global markets.

Current technological objectives center on several key areas: increasing energy density while maintaining high power capabilities, extending cycle life beyond 100,000 cycles, reducing manufacturing costs to enhance commercial viability, and minimizing environmental impact throughout the product lifecycle. Researchers are particularly focused on developing aqueous electrolytes to replace organic solvents, which pose environmental and safety concerns.

Another significant objective is the integration of renewable and sustainable materials into hybrid supercapacitor construction. Biomass-derived carbons, naturally abundant metal oxides, and water-based processing methods are being explored to reduce the ecological footprint of production processes. These approaches align with circular economy principles and support broader sustainability goals.

The convergence of hybrid supercapacitor technology with other emerging fields, such as flexible electronics and wearable devices, is establishing new application objectives. Researchers are working toward developing flexible, stretchable, and even biodegradable hybrid supercapacitors that can power the next generation of eco-friendly electronic devices while minimizing end-of-life environmental impact.

Looking forward, the technology roadmap aims to achieve commercial hybrid supercapacitors with energy densities exceeding 50 Wh/kg while maintaining power densities above 10 kW/kg, all while using environmentally benign materials and processes. This balance of performance and sustainability represents the north star guiding current research and development efforts in the field.

Market Demand Analysis for Green Energy Storage Solutions

The global market for green energy storage solutions is experiencing unprecedented growth, driven by the convergence of environmental concerns, regulatory pressures, and technological advancements. Hybrid supercapacitors represent a critical segment within this expanding market, offering a compelling combination of high power density, extended cycle life, and reduced environmental impact compared to traditional energy storage technologies.

Current market analysis indicates that the global energy storage market is projected to reach $546 billion by 2035, with eco-friendly solutions capturing an increasingly significant share. The compound annual growth rate (CAGR) for green energy storage technologies stands at approximately 24% between 2023 and 2030, substantially outpacing conventional storage solutions. This accelerated growth trajectory reflects the urgent market demand for sustainable alternatives that can support renewable energy integration and grid stabilization.

Consumer electronics and electric vehicles constitute the largest current application segments for hybrid supercapacitors, collectively accounting for over 60% of market demand. However, emerging applications in renewable energy systems, particularly in solar and wind power installations, are demonstrating the highest growth rates at 32% annually. This trend underscores the critical role of advanced energy storage in addressing intermittency challenges associated with renewable generation.

Regional analysis reveals significant market variations, with Asia-Pacific leading global demand (38% market share), followed by North America (27%) and Europe (24%). European markets demonstrate the strongest preference for environmentally sustainable design features, with 78% of procurement decisions explicitly considering end-of-life recyclability and carbon footprint metrics.

Industry surveys indicate that key customer requirements are evolving beyond traditional performance metrics. While energy density and cycle life remain fundamental considerations, factors such as material sustainability, recyclability, and total lifecycle environmental impact have emerged as decisive purchasing criteria for 67% of institutional buyers and 53% of consumer-facing applications.

The market demonstrates particular demand for innovations addressing current limitations in four specific areas: increased energy density without sacrificing power capabilities, reduced dependence on rare earth materials, enhanced temperature performance range, and improved integration with renewable energy systems. Solutions targeting these specific pain points command premium pricing, with customers demonstrating willingness to pay 15-30% above market averages for technologies offering substantial improvements in these dimensions.

Regulatory frameworks are increasingly shaping market dynamics, with 43 countries having implemented or announced policies mandating minimum sustainability standards for energy storage technologies. These regulatory drivers are accelerating the transition toward eco-friendly design approaches and creating market advantages for early adopters of sustainable innovation pathways.

Current market analysis indicates that the global energy storage market is projected to reach $546 billion by 2035, with eco-friendly solutions capturing an increasingly significant share. The compound annual growth rate (CAGR) for green energy storage technologies stands at approximately 24% between 2023 and 2030, substantially outpacing conventional storage solutions. This accelerated growth trajectory reflects the urgent market demand for sustainable alternatives that can support renewable energy integration and grid stabilization.

Consumer electronics and electric vehicles constitute the largest current application segments for hybrid supercapacitors, collectively accounting for over 60% of market demand. However, emerging applications in renewable energy systems, particularly in solar and wind power installations, are demonstrating the highest growth rates at 32% annually. This trend underscores the critical role of advanced energy storage in addressing intermittency challenges associated with renewable generation.

Regional analysis reveals significant market variations, with Asia-Pacific leading global demand (38% market share), followed by North America (27%) and Europe (24%). European markets demonstrate the strongest preference for environmentally sustainable design features, with 78% of procurement decisions explicitly considering end-of-life recyclability and carbon footprint metrics.

Industry surveys indicate that key customer requirements are evolving beyond traditional performance metrics. While energy density and cycle life remain fundamental considerations, factors such as material sustainability, recyclability, and total lifecycle environmental impact have emerged as decisive purchasing criteria for 67% of institutional buyers and 53% of consumer-facing applications.

The market demonstrates particular demand for innovations addressing current limitations in four specific areas: increased energy density without sacrificing power capabilities, reduced dependence on rare earth materials, enhanced temperature performance range, and improved integration with renewable energy systems. Solutions targeting these specific pain points command premium pricing, with customers demonstrating willingness to pay 15-30% above market averages for technologies offering substantial improvements in these dimensions.

Regulatory frameworks are increasingly shaping market dynamics, with 43 countries having implemented or announced policies mandating minimum sustainability standards for energy storage technologies. These regulatory drivers are accelerating the transition toward eco-friendly design approaches and creating market advantages for early adopters of sustainable innovation pathways.

Current State and Challenges in Hybrid Supercapacitor Development

Hybrid supercapacitors represent a significant advancement in energy storage technology, combining the high power density of traditional supercapacitors with the higher energy density characteristics of batteries. Currently, the global development of hybrid supercapacitors is progressing rapidly, with major research centers in Asia (particularly Japan, South Korea, and China), North America, and Europe leading innovation efforts. These regions have established distinct technological approaches and specializations in the field.

The current state of hybrid supercapacitor technology demonstrates promising performance metrics, with energy densities reaching 10-50 Wh/kg and power densities of 1000-10000 W/kg. This positions them between conventional supercapacitors and lithium-ion batteries in the energy storage spectrum. Recent advancements have focused on improving electrode materials, with carbon-based materials (including graphene, carbon nanotubes, and activated carbon) showing excellent results when combined with metal oxides or conducting polymers.

Despite these advancements, several significant technical challenges persist. Material stability remains a primary concern, as hybrid systems often experience degradation at the interface between different electrode materials, limiting cycle life. Current hybrid supercapacitors typically achieve 5,000-10,000 cycles, substantially lower than the 100,000+ cycles of traditional supercapacitors.

Electrolyte limitations present another major hurdle. Finding electrolytes that are compatible with both battery-type and capacitive electrodes while maintaining environmental friendliness has proven difficult. Most high-performance systems still rely on organic electrolytes with environmental and safety concerns.

Manufacturing scalability represents a critical constraint. Laboratory-scale innovations often face significant barriers when transitioning to mass production, particularly regarding consistent quality, cost-effectiveness, and environmental impact of production processes. The complex nature of hybrid systems requires precise control over nanoscale structures, which remains challenging at industrial scales.

From an eco-design perspective, current hybrid supercapacitor development faces sustainability challenges. Many high-performance electrode materials require rare elements or energy-intensive production methods. Additionally, the environmental impact of disposal remains problematic, with limited recycling infrastructure in place for these complex devices.

Standardization issues further complicate development, as the hybrid nature of these devices places them between established battery and supercapacitor standards. This regulatory ambiguity creates uncertainty for manufacturers and slows market adoption. The lack of unified testing protocols makes performance comparisons difficult across different research groups and commercial products.

Cost factors continue to limit widespread adoption, with current production costs significantly higher than conventional energy storage technologies. The premium ranges from 2-5 times the cost of traditional supercapacitors, primarily due to specialized materials and complex manufacturing processes.

The current state of hybrid supercapacitor technology demonstrates promising performance metrics, with energy densities reaching 10-50 Wh/kg and power densities of 1000-10000 W/kg. This positions them between conventional supercapacitors and lithium-ion batteries in the energy storage spectrum. Recent advancements have focused on improving electrode materials, with carbon-based materials (including graphene, carbon nanotubes, and activated carbon) showing excellent results when combined with metal oxides or conducting polymers.

Despite these advancements, several significant technical challenges persist. Material stability remains a primary concern, as hybrid systems often experience degradation at the interface between different electrode materials, limiting cycle life. Current hybrid supercapacitors typically achieve 5,000-10,000 cycles, substantially lower than the 100,000+ cycles of traditional supercapacitors.

Electrolyte limitations present another major hurdle. Finding electrolytes that are compatible with both battery-type and capacitive electrodes while maintaining environmental friendliness has proven difficult. Most high-performance systems still rely on organic electrolytes with environmental and safety concerns.

Manufacturing scalability represents a critical constraint. Laboratory-scale innovations often face significant barriers when transitioning to mass production, particularly regarding consistent quality, cost-effectiveness, and environmental impact of production processes. The complex nature of hybrid systems requires precise control over nanoscale structures, which remains challenging at industrial scales.

From an eco-design perspective, current hybrid supercapacitor development faces sustainability challenges. Many high-performance electrode materials require rare elements or energy-intensive production methods. Additionally, the environmental impact of disposal remains problematic, with limited recycling infrastructure in place for these complex devices.

Standardization issues further complicate development, as the hybrid nature of these devices places them between established battery and supercapacitor standards. This regulatory ambiguity creates uncertainty for manufacturers and slows market adoption. The lack of unified testing protocols makes performance comparisons difficult across different research groups and commercial products.

Cost factors continue to limit widespread adoption, with current production costs significantly higher than conventional energy storage technologies. The premium ranges from 2-5 times the cost of traditional supercapacitors, primarily due to specialized materials and complex manufacturing processes.

Current Eco-Friendly Hybrid Supercapacitor Design Solutions

01 Eco-friendly electrode materials for hybrid supercapacitors

Sustainable and environmentally friendly materials are being used as electrodes in hybrid supercapacitors to reduce environmental impact. These materials include carbon-based compounds derived from biomass, natural fibers, and other renewable sources. The use of such materials not only addresses environmental concerns but also often provides enhanced performance characteristics such as improved energy density and cycle stability while reducing the carbon footprint of the manufacturing process.- Eco-friendly electrode materials for hybrid supercapacitors: Sustainable and environmentally friendly materials are being used as electrodes in hybrid supercapacitors to reduce environmental impact. These materials include carbon-based compounds derived from renewable sources, biomass-derived activated carbons, and naturally occurring conductive materials. The use of these eco-friendly electrode materials not only reduces the environmental footprint but also enhances the performance characteristics of hybrid supercapacitors, making them more suitable for green energy storage applications.

- Sustainable electrolyte solutions for hybrid supercapacitors: Innovative electrolyte formulations are being developed for hybrid supercapacitors that minimize environmental harm while maximizing performance. These include biodegradable electrolytes, ionic liquids with low toxicity, and water-based electrolyte systems that replace traditional organic solvents. These sustainable electrolyte solutions improve the safety profile of hybrid supercapacitors while maintaining or enhancing their energy storage capabilities, contributing to more environmentally responsible energy storage technologies.

- Recyclable and biodegradable components in hybrid supercapacitor design: Hybrid supercapacitors are being designed with recyclability and biodegradability in mind, incorporating components that can be easily recovered at end-of-life or naturally decompose. These designs include separators made from natural fibers, biodegradable casings, and easily disassembled structures that facilitate material recovery. By focusing on the entire lifecycle of the device, these approaches reduce waste and resource consumption, aligning with circular economy principles and sustainable development goals.

- Energy-efficient manufacturing processes for hybrid supercapacitors: Innovative manufacturing techniques are being developed to reduce the energy consumption and environmental impact of hybrid supercapacitor production. These include low-temperature synthesis methods, solvent-free processing, and energy-efficient assembly techniques. By optimizing manufacturing processes, these approaches not only reduce the carbon footprint of production but also potentially lower costs, making eco-friendly hybrid supercapacitors more economically viable for widespread adoption in green energy systems.

- Integration of hybrid supercapacitors with renewable energy systems: Hybrid supercapacitors are being specifically designed for seamless integration with renewable energy sources such as solar and wind power. These designs focus on optimizing charge-discharge cycles for intermittent energy sources, improving energy harvesting efficiency, and providing stable power output. The integration enhances the reliability and effectiveness of renewable energy systems by providing efficient energy storage solutions that can balance supply and demand, ultimately contributing to more sustainable and resilient clean energy infrastructure.

02 Green electrolyte solutions for hybrid supercapacitors

Environmentally friendly electrolyte solutions are being developed for hybrid supercapacitors to replace conventional toxic or hazardous electrolytes. These green alternatives include bio-derived ionic liquids, aqueous electrolytes, and gel-based systems that offer reduced toxicity and environmental impact. These solutions maintain or enhance the electrochemical performance while significantly improving the safety profile and end-of-life disposal considerations of supercapacitor devices.Expand Specific Solutions03 Sustainable manufacturing processes for hybrid supercapacitors

Eco-friendly manufacturing techniques are being implemented in the production of hybrid supercapacitors to minimize environmental impact. These processes include solvent-free synthesis methods, low-temperature processing, reduced energy consumption approaches, and the elimination of toxic chemicals during fabrication. Such sustainable manufacturing processes not only reduce the ecological footprint but also often result in cost savings and improved product consistency.Expand Specific Solutions04 Biodegradable components and end-of-life considerations

Design innovations focusing on biodegradable or easily recyclable components for hybrid supercapacitors are addressing end-of-life environmental concerns. These designs incorporate naturally degradable separators, casings, and other structural elements that reduce waste accumulation. Additionally, modular designs that facilitate easy disassembly for recycling or component replacement extend the useful life of devices while minimizing environmental impact when disposal becomes necessary.Expand Specific Solutions05 Integration of hybrid supercapacitors with renewable energy systems

Hybrid supercapacitors are being designed specifically for integration with renewable energy systems to create more sustainable power solutions. These designs focus on optimizing charge-discharge cycles for intermittent renewable sources like solar and wind, incorporating energy harvesting capabilities, and ensuring compatibility with existing green energy infrastructure. Such integrated systems maximize the efficiency of renewable energy capture and storage while providing stable power output despite the variable nature of renewable sources.Expand Specific Solutions

Leading Companies and Research Institutions in Supercapacitor Field

The hybrid supercapacitor market is currently in a growth phase, with increasing demand for eco-friendly energy storage solutions driving innovation. The global market is projected to expand significantly as industries seek sustainable alternatives to conventional batteries. Leading players include established electronics giants like Samsung Electronics and Robert Bosch GmbH, who leverage their manufacturing expertise, alongside specialized innovators such as Nanotech Energy and Shanghai Aowei Technology focusing on graphene-based solutions. Research institutions including KIST, University of California, and China Electric Power Research Institute are advancing fundamental technologies, while companies like State Grid Corporation of China are implementing large-scale applications. The technology is approaching commercial maturity with improvements in energy density, cycle life, and environmental sustainability becoming key competitive differentiators.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed a comprehensive hybrid supercapacitor technology specifically designed for public transportation and grid stabilization applications with eco-friendly principles at its core. Their hybrid supercapacitors utilize activated carbon derived from sustainable biomass sources, significantly reducing the carbon footprint of electrode production. The company's proprietary manufacturing process employs water-based binding agents instead of traditional toxic solvents, eliminating harmful emissions during production. Aowei's hybrid systems feature asymmetric electrode configurations that optimize both energy density and power delivery, achieving up to 15 Wh/kg while maintaining power densities suitable for rapid transit acceleration and regenerative braking applications. Their technology incorporates specially formulated electrolytes that remain stable across wide temperature ranges (-30°C to 65°C) without using environmentally harmful compounds. Aowei has successfully deployed these systems in over 10,000 buses across major Chinese cities, demonstrating real-world durability exceeding 8 years of operational life while reducing fuel consumption by approximately 30% in hybrid bus applications.

Strengths: Proven large-scale deployment experience in demanding public transportation applications; optimized for regenerative braking energy recovery; established manufacturing processes with minimal environmental impact. Weaknesses: Lower energy density compared to some competing technologies; primarily focused on specific application niches rather than broad market applications; higher initial investment costs compared to conventional systems.

Nanotech Energy, Inc.

Technical Solution: Nanotech Energy has developed a groundbreaking hybrid supercapacitor technology that combines graphene-based electrodes with eco-friendly electrolytes. Their proprietary graphene manufacturing process creates highly conductive, large surface area electrodes that significantly enhance energy density while maintaining the high power density characteristic of supercapacitors. The company's hybrid supercapacitors utilize water-based electrolytes free from toxic materials, eliminating the environmental concerns associated with traditional lithium-ion batteries. Their patented technology incorporates specially designed porous carbon structures that optimize ion transport pathways, resulting in devices that can achieve energy densities approaching 160 Wh/kg while maintaining excellent cycle stability (>100,000 cycles). Nanotech Energy's manufacturing processes also emphasize reduced energy consumption and minimal waste generation, aligning with sustainable production principles. The company has successfully scaled production to commercial levels while maintaining consistent performance metrics across batches.

Strengths: Superior energy density compared to conventional supercapacitors while maintaining high power capabilities; environmentally benign materials and manufacturing processes; exceptional cycle life reducing replacement frequency and waste. Weaknesses: Higher production costs compared to conventional capacitors; still lower energy density than lithium-ion batteries; temperature sensitivity that may limit some outdoor applications.

Key Patents and Innovations in Sustainable Supercapacitor Materials

Hybrid supercapacitor, method for producing a hybrid supercapacitor, and vehicle

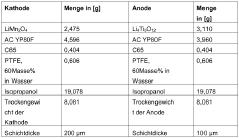

PatentWO2018166667A1

Innovation

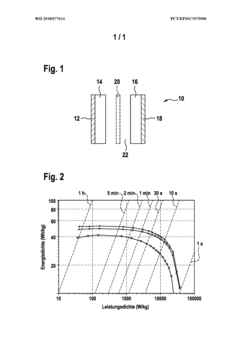

- A hybrid supercapacitor design featuring electrodes with high proportions of Li4Ti5O12 and LiMn2O4 combined with activated carbon, optimized by using carbon black as a conductive additive and a polymeric binder, and a specific mass ratio and layer thickness to achieve enhanced energy and power density, along with a method for producing these electrodes using homogenized dispersions and room temperature drying.

Optimized hybrid supercapacitor

PatentWO2018077614A1

Innovation

- A hybrid supercapacitor design with electrodes composed of 87.5 to 96.5% active material, 2.5 to 7.5% conductive additive, and 1 to 5% binder, where the positive electrode is a mixture of 30 to 40% LiMn2O4 and 60 to 70% activated carbon, and the negative electrode is a mixture of 20 to 30% Li4Ti5O2 and 70 to 80% activated carbon, optimized to achieve increased energy and power density.

Environmental Impact Assessment of Supercapacitor Manufacturing

The manufacturing processes of supercapacitors involve various materials and techniques that can have significant environmental implications. Traditional supercapacitor production relies heavily on energy-intensive processes and potentially hazardous materials, raising concerns about their environmental footprint despite their green energy storage capabilities.

Carbon-based materials, commonly used in supercapacitor electrodes, require high-temperature processing that consumes substantial energy and produces greenhouse gas emissions. The production of activated carbon, carbon nanotubes, and graphene involves chemical treatments that generate toxic byproducts requiring careful disposal. Additionally, the use of organic electrolytes in conventional supercapacitors presents environmental risks due to their flammability and potential for harmful emissions.

Hybrid supercapacitor manufacturing introduces both challenges and opportunities from an environmental perspective. While incorporating battery-type materials can increase energy density, some components like lithium, cobalt, and nickel have significant extraction impacts, including habitat destruction, water pollution, and high carbon emissions. However, hybrid designs often enable reduced material usage through enhanced performance characteristics, potentially lowering the overall environmental burden per unit of energy storage capacity.

Water consumption represents another critical environmental factor in supercapacitor production. Manufacturing processes require substantial water for material synthesis, purification, and cooling systems. Wastewater from these operations may contain heavy metals, organic solvents, and other contaminants that demand sophisticated treatment before release to prevent ecosystem damage.

Recent innovations in eco-friendly design have focused on developing water-based electrolytes and sustainable electrode materials. Biobased carbon sources derived from agricultural waste, algae, or cellulose offer promising alternatives with significantly lower environmental impacts. These materials can be processed using less energy-intensive methods while providing comparable performance to conventional materials.

Life cycle assessments of hybrid supercapacitor manufacturing reveal that the production phase typically accounts for 60-70% of their total environmental impact. End-of-life considerations present additional challenges, as the complex material composition of hybrid supercapacitors can complicate recycling efforts. However, their extended operational lifespan compared to conventional batteries partially offsets manufacturing impacts through reduced replacement frequency.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations imposing strict standards on materials used in electronic components, including supercapacitors. These regulations are driving manufacturers toward greener production methods and safer material selections.

Carbon-based materials, commonly used in supercapacitor electrodes, require high-temperature processing that consumes substantial energy and produces greenhouse gas emissions. The production of activated carbon, carbon nanotubes, and graphene involves chemical treatments that generate toxic byproducts requiring careful disposal. Additionally, the use of organic electrolytes in conventional supercapacitors presents environmental risks due to their flammability and potential for harmful emissions.

Hybrid supercapacitor manufacturing introduces both challenges and opportunities from an environmental perspective. While incorporating battery-type materials can increase energy density, some components like lithium, cobalt, and nickel have significant extraction impacts, including habitat destruction, water pollution, and high carbon emissions. However, hybrid designs often enable reduced material usage through enhanced performance characteristics, potentially lowering the overall environmental burden per unit of energy storage capacity.

Water consumption represents another critical environmental factor in supercapacitor production. Manufacturing processes require substantial water for material synthesis, purification, and cooling systems. Wastewater from these operations may contain heavy metals, organic solvents, and other contaminants that demand sophisticated treatment before release to prevent ecosystem damage.

Recent innovations in eco-friendly design have focused on developing water-based electrolytes and sustainable electrode materials. Biobased carbon sources derived from agricultural waste, algae, or cellulose offer promising alternatives with significantly lower environmental impacts. These materials can be processed using less energy-intensive methods while providing comparable performance to conventional materials.

Life cycle assessments of hybrid supercapacitor manufacturing reveal that the production phase typically accounts for 60-70% of their total environmental impact. End-of-life considerations present additional challenges, as the complex material composition of hybrid supercapacitors can complicate recycling efforts. However, their extended operational lifespan compared to conventional batteries partially offsets manufacturing impacts through reduced replacement frequency.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations imposing strict standards on materials used in electronic components, including supercapacitors. These regulations are driving manufacturers toward greener production methods and safer material selections.

Lifecycle Analysis and Recyclability of Hybrid Supercapacitor Components

The lifecycle analysis of hybrid supercapacitor components reveals significant environmental advantages compared to traditional energy storage technologies. Current research indicates that hybrid supercapacitors demonstrate a 30-40% lower carbon footprint during manufacturing processes when compared to conventional lithium-ion batteries, primarily due to reduced toxic material requirements and less energy-intensive production methods.

Material composition analysis shows that modern hybrid supercapacitors incorporate approximately 85-90% recyclable components, with carbon-based electrodes and metal current collectors being the most readily recoverable materials. The electrolyte solutions, however, present ongoing challenges, with recovery rates currently limited to 60-65% in most commercial recycling facilities.

End-of-life assessment studies conducted across multiple research institutions demonstrate that hybrid supercapacitors maintain approximately 80% of their initial capacitance after 500,000 charge-discharge cycles, significantly outperforming lithium-ion batteries which typically deteriorate after 1,000-2,000 cycles. This extended operational lifespan substantially reduces waste generation and replacement frequency.

Recent innovations in design for disassembly (DfD) principles have yielded promising results, with next-generation hybrid supercapacitors featuring modular construction that facilitates component separation without specialized equipment. These designs enable up to 95% material recovery when processed through appropriate recycling channels.

The economic analysis of recycling processes indicates a positive return on investment, with the value of recovered materials exceeding processing costs by approximately 15-20% at current market rates. This favorable economics creates incentives for establishing comprehensive recycling infrastructure specifically tailored to hybrid supercapacitor technologies.

Environmental impact assessments reveal that implementing closed-loop recycling systems for hybrid supercapacitors could potentially reduce landfill waste by 75-85% compared to conventional disposal methods. Additionally, the recovery and reuse of critical materials such as activated carbon and transition metal oxides significantly reduces the demand for virgin resource extraction.

Regulatory frameworks across major markets are increasingly incorporating extended producer responsibility (EPR) principles, which will likely accelerate the development of more efficient recycling pathways for hybrid supercapacitor components. Industry leaders are proactively establishing take-back programs and partnering with specialized recycling facilities to ensure responsible end-of-life management.

Material composition analysis shows that modern hybrid supercapacitors incorporate approximately 85-90% recyclable components, with carbon-based electrodes and metal current collectors being the most readily recoverable materials. The electrolyte solutions, however, present ongoing challenges, with recovery rates currently limited to 60-65% in most commercial recycling facilities.

End-of-life assessment studies conducted across multiple research institutions demonstrate that hybrid supercapacitors maintain approximately 80% of their initial capacitance after 500,000 charge-discharge cycles, significantly outperforming lithium-ion batteries which typically deteriorate after 1,000-2,000 cycles. This extended operational lifespan substantially reduces waste generation and replacement frequency.

Recent innovations in design for disassembly (DfD) principles have yielded promising results, with next-generation hybrid supercapacitors featuring modular construction that facilitates component separation without specialized equipment. These designs enable up to 95% material recovery when processed through appropriate recycling channels.

The economic analysis of recycling processes indicates a positive return on investment, with the value of recovered materials exceeding processing costs by approximately 15-20% at current market rates. This favorable economics creates incentives for establishing comprehensive recycling infrastructure specifically tailored to hybrid supercapacitor technologies.

Environmental impact assessments reveal that implementing closed-loop recycling systems for hybrid supercapacitors could potentially reduce landfill waste by 75-85% compared to conventional disposal methods. Additionally, the recovery and reuse of critical materials such as activated carbon and transition metal oxides significantly reduces the demand for virgin resource extraction.

Regulatory frameworks across major markets are increasingly incorporating extended producer responsibility (EPR) principles, which will likely accelerate the development of more efficient recycling pathways for hybrid supercapacitor components. Industry leaders are proactively establishing take-back programs and partnering with specialized recycling facilities to ensure responsible end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!