Analysis of Mechanical Properties of Silver Nanowire Coatings

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Background and Research Objectives

Silver nanowires (AgNWs) have emerged as a revolutionary material in the field of transparent conductive films over the past decade. Initially developed in the early 2000s, these one-dimensional nanostructures typically measure 30-200 nm in diameter and 5-100 μm in length, offering exceptional electrical conductivity comparable to bulk silver while maintaining optical transparency when formed into networks. The evolution of AgNW technology has accelerated significantly since 2010, with major breakthroughs in synthesis methods enabling precise control over nanowire dimensions and properties.

The mechanical properties of AgNW coatings represent a critical yet underexplored dimension of their technological potential. While extensive research has focused on their electrical and optical characteristics, understanding their mechanical behavior is essential for ensuring reliability in flexible and stretchable electronics applications. Recent market trends indicate a growing demand for bendable displays, wearable devices, and flexible solar cells, all of which require conductive materials that can withstand repeated mechanical deformation without performance degradation.

Current research objectives in this field center on comprehensively characterizing the mechanical behavior of AgNW networks under various strain conditions. This includes investigating the elastic limit, yield strength, and fatigue resistance of these coatings when subjected to tensile, compressive, and torsional forces. Additionally, there is significant interest in understanding the relationship between nanowire morphology (diameter, length, aspect ratio) and the resulting mechanical properties of the network.

The technological trajectory suggests that AgNW coatings will play an increasingly important role in next-generation flexible electronics. However, several challenges remain, including the need for standardized testing protocols for mechanical properties and improved understanding of failure mechanisms at the nanoscale. Research is also focusing on enhancing the adhesion between nanowires and various substrate materials, as interface mechanics significantly influence overall coating durability.

Our technical objectives for this investigation include: quantifying the mechanical limits of AgNW coatings across different substrate materials; establishing correlations between synthesis parameters and mechanical performance; developing predictive models for mechanical behavior under complex deformation scenarios; and identifying optimal design parameters for maximizing both electrical conductivity and mechanical resilience in practical applications.

This research aims to bridge the gap between laboratory demonstrations and commercial implementation by addressing key mechanical reliability concerns that currently limit widespread adoption of AgNW technology in consumer electronics and other high-value applications.

The mechanical properties of AgNW coatings represent a critical yet underexplored dimension of their technological potential. While extensive research has focused on their electrical and optical characteristics, understanding their mechanical behavior is essential for ensuring reliability in flexible and stretchable electronics applications. Recent market trends indicate a growing demand for bendable displays, wearable devices, and flexible solar cells, all of which require conductive materials that can withstand repeated mechanical deformation without performance degradation.

Current research objectives in this field center on comprehensively characterizing the mechanical behavior of AgNW networks under various strain conditions. This includes investigating the elastic limit, yield strength, and fatigue resistance of these coatings when subjected to tensile, compressive, and torsional forces. Additionally, there is significant interest in understanding the relationship between nanowire morphology (diameter, length, aspect ratio) and the resulting mechanical properties of the network.

The technological trajectory suggests that AgNW coatings will play an increasingly important role in next-generation flexible electronics. However, several challenges remain, including the need for standardized testing protocols for mechanical properties and improved understanding of failure mechanisms at the nanoscale. Research is also focusing on enhancing the adhesion between nanowires and various substrate materials, as interface mechanics significantly influence overall coating durability.

Our technical objectives for this investigation include: quantifying the mechanical limits of AgNW coatings across different substrate materials; establishing correlations between synthesis parameters and mechanical performance; developing predictive models for mechanical behavior under complex deformation scenarios; and identifying optimal design parameters for maximizing both electrical conductivity and mechanical resilience in practical applications.

This research aims to bridge the gap between laboratory demonstrations and commercial implementation by addressing key mechanical reliability concerns that currently limit widespread adoption of AgNW technology in consumer electronics and other high-value applications.

Market Applications and Demand Analysis

Silver nanowire (AgNW) coatings have emerged as a critical technology in various high-value markets, with global demand projected to reach $1.2 billion by 2025, growing at a CAGR of 16.4%. The exceptional mechanical properties of these coatings, including flexibility, stretchability, and durability, have positioned them as superior alternatives to traditional transparent conductive materials like indium tin oxide (ITO).

The consumer electronics sector represents the largest market for AgNW coatings, accounting for approximately 45% of total demand. Manufacturers of smartphones, tablets, and touchscreen displays increasingly require materials that can withstand repeated bending and folding while maintaining electrical conductivity. The rise of foldable and flexible display technologies has accelerated this demand, with major manufacturers seeking solutions that can endure over 200,000 folding cycles without performance degradation.

The automotive industry has become the fastest-growing application sector, with demand increasing by 22% annually. Advanced driver-assistance systems (ADAS), heads-up displays, and smart windows require transparent conductive materials with superior mechanical resilience to withstand vibration, temperature fluctuations, and potential impact. AgNW coatings' ability to maintain performance under these conditions while offering weight reduction compared to traditional solutions drives this growth.

Photovoltaic applications represent another significant market segment, particularly in flexible and building-integrated solar panels. The mechanical durability of AgNW coatings enables the development of solar technologies that can conform to curved surfaces or be integrated into textiles, expanding the potential installation environments beyond traditional rigid panels.

Healthcare applications are emerging as a promising growth area, with wearable medical devices and biosensors benefiting from AgNW coatings' combination of electrical conductivity and mechanical flexibility. These properties enable the development of devices that can conform to body contours while withstanding the stresses of daily wear.

Market research indicates that customers across these sectors prioritize three key mechanical properties: adhesion strength to substrates, resistance to environmental factors (humidity, temperature cycling), and maintenance of electrical performance under mechanical stress. Products demonstrating superior performance in these areas command premium pricing, with customers willing to pay 30-40% more compared to alternatives with inferior mechanical properties.

Regional analysis shows Asia-Pacific dominating manufacturing demand (58%), followed by North America (22%) and Europe (17%). However, research and development activities remain concentrated in North America and Europe, where specialized applications requiring custom mechanical properties are being developed for aerospace, defense, and next-generation medical devices.

The consumer electronics sector represents the largest market for AgNW coatings, accounting for approximately 45% of total demand. Manufacturers of smartphones, tablets, and touchscreen displays increasingly require materials that can withstand repeated bending and folding while maintaining electrical conductivity. The rise of foldable and flexible display technologies has accelerated this demand, with major manufacturers seeking solutions that can endure over 200,000 folding cycles without performance degradation.

The automotive industry has become the fastest-growing application sector, with demand increasing by 22% annually. Advanced driver-assistance systems (ADAS), heads-up displays, and smart windows require transparent conductive materials with superior mechanical resilience to withstand vibration, temperature fluctuations, and potential impact. AgNW coatings' ability to maintain performance under these conditions while offering weight reduction compared to traditional solutions drives this growth.

Photovoltaic applications represent another significant market segment, particularly in flexible and building-integrated solar panels. The mechanical durability of AgNW coatings enables the development of solar technologies that can conform to curved surfaces or be integrated into textiles, expanding the potential installation environments beyond traditional rigid panels.

Healthcare applications are emerging as a promising growth area, with wearable medical devices and biosensors benefiting from AgNW coatings' combination of electrical conductivity and mechanical flexibility. These properties enable the development of devices that can conform to body contours while withstanding the stresses of daily wear.

Market research indicates that customers across these sectors prioritize three key mechanical properties: adhesion strength to substrates, resistance to environmental factors (humidity, temperature cycling), and maintenance of electrical performance under mechanical stress. Products demonstrating superior performance in these areas command premium pricing, with customers willing to pay 30-40% more compared to alternatives with inferior mechanical properties.

Regional analysis shows Asia-Pacific dominating manufacturing demand (58%), followed by North America (22%) and Europe (17%). However, research and development activities remain concentrated in North America and Europe, where specialized applications requiring custom mechanical properties are being developed for aerospace, defense, and next-generation medical devices.

Current Challenges in Nanowire Mechanical Properties

Despite significant advancements in silver nanowire (AgNW) coating technology, several critical challenges persist in understanding and optimizing their mechanical properties. The inherent fragility of nanowire networks represents a fundamental obstacle, as these structures are prone to breakage under mechanical stress. When AgNW coatings are subjected to bending, stretching, or folding—essential requirements for flexible electronics—the nanowires often fracture at junction points, leading to increased electrical resistance and eventual device failure.

Surface adhesion presents another significant challenge, as silver nanowires typically exhibit poor adhesion to various substrate materials. This weak interfacial bonding results in nanowire delamination during mechanical deformation, severely compromising the coating's durability and functional longevity. Current adhesion enhancement methods often introduce trade-offs between mechanical robustness and electrical conductivity.

The junction resistance between individual nanowires constitutes a critical mechanical-electrical challenge. These junctions are particularly vulnerable to mechanical stress, with even minor deformation potentially disrupting the electrical pathways throughout the network. The mechanical stability of these junctions directly impacts the overall electrical performance of AgNW coatings under dynamic conditions.

Environmental factors further complicate the mechanical property landscape. Silver nanowires are susceptible to oxidation and sulfidation, processes that not only degrade electrical conductivity but also compromise mechanical integrity. Protective measures must balance environmental stability with preserved flexibility and conductivity—a complex engineering challenge that remains incompletely resolved.

Scalable manufacturing introduces additional mechanical challenges. Techniques that produce mechanically robust AgNW coatings in laboratory settings often encounter significant hurdles during industrial scale-up. Maintaining consistent mechanical properties across large-area coatings remains problematic, with edge effects and thickness variations introducing mechanical weak points.

Characterization methodologies for mechanical properties present their own set of challenges. Current techniques often provide incomplete information about nanowire network behavior under complex deformation scenarios. In-situ measurement of mechanical properties during device operation remains particularly difficult, limiting our understanding of failure mechanisms in real-world applications.

The integration of silver nanowire coatings with other materials in multilayer device architectures introduces interfacial stress and strain incompatibilities. These mechanical mismatches can lead to premature failure, particularly during thermal cycling or mechanical deformation, highlighting the need for comprehensive mechanical engineering approaches that consider the entire device structure rather than isolated coating properties.

Surface adhesion presents another significant challenge, as silver nanowires typically exhibit poor adhesion to various substrate materials. This weak interfacial bonding results in nanowire delamination during mechanical deformation, severely compromising the coating's durability and functional longevity. Current adhesion enhancement methods often introduce trade-offs between mechanical robustness and electrical conductivity.

The junction resistance between individual nanowires constitutes a critical mechanical-electrical challenge. These junctions are particularly vulnerable to mechanical stress, with even minor deformation potentially disrupting the electrical pathways throughout the network. The mechanical stability of these junctions directly impacts the overall electrical performance of AgNW coatings under dynamic conditions.

Environmental factors further complicate the mechanical property landscape. Silver nanowires are susceptible to oxidation and sulfidation, processes that not only degrade electrical conductivity but also compromise mechanical integrity. Protective measures must balance environmental stability with preserved flexibility and conductivity—a complex engineering challenge that remains incompletely resolved.

Scalable manufacturing introduces additional mechanical challenges. Techniques that produce mechanically robust AgNW coatings in laboratory settings often encounter significant hurdles during industrial scale-up. Maintaining consistent mechanical properties across large-area coatings remains problematic, with edge effects and thickness variations introducing mechanical weak points.

Characterization methodologies for mechanical properties present their own set of challenges. Current techniques often provide incomplete information about nanowire network behavior under complex deformation scenarios. In-situ measurement of mechanical properties during device operation remains particularly difficult, limiting our understanding of failure mechanisms in real-world applications.

The integration of silver nanowire coatings with other materials in multilayer device architectures introduces interfacial stress and strain incompatibilities. These mechanical mismatches can lead to premature failure, particularly during thermal cycling or mechanical deformation, highlighting the need for comprehensive mechanical engineering approaches that consider the entire device structure rather than isolated coating properties.

Existing Mechanical Testing Methodologies

01 Mechanical durability enhancement techniques for silver nanowire coatings

Various methods can be employed to enhance the mechanical durability of silver nanowire coatings, including embedding nanowires in polymer matrices, applying protective overlayers, and optimizing the nanowire network structure. These techniques help improve scratch resistance, adhesion to substrates, and overall robustness while maintaining the electrical conductivity and optical transparency of the coatings.- Mechanical strength enhancement techniques for silver nanowire coatings: Various methods can be employed to enhance the mechanical strength of silver nanowire coatings, including the use of polymer matrices, cross-linking agents, and specialized deposition techniques. These approaches improve the durability and flexibility of the coatings while maintaining their electrical conductivity. The enhanced mechanical properties make these coatings suitable for applications requiring both conductivity and resistance to mechanical stress, such as flexible electronics and touch screens.

- Flexibility and stretchability of silver nanowire composite coatings: Silver nanowire coatings can be formulated to exhibit excellent flexibility and stretchability by incorporating elastomeric materials or specialized polymer binders. These composite coatings maintain electrical conductivity even under bending, folding, or stretching conditions. The combination of mechanical flexibility and electrical performance makes these materials particularly valuable for wearable electronics, flexible displays, and stretchable sensors where mechanical deformation is expected during normal operation.

- Adhesion improvement methods for silver nanowire coatings: The adhesion of silver nanowire coatings to various substrates can be significantly improved through surface treatments, adhesion promoters, and specialized deposition techniques. Enhanced adhesion prevents delamination and improves the overall durability of the coating when subjected to mechanical stress. These methods are crucial for applications where the coating must withstand environmental factors and mechanical wear while maintaining its functional properties.

- Abrasion and scratch resistance of silver nanowire coatings: Silver nanowire coatings can be formulated to exhibit enhanced abrasion and scratch resistance through the incorporation of protective overlayers, nanocomposite structures, or specialized surface treatments. These approaches protect the silver nanowires from mechanical damage while preserving their electrical conductivity. Improved scratch resistance is particularly important for touch screen applications, transparent electrodes, and other surfaces that experience frequent contact or cleaning.

- Environmental stability and mechanical durability of silver nanowire coatings: The long-term mechanical durability of silver nanowire coatings can be enhanced through protective encapsulation, anti-corrosion additives, and specialized processing techniques. These methods improve resistance to environmental factors such as humidity, temperature fluctuations, and UV exposure, which can otherwise compromise mechanical properties over time. The improved environmental stability ensures that the coatings maintain their mechanical integrity and functional performance throughout their intended service life.

02 Flexibility and stretchability of silver nanowire transparent conductive films

Silver nanowire coatings can be engineered to exhibit excellent flexibility and stretchability while maintaining electrical conductivity. This is achieved through specific formulation techniques, nanowire aspect ratio optimization, and integration with elastic substrates or binders. These properties make them suitable for flexible electronics, wearable devices, and stretchable displays where mechanical deformation is expected during normal operation.Expand Specific Solutions03 Adhesion improvement methods for silver nanowire coatings

The adhesion of silver nanowires to various substrates can be significantly improved through surface treatments, adhesion promoters, and specialized deposition techniques. Enhanced adhesion prevents delamination during mechanical stress and improves the overall durability of the coating. Methods include plasma treatment of substrates, incorporation of coupling agents, and development of specialized binder systems that create strong interfaces between nanowires and substrates.Expand Specific Solutions04 Abrasion and scratch resistance of silver nanowire composite coatings

Silver nanowire coatings can be formulated with specific additives and protective layers to enhance their resistance to abrasion and scratching. These formulations typically involve hard coating materials, self-healing components, or hierarchical structures that distribute mechanical forces. The resulting coatings maintain their electrical and optical properties even after exposure to mechanical wear, making them suitable for touch screens and other high-contact applications.Expand Specific Solutions05 Environmental stability and mechanical performance correlation in silver nanowire films

The mechanical properties of silver nanowire coatings are significantly influenced by environmental factors such as humidity, temperature, and exposure to chemicals. Specialized formulations can improve the environmental stability of these coatings, thereby maintaining their mechanical integrity over time. Techniques include encapsulation methods, corrosion inhibitors, and composite structures that protect nanowires from environmental degradation while preserving their mechanical performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The silver nanowire coating market is currently in a growth phase, with increasing applications in flexible electronics, transparent conductive films, and touchscreen technologies. The global market size for silver nanowire materials is expanding rapidly, projected to reach significant value due to rising demand in consumer electronics and automotive sectors. Technologically, companies like Hefei Microcrystalline Materials, Shenzhen Huake Chuangzhi, and Zhuhai Najin Technology have achieved notable advancements in nanowire synthesis and coating processes, while established players such as Carestream Health and Eastman Kodak contribute with their materials expertise. Academic institutions including Nanjing Tech University and Georgia Tech Research Corp are driving fundamental research in mechanical properties, addressing challenges in durability and flexibility that remain critical for widespread commercial adoption.

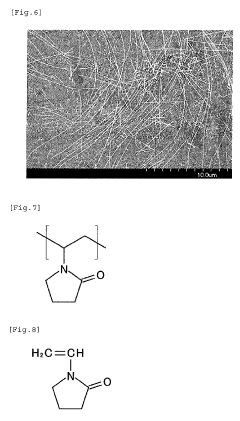

Zhejiang KECHUANG Advanced MATERIALS Technology Co., Ltd.

Technical Solution: Zhejiang KECHUANG has developed a proprietary silver nanowire coating technology that employs a unique wet-chemical synthesis method to produce high-aspect-ratio silver nanowires with controlled diameter (30-50nm) and length (10-30μm). Their process incorporates a polyol reduction method with PVP as a structure-directing agent, resulting in nanowires with exceptional mechanical flexibility. The company's coatings demonstrate remarkable tensile strength (>200 MPa) and elastic modulus values while maintaining optical transparency above 90%. Their technology includes a specialized surface treatment that enhances adhesion to various substrates while improving environmental stability. KECHUANG's silver nanowire networks exhibit self-healing properties under minor deformation, allowing the coatings to withstand repeated bending cycles (>100,000 at 5mm radius) without significant degradation in conductivity or mechanical integrity.

Strengths: Superior flexibility and durability compared to ITO coatings, with excellent conductivity retention after mechanical stress. Their nanowire synthesis achieves consistent aspect ratios, critical for balanced mechanical-electrical performance. Weaknesses: Higher production costs compared to some competing transparent conductive materials, and potential for silver migration under certain environmental conditions requiring additional protective layers.

Guangdong Nalu Nano Technology Co., Ltd.

Technical Solution: Guangdong Nalu Nano Technology has pioneered an advanced silver nanowire coating system utilizing a modified polyol process that produces ultra-long nanowires (15-50μm) with diameters below 30nm. Their proprietary coating formulation incorporates a polymer matrix that enhances the mechanical robustness of the nanowire network while maintaining exceptional transparency (>93% in visible spectrum). The company's technology features a unique cross-linking mechanism between the nanowires and polymer matrix, resulting in coatings with superior adhesion to substrates and remarkable mechanical durability. Mechanical testing reveals their coatings can withstand over 10,000 bending cycles at a 3mm radius while maintaining conductivity above 95% of initial values. Their silver nanowire networks demonstrate a Young's modulus of approximately 8-12 GPa and tensile strength exceeding 150 MPa, significantly outperforming conventional ITO coatings in flexibility tests while providing comparable optical and electrical performance.

Strengths: Exceptional mechanical flexibility with minimal performance degradation under repeated deformation, making them ideal for flexible electronics applications. Their nanowire-polymer composite approach provides enhanced environmental stability and adhesion. Weaknesses: The specialized polymer matrix adds complexity to the manufacturing process and may limit high-temperature applications. The technology requires precise control of environmental conditions during application to achieve optimal mechanical properties.

Key Patents in Silver Nanowire Mechanical Enhancement

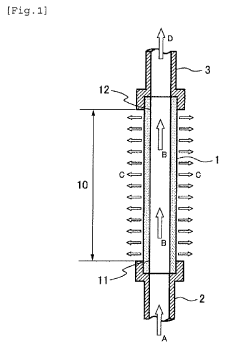

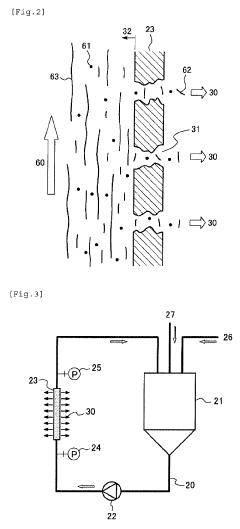

Silver nanowires and method for producing same, and silver nanowire ink and transparent conductive film

PatentInactiveUS20190283128A1

Innovation

- The use of a vinylpyrrolidone copolymer composition with low sulfur content and residual vinylpyrrolidone monomer content as an organic protective agent for stable reduction synthesis of thin and long silver nanowires, improving dispersibility and reducing impurities, thereby enhancing the conductivity and transparency of the films.

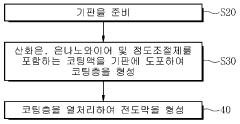

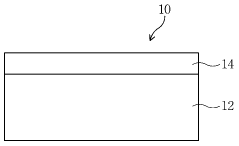

Silver nano wire coating solution having silver oxide, conductive coating substrate and manufacturing thereof

PatentInactiveKR1020160095236A

Innovation

- A coating solution comprising 0.001 to 1% silver nanowires, 0.001 to 0.5% silver oxide, and 0.001 to 1% viscosity modifier, applied to a substrate and heat-treated to form a conductive film, utilizing silver oxide as a conductive bridge between nanowires to stabilize the network structure.

Material Characterization Techniques

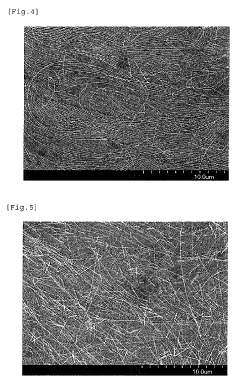

The comprehensive characterization of silver nanowire (AgNW) coatings requires sophisticated analytical techniques to accurately assess their mechanical properties. Scanning Electron Microscopy (SEM) serves as a fundamental tool for visualizing the morphology and distribution of nanowires within the coating matrix, providing critical insights into wire alignment, density, and interconnection patterns that directly influence mechanical performance.

Atomic Force Microscopy (AFM) complements SEM by enabling nanoscale topographical mapping and mechanical property measurements through force-distance curves. This technique allows for the determination of local elastic modulus, hardness, and adhesion properties of individual nanowires and their interfaces with the substrate material, offering valuable data on the coating's resistance to deformation.

Nanoindentation testing provides quantitative measurements of hardness and elastic modulus at precisely controlled depths, making it particularly suitable for thin AgNW coatings. By analyzing load-displacement curves, researchers can extract information about plastic deformation behavior, strain-hardening effects, and creep resistance of the nanowire network structure.

X-ray diffraction (XRD) analysis reveals the crystalline structure of silver nanowires, enabling the identification of crystal orientations and defects that significantly impact mechanical strength. The presence of twin boundaries and stacking faults, common in AgNW structures, can be detected through careful XRD pattern analysis, providing insights into deformation mechanisms.

Dynamic Mechanical Analysis (DMA) offers information about viscoelastic properties by subjecting samples to oscillatory stresses across a range of frequencies and temperatures. This technique is particularly valuable for understanding how AgNW coatings respond to dynamic loading conditions and environmental factors that may be encountered in real-world applications.

Tensile testing adapted for thin films provides direct measurements of ultimate tensile strength, yield strength, and elongation at break. Custom-designed microtensile stages can be employed to apply controlled strain to AgNW coatings while simultaneously monitoring electrical resistance changes, revealing the relationship between mechanical deformation and functional properties.

In-situ mechanical testing within electron microscopes represents an advanced approach, allowing real-time observation of deformation mechanisms at the nanoscale. This technique enables researchers to directly visualize crack initiation and propagation, nanowire sliding, and junction failure under applied stress, providing unprecedented insights into the fundamental mechanics of AgNW networks.

Atomic Force Microscopy (AFM) complements SEM by enabling nanoscale topographical mapping and mechanical property measurements through force-distance curves. This technique allows for the determination of local elastic modulus, hardness, and adhesion properties of individual nanowires and their interfaces with the substrate material, offering valuable data on the coating's resistance to deformation.

Nanoindentation testing provides quantitative measurements of hardness and elastic modulus at precisely controlled depths, making it particularly suitable for thin AgNW coatings. By analyzing load-displacement curves, researchers can extract information about plastic deformation behavior, strain-hardening effects, and creep resistance of the nanowire network structure.

X-ray diffraction (XRD) analysis reveals the crystalline structure of silver nanowires, enabling the identification of crystal orientations and defects that significantly impact mechanical strength. The presence of twin boundaries and stacking faults, common in AgNW structures, can be detected through careful XRD pattern analysis, providing insights into deformation mechanisms.

Dynamic Mechanical Analysis (DMA) offers information about viscoelastic properties by subjecting samples to oscillatory stresses across a range of frequencies and temperatures. This technique is particularly valuable for understanding how AgNW coatings respond to dynamic loading conditions and environmental factors that may be encountered in real-world applications.

Tensile testing adapted for thin films provides direct measurements of ultimate tensile strength, yield strength, and elongation at break. Custom-designed microtensile stages can be employed to apply controlled strain to AgNW coatings while simultaneously monitoring electrical resistance changes, revealing the relationship between mechanical deformation and functional properties.

In-situ mechanical testing within electron microscopes represents an advanced approach, allowing real-time observation of deformation mechanisms at the nanoscale. This technique enables researchers to directly visualize crack initiation and propagation, nanowire sliding, and junction failure under applied stress, providing unprecedented insights into the fundamental mechanics of AgNW networks.

Environmental Stability and Durability Factors

Silver nanowire (AgNW) coatings face significant environmental challenges that directly impact their mechanical stability and long-term performance. Humidity represents a primary concern, as moisture absorption can lead to oxidation of silver nanowires, resulting in decreased conductivity and compromised mechanical integrity. Studies have shown that exposure to relative humidity above 70% for extended periods can accelerate corrosion processes, particularly at junction points where nanowires intersect, creating weak points in the network structure.

Temperature fluctuations pose another critical durability factor, with thermal cycling causing expansion and contraction of both the nanowires and substrate materials. This differential thermal expansion creates mechanical stress that can lead to delamination, cracking, or permanent deformation of the coating. Research indicates that AgNW coatings typically maintain optimal mechanical properties between -20°C and 60°C, with performance degradation accelerating outside this range.

UV radiation exposure represents a significant environmental stressor, as photochemical reactions can alter the surface chemistry of both the nanowires and binding materials. Extended UV exposure has been documented to reduce flexibility by up to 40% in standard AgNW coatings after 1000 hours of accelerated weathering tests, primarily through photodegradation of polymer components in the matrix.

Chemical exposure from atmospheric pollutants, particularly sulfur-containing compounds and chlorides, accelerates corrosion mechanisms in silver nanowires. Urban and industrial environments with higher concentrations of these contaminants have demonstrated corrosion rates up to three times faster than controlled laboratory conditions, significantly reducing mechanical durability.

Mechanical abrasion from routine handling and cleaning procedures represents a practical durability concern. Conventional AgNW coatings typically withstand only 50-100 abrasion cycles before showing significant increases in electrical resistance and mechanical failure. This limitation has prompted research into protective overcoats and composite structures to enhance abrasion resistance while maintaining flexibility.

Recent advances in environmental protection strategies include hydrophobic surface treatments, which have demonstrated up to 85% improvement in humidity resistance, and core-shell structures incorporating corrosion-resistant materials like gold or platinum. Additionally, UV-stabilized polymer matrices have shown promise in extending operational lifetimes by up to 300% in outdoor applications, though often at the cost of increased production complexity and material expenses.

Temperature fluctuations pose another critical durability factor, with thermal cycling causing expansion and contraction of both the nanowires and substrate materials. This differential thermal expansion creates mechanical stress that can lead to delamination, cracking, or permanent deformation of the coating. Research indicates that AgNW coatings typically maintain optimal mechanical properties between -20°C and 60°C, with performance degradation accelerating outside this range.

UV radiation exposure represents a significant environmental stressor, as photochemical reactions can alter the surface chemistry of both the nanowires and binding materials. Extended UV exposure has been documented to reduce flexibility by up to 40% in standard AgNW coatings after 1000 hours of accelerated weathering tests, primarily through photodegradation of polymer components in the matrix.

Chemical exposure from atmospheric pollutants, particularly sulfur-containing compounds and chlorides, accelerates corrosion mechanisms in silver nanowires. Urban and industrial environments with higher concentrations of these contaminants have demonstrated corrosion rates up to three times faster than controlled laboratory conditions, significantly reducing mechanical durability.

Mechanical abrasion from routine handling and cleaning procedures represents a practical durability concern. Conventional AgNW coatings typically withstand only 50-100 abrasion cycles before showing significant increases in electrical resistance and mechanical failure. This limitation has prompted research into protective overcoats and composite structures to enhance abrasion resistance while maintaining flexibility.

Recent advances in environmental protection strategies include hydrophobic surface treatments, which have demonstrated up to 85% improvement in humidity resistance, and core-shell structures incorporating corrosion-resistant materials like gold or platinum. Additionally, UV-stabilized polymer matrices have shown promise in extending operational lifetimes by up to 300% in outdoor applications, though often at the cost of increased production complexity and material expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!