Why Silver Nanowire Is Critical for Next-Generation Transparent Electrodes

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Technology Evolution and Objectives

Silver nanowire (AgNW) technology represents a significant breakthrough in the field of transparent conductive materials, evolving from early experimental studies in the early 2000s to becoming a promising alternative to indium tin oxide (ITO). The journey began with fundamental research on metal nanowire synthesis methods, particularly the polyol process developed by Xia and colleagues, which enabled controlled production of high-aspect-ratio silver nanowires with excellent conductivity properties.

The evolution of AgNW technology has been marked by several key milestones. Initially, researchers focused on basic synthesis and characterization, demonstrating the theoretical potential of these materials. By the mid-2000s, the focus shifted to improving production methods and enhancing performance metrics such as sheet resistance and optical transparency. The 2010s saw significant advancements in scalable manufacturing techniques and integration methods, enabling AgNW networks to achieve performance levels comparable to or exceeding traditional ITO.

Recent technological developments have centered on addressing stability challenges through protective coatings, hybrid structures, and novel deposition methods. The integration of AgNWs with other nanomaterials like graphene and carbon nanotubes has created synergistic composites with enhanced properties, representing the current frontier of research.

The primary objective of AgNW technology development is to create transparent electrodes that combine exceptional electrical conductivity with high optical transparency, mechanical flexibility, and cost-effectiveness. These electrodes aim to overcome the limitations of ITO, particularly its brittleness and high processing temperatures, which restrict its use in flexible electronics applications.

Technical goals include achieving sheet resistance below 10 ohms/square with transparency exceeding 90%, developing manufacturing processes compatible with roll-to-roll production for large-scale, low-cost fabrication, and ensuring long-term stability under various environmental conditions and mechanical stresses.

The technology trajectory is moving toward more sophisticated hybrid structures, environmentally friendly synthesis methods, and integration with emerging technologies such as stretchable electronics and Internet of Things (IoT) devices. Researchers are also exploring the potential of AgNWs in next-generation applications including transparent heaters, electromagnetic interference shielding, and smart windows.

As the demand for flexible, transparent electronics continues to grow across multiple industries, silver nanowire technology stands at a critical juncture, poised to enable innovations that were previously unattainable with conventional transparent conductive materials.

The evolution of AgNW technology has been marked by several key milestones. Initially, researchers focused on basic synthesis and characterization, demonstrating the theoretical potential of these materials. By the mid-2000s, the focus shifted to improving production methods and enhancing performance metrics such as sheet resistance and optical transparency. The 2010s saw significant advancements in scalable manufacturing techniques and integration methods, enabling AgNW networks to achieve performance levels comparable to or exceeding traditional ITO.

Recent technological developments have centered on addressing stability challenges through protective coatings, hybrid structures, and novel deposition methods. The integration of AgNWs with other nanomaterials like graphene and carbon nanotubes has created synergistic composites with enhanced properties, representing the current frontier of research.

The primary objective of AgNW technology development is to create transparent electrodes that combine exceptional electrical conductivity with high optical transparency, mechanical flexibility, and cost-effectiveness. These electrodes aim to overcome the limitations of ITO, particularly its brittleness and high processing temperatures, which restrict its use in flexible electronics applications.

Technical goals include achieving sheet resistance below 10 ohms/square with transparency exceeding 90%, developing manufacturing processes compatible with roll-to-roll production for large-scale, low-cost fabrication, and ensuring long-term stability under various environmental conditions and mechanical stresses.

The technology trajectory is moving toward more sophisticated hybrid structures, environmentally friendly synthesis methods, and integration with emerging technologies such as stretchable electronics and Internet of Things (IoT) devices. Researchers are also exploring the potential of AgNWs in next-generation applications including transparent heaters, electromagnetic interference shielding, and smart windows.

As the demand for flexible, transparent electronics continues to grow across multiple industries, silver nanowire technology stands at a critical juncture, poised to enable innovations that were previously unattainable with conventional transparent conductive materials.

Market Demand Analysis for Transparent Conductive Materials

The transparent conductive materials market is experiencing robust growth driven by the expanding electronics industry, particularly in touch screens, displays, and photovoltaic applications. The global market for transparent conductive films was valued at approximately $4.9 billion in 2022 and is projected to reach $8.3 billion by 2028, growing at a CAGR of 9.2% during the forecast period. This growth trajectory underscores the critical importance of next-generation transparent electrode materials like silver nanowires.

Consumer electronics represents the largest application segment, accounting for over 40% of market demand. The rapid proliferation of smartphones, tablets, and wearable devices has significantly increased the need for high-performance transparent electrodes that can deliver both optical clarity and electrical conductivity. Additionally, the transition to flexible and foldable display technologies has created new requirements that traditional materials struggle to meet.

The renewable energy sector, particularly solar photovoltaics, constitutes another major demand driver. As global solar installation capacity continues to expand at double-digit rates annually, the need for efficient transparent electrodes in solar cells has intensified. Silver nanowire-based electrodes offer superior performance in terms of power conversion efficiency and durability compared to conventional alternatives.

Regionally, Asia-Pacific dominates the market with approximately 65% share, primarily due to the concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. North America and Europe follow with significant contributions to market demand, particularly in high-end applications and emerging technologies.

The automotive industry represents an emerging but rapidly growing market segment. The integration of transparent displays in vehicle dashboards, heads-up displays, and smart windows is creating new opportunities for advanced transparent conductive materials. Industry analysts project that automotive applications could grow at a CAGR of 12-15% through 2030.

A notable market trend is the shift away from indium tin oxide (ITO), which has traditionally dominated the transparent conductor market. Supply constraints of indium, coupled with ITO's brittleness and high processing costs, have accelerated the search for alternatives. Silver nanowires have emerged as a leading replacement candidate due to their superior flexibility, comparable conductivity, and improving cost-effectiveness.

The market is also witnessing increased demand for materials that enable new form factors and functionalities, such as stretchable electronics and 3D-shaped displays. Silver nanowires' inherent flexibility and ability to maintain conductivity under mechanical stress position them favorably in these emerging application spaces.

Consumer electronics represents the largest application segment, accounting for over 40% of market demand. The rapid proliferation of smartphones, tablets, and wearable devices has significantly increased the need for high-performance transparent electrodes that can deliver both optical clarity and electrical conductivity. Additionally, the transition to flexible and foldable display technologies has created new requirements that traditional materials struggle to meet.

The renewable energy sector, particularly solar photovoltaics, constitutes another major demand driver. As global solar installation capacity continues to expand at double-digit rates annually, the need for efficient transparent electrodes in solar cells has intensified. Silver nanowire-based electrodes offer superior performance in terms of power conversion efficiency and durability compared to conventional alternatives.

Regionally, Asia-Pacific dominates the market with approximately 65% share, primarily due to the concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. North America and Europe follow with significant contributions to market demand, particularly in high-end applications and emerging technologies.

The automotive industry represents an emerging but rapidly growing market segment. The integration of transparent displays in vehicle dashboards, heads-up displays, and smart windows is creating new opportunities for advanced transparent conductive materials. Industry analysts project that automotive applications could grow at a CAGR of 12-15% through 2030.

A notable market trend is the shift away from indium tin oxide (ITO), which has traditionally dominated the transparent conductor market. Supply constraints of indium, coupled with ITO's brittleness and high processing costs, have accelerated the search for alternatives. Silver nanowires have emerged as a leading replacement candidate due to their superior flexibility, comparable conductivity, and improving cost-effectiveness.

The market is also witnessing increased demand for materials that enable new form factors and functionalities, such as stretchable electronics and 3D-shaped displays. Silver nanowires' inherent flexibility and ability to maintain conductivity under mechanical stress position them favorably in these emerging application spaces.

Current Status and Challenges in Transparent Electrode Development

Transparent electrodes represent a critical component in modern optoelectronic devices, with indium tin oxide (ITO) dominating the market for decades. However, the transparent electrode landscape is undergoing significant transformation due to several challenges and emerging alternatives. The global supply of indium faces increasing constraints, with reserves concentrated primarily in China, leading to price volatility and supply chain vulnerabilities. This geographical concentration poses strategic risks for manufacturers worldwide.

From a technical perspective, ITO exhibits inherent limitations that impede next-generation device development. Its brittleness restricts applications in flexible electronics, while its high processing temperature (>300°C) proves incompatible with temperature-sensitive substrates. Additionally, ITO's sheet resistance increases dramatically when stretched, rendering it unsuitable for stretchable electronics applications that are gaining prominence in wearable technology markets.

Alternative transparent electrode technologies have emerged to address these limitations, each with distinct advantages and challenges. Graphene offers exceptional theoretical properties but faces significant manufacturing hurdles in producing large-area, defect-free sheets at commercially viable costs. Carbon nanotubes provide flexibility but struggle with achieving sufficiently low sheet resistance without compromising optical transparency.

Metal mesh structures deliver excellent conductivity but often introduce visible patterns that interfere with display quality. Conductive polymers like PEDOT:PSS offer flexibility and solution processability but suffer from limited conductivity and stability issues in ambient conditions, particularly humidity sensitivity that degrades performance over time.

Silver nanowire (AgNW) networks have emerged as a promising alternative, offering a compelling combination of high transparency, low sheet resistance, and mechanical flexibility. However, challenges persist in junction resistance between nanowires, long-term stability against oxidation, and adhesion to various substrates. Current manufacturing processes also face scalability issues for uniform, large-area deposition.

The industry is witnessing a transition period where different transparent electrode technologies are finding specific application niches based on their performance characteristics. ITO continues to dominate conventional rigid displays, while AgNWs are gaining traction in flexible electronics. The development of hybrid systems combining multiple materials represents another significant trend, aiming to leverage complementary properties.

Research efforts are increasingly focused on addressing nanowire network stability through encapsulation strategies, improving junction conductivity through sintering techniques, and developing scalable manufacturing processes compatible with roll-to-roll production for cost-effective implementation in consumer electronics.

From a technical perspective, ITO exhibits inherent limitations that impede next-generation device development. Its brittleness restricts applications in flexible electronics, while its high processing temperature (>300°C) proves incompatible with temperature-sensitive substrates. Additionally, ITO's sheet resistance increases dramatically when stretched, rendering it unsuitable for stretchable electronics applications that are gaining prominence in wearable technology markets.

Alternative transparent electrode technologies have emerged to address these limitations, each with distinct advantages and challenges. Graphene offers exceptional theoretical properties but faces significant manufacturing hurdles in producing large-area, defect-free sheets at commercially viable costs. Carbon nanotubes provide flexibility but struggle with achieving sufficiently low sheet resistance without compromising optical transparency.

Metal mesh structures deliver excellent conductivity but often introduce visible patterns that interfere with display quality. Conductive polymers like PEDOT:PSS offer flexibility and solution processability but suffer from limited conductivity and stability issues in ambient conditions, particularly humidity sensitivity that degrades performance over time.

Silver nanowire (AgNW) networks have emerged as a promising alternative, offering a compelling combination of high transparency, low sheet resistance, and mechanical flexibility. However, challenges persist in junction resistance between nanowires, long-term stability against oxidation, and adhesion to various substrates. Current manufacturing processes also face scalability issues for uniform, large-area deposition.

The industry is witnessing a transition period where different transparent electrode technologies are finding specific application niches based on their performance characteristics. ITO continues to dominate conventional rigid displays, while AgNWs are gaining traction in flexible electronics. The development of hybrid systems combining multiple materials represents another significant trend, aiming to leverage complementary properties.

Research efforts are increasingly focused on addressing nanowire network stability through encapsulation strategies, improving junction conductivity through sintering techniques, and developing scalable manufacturing processes compatible with roll-to-roll production for cost-effective implementation in consumer electronics.

Existing Silver Nanowire Implementation Approaches

01 Fabrication methods for transparent silver nanowire electrodes

Various techniques for manufacturing transparent electrodes using silver nanowires, including solution-based processes, printing methods, and coating technologies. These methods focus on achieving high transparency while maintaining electrical conductivity. The fabrication processes often involve deposition of silver nanowires on substrates followed by treatments to enhance adhesion and performance.- Silver nanowire transparent conductive films: Silver nanowires can be used to create highly transparent conductive films that combine excellent optical transparency with electrical conductivity. These films are fabricated by depositing silver nanowires onto substrates, creating a network that allows light to pass through while maintaining electrical pathways. The transparency and conductivity can be tuned by adjusting the density and dimensions of the nanowires, making them suitable for various optoelectronic applications.

- Manufacturing methods for transparent silver nanowire electrodes: Various manufacturing techniques have been developed to produce transparent silver nanowire electrodes with optimized properties. These methods include solution processing, spray coating, roll-to-roll printing, and vacuum filtration. Post-deposition treatments such as thermal annealing, mechanical pressing, or chemical treatments can further enhance the transparency and conductivity by improving the contact between nanowires. These manufacturing approaches enable scalable production of transparent conductive films for commercial applications.

- Silver nanowire composites for enhanced transparency: Silver nanowires can be combined with other materials to form composites with enhanced transparency and additional functional properties. These composites may incorporate polymers, metal oxides, graphene, or carbon nanotubes to improve mechanical flexibility, stability, and optical performance. The synergistic effects between silver nanowires and complementary materials can result in transparent films with superior characteristics compared to single-component systems.

- Applications of transparent silver nanowire technology: Transparent silver nanowire technology finds applications in various fields requiring both transparency and conductivity. These include touch screens, flexible displays, solar cells, smart windows, transparent heaters, and electromagnetic interference shielding. The unique combination of high optical transparency and electrical conductivity makes silver nanowire networks particularly valuable for next-generation electronic devices that require transparent electrodes with performance superior to traditional indium tin oxide.

- Enhancing stability and durability of transparent silver nanowire films: Methods to improve the stability and durability of transparent silver nanowire films have been developed to address challenges such as oxidation, corrosion, and mechanical damage. These approaches include protective coatings, encapsulation techniques, alloying with other metals, and surface modifications. By enhancing the environmental and mechanical stability of silver nanowire networks, their long-term performance and reliability in transparent conductive applications can be significantly improved.

02 Silver nanowire composite structures for enhanced transparency

Composite structures combining silver nanowires with other materials such as graphene, carbon nanotubes, or metal oxides to improve optical transparency and electrical properties. These hybrid structures leverage the synergistic effects of different materials to achieve higher transparency while maintaining or enhancing conductivity. The composites often show improved stability and performance compared to pure silver nanowire networks.Expand Specific Solutions03 Surface treatment techniques for transparency optimization

Methods for treating silver nanowire surfaces to enhance transparency, including plasma treatment, chemical modification, and thermal annealing. These treatments can reduce junction resistance between nanowires, improve light transmission, and enhance overall optical clarity. Surface modifications also help in achieving better adhesion to substrates and longer-term stability of the transparent conductive films.Expand Specific Solutions04 Applications of transparent silver nanowire films

Implementation of transparent silver nanowire films in various applications such as touch screens, solar cells, flexible displays, and smart windows. The high transparency combined with electrical conductivity makes these films ideal for optoelectronic devices. The applications leverage the unique properties of silver nanowires to create transparent conductive surfaces that can be integrated into various electronic and optical systems.Expand Specific Solutions05 Dimensional control for optimizing transparency

Techniques for controlling the dimensions (length, diameter, aspect ratio) of silver nanowires to achieve optimal transparency. By manipulating the physical characteristics of nanowires, researchers can balance the trade-off between transparency and conductivity. Methods include selective synthesis approaches, filtration techniques, and post-processing treatments that allow for precise control over nanowire dimensions to maximize light transmission.Expand Specific Solutions

Key Patents and Breakthroughs in Silver Nanowire Technology

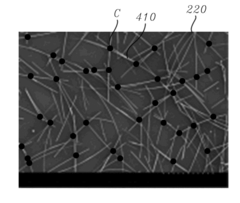

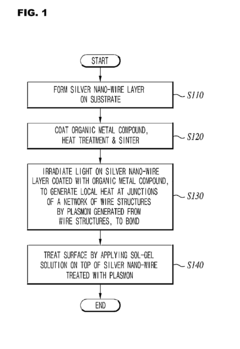

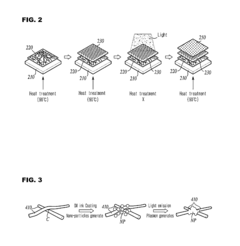

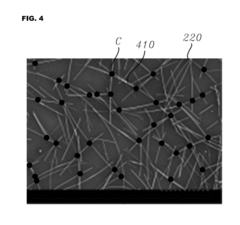

Electrode element using silver nano-wire and manufacturing method thereof

PatentInactiveUS20150034368A1

Innovation

- A manufacturing method for silver nano-wire electrodes involving the formation of a silver nano-wire layer on a substrate, followed by coating with an organo-metal compound solution, reinforcing junctions with localized thermal energy generated by surface Plasmon irradiation, and treating with a sol-gel solution to improve bonding and reduce haze and resistance issues, all at low temperatures suitable for polymer substrates.

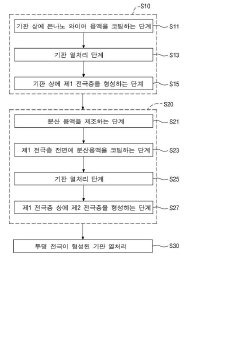

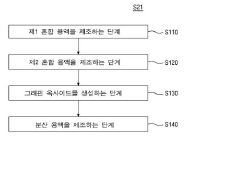

Transparent electrode based on the silver nanowires and manufacturing method thereof

PatentActiveKR1020200065476A

Innovation

- A silver nanowire-based transparent electrode with a double-layer structure comprising a first electrode layer of silver nanowires and a second layer of graphene oxide to which silver nanoparticles are chemically bonded, formed through specific coating and heat treatment processes.

Environmental Impact and Sustainability Considerations

The environmental impact of silver nanowire (AgNW) technology presents a complex sustainability profile that requires careful consideration as this material becomes increasingly critical for next-generation transparent electrodes. The extraction and processing of silver, a precious metal with limited natural reserves, raises significant sustainability concerns. Current mining practices for silver are energy-intensive and often result in habitat disruption, soil contamination, and water pollution. As demand for transparent electrodes in consumer electronics, solar panels, and touch displays grows exponentially, the environmental footprint of silver extraction could expand considerably without intervention.

Manufacturing processes for silver nanowires typically involve chemical synthesis methods that utilize potentially harmful reagents such as polyvinyl pyrrolidone (PVP) and ethylene glycol. These chemicals, if improperly managed, can contribute to environmental pollution through industrial waste streams. Additionally, the energy requirements for nanowire synthesis and purification contribute to the carbon footprint of AgNW-based transparent electrodes, although this impact is generally lower than that of competing technologies like indium tin oxide (ITO).

End-of-life considerations present both challenges and opportunities for AgNW technology. Unlike many nanomaterials, silver nanowires offer potential recyclability, as silver can be recovered and repurposed through appropriate recycling processes. However, current electronic waste management systems are rarely optimized for nanomaterial recovery, resulting in significant material loss and potential environmental release of nanoparticles with uncertain ecological effects.

Recent research has focused on developing more sustainable approaches to AgNW production and implementation. These include aqueous synthesis methods that reduce reliance on harmful solvents, lower-temperature processing techniques that decrease energy consumption, and the exploration of hybrid materials that minimize silver content while maintaining performance characteristics. Some manufacturers have begun implementing closed-loop production systems that capture and reuse chemical reagents, significantly reducing waste generation.

The potential toxicity of silver nanowires in the environment remains an area requiring further investigation. While bulk silver has well-understood environmental impacts, the unique properties of nanoscale silver may result in different bioavailability and ecological interactions. Preliminary studies suggest that silver nanowires may have antimicrobial effects in natural systems, potentially disrupting microbial communities if released into the environment in significant quantities.

Despite these challenges, when evaluated against alternative transparent electrode technologies, AgNW often demonstrates favorable sustainability metrics, particularly in terms of energy payback time when used in solar applications and reduced rare earth element dependence compared to ITO. The development of effective recycling pathways and continued improvement in green synthesis methods will be crucial for ensuring that silver nanowire technology contributes positively to global sustainability goals as it becomes increasingly central to next-generation electronics.

Manufacturing processes for silver nanowires typically involve chemical synthesis methods that utilize potentially harmful reagents such as polyvinyl pyrrolidone (PVP) and ethylene glycol. These chemicals, if improperly managed, can contribute to environmental pollution through industrial waste streams. Additionally, the energy requirements for nanowire synthesis and purification contribute to the carbon footprint of AgNW-based transparent electrodes, although this impact is generally lower than that of competing technologies like indium tin oxide (ITO).

End-of-life considerations present both challenges and opportunities for AgNW technology. Unlike many nanomaterials, silver nanowires offer potential recyclability, as silver can be recovered and repurposed through appropriate recycling processes. However, current electronic waste management systems are rarely optimized for nanomaterial recovery, resulting in significant material loss and potential environmental release of nanoparticles with uncertain ecological effects.

Recent research has focused on developing more sustainable approaches to AgNW production and implementation. These include aqueous synthesis methods that reduce reliance on harmful solvents, lower-temperature processing techniques that decrease energy consumption, and the exploration of hybrid materials that minimize silver content while maintaining performance characteristics. Some manufacturers have begun implementing closed-loop production systems that capture and reuse chemical reagents, significantly reducing waste generation.

The potential toxicity of silver nanowires in the environment remains an area requiring further investigation. While bulk silver has well-understood environmental impacts, the unique properties of nanoscale silver may result in different bioavailability and ecological interactions. Preliminary studies suggest that silver nanowires may have antimicrobial effects in natural systems, potentially disrupting microbial communities if released into the environment in significant quantities.

Despite these challenges, when evaluated against alternative transparent electrode technologies, AgNW often demonstrates favorable sustainability metrics, particularly in terms of energy payback time when used in solar applications and reduced rare earth element dependence compared to ITO. The development of effective recycling pathways and continued improvement in green synthesis methods will be crucial for ensuring that silver nanowire technology contributes positively to global sustainability goals as it becomes increasingly central to next-generation electronics.

Cost-Performance Analysis of Silver Nanowire vs. Alternative Materials

When evaluating silver nanowire (AgNW) technology for transparent electrode applications, cost-performance analysis reveals significant advantages over competing materials. The production cost of silver nanowires has decreased substantially over the past decade, with manufacturing innovations reducing costs by approximately 40% since 2015. Despite silver being a precious metal, the minimal material usage in nanowire form (typically less than 100mg/m²) keeps overall material costs competitive.

Compared to indium tin oxide (ITO), the current industry standard, AgNW offers superior cost efficiency in several dimensions. While ITO requires expensive vacuum deposition processes and high-temperature annealing (300-400°C), silver nanowires can be solution-processed at temperatures below 150°C, reducing energy consumption by up to 70%. This lower processing temperature also enables compatibility with flexible plastic substrates, expanding application possibilities.

Alternative materials like carbon nanotubes (CNTs) and graphene present lower material costs but suffer from performance limitations. CNTs typically achieve sheet resistances of 100-300 Ω/sq at 90% transparency, whereas AgNW can reach 10-30 Ω/sq at the same transparency level. This performance gap necessitates additional processing or material usage for CNTs to match AgNW performance, ultimately negating potential cost advantages.

PEDOT:PSS, another competitor, offers cost benefits but demonstrates limited conductivity and stability issues in humid environments. Its sheet resistance typically ranges from 100-500 Ω/sq, requiring additional treatments or thicker coatings that reduce transparency to achieve performance comparable to AgNW.

From a lifecycle perspective, AgNW demonstrates favorable economics. The estimated cost per square meter for AgNW transparent electrodes ranges from $8-15 depending on performance requirements, compared to $20-30 for ITO on glass. For flexible applications, this cost differential becomes even more pronounced, with AgNW solutions costing 40-60% less than flexible ITO alternatives.

Manufacturing scalability further enhances AgNW's cost position. Roll-to-roll compatible coating methods like slot-die coating, gravure, and spray coating enable high-throughput production with yields exceeding 90%, significantly reducing per-unit costs in volume production. Recent advancements in nanowire synthesis have also improved length-to-diameter ratios, allowing for reduced material loading while maintaining performance specifications.

When factoring in total ownership costs including manufacturing yield, process complexity, and equipment depreciation, AgNW technology demonstrates a 30-45% cost advantage over ITO for next-generation flexible display and touch sensor applications, positioning it as the most economically viable option for transparent electrode requirements in emerging electronic devices.

Compared to indium tin oxide (ITO), the current industry standard, AgNW offers superior cost efficiency in several dimensions. While ITO requires expensive vacuum deposition processes and high-temperature annealing (300-400°C), silver nanowires can be solution-processed at temperatures below 150°C, reducing energy consumption by up to 70%. This lower processing temperature also enables compatibility with flexible plastic substrates, expanding application possibilities.

Alternative materials like carbon nanotubes (CNTs) and graphene present lower material costs but suffer from performance limitations. CNTs typically achieve sheet resistances of 100-300 Ω/sq at 90% transparency, whereas AgNW can reach 10-30 Ω/sq at the same transparency level. This performance gap necessitates additional processing or material usage for CNTs to match AgNW performance, ultimately negating potential cost advantages.

PEDOT:PSS, another competitor, offers cost benefits but demonstrates limited conductivity and stability issues in humid environments. Its sheet resistance typically ranges from 100-500 Ω/sq, requiring additional treatments or thicker coatings that reduce transparency to achieve performance comparable to AgNW.

From a lifecycle perspective, AgNW demonstrates favorable economics. The estimated cost per square meter for AgNW transparent electrodes ranges from $8-15 depending on performance requirements, compared to $20-30 for ITO on glass. For flexible applications, this cost differential becomes even more pronounced, with AgNW solutions costing 40-60% less than flexible ITO alternatives.

Manufacturing scalability further enhances AgNW's cost position. Roll-to-roll compatible coating methods like slot-die coating, gravure, and spray coating enable high-throughput production with yields exceeding 90%, significantly reducing per-unit costs in volume production. Recent advancements in nanowire synthesis have also improved length-to-diameter ratios, allowing for reduced material loading while maintaining performance specifications.

When factoring in total ownership costs including manufacturing yield, process complexity, and equipment depreciation, AgNW technology demonstrates a 30-45% cost advantage over ITO for next-generation flexible display and touch sensor applications, positioning it as the most economically viable option for transparent electrode requirements in emerging electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!