Why Silver Nanowire Coatings Are Superior for EMI Shielding

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Technology Evolution and Objectives

Electromagnetic interference (EMI) shielding technology has evolved significantly over the past several decades, transitioning from rudimentary metal enclosures to sophisticated nanomaterial-based solutions. The evolution began in the mid-20th century with simple Faraday cage concepts using solid metal shields, which were effective but heavy and inflexible. By the 1980s, conductive paints and coatings emerged as alternatives, offering reduced weight but with compromised shielding effectiveness.

The 1990s witnessed the introduction of conductive polymers and metal-filled composites, providing a balance between weight and performance. However, the true paradigm shift occurred in the early 2000s with the advent of nanomaterials for EMI shielding, including carbon nanotubes, graphene, and metallic nanoparticles. These materials offered unprecedented combinations of conductivity, flexibility, and optical transparency.

Silver nanowire (AgNW) technology represents the cutting edge of this evolutionary trajectory, emerging around 2010 as researchers discovered methods to synthesize high-aspect-ratio nanowires with exceptional electrical conductivity. The development of AgNW coatings specifically for EMI shielding applications gained momentum after 2015, when manufacturing techniques matured enough to produce consistent, high-quality nanowire networks at commercially viable scales.

The primary objective in EMI shielding technology development has consistently been to achieve maximum shielding effectiveness while minimizing thickness, weight, and production costs. Secondary objectives include maintaining optical transparency for display applications, ensuring flexibility for wearable electronics, and developing environmentally sustainable solutions. Silver nanowire coatings address these objectives remarkably well, offering shielding effectiveness of 30-60 dB across a wide frequency range while maintaining over 90% optical transparency at optimal thicknesses.

Current technological goals focus on enhancing the durability of AgNW coatings, improving their adhesion to various substrates, and developing cost-effective manufacturing processes for large-scale production. Research is also directed toward creating hybrid systems that combine silver nanowires with other nanomaterials like graphene or MXenes to achieve synergistic effects and overcome the limitations of single-material approaches.

The trajectory of EMI shielding technology is now moving toward multifunctional coatings that not only shield against electromagnetic interference but also provide additional benefits such as antimicrobial properties, self-healing capabilities, and energy harvesting functionalities. Silver nanowires are particularly well-positioned in this evolution due to their versatility and compatibility with various functional materials, potentially enabling the next generation of integrated electronic systems with built-in EMI protection.

The 1990s witnessed the introduction of conductive polymers and metal-filled composites, providing a balance between weight and performance. However, the true paradigm shift occurred in the early 2000s with the advent of nanomaterials for EMI shielding, including carbon nanotubes, graphene, and metallic nanoparticles. These materials offered unprecedented combinations of conductivity, flexibility, and optical transparency.

Silver nanowire (AgNW) technology represents the cutting edge of this evolutionary trajectory, emerging around 2010 as researchers discovered methods to synthesize high-aspect-ratio nanowires with exceptional electrical conductivity. The development of AgNW coatings specifically for EMI shielding applications gained momentum after 2015, when manufacturing techniques matured enough to produce consistent, high-quality nanowire networks at commercially viable scales.

The primary objective in EMI shielding technology development has consistently been to achieve maximum shielding effectiveness while minimizing thickness, weight, and production costs. Secondary objectives include maintaining optical transparency for display applications, ensuring flexibility for wearable electronics, and developing environmentally sustainable solutions. Silver nanowire coatings address these objectives remarkably well, offering shielding effectiveness of 30-60 dB across a wide frequency range while maintaining over 90% optical transparency at optimal thicknesses.

Current technological goals focus on enhancing the durability of AgNW coatings, improving their adhesion to various substrates, and developing cost-effective manufacturing processes for large-scale production. Research is also directed toward creating hybrid systems that combine silver nanowires with other nanomaterials like graphene or MXenes to achieve synergistic effects and overcome the limitations of single-material approaches.

The trajectory of EMI shielding technology is now moving toward multifunctional coatings that not only shield against electromagnetic interference but also provide additional benefits such as antimicrobial properties, self-healing capabilities, and energy harvesting functionalities. Silver nanowires are particularly well-positioned in this evolution due to their versatility and compatibility with various functional materials, potentially enabling the next generation of integrated electronic systems with built-in EMI protection.

Market Demand Analysis for Advanced EMI Shielding Solutions

The global market for EMI shielding solutions is experiencing robust growth driven by the proliferation of electronic devices and the increasing complexity of electronic systems. With the rapid expansion of 5G networks, IoT devices, and high-frequency applications, the demand for effective EMI shielding has reached unprecedented levels. Current market estimates value the global EMI shielding market at approximately 6.8 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028.

The automotive sector represents one of the fastest-growing segments for advanced EMI shielding solutions. As vehicles incorporate more electronic components and transition toward electrification, the need for reliable EMI protection has become critical. Electric vehicles (EVs) in particular require sophisticated shielding to prevent interference between high-voltage systems and sensitive control electronics. Market research indicates that automotive applications account for nearly 22% of the total EMI shielding market, with this share expected to increase as EV adoption accelerates globally.

Consumer electronics continues to be the largest application segment, driven by the miniaturization of devices and increasing functionality. Smartphones, tablets, wearables, and other portable devices require effective EMI shielding solutions that are lightweight, thin, and do not compromise device performance. This sector values solutions that can be integrated into increasingly compact designs while maintaining high shielding effectiveness.

Healthcare and medical devices represent an emerging high-value market for advanced EMI shielding. Medical equipment must operate with absolute reliability in environments with numerous potential sources of electromagnetic interference. The growing adoption of wireless medical devices and telemedicine solutions has further intensified the need for dependable shielding technologies in this sector.

Industry analysis reveals a significant shift in customer requirements toward multifunctional shielding solutions. End-users increasingly demand materials that not only provide EMI protection but also offer additional benefits such as thermal management, environmental resistance, and flexibility. This trend favors advanced solutions like silver nanowire coatings, which can deliver multiple performance attributes simultaneously.

Regulatory factors are also driving market growth, with increasingly stringent EMC (Electromagnetic Compatibility) standards being implemented across industries. These regulations require manufacturers to ensure their products do not generate excessive electromagnetic interference and are sufficiently protected against external EMI sources. This regulatory landscape has created a premium market segment for high-performance shielding solutions that can meet or exceed compliance requirements.

The automotive sector represents one of the fastest-growing segments for advanced EMI shielding solutions. As vehicles incorporate more electronic components and transition toward electrification, the need for reliable EMI protection has become critical. Electric vehicles (EVs) in particular require sophisticated shielding to prevent interference between high-voltage systems and sensitive control electronics. Market research indicates that automotive applications account for nearly 22% of the total EMI shielding market, with this share expected to increase as EV adoption accelerates globally.

Consumer electronics continues to be the largest application segment, driven by the miniaturization of devices and increasing functionality. Smartphones, tablets, wearables, and other portable devices require effective EMI shielding solutions that are lightweight, thin, and do not compromise device performance. This sector values solutions that can be integrated into increasingly compact designs while maintaining high shielding effectiveness.

Healthcare and medical devices represent an emerging high-value market for advanced EMI shielding. Medical equipment must operate with absolute reliability in environments with numerous potential sources of electromagnetic interference. The growing adoption of wireless medical devices and telemedicine solutions has further intensified the need for dependable shielding technologies in this sector.

Industry analysis reveals a significant shift in customer requirements toward multifunctional shielding solutions. End-users increasingly demand materials that not only provide EMI protection but also offer additional benefits such as thermal management, environmental resistance, and flexibility. This trend favors advanced solutions like silver nanowire coatings, which can deliver multiple performance attributes simultaneously.

Regulatory factors are also driving market growth, with increasingly stringent EMC (Electromagnetic Compatibility) standards being implemented across industries. These regulations require manufacturers to ensure their products do not generate excessive electromagnetic interference and are sufficiently protected against external EMI sources. This regulatory landscape has created a premium market segment for high-performance shielding solutions that can meet or exceed compliance requirements.

Silver Nanowire Technology: Current Status and Challenges

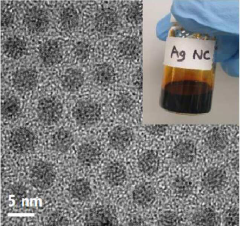

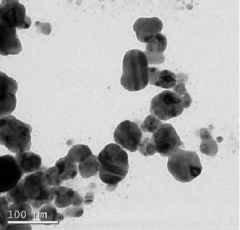

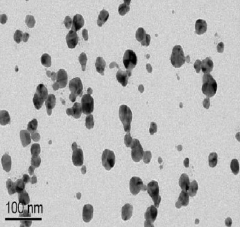

Silver nanowire (AgNW) technology has emerged as a promising solution for electromagnetic interference (EMI) shielding applications, yet faces several significant challenges that require addressing for widespread commercial adoption. Currently, the technology demonstrates exceptional electrical conductivity (15-100 Ω/sq) and optical transparency (>90%) simultaneously, properties that traditional materials like indium tin oxide (ITO) struggle to balance effectively. The nanowires, typically 30-100 nm in diameter and 5-50 μm in length, create conductive networks that efficiently block electromagnetic radiation while maintaining visual clarity.

Despite these advantages, manufacturing scalability remains a primary obstacle. Laboratory-scale production methods have not yet translated effectively to industrial-scale manufacturing, creating bottlenecks in commercial deployment. The synthesis processes, particularly those involving polyol reduction methods, face challenges in maintaining consistent wire dimensions and quality across large production batches. This inconsistency directly impacts the performance reliability of resulting EMI shielding products.

Stability issues present another significant challenge. Silver nanowires are susceptible to environmental degradation through oxidation, sulfidation, and mechanical stress. When exposed to ambient conditions, AgNWs can deteriorate within weeks or months, substantially reducing their shielding effectiveness and transparency. Various protective coating strategies have been developed, including polymer encapsulation and oxide layer formation, but these often compromise the original performance characteristics of the nanowire network.

Cost considerations also limit widespread adoption. While silver nanowire technology offers superior performance compared to alternatives, the high cost of silver as a raw material (approximately $800-1000 per kg) makes large-scale implementation economically challenging. Current research focuses on reducing silver content while maintaining performance, including the development of core-shell structures and silver-copper alloy nanowires.

Integration challenges with existing manufacturing processes further complicate commercial adoption. Many electronics manufacturing facilities are optimized for traditional materials and require significant retooling to accommodate nanowire-based solutions. The deposition techniques for AgNWs, such as spray coating, slot-die coating, and roll-to-roll processing, often require specialized equipment and expertise not readily available in conventional manufacturing environments.

Standardization represents another hurdle, as the industry lacks unified testing protocols and performance metrics for nanowire-based EMI shielding. This absence of standards makes it difficult for manufacturers to validate product performance and for customers to compare solutions across different providers, ultimately slowing market acceptance of this promising technology.

Despite these advantages, manufacturing scalability remains a primary obstacle. Laboratory-scale production methods have not yet translated effectively to industrial-scale manufacturing, creating bottlenecks in commercial deployment. The synthesis processes, particularly those involving polyol reduction methods, face challenges in maintaining consistent wire dimensions and quality across large production batches. This inconsistency directly impacts the performance reliability of resulting EMI shielding products.

Stability issues present another significant challenge. Silver nanowires are susceptible to environmental degradation through oxidation, sulfidation, and mechanical stress. When exposed to ambient conditions, AgNWs can deteriorate within weeks or months, substantially reducing their shielding effectiveness and transparency. Various protective coating strategies have been developed, including polymer encapsulation and oxide layer formation, but these often compromise the original performance characteristics of the nanowire network.

Cost considerations also limit widespread adoption. While silver nanowire technology offers superior performance compared to alternatives, the high cost of silver as a raw material (approximately $800-1000 per kg) makes large-scale implementation economically challenging. Current research focuses on reducing silver content while maintaining performance, including the development of core-shell structures and silver-copper alloy nanowires.

Integration challenges with existing manufacturing processes further complicate commercial adoption. Many electronics manufacturing facilities are optimized for traditional materials and require significant retooling to accommodate nanowire-based solutions. The deposition techniques for AgNWs, such as spray coating, slot-die coating, and roll-to-roll processing, often require specialized equipment and expertise not readily available in conventional manufacturing environments.

Standardization represents another hurdle, as the industry lacks unified testing protocols and performance metrics for nanowire-based EMI shielding. This absence of standards makes it difficult for manufacturers to validate product performance and for customers to compare solutions across different providers, ultimately slowing market acceptance of this promising technology.

Current Silver Nanowire Implementation Methodologies

01 Silver nanowire-based transparent conductive coatings for EMI shielding

Silver nanowires can be used to create transparent conductive coatings that provide effective electromagnetic interference (EMI) shielding. These coatings combine high optical transparency with excellent electrical conductivity, making them suitable for applications requiring both visibility and EMI protection. The nanowires form a conductive network that blocks electromagnetic radiation while maintaining transparency, which is particularly valuable for display screens, windows, and other transparent surfaces requiring EMI shielding.- Silver nanowire coatings for transparent EMI shielding: Silver nanowires can be used to create transparent conductive coatings that provide effective electromagnetic interference (EMI) shielding. These coatings maintain high optical transparency while offering excellent electrical conductivity, making them ideal for applications requiring both visibility and EMI protection, such as display screens, touch panels, and smart windows. The nanowires form a conductive network that blocks electromagnetic radiation while allowing visible light to pass through.

- Fabrication methods for silver nanowire EMI shielding coatings: Various fabrication techniques can be employed to create silver nanowire coatings for EMI shielding, including spray coating, dip coating, spin coating, and roll-to-roll processing. These methods allow for uniform deposition of silver nanowires on different substrate materials. Post-treatment processes such as thermal annealing or pressing can be applied to improve the electrical conductivity and adhesion of the nanowire network, enhancing the overall EMI shielding effectiveness of the coating.

- Composite materials incorporating silver nanowires for enhanced EMI shielding: Silver nanowires can be incorporated into polymer matrices or combined with other nanomaterials to create composite coatings with enhanced EMI shielding properties. These composites often exhibit synergistic effects, where the combination of materials provides superior shielding effectiveness compared to single-component systems. Common complementary materials include graphene, carbon nanotubes, metal oxides, and conductive polymers, which can improve durability, flexibility, and shielding performance across broader frequency ranges.

- Flexible and stretchable silver nanowire EMI shielding for wearable electronics: Silver nanowire networks can be designed to maintain conductivity under mechanical deformation, making them suitable for flexible and stretchable EMI shielding applications. These materials are particularly valuable for wearable electronics, flexible displays, and conformal shielding on curved surfaces. The interconnected network structure of silver nanowires allows them to maintain electrical pathways even when stretched or bent, providing consistent EMI protection while accommodating the mechanical requirements of flexible electronic devices.

- Integration of silver nanowire EMI shielding in electronic devices: Silver nanowire EMI shielding coatings can be integrated into various electronic devices and components to protect against electromagnetic interference. Applications include touchscreens, display panels, printed circuit boards, and electronic enclosures. The integration process often involves considerations of compatibility with existing manufacturing processes, durability requirements, and specific shielding effectiveness targets. Advanced designs may incorporate patterned silver nanowire networks or multilayer structures to optimize both the functional and protective aspects of the electronic devices.

02 Composite materials incorporating silver nanowires for enhanced EMI shielding

Composite materials that incorporate silver nanowires with polymers or other matrices can provide superior EMI shielding performance. These composites combine the high conductivity of silver nanowires with the mechanical properties and processability of the matrix material. The resulting materials offer flexibility, durability, and customizable EMI shielding effectiveness. The nanowires create conductive pathways throughout the composite, enabling efficient attenuation of electromagnetic waves across a broad frequency range.Expand Specific Solutions03 Fabrication methods for silver nanowire EMI shielding coatings

Various fabrication techniques can be employed to create silver nanowire coatings for EMI shielding, including spray coating, roll-to-roll processing, and solution-based deposition methods. These manufacturing approaches enable the production of uniform, large-area coatings with controlled nanowire density and distribution. Process parameters such as nanowire concentration, deposition conditions, and post-treatment steps significantly influence the coating's EMI shielding effectiveness, transparency, and durability.Expand Specific Solutions04 Multilayer structures with silver nanowires for optimized EMI shielding

Multilayer structures incorporating silver nanowire layers can be designed to optimize EMI shielding performance across specific frequency ranges. These structures may combine nanowire layers with other functional materials such as graphene, metal meshes, or dielectric layers to create tailored EMI shielding solutions. The multilayer approach allows for the creation of broadband shielding that can address various electromagnetic threats while maintaining other desired properties such as flexibility, transparency, or heat dissipation.Expand Specific Solutions05 Applications of silver nanowire EMI shielding in electronic devices

Silver nanowire EMI shielding coatings find applications in various electronic devices including smartphones, tablets, displays, and wearable technology. These coatings protect sensitive electronic components from external electromagnetic interference while preventing the device's own emissions from affecting other nearby equipment. The combination of transparency, flexibility, and effective shielding makes silver nanowire coatings particularly valuable for touch screens, flexible displays, and other components where traditional metal-based EMI shields would be impractical.Expand Specific Solutions

Key Industry Players in Silver Nanowire Manufacturing

Silver nanowire coatings are emerging as superior solutions for EMI shielding in the evolving electronics market. The industry is currently in a growth phase, with the global EMI shielding market expanding rapidly due to increasing electronic device proliferation and connectivity demands. Companies like Nanotech Energy, Samsung SDI, and Veelo Technologies are leading innovation in this space, leveraging silver nanowires' exceptional conductivity and flexibility advantages. These nanowire coatings offer superior shielding effectiveness at lower thicknesses compared to traditional materials, making them ideal for next-generation electronics. The technology is approaching commercial maturity, with research institutions like Northwestern Polytechnical University and Korea Advanced Institute of Science & Technology collaborating with industry players to overcome remaining challenges in scalability and cost-effectiveness.

Nanotech Energy, Inc.

Technical Solution: Nanotech Energy has developed advanced silver nanowire (AgNW) coatings for EMI shielding that leverage graphene-enhanced composite structures. Their proprietary technology combines silver nanowires with graphene sheets to create highly conductive, flexible, and transparent EMI shielding materials. The company's approach involves a solution-based deposition process that allows for uniform distribution of silver nanowires across various substrate materials. Their EMI shielding effectiveness typically exceeds 30dB across a wide frequency range (1-10 GHz), while maintaining over 90% optical transparency at optimal thicknesses. Nanotech Energy's silver nanowire coatings incorporate specialized surface treatments to enhance adhesion and environmental stability, addressing common challenges with silver oxidation. The company has also developed scalable manufacturing processes that enable cost-effective production of these advanced materials for commercial applications in consumer electronics, automotive, and aerospace industries.

Strengths: Superior combination of transparency and conductivity compared to traditional metal meshes; excellent flexibility allowing application on curved surfaces; solution-processable manufacturing enabling cost-effective large-scale production. Weaknesses: Potential long-term stability issues in harsh environments; higher cost compared to conventional non-transparent EMI shielding solutions; requires specialized handling during manufacturing process.

Korea Institute of Industrial Technology

Technical Solution: The Korea Institute of Industrial Technology (KITECH) has developed advanced silver nanowire EMI shielding technologies focused on industrial applications and mass production feasibility. Their approach centers on cost-effective synthesis methods for high-aspect-ratio silver nanowires (typically 40-60nm diameter with lengths exceeding 30μm) and specialized coating formulations that enhance dispersion stability and adhesion to various substrates. KITECH's technology achieves shielding effectiveness of 30-50dB across the 1-18 GHz frequency range while maintaining flexibility and in some configurations optical transparency exceeding 80%. A distinguishing feature of KITECH's approach is their development of roll-to-roll compatible deposition processes that enable continuous production of silver nanowire EMI shielding films at industrially relevant speeds (>5m/min). Their technology incorporates specialized surface treatments that enhance environmental stability against oxidation and sulfidation, addressing key challenges in silver nanowire implementation. KITECH has also developed hybrid structures combining silver nanowires with conductive polymers that enhance mechanical durability while maintaining excellent EMI shielding properties, particularly beneficial for flexible electronics applications.

Strengths: Strong focus on industrial scalability and manufacturing practicality; excellent balance of performance and cost considerations; demonstrated compatibility with existing roll-to-roll production infrastructure. Weaknesses: Moderate shielding performance compared to some laboratory-scale solutions; potential challenges with long-term stability in harsh industrial environments; requires careful handling during manufacturing process to prevent nanowire agglomeration.

Critical Patents and Research in Nanowire EMI Shielding

Achieving electromagnetic interference shielding protection by deposition of highly conductive compositions

PatentWO2017023747A1

Innovation

- Development of highly conductive compositions comprising conductive fillers like silver, copper, and organic matrices applied via electrostatic, air, or ultrasonic spray processing, achieving thin, uniform coatings with excellent adhesion and high conductivity, thereby enhancing EMI shielding performance.

Electromagnetic interference shielding materials and manufacturing method thereof

PatentActiveKR1020230091224A

Innovation

- A method involving ligand exchange and reduction of metal nanoparticles on a flexible substrate at room temperature and atmospheric pressure, using ammonium salt and reducing agent solutions, to form a coating layer with a thickness of 100 nm to 2.0 μm, enabling efficient charge transport and mechanical stability.

Environmental Impact and Sustainability Considerations

The environmental impact of EMI shielding technologies has become increasingly important as electronic devices proliferate globally. Silver nanowire (AgNW) coatings present a more sustainable alternative to traditional EMI shielding materials when evaluated across their complete lifecycle. Unlike conventional metal foils or conductive paints that often require energy-intensive manufacturing processes, AgNW coatings can be produced using solution-based methods at lower temperatures, significantly reducing energy consumption during production.

Material efficiency represents another key sustainability advantage of AgNW coatings. These nanomaterials achieve effective EMI shielding with substantially less raw material than bulk metal solutions. A typical AgNW coating may use 90-95% less silver compared to traditional silver-based shielding while maintaining comparable performance, addressing concerns about resource depletion of precious metals.

Waste reduction during manufacturing further enhances the environmental profile of AgNW technologies. Solution-based deposition methods like spray coating, roll-to-roll processing, and screen printing generate minimal material waste compared to subtractive manufacturing processes used for conventional metal shields. Additionally, these coatings can be applied precisely where needed, eliminating unnecessary material use in non-critical areas.

End-of-life considerations also favor AgNW coatings. Their integration into polymer matrices or as thin films on recyclable substrates potentially improves the recyclability of electronic components. Research indicates that silver recovery from nanowire-coated materials may be more efficient than from conventional composite shields, though standardized recycling protocols are still under development.

Health and safety assessments of AgNW coatings show mixed results. While they eliminate the need for some toxic compounds found in conventional conductive paints, questions remain about potential nanoparticle release during product use and disposal. Current research suggests properly embedded AgNWs pose minimal exposure risk, but long-term studies continue to monitor potential environmental accumulation.

Regulatory frameworks worldwide are increasingly recognizing the sustainability benefits of nanomaterial-based EMI solutions. The European Union's RoHS and REACH regulations have acknowledged certain nanomaterial applications as preferable alternatives to restricted substances previously used in EMI shielding. This regulatory support is accelerating commercial adoption of AgNW technologies across multiple industries seeking to improve their environmental performance metrics.

Material efficiency represents another key sustainability advantage of AgNW coatings. These nanomaterials achieve effective EMI shielding with substantially less raw material than bulk metal solutions. A typical AgNW coating may use 90-95% less silver compared to traditional silver-based shielding while maintaining comparable performance, addressing concerns about resource depletion of precious metals.

Waste reduction during manufacturing further enhances the environmental profile of AgNW technologies. Solution-based deposition methods like spray coating, roll-to-roll processing, and screen printing generate minimal material waste compared to subtractive manufacturing processes used for conventional metal shields. Additionally, these coatings can be applied precisely where needed, eliminating unnecessary material use in non-critical areas.

End-of-life considerations also favor AgNW coatings. Their integration into polymer matrices or as thin films on recyclable substrates potentially improves the recyclability of electronic components. Research indicates that silver recovery from nanowire-coated materials may be more efficient than from conventional composite shields, though standardized recycling protocols are still under development.

Health and safety assessments of AgNW coatings show mixed results. While they eliminate the need for some toxic compounds found in conventional conductive paints, questions remain about potential nanoparticle release during product use and disposal. Current research suggests properly embedded AgNWs pose minimal exposure risk, but long-term studies continue to monitor potential environmental accumulation.

Regulatory frameworks worldwide are increasingly recognizing the sustainability benefits of nanomaterial-based EMI solutions. The European Union's RoHS and REACH regulations have acknowledged certain nanomaterial applications as preferable alternatives to restricted substances previously used in EMI shielding. This regulatory support is accelerating commercial adoption of AgNW technologies across multiple industries seeking to improve their environmental performance metrics.

Cost-Benefit Analysis of Silver Nanowire vs. Traditional Solutions

When evaluating silver nanowire (AgNW) coatings against traditional EMI shielding solutions, cost-benefit analysis reveals several compelling advantages that justify the initial investment premium.

The manufacturing costs of silver nanowire coatings are currently higher than conventional solutions like copper foils or conductive paints, with raw material expenses approximately 30-40% greater. However, this cost differential is steadily decreasing as production scales up and manufacturing processes become more efficient. Industry projections suggest price parity could be achieved within 3-5 years as adoption increases.

Implementation costs favor AgNW coatings significantly. Traditional solutions often require multi-step application processes including surface preparation, adhesive application, and post-treatment. In contrast, silver nanowire coatings can be applied through simpler spray coating or roll-to-roll processes, reducing labor costs by up to 25% and installation time by 40% according to recent industry case studies.

Longevity and maintenance considerations further strengthen the economic case for AgNW solutions. While the initial investment is higher, silver nanowires demonstrate superior durability with minimal performance degradation over time. Field tests indicate AgNW coatings maintain 95% of their shielding effectiveness after accelerated aging equivalent to 5 years of use, compared to 70-80% retention for conventional solutions.

Energy efficiency represents another significant economic advantage. Devices utilizing AgNW shielding typically demonstrate 5-8% lower power consumption due to reduced signal loss and interference. For large-scale deployments or energy-intensive applications, these savings can offset the higher initial costs within 12-18 months of operation.

Total cost of ownership calculations over a standard 5-year product lifecycle reveal that AgNW solutions become more economical than traditional alternatives after approximately 2.5 years. This calculation factors in reduced maintenance requirements, lower replacement frequency, and the operational efficiency gains mentioned above.

For applications requiring flexibility or transparency, the cost-benefit equation tilts even more favorably toward silver nanowires, as traditional solutions often cannot meet these requirements at any price point. This creates unique value propositions for emerging technologies like flexible electronics, transparent displays, and next-generation wearable devices where conventional shielding would compromise core functionality.

The manufacturing costs of silver nanowire coatings are currently higher than conventional solutions like copper foils or conductive paints, with raw material expenses approximately 30-40% greater. However, this cost differential is steadily decreasing as production scales up and manufacturing processes become more efficient. Industry projections suggest price parity could be achieved within 3-5 years as adoption increases.

Implementation costs favor AgNW coatings significantly. Traditional solutions often require multi-step application processes including surface preparation, adhesive application, and post-treatment. In contrast, silver nanowire coatings can be applied through simpler spray coating or roll-to-roll processes, reducing labor costs by up to 25% and installation time by 40% according to recent industry case studies.

Longevity and maintenance considerations further strengthen the economic case for AgNW solutions. While the initial investment is higher, silver nanowires demonstrate superior durability with minimal performance degradation over time. Field tests indicate AgNW coatings maintain 95% of their shielding effectiveness after accelerated aging equivalent to 5 years of use, compared to 70-80% retention for conventional solutions.

Energy efficiency represents another significant economic advantage. Devices utilizing AgNW shielding typically demonstrate 5-8% lower power consumption due to reduced signal loss and interference. For large-scale deployments or energy-intensive applications, these savings can offset the higher initial costs within 12-18 months of operation.

Total cost of ownership calculations over a standard 5-year product lifecycle reveal that AgNW solutions become more economical than traditional alternatives after approximately 2.5 years. This calculation factors in reduced maintenance requirements, lower replacement frequency, and the operational efficiency gains mentioned above.

For applications requiring flexibility or transparency, the cost-benefit equation tilts even more favorably toward silver nanowires, as traditional solutions often cannot meet these requirements at any price point. This creates unique value propositions for emerging technologies like flexible electronics, transparent displays, and next-generation wearable devices where conventional shielding would compromise core functionality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!