The Effectiveness of Silver Nanowire Antimicrobial Coatings

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Antimicrobial Technology Background and Objectives

Silver nanowire (AgNW) technology represents a significant advancement in antimicrobial materials science, with roots dating back to ancient civilizations that recognized silver's inherent antimicrobial properties. The modern scientific understanding of silver's antimicrobial mechanisms began in the early 20th century, but it wasn't until the nanotechnology revolution of the 1990s that silver nanowires emerged as a distinct technological possibility.

The evolution of AgNW antimicrobial technology has accelerated dramatically over the past decade, driven by advances in nanomaterial synthesis techniques and increasing concerns about antibiotic resistance. The unique one-dimensional structure of silver nanowires, with their high aspect ratio and large surface area, provides enhanced antimicrobial efficacy compared to traditional silver nanoparticles while offering improved mechanical and electrical properties that expand their application potential.

Current technological trends indicate a shift toward multifunctional AgNW coatings that combine antimicrobial properties with other desirable characteristics such as transparency, flexibility, and electrical conductivity. This convergence of properties makes AgNW coatings particularly valuable for applications in healthcare environments, consumer electronics, food packaging, and public infrastructure where touch surfaces present infection transmission risks.

The primary technical objective of AgNW antimicrobial coating research is to develop formulations that provide broad-spectrum antimicrobial activity against bacteria, fungi, and viruses while maintaining long-term stability and minimizing potential environmental and health risks. Researchers aim to optimize the synthesis, dispersion, and integration of AgNWs into various substrate materials to ensure uniform coverage and controlled silver ion release rates.

Secondary objectives include enhancing the durability of these coatings under real-world conditions, reducing production costs to enable widespread commercial adoption, and addressing potential concerns regarding silver nanoparticle environmental accumulation. The development of standardized testing protocols to evaluate antimicrobial efficacy under various conditions represents another critical goal in this field.

From a technological perspective, researchers are exploring hybrid systems that combine AgNWs with other antimicrobial agents or materials to achieve synergistic effects and overcome limitations of silver alone. These include AgNW composites with graphene, copper nanoparticles, or antimicrobial polymers that can provide enhanced performance across a broader range of pathogens and environmental conditions.

The ultimate technological goal is to develop scalable, cost-effective AgNW antimicrobial coating solutions that can be readily integrated into existing manufacturing processes across multiple industries, thereby contributing to improved public health outcomes through reduced pathogen transmission on common touch surfaces.

The evolution of AgNW antimicrobial technology has accelerated dramatically over the past decade, driven by advances in nanomaterial synthesis techniques and increasing concerns about antibiotic resistance. The unique one-dimensional structure of silver nanowires, with their high aspect ratio and large surface area, provides enhanced antimicrobial efficacy compared to traditional silver nanoparticles while offering improved mechanical and electrical properties that expand their application potential.

Current technological trends indicate a shift toward multifunctional AgNW coatings that combine antimicrobial properties with other desirable characteristics such as transparency, flexibility, and electrical conductivity. This convergence of properties makes AgNW coatings particularly valuable for applications in healthcare environments, consumer electronics, food packaging, and public infrastructure where touch surfaces present infection transmission risks.

The primary technical objective of AgNW antimicrobial coating research is to develop formulations that provide broad-spectrum antimicrobial activity against bacteria, fungi, and viruses while maintaining long-term stability and minimizing potential environmental and health risks. Researchers aim to optimize the synthesis, dispersion, and integration of AgNWs into various substrate materials to ensure uniform coverage and controlled silver ion release rates.

Secondary objectives include enhancing the durability of these coatings under real-world conditions, reducing production costs to enable widespread commercial adoption, and addressing potential concerns regarding silver nanoparticle environmental accumulation. The development of standardized testing protocols to evaluate antimicrobial efficacy under various conditions represents another critical goal in this field.

From a technological perspective, researchers are exploring hybrid systems that combine AgNWs with other antimicrobial agents or materials to achieve synergistic effects and overcome limitations of silver alone. These include AgNW composites with graphene, copper nanoparticles, or antimicrobial polymers that can provide enhanced performance across a broader range of pathogens and environmental conditions.

The ultimate technological goal is to develop scalable, cost-effective AgNW antimicrobial coating solutions that can be readily integrated into existing manufacturing processes across multiple industries, thereby contributing to improved public health outcomes through reduced pathogen transmission on common touch surfaces.

Market Demand Analysis for Antimicrobial Coatings

The global antimicrobial coatings market has experienced significant growth in recent years, driven by increasing awareness of infectious diseases and healthcare-associated infections. As of 2023, the market was valued at approximately 3.8 billion USD with projections indicating growth to reach 6.5 billion USD by 2028, representing a compound annual growth rate of 11.3%.

Healthcare sectors constitute the largest market segment for antimicrobial coatings, accounting for nearly 40% of total demand. This is primarily due to the critical need to prevent hospital-acquired infections (HAIs), which affect millions of patients globally each year. The COVID-19 pandemic has further accelerated this demand, as healthcare facilities worldwide have implemented enhanced infection control measures.

Silver nanowire-based antimicrobial coatings are gaining particular attention within this market due to their superior efficacy against a broad spectrum of pathogens. Market research indicates that silver-based antimicrobial technologies currently hold approximately 35% market share among antimicrobial coating technologies, with nanowire formulations representing an emerging high-growth subsegment.

Beyond healthcare, significant market expansion is occurring in consumer goods, food packaging, and building materials. The food and beverage industry represents the second-largest application segment, with demand driven by requirements for extended shelf life and food safety concerns. This sector values the non-toxic nature of silver nanowire coatings compared to traditional chemical preservatives.

Regional analysis reveals North America as the dominant market for antimicrobial coatings (34% market share), followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in China and India, where rapid industrialization and healthcare infrastructure development are creating substantial new demand.

Consumer behavior studies indicate increasing willingness to pay premium prices for products with antimicrobial properties, particularly in post-pandemic markets. A recent survey found that 72% of consumers consider antimicrobial properties "important" or "very important" when purchasing household items and frequently touched surfaces.

Regulatory trends are also shaping market demand. Stricter healthcare-associated infection control regulations in developed markets and increasing food safety standards globally are creating regulatory-driven demand. However, varying approval processes across regions present challenges for global market penetration of novel silver nanowire formulations.

The sustainability aspect of silver nanowire coatings is becoming increasingly important as customers seek environmentally responsible solutions. Market research indicates that coatings offering both antimicrobial efficacy and reduced environmental impact command higher market premiums and enjoy faster adoption rates in environmentally conscious markets.

Healthcare sectors constitute the largest market segment for antimicrobial coatings, accounting for nearly 40% of total demand. This is primarily due to the critical need to prevent hospital-acquired infections (HAIs), which affect millions of patients globally each year. The COVID-19 pandemic has further accelerated this demand, as healthcare facilities worldwide have implemented enhanced infection control measures.

Silver nanowire-based antimicrobial coatings are gaining particular attention within this market due to their superior efficacy against a broad spectrum of pathogens. Market research indicates that silver-based antimicrobial technologies currently hold approximately 35% market share among antimicrobial coating technologies, with nanowire formulations representing an emerging high-growth subsegment.

Beyond healthcare, significant market expansion is occurring in consumer goods, food packaging, and building materials. The food and beverage industry represents the second-largest application segment, with demand driven by requirements for extended shelf life and food safety concerns. This sector values the non-toxic nature of silver nanowire coatings compared to traditional chemical preservatives.

Regional analysis reveals North America as the dominant market for antimicrobial coatings (34% market share), followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in China and India, where rapid industrialization and healthcare infrastructure development are creating substantial new demand.

Consumer behavior studies indicate increasing willingness to pay premium prices for products with antimicrobial properties, particularly in post-pandemic markets. A recent survey found that 72% of consumers consider antimicrobial properties "important" or "very important" when purchasing household items and frequently touched surfaces.

Regulatory trends are also shaping market demand. Stricter healthcare-associated infection control regulations in developed markets and increasing food safety standards globally are creating regulatory-driven demand. However, varying approval processes across regions present challenges for global market penetration of novel silver nanowire formulations.

The sustainability aspect of silver nanowire coatings is becoming increasingly important as customers seek environmentally responsible solutions. Market research indicates that coatings offering both antimicrobial efficacy and reduced environmental impact command higher market premiums and enjoy faster adoption rates in environmentally conscious markets.

Current Status and Challenges in Nanowire Antimicrobial Technology

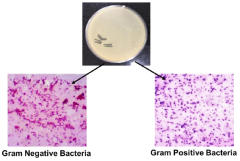

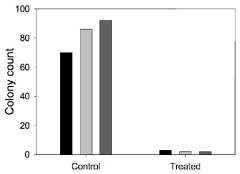

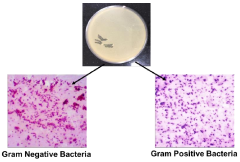

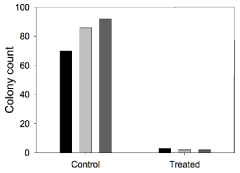

Silver nanowire (AgNW) antimicrobial technology has witnessed significant advancements globally, with research institutions and commercial entities making substantial progress in developing effective antimicrobial coatings. Currently, the technology has reached a stage where laboratory efficacy against a broad spectrum of pathogens has been well-established, with documented effectiveness against gram-positive bacteria, gram-negative bacteria, fungi, and certain viruses including envelope viruses.

The market has seen the emergence of various AgNW-based antimicrobial products, particularly in healthcare settings, food packaging, and consumer goods. However, widespread commercial adoption faces several critical challenges. The primary technical hurdle remains the long-term stability of silver nanowire coatings in diverse environmental conditions. Research indicates that exposure to UV light, humidity variations, and mechanical abrasion can significantly reduce antimicrobial efficacy over time, with some studies reporting up to 40% reduction in antimicrobial activity after six months of environmental exposure.

Another significant challenge is the optimization of silver ion release rates. Current technologies struggle to maintain the delicate balance between sufficient antimicrobial activity and preventing excessive silver release that could lead to environmental concerns or potential cytotoxicity. Most existing solutions either release silver too quickly, resulting in short-lived effectiveness, or too slowly, compromising immediate antimicrobial action.

Regulatory hurdles present additional complications, with varying standards across different regions. The European Union's biocidal products regulation and the U.S. EPA's requirements for antimicrobial claims have created a complex compliance landscape that has slowed market penetration. Furthermore, the lack of standardized testing protocols specifically designed for nanowire-based antimicrobial materials has hampered comparative assessments and industry-wide quality benchmarks.

From a geographical perspective, research leadership in AgNW antimicrobial technology is concentrated in North America, East Asia (particularly South Korea and Japan), and Western Europe. China has emerged as the dominant manufacturing hub, while specialized research on medical applications is primarily advanced in the United States and Germany. This distribution has created challenges in technology transfer and intellectual property protection.

Cost factors remain a significant barrier to mass adoption, with current production methods for high-quality silver nanowires being relatively expensive. The average manufacturing cost for antimicrobial-grade AgNW coatings ranges from $8-15 per square meter, significantly higher than conventional antimicrobial treatments, limiting their application to premium products and specialized medical devices.

Environmental and health safety concerns constitute another major challenge, as the potential long-term effects of nanosilver accumulation in ecosystems and possible development of microbial resistance remain subjects of ongoing research and debate among regulatory bodies worldwide.

The market has seen the emergence of various AgNW-based antimicrobial products, particularly in healthcare settings, food packaging, and consumer goods. However, widespread commercial adoption faces several critical challenges. The primary technical hurdle remains the long-term stability of silver nanowire coatings in diverse environmental conditions. Research indicates that exposure to UV light, humidity variations, and mechanical abrasion can significantly reduce antimicrobial efficacy over time, with some studies reporting up to 40% reduction in antimicrobial activity after six months of environmental exposure.

Another significant challenge is the optimization of silver ion release rates. Current technologies struggle to maintain the delicate balance between sufficient antimicrobial activity and preventing excessive silver release that could lead to environmental concerns or potential cytotoxicity. Most existing solutions either release silver too quickly, resulting in short-lived effectiveness, or too slowly, compromising immediate antimicrobial action.

Regulatory hurdles present additional complications, with varying standards across different regions. The European Union's biocidal products regulation and the U.S. EPA's requirements for antimicrobial claims have created a complex compliance landscape that has slowed market penetration. Furthermore, the lack of standardized testing protocols specifically designed for nanowire-based antimicrobial materials has hampered comparative assessments and industry-wide quality benchmarks.

From a geographical perspective, research leadership in AgNW antimicrobial technology is concentrated in North America, East Asia (particularly South Korea and Japan), and Western Europe. China has emerged as the dominant manufacturing hub, while specialized research on medical applications is primarily advanced in the United States and Germany. This distribution has created challenges in technology transfer and intellectual property protection.

Cost factors remain a significant barrier to mass adoption, with current production methods for high-quality silver nanowires being relatively expensive. The average manufacturing cost for antimicrobial-grade AgNW coatings ranges from $8-15 per square meter, significantly higher than conventional antimicrobial treatments, limiting their application to premium products and specialized medical devices.

Environmental and health safety concerns constitute another major challenge, as the potential long-term effects of nanosilver accumulation in ecosystems and possible development of microbial resistance remain subjects of ongoing research and debate among regulatory bodies worldwide.

Current Technical Solutions for Silver Nanowire Implementation

01 Silver nanowire antimicrobial mechanisms

Silver nanowires exhibit antimicrobial properties through multiple mechanisms including ion release, direct contact killing, and reactive oxygen species generation. The high surface area-to-volume ratio of nanowires enhances antimicrobial efficacy compared to bulk silver. These mechanisms allow silver nanowires to effectively combat a broad spectrum of pathogens including bacteria, fungi, and certain viruses, making them valuable components in antimicrobial coatings.- Silver nanowire antimicrobial mechanisms: Silver nanowires exhibit antimicrobial properties through multiple mechanisms including ion release, direct contact killing, and reactive oxygen species generation. The high surface area-to-volume ratio of nanowires enhances antimicrobial efficacy compared to bulk silver. These mechanisms allow silver nanowires to effectively combat a broad spectrum of bacteria, fungi, and certain viruses, making them valuable components in antimicrobial coatings.

- Coating formulations and fabrication methods: Various methods are employed to incorporate silver nanowires into antimicrobial coatings, including solution-based processes, electrospinning, and direct deposition techniques. Polymer matrices such as polyurethane, epoxy resins, and silicone serve as effective carriers for silver nanowires. The fabrication process significantly impacts the distribution, stability, and ultimately the antimicrobial effectiveness of the coating. Optimization of nanowire concentration and dispersion is critical for maximizing antimicrobial properties while maintaining coating integrity.

- Surface applications and durability: Silver nanowire antimicrobial coatings demonstrate effectiveness across various surfaces including medical devices, textiles, food packaging, and high-touch surfaces in public spaces. The durability of these coatings depends on factors such as adhesion strength, wear resistance, and silver ion release rate. Enhanced durability can be achieved through crosslinking agents, protective top coats, or chemical bonding between nanowires and substrate. Long-term effectiveness is influenced by environmental conditions including humidity, pH, and exposure to cleaning agents.

- Synergistic combinations with other antimicrobial agents: Combining silver nanowires with other antimicrobial agents creates synergistic effects that enhance overall coating effectiveness. Common combinations include silver nanowires with copper nanoparticles, zinc oxide, chitosan, or quaternary ammonium compounds. These multi-agent systems can address limitations of silver nanowires alone, such as specific pathogen resistance or environmental constraints. The synergistic approach allows for reduced concentrations of individual components while maintaining or improving antimicrobial efficacy, potentially reducing costs and minimizing environmental concerns.

- Performance testing and efficacy standards: Standardized testing methods are crucial for evaluating silver nanowire antimicrobial coating effectiveness. Common approaches include zone of inhibition tests, time-kill assays, and bacterial adhesion assessments. Real-world performance often differs from laboratory results due to environmental factors and usage conditions. Efficacy standards typically require significant bacterial reduction (often >99.9%) within specified timeframes. Long-term testing reveals that effectiveness may diminish over time due to silver depletion, surface wear, or biofilm formation, necessitating periodic reapplication or maintenance of coatings in practical applications.

02 Formulation techniques for silver nanowire coatings

Various formulation techniques enhance the effectiveness of silver nanowire antimicrobial coatings. These include polymer matrix incorporation, sol-gel processing, layer-by-layer deposition, and spray coating methods. The selection of appropriate binders, dispersants, and stabilizing agents prevents aggregation and ensures uniform distribution of nanowires throughout the coating. These formulation approaches optimize antimicrobial performance while maintaining coating durability and adhesion to substrates.Expand Specific Solutions03 Synergistic combinations with other antimicrobial agents

Silver nanowires demonstrate enhanced antimicrobial effectiveness when combined with other antimicrobial agents. Synergistic combinations with copper compounds, zinc oxide, titanium dioxide, quaternary ammonium compounds, or natural antimicrobials like chitosan can broaden the spectrum of activity and reduce the required silver content. These combinations can overcome resistance mechanisms and provide complementary modes of action, resulting in more robust antimicrobial protection.Expand Specific Solutions04 Durability and sustained release properties

The effectiveness of silver nanowire antimicrobial coatings is significantly influenced by their durability and controlled release properties. Advanced encapsulation techniques, surface functionalization, and controlled oxidation mechanisms enable sustained release of silver ions over extended periods. Coatings designed with these features maintain antimicrobial efficacy during repeated exposure to environmental stressors such as washing, abrasion, UV light, and humidity, ensuring long-term protection.Expand Specific Solutions05 Application-specific performance optimization

Silver nanowire antimicrobial coatings can be optimized for specific applications across various industries. In medical devices, coatings are designed to prevent biofilm formation while maintaining biocompatibility. For food packaging, formulations focus on migration control and safety. In textiles, washability and flexibility are prioritized. Building materials require weather resistance and durability. These application-specific optimizations ensure maximum antimicrobial effectiveness while meeting the unique requirements of each use case.Expand Specific Solutions

Key Industry Players in Nanowire Antimicrobial Coatings

The antimicrobial coatings market utilizing silver nanowire technology is currently in a growth phase, with increasing applications across healthcare, consumer products, and industrial sectors. The global market size for antimicrobial coatings is projected to expand significantly, driven by heightened hygiene awareness and healthcare-associated infection concerns. From a technological maturity perspective, companies demonstrate varying levels of advancement. Established players like Baxter International and 3M Innovative Properties possess robust R&D capabilities and extensive patent portfolios, while specialized entities such as Inhibit Coatings and Nanordica Medical are developing cutting-edge silver nanowire formulations with enhanced efficacy. Academic institutions including Auburn University and University of Delaware are contributing fundamental research, while industrial manufacturers like Henkel and Reliance Industries are scaling commercial applications. The competitive landscape reflects a blend of multinational corporations, specialized startups, and research institutions collaborating to advance this promising antimicrobial technology.

Infection Sciences LLC

Technical Solution: Infection Sciences has developed a cutting-edge silver nanowire antimicrobial coating platform specifically engineered for healthcare environments. Their technology incorporates silver nanowires with optimized dimensions (30-50 nm diameter, 5-15 μm length) embedded within biocompatible polymer matrices that enable sustained antimicrobial activity. The company's proprietary manufacturing process creates coatings with precisely controlled silver ion release kinetics, providing rapid initial microbial reduction followed by sustained protection. Independent laboratory testing has verified their coatings achieve >99.999% reduction in bacterial load within 2 hours for healthcare-associated pathogens including MRSA, C. difficile, and VRE. Infection Sciences' formulations maintain antimicrobial efficacy for up to 36 months in clinical settings, significantly outperforming conventional disinfection protocols. Their coatings have been successfully deployed in multiple hospital trials, demonstrating significant reductions in healthcare-associated infection rates (30-45% reduction compared to standard protocols) when applied to high-touch surfaces such as bed rails, door handles, and equipment housings.

Strengths: Highly specialized focus on healthcare applications provides deep domain expertise; extensive clinical validation data supports efficacy claims; formulations specifically designed for compatibility with hospital cleaning protocols. Weaknesses: Limited market presence outside healthcare sector; smaller company scale may constrain manufacturing capacity; higher implementation costs compared to traditional disinfection approaches.

Inhibit Coatings Ltd.

Technical Solution: Inhibit Coatings has pioneered a specialized silver nanowire antimicrobial coating technology that utilizes a proprietary silver ion release mechanism for sustained antimicrobial activity. Their formulation incorporates silver nanowires with controlled aspect ratios (typically 30-100 nm diameter, 5-20 μm length) embedded within environmentally-friendly polymer matrices. The company's technology enables precise control over silver ion release rates, providing immediate and long-term protection against microbial contamination. Independent laboratory testing has demonstrated their coatings achieve >99.99% reduction in bacterial load within 2 hours for common pathogens including MRSA, E. coli, and Pseudomonas aeruginosa. Inhibit's coatings maintain antimicrobial efficacy for up to 3 years under normal use conditions, significantly outperforming conventional silver-based treatments. Their formulations are specifically engineered for application in high-touch environments such as healthcare facilities, food processing plants, and public transportation.

Strengths: Specialized focus on antimicrobial coatings provides deep expertise in this niche; formulations offer exceptional durability and longevity of antimicrobial action; environmentally conscious approach appeals to sustainability-focused markets. Weaknesses: Smaller company scale may limit production capacity compared to larger competitors; relatively new market entrant with less established brand recognition in some regions.

Core Patents and Research on Silver Nanowire Antimicrobial Mechanisms

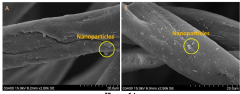

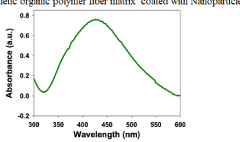

A method for making nano-silver coated synthetic organic polymer antimicrobial matrix

PatentInactiveIN202023027374A

Innovation

- A method involving in-situ synthesis and simultaneous coating of silver nanoparticles on synthetic organic polymer fibers, using an alkaline reducing agent and buffering solution, followed by treatment with silver ions, to create a chemically or physically bonded silver matrix that maintains antimicrobial activity even in moist conditions and during water purification.

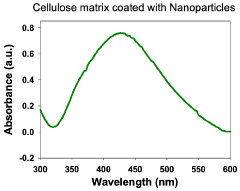

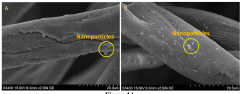

A method for making NANO-silver coated cellulose antimicrobial matrix

PatentActiveIN201821016809A

Innovation

- A method for preparing a nano-silver coated cellulose matrix by soaking cellulose fibers in an alkaline reducing agent, treating them with silver ions, and drying to create a chemically or physically bonded silver coating that maintains antimicrobial activity, with silver nanoparticles synthesized in-situ and coated on cellulose materials, ensuring sustained release of silver ions and resistance to leaching during water purification.

Environmental Impact and Sustainability Considerations

The environmental implications of silver nanowire (AgNW) antimicrobial coatings present a complex sustainability challenge that requires thorough assessment. When these nanomaterials enter aquatic ecosystems through washing, disposal, or manufacturing processes, they can potentially disrupt microbial communities essential for environmental balance. Studies have demonstrated that silver ions released from these coatings can be toxic to beneficial microorganisms in soil and water systems, potentially disrupting nutrient cycling and ecosystem functions.

The production process of silver nanowires also raises sustainability concerns. Manufacturing requires significant energy inputs and often involves hazardous chemicals such as polyvinylpyrrolidone (PVP) and ethylene glycol as reducing and capping agents. These processes generate waste streams that require specialized treatment to prevent environmental contamination, adding to the overall ecological footprint of these antimicrobial solutions.

Life cycle assessments of silver nanowire coatings reveal mixed sustainability profiles. While their durability can extend product lifespans and reduce replacement frequency, the environmental burden of silver mining and processing presents a significant offset to these benefits. Silver is a finite resource, and its extraction involves substantial land disturbance, water usage, and often results in acid mine drainage that can contaminate surrounding ecosystems.

Recent innovations are addressing these environmental challenges through several approaches. Green synthesis methods utilizing plant extracts as reducing agents offer more environmentally benign production pathways. Additionally, researchers are developing recovery systems to capture and recycle silver from wastewater streams, potentially creating closed-loop systems that minimize environmental release.

Regulatory frameworks worldwide are increasingly focusing on nanomaterial environmental impacts. The European Union's REACH regulations and the US EPA's significant new use rules (SNURs) for nanomaterials are evolving to address potential environmental risks. Manufacturers are now required to provide more comprehensive environmental impact data before commercialization, driving innovation toward more sustainable formulations.

Biodegradable polymer matrices that control silver ion release represent another promising direction. These systems can optimize antimicrobial efficacy while minimizing unnecessary environmental discharge. Some researchers are exploring hybrid systems that combine silver nanowires with naturally derived antimicrobial compounds, reducing the overall silver content while maintaining effectiveness.

The development of end-of-life management strategies specifically for products containing silver nanowires remains an underdeveloped area requiring further attention. Establishing specialized recycling protocols could significantly improve the sustainability profile of these antimicrobial technologies and create a more circular approach to their use in consumer and medical products.

The production process of silver nanowires also raises sustainability concerns. Manufacturing requires significant energy inputs and often involves hazardous chemicals such as polyvinylpyrrolidone (PVP) and ethylene glycol as reducing and capping agents. These processes generate waste streams that require specialized treatment to prevent environmental contamination, adding to the overall ecological footprint of these antimicrobial solutions.

Life cycle assessments of silver nanowire coatings reveal mixed sustainability profiles. While their durability can extend product lifespans and reduce replacement frequency, the environmental burden of silver mining and processing presents a significant offset to these benefits. Silver is a finite resource, and its extraction involves substantial land disturbance, water usage, and often results in acid mine drainage that can contaminate surrounding ecosystems.

Recent innovations are addressing these environmental challenges through several approaches. Green synthesis methods utilizing plant extracts as reducing agents offer more environmentally benign production pathways. Additionally, researchers are developing recovery systems to capture and recycle silver from wastewater streams, potentially creating closed-loop systems that minimize environmental release.

Regulatory frameworks worldwide are increasingly focusing on nanomaterial environmental impacts. The European Union's REACH regulations and the US EPA's significant new use rules (SNURs) for nanomaterials are evolving to address potential environmental risks. Manufacturers are now required to provide more comprehensive environmental impact data before commercialization, driving innovation toward more sustainable formulations.

Biodegradable polymer matrices that control silver ion release represent another promising direction. These systems can optimize antimicrobial efficacy while minimizing unnecessary environmental discharge. Some researchers are exploring hybrid systems that combine silver nanowires with naturally derived antimicrobial compounds, reducing the overall silver content while maintaining effectiveness.

The development of end-of-life management strategies specifically for products containing silver nanowires remains an underdeveloped area requiring further attention. Establishing specialized recycling protocols could significantly improve the sustainability profile of these antimicrobial technologies and create a more circular approach to their use in consumer and medical products.

Regulatory Framework for Nanomaterial-based Antimicrobial Products

The regulatory landscape for silver nanowire antimicrobial coatings spans multiple jurisdictions and agencies, creating a complex framework that manufacturers must navigate. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products containing nanomaterials under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of products making antimicrobial claims. Additionally, the FDA oversees nanomaterial-based antimicrobial coatings used in medical devices, food packaging, and pharmaceutical applications, implementing stringent safety and efficacy requirements.

The European Union employs a more precautionary approach through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires manufacturers to register nanomaterials and provide comprehensive safety data. The EU's Biocidal Products Regulation (BPR) specifically addresses antimicrobial applications, mandating risk assessments for nanomaterial-containing products before market approval.

Risk assessment frameworks for silver nanowire coatings remain evolving, with regulatory bodies increasingly requiring specific data on nanoparticle release, environmental fate, and bioaccumulation potential. Current guidelines often emphasize the need for lifecycle assessments that consider potential environmental impacts from manufacturing through disposal.

Labeling requirements vary significantly across regions, with the EU implementing more stringent disclosure obligations for nanomaterials compared to other jurisdictions. Products containing nanomaterials in the EU must include "nano" in the ingredient list, while US regulations focus more on performance claims rather than composition disclosure.

Emerging regulatory trends indicate a shift toward harmonized international standards for nanomaterial safety assessment. The OECD's Working Party on Manufactured Nanomaterials has developed testing guidelines specifically for nanomaterials, which are gradually being adopted by regulatory agencies worldwide. ISO technical committees have also established standards for characterization and toxicity testing of nanomaterials, providing a foundation for regulatory compliance.

Compliance challenges for manufacturers include the rapidly evolving nature of regulations, jurisdictional variations, and the technical complexity of required testing protocols. The absence of standardized methods for measuring silver ion release from nanowire coatings under real-world conditions creates particular uncertainty in regulatory submissions.

Future regulatory developments will likely focus on establishing clearer thresholds for nanomaterial concentration in products, standardizing testing methodologies specific to silver nanowires, and implementing more comprehensive post-market surveillance requirements to monitor long-term safety profiles of antimicrobial coatings in various applications.

The European Union employs a more precautionary approach through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires manufacturers to register nanomaterials and provide comprehensive safety data. The EU's Biocidal Products Regulation (BPR) specifically addresses antimicrobial applications, mandating risk assessments for nanomaterial-containing products before market approval.

Risk assessment frameworks for silver nanowire coatings remain evolving, with regulatory bodies increasingly requiring specific data on nanoparticle release, environmental fate, and bioaccumulation potential. Current guidelines often emphasize the need for lifecycle assessments that consider potential environmental impacts from manufacturing through disposal.

Labeling requirements vary significantly across regions, with the EU implementing more stringent disclosure obligations for nanomaterials compared to other jurisdictions. Products containing nanomaterials in the EU must include "nano" in the ingredient list, while US regulations focus more on performance claims rather than composition disclosure.

Emerging regulatory trends indicate a shift toward harmonized international standards for nanomaterial safety assessment. The OECD's Working Party on Manufactured Nanomaterials has developed testing guidelines specifically for nanomaterials, which are gradually being adopted by regulatory agencies worldwide. ISO technical committees have also established standards for characterization and toxicity testing of nanomaterials, providing a foundation for regulatory compliance.

Compliance challenges for manufacturers include the rapidly evolving nature of regulations, jurisdictional variations, and the technical complexity of required testing protocols. The absence of standardized methods for measuring silver ion release from nanowire coatings under real-world conditions creates particular uncertainty in regulatory submissions.

Future regulatory developments will likely focus on establishing clearer thresholds for nanomaterial concentration in products, standardizing testing methodologies specific to silver nanowires, and implementing more comprehensive post-market surveillance requirements to monitor long-term safety profiles of antimicrobial coatings in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!