The Development of Silver Nanowire Regulations for Environmental Safety

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Technology Background and Objectives

Silver nanowires (AgNWs) have emerged as a revolutionary material in the field of nanotechnology over the past two decades. These one-dimensional nanostructures, typically 30-200 nm in diameter and several micrometers in length, possess exceptional electrical conductivity, optical transparency, and mechanical flexibility. The development of AgNWs can be traced back to the early 2000s when researchers began exploring alternatives to indium tin oxide (ITO) for transparent conductive applications. The scarcity and rising cost of indium drove this technological evolution, positioning AgNWs as a promising substitute.

The technological trajectory of AgNWs has been characterized by continuous improvements in synthesis methods, from initial polyol processes to more sophisticated approaches enabling precise control over dimensions and properties. This evolution has expanded their application potential beyond transparent electrodes to include sensors, antimicrobial coatings, and biomedical devices. However, this rapid technological advancement has outpaced the development of appropriate regulatory frameworks addressing their environmental and health implications.

As AgNW production scales up for commercial applications, concerns regarding their environmental fate and potential toxicity have gained prominence. Silver is known for its antimicrobial properties, which while beneficial in certain contexts, raises questions about ecological impacts when nanowires are released into the environment. The unique physicochemical properties of AgNWs, including their high aspect ratio and surface reactivity, may lead to environmental behaviors distinct from both bulk silver and spherical silver nanoparticles.

The primary objective of developing silver nanowire regulations for environmental safety is to establish science-based guidelines that ensure responsible innovation without impeding technological progress. This requires comprehensive understanding of AgNW behavior throughout their lifecycle, from production and use to disposal and environmental release. Regulatory frameworks must address exposure pathways, transformation processes in environmental media, bioaccumulation potential, and ecotoxicological effects across different ecosystems.

Another critical goal is harmonizing international regulatory approaches to avoid market fragmentation while maintaining high safety standards. Current regulations for nanomaterials often fail to account for the unique properties of high-aspect-ratio nanomaterials like AgNWs, creating regulatory gaps. The development of standardized testing protocols specifically designed for AgNWs represents an essential step toward evidence-based regulation that can effectively balance innovation with precautionary principles.

The technological evolution of AgNWs continues to accelerate, with researchers exploring surface modifications and composite structures to enhance performance while potentially mitigating environmental risks. This parallel development of technology and safety assessment exemplifies the concept of responsible innovation, where environmental considerations are integrated into the research and development process rather than addressed as an afterthought.

The technological trajectory of AgNWs has been characterized by continuous improvements in synthesis methods, from initial polyol processes to more sophisticated approaches enabling precise control over dimensions and properties. This evolution has expanded their application potential beyond transparent electrodes to include sensors, antimicrobial coatings, and biomedical devices. However, this rapid technological advancement has outpaced the development of appropriate regulatory frameworks addressing their environmental and health implications.

As AgNW production scales up for commercial applications, concerns regarding their environmental fate and potential toxicity have gained prominence. Silver is known for its antimicrobial properties, which while beneficial in certain contexts, raises questions about ecological impacts when nanowires are released into the environment. The unique physicochemical properties of AgNWs, including their high aspect ratio and surface reactivity, may lead to environmental behaviors distinct from both bulk silver and spherical silver nanoparticles.

The primary objective of developing silver nanowire regulations for environmental safety is to establish science-based guidelines that ensure responsible innovation without impeding technological progress. This requires comprehensive understanding of AgNW behavior throughout their lifecycle, from production and use to disposal and environmental release. Regulatory frameworks must address exposure pathways, transformation processes in environmental media, bioaccumulation potential, and ecotoxicological effects across different ecosystems.

Another critical goal is harmonizing international regulatory approaches to avoid market fragmentation while maintaining high safety standards. Current regulations for nanomaterials often fail to account for the unique properties of high-aspect-ratio nanomaterials like AgNWs, creating regulatory gaps. The development of standardized testing protocols specifically designed for AgNWs represents an essential step toward evidence-based regulation that can effectively balance innovation with precautionary principles.

The technological evolution of AgNWs continues to accelerate, with researchers exploring surface modifications and composite structures to enhance performance while potentially mitigating environmental risks. This parallel development of technology and safety assessment exemplifies the concept of responsible innovation, where environmental considerations are integrated into the research and development process rather than addressed as an afterthought.

Market Demand Analysis for Environmentally Safe Nanomaterials

The global market for environmentally safe nanomaterials has experienced significant growth in recent years, driven by increasing awareness of potential environmental and health risks associated with conventional nanomaterials. Silver nanowires (AgNWs) represent a particularly important segment within this market, with applications spanning electronics, energy, healthcare, and consumer products. Current market analysis indicates that the demand for environmentally safe silver nanowire technologies is projected to grow at a compound annual growth rate of 17.8% through 2028, outpacing the broader nanomaterials market.

Consumer electronics remains the dominant application sector, accounting for approximately 38% of the total market share for silver nanowires. This is primarily due to the increasing adoption of touch screens, flexible displays, and wearable technology. However, the fastest-growing segment is in the renewable energy sector, where silver nanowires are being incorporated into next-generation solar cells and energy storage solutions, with demand increasing by 22.3% annually.

Market research reveals a significant shift in consumer and industrial preferences toward environmentally responsible nanomaterials. A recent industry survey conducted across 12 countries found that 76% of electronics manufacturers now consider environmental safety profiles when selecting nanomaterial suppliers, compared to just 31% five years ago. This trend is particularly pronounced in European and North American markets, where regulatory frameworks are more stringent.

The healthcare sector represents another substantial growth area, with medical device manufacturers increasingly seeking silver nanowires with demonstrated biocompatibility and minimal environmental impact. Market forecasts suggest this segment will expand by 19.5% annually over the next five years, driven by applications in biosensors, antimicrobial coatings, and drug delivery systems.

Regional analysis shows that Asia-Pacific currently dominates the production landscape, accounting for 57% of global silver nanowire manufacturing capacity. However, North America and Europe lead in the development of environmentally safe variants, reflecting their more advanced regulatory environments and consumer awareness. This geographical disparity is creating new market opportunities for companies that can bridge the gap between cost-effective production and environmental compliance.

End-user industries are increasingly willing to pay premium prices for silver nanowires with verified environmental safety profiles. Market data indicates a price premium of 15-20% for nanowires that meet stringent environmental standards, suggesting strong value proposition for investments in green manufacturing processes and environmentally responsible product development.

The market is also witnessing growing demand for comprehensive life-cycle assessments and environmental impact documentation, with 82% of institutional buyers now requiring such information as part of their procurement processes. This trend is creating new service opportunities in the testing, certification, and environmental compliance consulting sectors related to nanomaterials.

Consumer electronics remains the dominant application sector, accounting for approximately 38% of the total market share for silver nanowires. This is primarily due to the increasing adoption of touch screens, flexible displays, and wearable technology. However, the fastest-growing segment is in the renewable energy sector, where silver nanowires are being incorporated into next-generation solar cells and energy storage solutions, with demand increasing by 22.3% annually.

Market research reveals a significant shift in consumer and industrial preferences toward environmentally responsible nanomaterials. A recent industry survey conducted across 12 countries found that 76% of electronics manufacturers now consider environmental safety profiles when selecting nanomaterial suppliers, compared to just 31% five years ago. This trend is particularly pronounced in European and North American markets, where regulatory frameworks are more stringent.

The healthcare sector represents another substantial growth area, with medical device manufacturers increasingly seeking silver nanowires with demonstrated biocompatibility and minimal environmental impact. Market forecasts suggest this segment will expand by 19.5% annually over the next five years, driven by applications in biosensors, antimicrobial coatings, and drug delivery systems.

Regional analysis shows that Asia-Pacific currently dominates the production landscape, accounting for 57% of global silver nanowire manufacturing capacity. However, North America and Europe lead in the development of environmentally safe variants, reflecting their more advanced regulatory environments and consumer awareness. This geographical disparity is creating new market opportunities for companies that can bridge the gap between cost-effective production and environmental compliance.

End-user industries are increasingly willing to pay premium prices for silver nanowires with verified environmental safety profiles. Market data indicates a price premium of 15-20% for nanowires that meet stringent environmental standards, suggesting strong value proposition for investments in green manufacturing processes and environmentally responsible product development.

The market is also witnessing growing demand for comprehensive life-cycle assessments and environmental impact documentation, with 82% of institutional buyers now requiring such information as part of their procurement processes. This trend is creating new service opportunities in the testing, certification, and environmental compliance consulting sectors related to nanomaterials.

Current Regulatory Status and Environmental Challenges

Silver nanowire (AgNW) technology currently faces a complex regulatory landscape that varies significantly across different regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates AgNWs primarily under the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances. However, specific regulations tailored to the unique properties of AgNWs remain limited, creating regulatory gaps that may not adequately address their potential environmental impacts.

The European Union has implemented more stringent measures through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which requires comprehensive safety data for nanomaterials including AgNWs. Additionally, the EU's Biocidal Products Regulation specifically addresses silver-based materials with antimicrobial properties, a category that often includes AgNWs. Despite these frameworks, enforcement challenges persist due to difficulties in monitoring and detecting these nanomaterials in environmental samples.

In Asia, regulatory approaches vary widely, with Japan and South Korea adopting relatively advanced frameworks similar to those in the EU, while many developing economies have minimal specific regulations for nanomaterials. This regulatory inconsistency creates challenges for global manufacturers and may lead to regulatory arbitrage, where production shifts to regions with less stringent environmental controls.

From an environmental perspective, AgNWs present several significant challenges. Their high surface area-to-volume ratio and silver ion release potential create unique environmental risks that traditional regulatory frameworks were not designed to address. Studies have demonstrated that AgNWs can persist in aquatic environments and potentially bioaccumulate in organisms, raising concerns about long-term ecosystem impacts.

Wastewater treatment systems present another critical challenge, as conventional treatment processes may not effectively remove or neutralize AgNWs, potentially allowing them to enter natural water bodies. Research indicates that AgNWs can undergo transformations in environmental conditions, forming new compounds with potentially unknown toxicity profiles.

The lack of standardized testing protocols specifically designed for AgNWs further complicates regulatory efforts. Current ecotoxicological testing methods may not adequately capture the unique behaviors and impacts of these nanomaterials, leading to potential underestimation of environmental risks. This testing gap represents a significant obstacle to developing evidence-based regulations.

Addressing these challenges requires international coordination to harmonize regulatory approaches and develop standardized testing methodologies specifically designed for AgNWs. Additionally, increased research funding is needed to better understand the environmental fate and effects of these materials across their entire lifecycle, from production to disposal.

The European Union has implemented more stringent measures through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which requires comprehensive safety data for nanomaterials including AgNWs. Additionally, the EU's Biocidal Products Regulation specifically addresses silver-based materials with antimicrobial properties, a category that often includes AgNWs. Despite these frameworks, enforcement challenges persist due to difficulties in monitoring and detecting these nanomaterials in environmental samples.

In Asia, regulatory approaches vary widely, with Japan and South Korea adopting relatively advanced frameworks similar to those in the EU, while many developing economies have minimal specific regulations for nanomaterials. This regulatory inconsistency creates challenges for global manufacturers and may lead to regulatory arbitrage, where production shifts to regions with less stringent environmental controls.

From an environmental perspective, AgNWs present several significant challenges. Their high surface area-to-volume ratio and silver ion release potential create unique environmental risks that traditional regulatory frameworks were not designed to address. Studies have demonstrated that AgNWs can persist in aquatic environments and potentially bioaccumulate in organisms, raising concerns about long-term ecosystem impacts.

Wastewater treatment systems present another critical challenge, as conventional treatment processes may not effectively remove or neutralize AgNWs, potentially allowing them to enter natural water bodies. Research indicates that AgNWs can undergo transformations in environmental conditions, forming new compounds with potentially unknown toxicity profiles.

The lack of standardized testing protocols specifically designed for AgNWs further complicates regulatory efforts. Current ecotoxicological testing methods may not adequately capture the unique behaviors and impacts of these nanomaterials, leading to potential underestimation of environmental risks. This testing gap represents a significant obstacle to developing evidence-based regulations.

Addressing these challenges requires international coordination to harmonize regulatory approaches and develop standardized testing methodologies specifically designed for AgNWs. Additionally, increased research funding is needed to better understand the environmental fate and effects of these materials across their entire lifecycle, from production to disposal.

Current Environmental Safety Assessment Methodologies

01 Environmental impact assessment of silver nanowires

Silver nanowires have potential environmental impacts that require assessment. Research focuses on evaluating their toxicity, biodegradability, and persistence in ecosystems. Studies examine how these nanomaterials interact with aquatic organisms, soil microbes, and plants. Environmental impact assessments help establish safety thresholds and identify mitigation strategies to minimize ecological risks associated with silver nanowire production, use, and disposal.- Environmental impact assessment of silver nanowires: Silver nanowires pose potential environmental risks due to their unique properties and increasing industrial applications. Research focuses on assessing their ecological impact, toxicity levels in various ecosystems, and long-term environmental persistence. Studies evaluate how these nanomaterials interact with soil, water bodies, and living organisms, providing crucial data for developing comprehensive environmental safety guidelines and regulations.

- Regulatory frameworks for silver nanomaterial safety: Various regulatory frameworks have been established to govern the production, use, and disposal of silver nanowires. These regulations address manufacturing standards, handling protocols, and disposal requirements to minimize environmental contamination. Government agencies worldwide are developing specific guidelines for nanomaterial classification, risk assessment methodologies, and exposure limits to ensure proper management of potential hazards associated with silver nanowire technologies.

- Safe handling and disposal methods for silver nanowires: Proper handling and disposal of silver nanowires are critical for environmental protection. Innovations include specialized containment systems, waste treatment processes, and recycling technologies designed specifically for nanomaterials. These methods aim to prevent uncontrolled release into the environment, reduce workplace exposure risks, and establish sustainable end-of-life management practices for products containing silver nanowires.

- Eco-friendly production techniques for silver nanowires: Environmentally conscious manufacturing methods for silver nanowires focus on reducing toxic chemical usage, minimizing waste generation, and decreasing energy consumption. Green synthesis approaches utilize renewable resources, bio-based reducing agents, and closed-loop production systems. These sustainable techniques maintain nanowire performance while significantly reducing the environmental footprint associated with traditional manufacturing processes.

- Monitoring and detection systems for silver nanowire exposure: Advanced monitoring technologies have been developed to detect and measure silver nanowire concentrations in various environmental media. These systems employ sophisticated sensors, analytical instruments, and sampling methodologies to track nanomaterial release and migration patterns. Real-time monitoring capabilities enable rapid response to potential contamination events, while standardized detection protocols support consistent enforcement of safety regulations across different industries and regions.

02 Regulatory frameworks for nanomaterial safety

Regulatory frameworks are being developed globally to address the unique safety concerns of nanomaterials including silver nanowires. These regulations focus on classification, labeling, and risk management requirements specific to nanoscale materials. Frameworks include guidelines for toxicity testing, exposure assessment, and safety data reporting. Compliance with these regulations is essential for manufacturers and users of silver nanowire technologies to ensure environmental protection and public safety.Expand Specific Solutions03 Manufacturing processes with reduced environmental impact

Environmentally friendly manufacturing processes for silver nanowires are being developed to reduce ecological footprints. These include green synthesis methods using plant extracts or environmentally benign reducing agents, closed-loop production systems that minimize waste, and energy-efficient techniques. Such processes aim to reduce the release of potentially harmful chemicals, decrease water consumption, and lower energy requirements while maintaining the desired properties of silver nanowires.Expand Specific Solutions04 Waste management and recycling of silver nanomaterials

Proper waste management and recycling strategies are crucial for mitigating environmental risks associated with silver nanowires. Technologies focus on recovery methods for silver from nanowire-containing products, treatment processes for industrial wastewater containing nanomaterials, and safe disposal protocols. Advanced filtration systems, chemical precipitation techniques, and biological remediation approaches help prevent silver nanowires from entering ecosystems and potentially causing harm to aquatic life and microorganisms.Expand Specific Solutions05 Safety monitoring and exposure control measures

Safety monitoring and exposure control measures are essential for protecting workers and the environment from potential hazards of silver nanowires. These include specialized containment systems, air filtration technologies, personal protective equipment requirements, and workplace exposure limits. Continuous monitoring protocols help detect nanomaterial releases, while engineering controls minimize exposure during manufacturing, handling, and processing. Implementation of these measures ensures compliance with occupational safety regulations and environmental protection standards.Expand Specific Solutions

Key Stakeholders in Nanomaterial Regulation

The silver nanowire regulations for environmental safety landscape is currently in an emerging growth phase, with increasing market attention driven by expanding applications in electronics and medical sectors. The global market is projected to reach significant scale as environmental concerns gain prominence. Technologically, companies are at varying maturity levels: established players like Carestream Health and Kimberly-Clark possess advanced regulatory compliance frameworks, while specialized firms such as C3 Nano and Shenzhen Huake Chuangzhi are developing innovative safety protocols. Academic institutions including Kyoto University, Fudan University, and Cornell University are contributing fundamental research on toxicity assessment and sustainable manufacturing processes. This competitive environment reflects a growing recognition of balancing nanowire technology commercialization with environmental protection requirements.

Eastman Kodak Co.

Technical Solution: Eastman Kodak has leveraged its extensive experience in silver halide chemistry to develop environmentally responsible silver nanowire technologies. Their approach includes a patented silver recovery system that captures and recycles over 95% of silver materials throughout the manufacturing process, significantly reducing environmental release potential. The company has implemented a comprehensive Environmental Management System specifically for nanomaterials that includes specialized containment protocols, waste treatment processes, and monitoring systems to prevent workplace and environmental contamination. Kodak's silver nanowire formulations incorporate stabilizing agents that reduce nanowire mobility in environmental systems while maintaining desired functionality in target applications. Their research division has developed specialized testing protocols that evaluate nanowire behavior in various environmental compartments, including soil, water, and biological systems, providing data that informs both internal safety protocols and regulatory compliance strategies. Kodak actively participates in industry consortia focused on developing standardized approaches to nanomaterial environmental safety.

Strengths: Extensive experience with silver chemistry translates to effective recovery and recycling systems; comprehensive environmental management system specifically designed for nanomaterials; specialized testing protocols provide robust environmental behavior data. Weakness: Primary focus on imaging and printing applications limits broader regulatory influence; legacy manufacturing infrastructure requires significant adaptation for nanomaterial safety.

Cornell University

Technical Solution: Cornell University has established itself as a leading research institution in silver nanowire environmental safety regulations through its Center for Sustainable Nanotechnology. Their interdisciplinary approach combines materials science, environmental engineering, and regulatory policy to develop comprehensive frameworks for nanomaterial governance. Cornell researchers have pioneered advanced analytical techniques for tracking silver nanowire transformations in complex environmental matrices, enabling detection at concentrations as low as 1 part per billion. Their work has established standardized testing protocols that evaluate nanowire behavior across different environmental compartments, including freshwater, marine, and soil ecosystems. Cornell's research has identified specific surface modifications that can reduce silver ion release from nanowires by up to 80% while maintaining desired functionality. The university actively collaborates with regulatory agencies including the EPA and international organizations to translate research findings into practical regulatory frameworks. Their published guidelines for environmentally responsible silver nanowire manufacturing have been adopted by multiple industry partners and cited in policy documents worldwide.

Strengths: Interdisciplinary approach combines materials science, environmental engineering and regulatory expertise; advanced analytical techniques enable precise environmental tracking; research directly informs regulatory frameworks through agency partnerships. Weakness: As an academic institution, lacks direct manufacturing implementation capabilities; research findings require industry partners for commercial application; funding dependencies can limit long-term research continuity.

Critical Research on Silver Nanowire Ecotoxicology

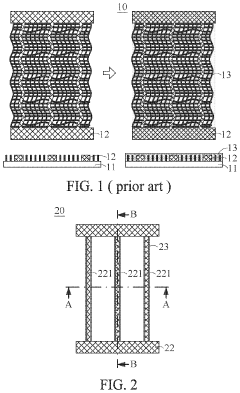

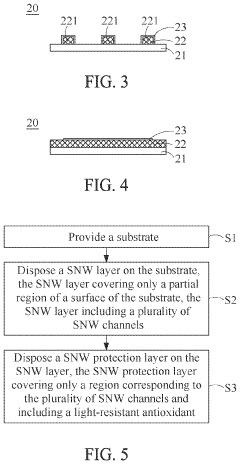

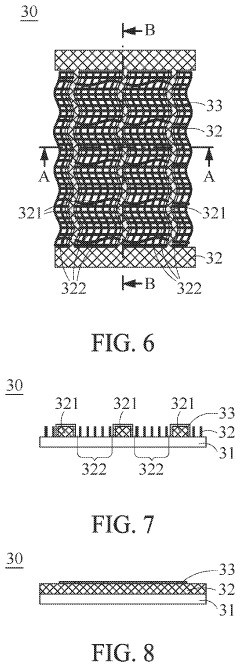

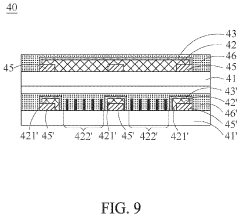

Silver nanowire protection layer structure and manufacturing method thereof

PatentActiveUS11513638B2

Innovation

- A novel SNW protection layer structure where the protection layer covers only the regions corresponding to SNW channels on a substrate, incorporating a light-resistant antioxidant and having a variable width and thickness, optionally including SNW dummies and conductive wires, to minimize yellowing and maintain conductivity.

International Compliance Framework for Nanomaterials

The global regulatory landscape for nanomaterials has evolved significantly in response to the growing use of silver nanowires and other nanomaterials across industries. The European Union leads with the most comprehensive framework through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which specifically addresses nanomaterials including silver nanowires. Under this regulation, manufacturers must register nanomaterials and provide safety data when production exceeds one ton annually. The EU's approach emphasizes the precautionary principle, requiring thorough risk assessment before market approval.

In the United States, regulatory oversight is distributed across multiple agencies. The EPA regulates nanomaterials under the Toxic Substances Control Act (TSCA), while the FDA oversees nanomaterials in food, drugs, and cosmetics. The NIOSH provides occupational exposure guidelines specific to nanomaterials, though these remain largely advisory rather than mandatory. Unlike the EU's unified approach, the US system addresses nanomaterial risks through existing regulatory frameworks rather than nanomaterial-specific legislation.

Asian regulatory frameworks show considerable variation. Japan has implemented the Chemical Substances Control Law with specific provisions for nanomaterials, while South Korea's K-REACH closely mirrors the European model. China has recently strengthened its approach through the Measures for Environmental Management of New Chemical Substances, which now includes nanomaterial-specific provisions, though enforcement remains inconsistent across regions.

International harmonization efforts are being coordinated through organizations like the OECD and ISO. The OECD's Working Party on Manufactured Nanomaterials has developed standardized testing protocols specifically for nanomaterials, while ISO Technical Committee 229 has established standardized terminology and measurement methods. These collaborative efforts aim to reduce regulatory fragmentation and facilitate international trade while maintaining safety standards.

Compliance challenges for silver nanowire manufacturers remain significant due to regulatory divergence across jurisdictions. Companies must navigate different threshold limits, testing requirements, and reporting obligations. The lack of standardized test methods specifically validated for silver nanowires creates additional uncertainty, as conventional toxicity testing protocols may not adequately capture nanomaterial-specific risks. This regulatory complexity increases compliance costs and may inhibit innovation, particularly for smaller manufacturers.

Recent trends indicate movement toward greater international alignment, with increasing recognition of the need for nanomaterial-specific regulations that balance innovation with precaution. The development of mutual recognition agreements between major regulatory bodies represents a promising approach to reducing compliance burdens while maintaining robust safety standards for silver nanowires and other nanomaterials.

In the United States, regulatory oversight is distributed across multiple agencies. The EPA regulates nanomaterials under the Toxic Substances Control Act (TSCA), while the FDA oversees nanomaterials in food, drugs, and cosmetics. The NIOSH provides occupational exposure guidelines specific to nanomaterials, though these remain largely advisory rather than mandatory. Unlike the EU's unified approach, the US system addresses nanomaterial risks through existing regulatory frameworks rather than nanomaterial-specific legislation.

Asian regulatory frameworks show considerable variation. Japan has implemented the Chemical Substances Control Law with specific provisions for nanomaterials, while South Korea's K-REACH closely mirrors the European model. China has recently strengthened its approach through the Measures for Environmental Management of New Chemical Substances, which now includes nanomaterial-specific provisions, though enforcement remains inconsistent across regions.

International harmonization efforts are being coordinated through organizations like the OECD and ISO. The OECD's Working Party on Manufactured Nanomaterials has developed standardized testing protocols specifically for nanomaterials, while ISO Technical Committee 229 has established standardized terminology and measurement methods. These collaborative efforts aim to reduce regulatory fragmentation and facilitate international trade while maintaining safety standards.

Compliance challenges for silver nanowire manufacturers remain significant due to regulatory divergence across jurisdictions. Companies must navigate different threshold limits, testing requirements, and reporting obligations. The lack of standardized test methods specifically validated for silver nanowires creates additional uncertainty, as conventional toxicity testing protocols may not adequately capture nanomaterial-specific risks. This regulatory complexity increases compliance costs and may inhibit innovation, particularly for smaller manufacturers.

Recent trends indicate movement toward greater international alignment, with increasing recognition of the need for nanomaterial-specific regulations that balance innovation with precaution. The development of mutual recognition agreements between major regulatory bodies represents a promising approach to reducing compliance burdens while maintaining robust safety standards for silver nanowires and other nanomaterials.

Life Cycle Assessment of Silver Nanowire Products

Life Cycle Assessment (LCA) of silver nanowire products provides a comprehensive framework for evaluating environmental impacts throughout the entire product lifecycle. This assessment begins with raw material extraction, where silver mining operations contribute significantly to environmental degradation through land disturbance, water consumption, and energy use. The refining process further compounds these impacts through chemical treatments and high-temperature processes required to achieve the purity levels necessary for nanowire production.

The manufacturing phase of silver nanowires involves specialized synthesis methods such as polyol process, template-directed synthesis, or electrochemical deposition. Each method presents distinct environmental considerations, with energy consumption and chemical waste generation being primary concerns. Studies indicate that the polyol process, while efficient for mass production, generates substantial organic solvent waste requiring specialized disposal protocols.

During the use phase, silver nanowires embedded in consumer electronics, photovoltaic cells, and medical devices demonstrate excellent performance characteristics. However, this phase presents potential environmental risks through gradual nanowire degradation and possible release into surrounding environments. Research indicates that silver ions released from nanowires can interact with aquatic ecosystems even at low concentrations, potentially disrupting microbial communities essential for environmental balance.

End-of-life management represents perhaps the most challenging aspect of silver nanowire product lifecycle. Current recycling infrastructure is inadequately equipped to handle nanomaterial-containing products, resulting in significant material loss and potential environmental contamination. Advanced recovery techniques such as selective dissolution and membrane filtration show promise but remain economically prohibitive for widespread implementation.

Quantitative LCA studies reveal that the environmental footprint of silver nanowire products varies significantly based on production method, application context, and end-of-life scenario. For instance, silver nanowire transparent electrodes in solar panels demonstrate favorable environmental profiles when accounting for energy generation benefits, despite intensive production processes. Conversely, single-use applications with limited recovery potential present less favorable environmental balances.

Emerging ISO standards for nanomaterial LCA (ISO/TR 14049:2012 and ISO/TS 12901-2:2014) provide methodological frameworks, though significant data gaps persist regarding nanomaterial-specific impact pathways. These knowledge gaps necessitate conservative approaches in environmental risk assessment and highlight the need for continued research into fate, transport, and toxicity mechanisms specific to silver nanowires in various environmental compartments.

The manufacturing phase of silver nanowires involves specialized synthesis methods such as polyol process, template-directed synthesis, or electrochemical deposition. Each method presents distinct environmental considerations, with energy consumption and chemical waste generation being primary concerns. Studies indicate that the polyol process, while efficient for mass production, generates substantial organic solvent waste requiring specialized disposal protocols.

During the use phase, silver nanowires embedded in consumer electronics, photovoltaic cells, and medical devices demonstrate excellent performance characteristics. However, this phase presents potential environmental risks through gradual nanowire degradation and possible release into surrounding environments. Research indicates that silver ions released from nanowires can interact with aquatic ecosystems even at low concentrations, potentially disrupting microbial communities essential for environmental balance.

End-of-life management represents perhaps the most challenging aspect of silver nanowire product lifecycle. Current recycling infrastructure is inadequately equipped to handle nanomaterial-containing products, resulting in significant material loss and potential environmental contamination. Advanced recovery techniques such as selective dissolution and membrane filtration show promise but remain economically prohibitive for widespread implementation.

Quantitative LCA studies reveal that the environmental footprint of silver nanowire products varies significantly based on production method, application context, and end-of-life scenario. For instance, silver nanowire transparent electrodes in solar panels demonstrate favorable environmental profiles when accounting for energy generation benefits, despite intensive production processes. Conversely, single-use applications with limited recovery potential present less favorable environmental balances.

Emerging ISO standards for nanomaterial LCA (ISO/TR 14049:2012 and ISO/TS 12901-2:2014) provide methodological frameworks, though significant data gaps persist regarding nanomaterial-specific impact pathways. These knowledge gaps necessitate conservative approaches in environmental risk assessment and highlight the need for continued research into fate, transport, and toxicity mechanisms specific to silver nanowires in various environmental compartments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!