Understanding the Role of Silver Nanowire in Biosensing Technologies

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Biosensing Background and Objectives

Silver nanowire (AgNW) technology has emerged as a revolutionary material in biosensing applications over the past decade. Initially developed in the early 2000s as a conductive material for transparent electrodes, AgNWs have since evolved to become integral components in advanced biosensing platforms. Their unique combination of electrical conductivity, optical transparency, mechanical flexibility, and large surface-to-volume ratio has positioned them as ideal candidates for next-generation biosensing technologies.

The evolution of AgNW technology in biosensing has followed a clear trajectory from basic research to practical applications. Early research focused primarily on synthesis methods and fundamental properties, while recent developments have emphasized integration into functional devices. The transition from laboratory curiosities to commercially viable technologies has been accelerated by improvements in nanowire synthesis techniques, surface functionalization methods, and device fabrication processes.

Current technological trends indicate a growing convergence between AgNW technology and other emerging fields such as Internet of Things (IoT), wearable electronics, and point-of-care diagnostics. This convergence is driving the development of increasingly sophisticated biosensing platforms capable of real-time, multiplexed detection of biomarkers with unprecedented sensitivity and specificity.

The primary objective of AgNW biosensing research is to develop highly sensitive, selective, and reliable detection platforms for various biomarkers including proteins, nucleic acids, cells, and small molecules. These platforms aim to address critical challenges in healthcare, environmental monitoring, and food safety through rapid, cost-effective, and user-friendly testing solutions.

Specific technical goals include enhancing the sensitivity of AgNW-based biosensors to reach sub-femtomolar detection limits, improving selectivity through advanced surface functionalization strategies, increasing stability under various environmental conditions, and developing scalable manufacturing processes for commercial production.

Long-term objectives extend to creating fully integrated biosensing systems that combine sample preparation, detection, signal processing, and data analysis in a single platform. These systems would ideally operate autonomously, require minimal user intervention, and provide actionable information in real-time, potentially revolutionizing fields such as personalized medicine, environmental monitoring, and biodefense.

The ultimate vision for AgNW biosensing technology is to enable ubiquitous health and environmental monitoring through affordable, accessible, and reliable sensing platforms that can be deployed in diverse settings from sophisticated clinical laboratories to resource-limited environments in developing countries.

The evolution of AgNW technology in biosensing has followed a clear trajectory from basic research to practical applications. Early research focused primarily on synthesis methods and fundamental properties, while recent developments have emphasized integration into functional devices. The transition from laboratory curiosities to commercially viable technologies has been accelerated by improvements in nanowire synthesis techniques, surface functionalization methods, and device fabrication processes.

Current technological trends indicate a growing convergence between AgNW technology and other emerging fields such as Internet of Things (IoT), wearable electronics, and point-of-care diagnostics. This convergence is driving the development of increasingly sophisticated biosensing platforms capable of real-time, multiplexed detection of biomarkers with unprecedented sensitivity and specificity.

The primary objective of AgNW biosensing research is to develop highly sensitive, selective, and reliable detection platforms for various biomarkers including proteins, nucleic acids, cells, and small molecules. These platforms aim to address critical challenges in healthcare, environmental monitoring, and food safety through rapid, cost-effective, and user-friendly testing solutions.

Specific technical goals include enhancing the sensitivity of AgNW-based biosensors to reach sub-femtomolar detection limits, improving selectivity through advanced surface functionalization strategies, increasing stability under various environmental conditions, and developing scalable manufacturing processes for commercial production.

Long-term objectives extend to creating fully integrated biosensing systems that combine sample preparation, detection, signal processing, and data analysis in a single platform. These systems would ideally operate autonomously, require minimal user intervention, and provide actionable information in real-time, potentially revolutionizing fields such as personalized medicine, environmental monitoring, and biodefense.

The ultimate vision for AgNW biosensing technology is to enable ubiquitous health and environmental monitoring through affordable, accessible, and reliable sensing platforms that can be deployed in diverse settings from sophisticated clinical laboratories to resource-limited environments in developing countries.

Market Analysis for Nanowire-Based Biosensors

The global market for nanowire-based biosensors is experiencing robust growth, driven by increasing demand for rapid, sensitive, and portable diagnostic solutions across healthcare, environmental monitoring, and food safety sectors. Silver nanowire (AgNW) technology has emerged as a particularly promising component within this market due to its exceptional electrical conductivity, optical properties, and biocompatibility advantages over traditional materials.

Current market valuations indicate the nanobiosensor market reached approximately $2.1 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 9.8% through 2028. Within this broader market, silver nanowire-based biosensing technologies are gaining significant traction, currently representing about 18% of the total market share with accelerating adoption rates.

Healthcare applications dominate the market landscape, accounting for nearly 65% of nanowire biosensor deployments. Point-of-care diagnostics represents the fastest-growing segment, expanding at 12.3% annually as healthcare systems worldwide seek decentralized testing capabilities. The COVID-19 pandemic has substantially accelerated this trend, creating unprecedented demand for rapid diagnostic platforms that can leverage silver nanowire technology.

Environmental monitoring applications constitute the second-largest market segment at 20%, with water quality testing and airborne pathogen detection showing particular promise. Agricultural and food safety applications represent smaller but rapidly expanding market opportunities, growing at 11.7% annually as regulatory requirements for contaminant testing become more stringent globally.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 13.2% annually, driven by substantial healthcare infrastructure investments in China and India, coupled with expanding manufacturing capabilities for nanowire components.

Key market drivers include increasing incidence of chronic and infectious diseases, growing demand for personalized medicine, technological advancements in nanomaterial fabrication, and supportive regulatory frameworks for novel diagnostic technologies. Conversely, market restraints include high development costs, technical challenges in mass production of consistent nanowire structures, and regulatory hurdles for clinical approval.

Consumer trends indicate growing preference for wearable health monitoring devices, creating significant opportunities for flexible silver nanowire-based biosensors that can be integrated into everyday items. Additionally, the push toward sustainable healthcare solutions is driving interest in biodegradable and environmentally friendly nanowire formulations, representing an emerging market niche with substantial growth potential.

Current market valuations indicate the nanobiosensor market reached approximately $2.1 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 9.8% through 2028. Within this broader market, silver nanowire-based biosensing technologies are gaining significant traction, currently representing about 18% of the total market share with accelerating adoption rates.

Healthcare applications dominate the market landscape, accounting for nearly 65% of nanowire biosensor deployments. Point-of-care diagnostics represents the fastest-growing segment, expanding at 12.3% annually as healthcare systems worldwide seek decentralized testing capabilities. The COVID-19 pandemic has substantially accelerated this trend, creating unprecedented demand for rapid diagnostic platforms that can leverage silver nanowire technology.

Environmental monitoring applications constitute the second-largest market segment at 20%, with water quality testing and airborne pathogen detection showing particular promise. Agricultural and food safety applications represent smaller but rapidly expanding market opportunities, growing at 11.7% annually as regulatory requirements for contaminant testing become more stringent globally.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 13.2% annually, driven by substantial healthcare infrastructure investments in China and India, coupled with expanding manufacturing capabilities for nanowire components.

Key market drivers include increasing incidence of chronic and infectious diseases, growing demand for personalized medicine, technological advancements in nanomaterial fabrication, and supportive regulatory frameworks for novel diagnostic technologies. Conversely, market restraints include high development costs, technical challenges in mass production of consistent nanowire structures, and regulatory hurdles for clinical approval.

Consumer trends indicate growing preference for wearable health monitoring devices, creating significant opportunities for flexible silver nanowire-based biosensors that can be integrated into everyday items. Additionally, the push toward sustainable healthcare solutions is driving interest in biodegradable and environmentally friendly nanowire formulations, representing an emerging market niche with substantial growth potential.

Current Technological Landscape and Challenges

Silver nanowire (AgNW) technology has emerged as a promising material in biosensing applications, with significant advancements observed globally over the past decade. Currently, AgNWs are being extensively investigated for their exceptional electrical conductivity, optical transparency, and mechanical flexibility, making them ideal candidates for next-generation biosensors. The global biosensor market, valued at approximately $25.5 billion in 2023, is projected to reach $41.8 billion by 2028, with AgNW-based technologies potentially capturing a substantial portion of this growth.

The current technological landscape reveals several key applications of AgNWs in biosensing, including electrochemical sensors, surface-enhanced Raman spectroscopy (SERS) platforms, and flexible wearable biosensors. Research institutions across North America, Europe, and East Asia are leading developments, with China, the United States, and South Korea publishing the highest number of related patents and research papers in the last five years.

Despite promising advancements, significant challenges persist in AgNW biosensor development. Stability issues remain paramount, as AgNWs tend to oxidize under ambient conditions, affecting long-term sensor performance. This oxidation challenge is particularly problematic for implantable or continuous monitoring biosensors where reliability is critical. Additionally, the reproducibility of AgNW synthesis with consistent dimensions and properties presents a manufacturing hurdle that impacts sensor standardization.

Biocompatibility concerns also represent a major technical obstacle. While silver possesses antimicrobial properties, potential cytotoxicity of AgNWs, particularly at higher concentrations or with certain dimensions, limits their application in direct-contact biosensing scenarios. Research indicates that AgNW length and diameter significantly influence their cytotoxicity profile, necessitating careful optimization for in vivo applications.

From a production perspective, scalable manufacturing techniques for AgNW-based biosensors remain underdeveloped. Current laboratory-scale synthesis methods often yield inconsistent results when scaled up, creating barriers to commercial viability. The high cost of silver as a raw material further compounds economic feasibility challenges, particularly for disposable biosensor applications.

Regulatory hurdles constitute another significant challenge. The novel nature of AgNW materials means that comprehensive safety and efficacy standards specific to these nanomaterials are still evolving. This regulatory uncertainty delays market entry and increases development costs as companies navigate complex approval pathways across different jurisdictions.

Integration challenges with existing biomedical systems and electronic interfaces also limit widespread adoption. Many AgNW biosensors require specialized readout equipment or complex signal processing, creating barriers to point-of-care applications where simplicity and accessibility are paramount.

The current technological landscape reveals several key applications of AgNWs in biosensing, including electrochemical sensors, surface-enhanced Raman spectroscopy (SERS) platforms, and flexible wearable biosensors. Research institutions across North America, Europe, and East Asia are leading developments, with China, the United States, and South Korea publishing the highest number of related patents and research papers in the last five years.

Despite promising advancements, significant challenges persist in AgNW biosensor development. Stability issues remain paramount, as AgNWs tend to oxidize under ambient conditions, affecting long-term sensor performance. This oxidation challenge is particularly problematic for implantable or continuous monitoring biosensors where reliability is critical. Additionally, the reproducibility of AgNW synthesis with consistent dimensions and properties presents a manufacturing hurdle that impacts sensor standardization.

Biocompatibility concerns also represent a major technical obstacle. While silver possesses antimicrobial properties, potential cytotoxicity of AgNWs, particularly at higher concentrations or with certain dimensions, limits their application in direct-contact biosensing scenarios. Research indicates that AgNW length and diameter significantly influence their cytotoxicity profile, necessitating careful optimization for in vivo applications.

From a production perspective, scalable manufacturing techniques for AgNW-based biosensors remain underdeveloped. Current laboratory-scale synthesis methods often yield inconsistent results when scaled up, creating barriers to commercial viability. The high cost of silver as a raw material further compounds economic feasibility challenges, particularly for disposable biosensor applications.

Regulatory hurdles constitute another significant challenge. The novel nature of AgNW materials means that comprehensive safety and efficacy standards specific to these nanomaterials are still evolving. This regulatory uncertainty delays market entry and increases development costs as companies navigate complex approval pathways across different jurisdictions.

Integration challenges with existing biomedical systems and electronic interfaces also limit widespread adoption. Many AgNW biosensors require specialized readout equipment or complex signal processing, creating barriers to point-of-care applications where simplicity and accessibility are paramount.

Current Silver Nanowire Biosensing Implementations

01 Synthesis and preparation methods of silver nanowires

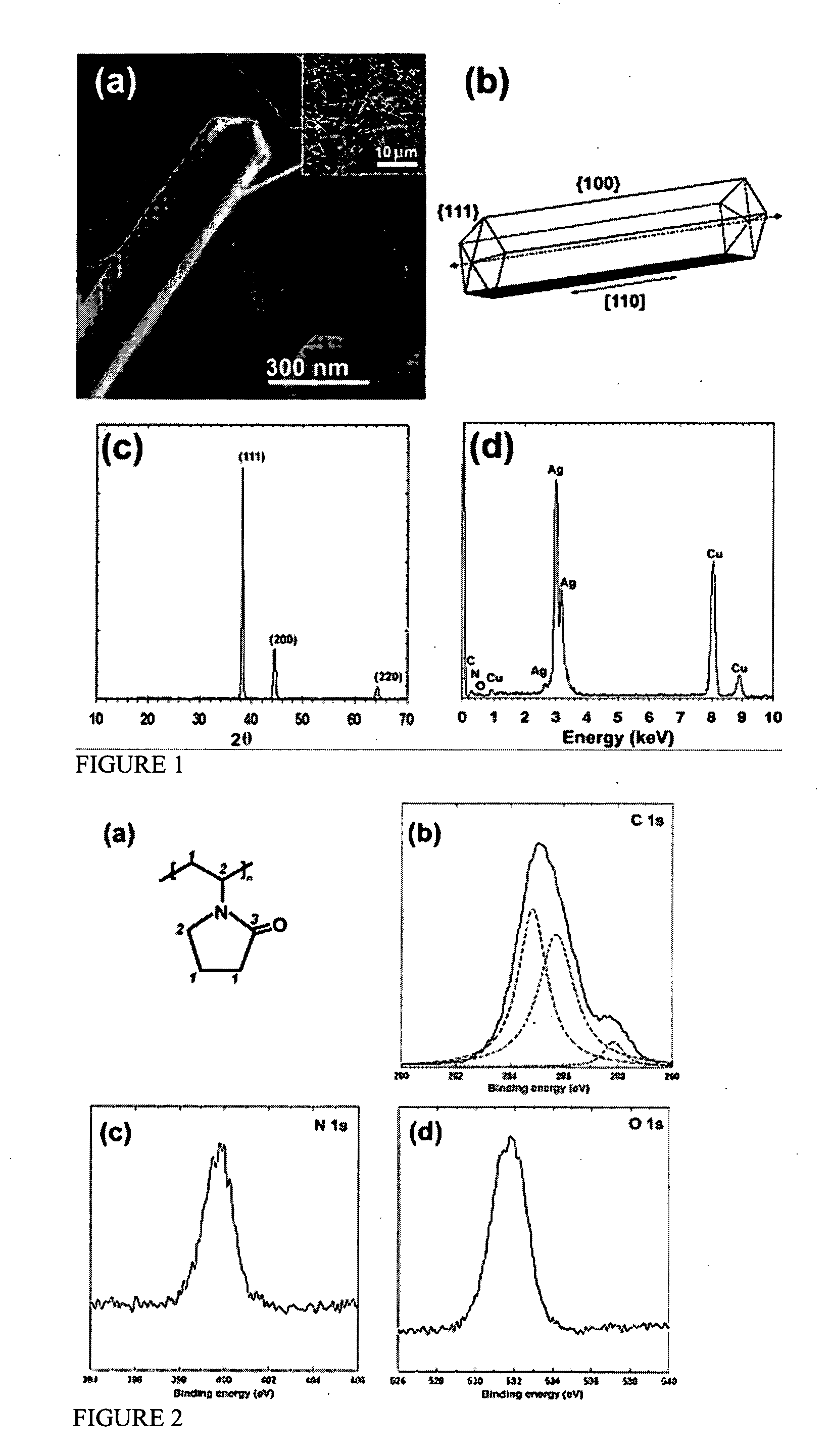

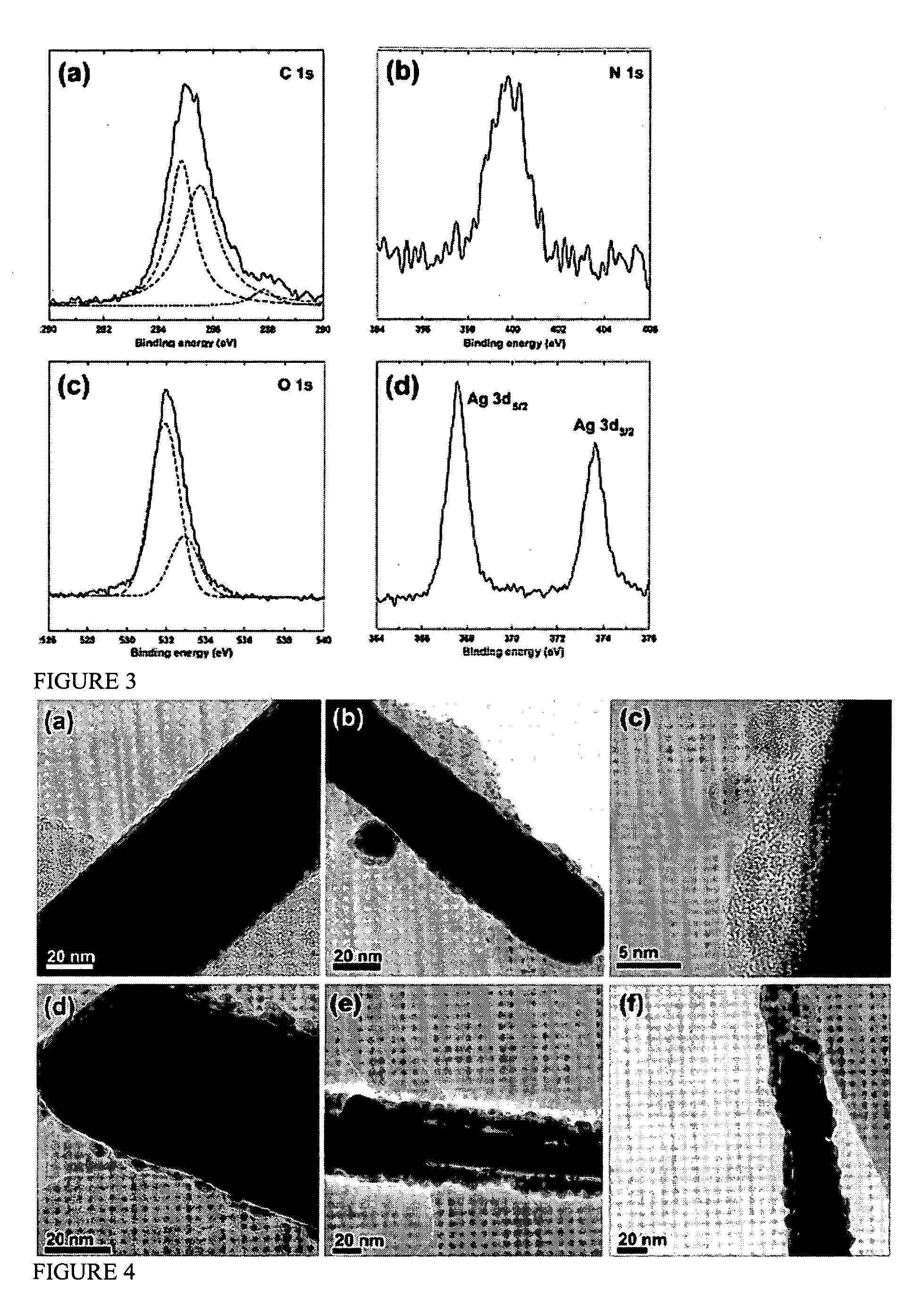

Various methods for synthesizing and preparing silver nanowires with controlled dimensions and properties. These methods include chemical reduction, polyol process, and template-assisted growth. The synthesis parameters such as temperature, reaction time, and precursor concentrations can be adjusted to control the length, diameter, and aspect ratio of the silver nanowires, which are critical for their performance in various applications.- Synthesis and preparation methods of silver nanowires: Various methods for synthesizing and preparing silver nanowires with controlled dimensions and properties. These methods include chemical reduction, polyol process, and template-assisted growth techniques. The processes often involve specific reaction conditions, reducing agents, and stabilizers to control the growth direction and aspect ratio of the nanowires, resulting in high-quality silver nanowires with uniform dimensions suitable for various applications.

- Transparent conductive films using silver nanowires: Silver nanowires are used to create transparent conductive films for applications in touch screens, displays, and flexible electronics. These films combine high electrical conductivity with optical transparency, making them superior alternatives to traditional indium tin oxide (ITO) films. The manufacturing processes include coating, printing, or embedding silver nanowire networks onto various substrates, followed by post-treatments to enhance conductivity and adhesion.

- Silver nanowire composites and hybrid materials: Development of composite and hybrid materials incorporating silver nanowires with polymers, carbon materials, or other nanomaterials. These composites combine the electrical conductivity of silver nanowires with mechanical, thermal, or optical properties of the matrix materials. Applications include flexible electronics, electromagnetic shielding, sensors, and conductive adhesives with enhanced performance characteristics.

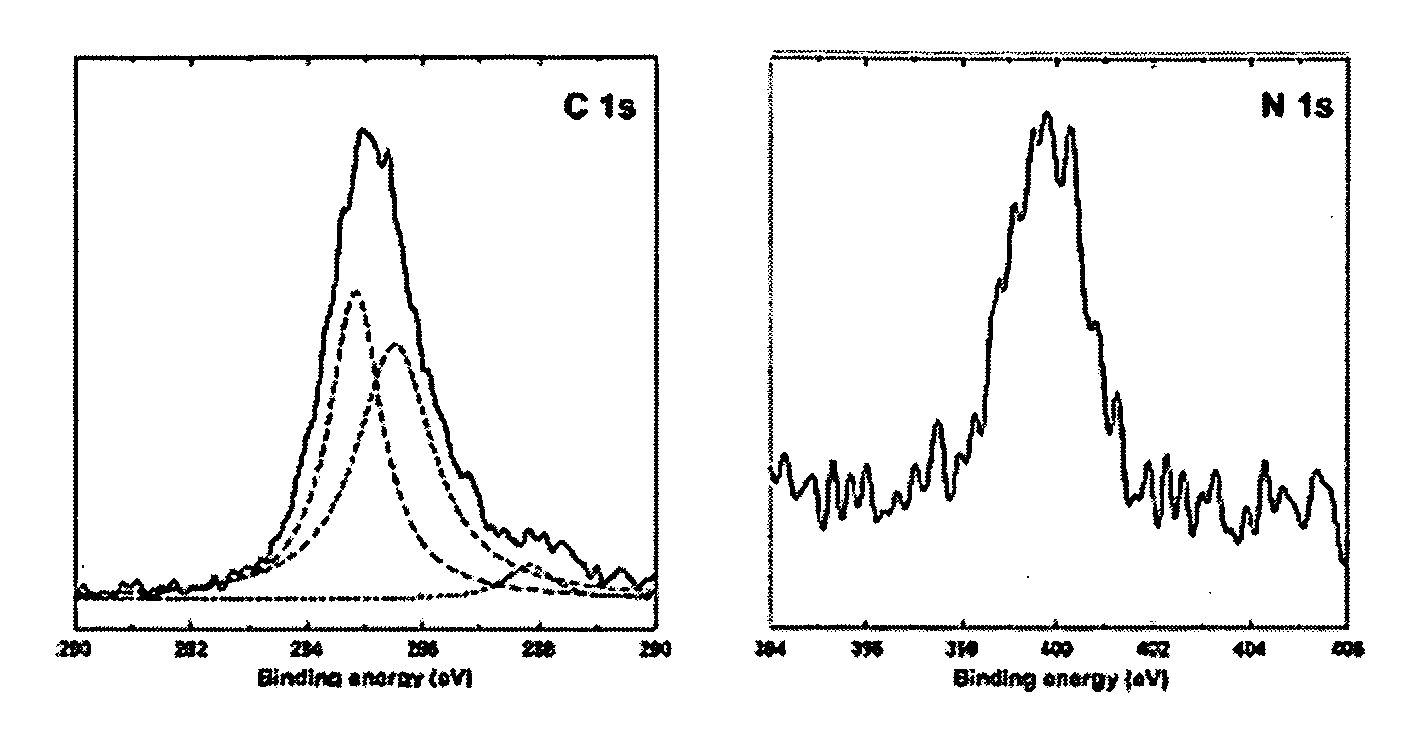

- Surface modification and functionalization of silver nanowires: Techniques for modifying the surface of silver nanowires to enhance their properties or add functionality. These modifications include coating with protective layers, functionalization with specific chemical groups, or creating core-shell structures. Surface treatments improve stability against oxidation, enhance dispersibility in various media, and enable better integration with other materials for specific applications.

- Applications of silver nanowires in sensors and devices: Implementation of silver nanowires in various sensing devices and electronic components. Silver nanowires are utilized in pressure sensors, strain gauges, temperature sensors, and other detection systems due to their excellent electrical properties and mechanical flexibility. These applications leverage the unique properties of silver nanowires to create highly sensitive, flexible, and durable sensing platforms for wearable electronics, healthcare monitoring, and industrial sensing.

02 Transparent conductive films using silver nanowires

Silver nanowires are used to create transparent conductive films for applications in touch screens, displays, and flexible electronics. These films combine high electrical conductivity with optical transparency. The nanowires form a conductive network while allowing light to pass through the gaps between them. Various methods for depositing and patterning these nanowires on substrates are described, along with techniques to improve their adhesion, stability, and performance.Expand Specific Solutions03 Surface modification and functionalization of silver nanowires

Techniques for modifying the surface of silver nanowires to enhance their properties and compatibility with various matrices. Surface functionalization can improve dispersion stability, prevent aggregation, enhance adhesion to substrates, and protect against oxidation and corrosion. Various coating materials including polymers, metal oxides, and other functional materials are used to create core-shell structures or hybrid nanomaterials with enhanced performance characteristics.Expand Specific Solutions04 Silver nanowire-based flexible and stretchable electronics

Applications of silver nanowires in flexible and stretchable electronic devices. Silver nanowires embedded in elastic polymers or deposited on flexible substrates can maintain electrical conductivity under bending, folding, or stretching conditions. These materials are used in wearable electronics, flexible displays, stretchable sensors, and other applications requiring mechanical flexibility while maintaining electrical functionality.Expand Specific Solutions05 Silver nanowire composites and hybrid materials

Development of composite and hybrid materials incorporating silver nanowires to achieve enhanced or multifunctional properties. Silver nanowires are combined with polymers, carbon nanomaterials (such as graphene or carbon nanotubes), metal oxides, or other functional materials to create composites with synergistic properties. These hybrid materials find applications in electromagnetic shielding, thermal management, antibacterial surfaces, and energy storage devices.Expand Specific Solutions

Leading Companies and Research Institutions

The silver nanowire biosensing technology market is currently in a growth phase, with increasing applications in healthcare diagnostics and monitoring. The global biosensor market is projected to reach significant scale, driven by demand for rapid, sensitive detection methods. Leading academic institutions like University of California, Cornell, Northwestern, and Yale are advancing fundamental research, while companies such as Shenzhen Huake Chuangzhi Technology, IBM, and Nanomix are commercializing applications. The technology is approaching maturity in certain segments, with silver nanowires offering advantages in conductivity, flexibility, and biocompatibility. Research collaborations between institutions like KIST, ETRI, and companies are accelerating development of next-generation biosensing platforms, indicating a competitive landscape poised for innovation-driven expansion.

The Regents of the University of California

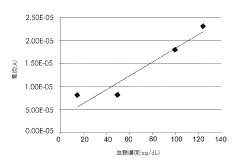

Technical Solution: The University of California has developed advanced silver nanowire (AgNW) biosensing platforms that leverage the unique electrical, optical, and plasmonic properties of AgNWs. Their technology incorporates AgNWs into flexible, transparent electrodes for wearable biosensors capable of real-time health monitoring. These sensors utilize surface-enhanced Raman spectroscopy (SERS) where AgNWs serve as excellent substrates due to their high surface-to-volume ratio and strong localized surface plasmon resonance (LSPR) effects[1]. The university's research teams have demonstrated AgNW-based electrochemical biosensors with enhanced sensitivity for detecting various biomarkers, including glucose, proteins, and nucleic acids at concentrations as low as femtomolar levels[2]. Their innovative approach includes functionalizing AgNWs with specific recognition elements like antibodies or aptamers to achieve highly selective detection capabilities while maintaining excellent electrical conductivity.

Strengths: Superior sensitivity due to enhanced LSPR effects and high surface area; excellent flexibility and transparency enabling wearable applications; demonstrated compatibility with various biological recognition elements. Weaknesses: Potential silver ion leaching causing cytotoxicity concerns; long-term stability issues in biological environments; relatively higher production costs compared to traditional electrode materials.

Fudan University

Technical Solution: Fudan University has pioneered innovative silver nanowire (AgNW) biosensing technologies focusing on electrochemical and optical detection methods. Their research teams have developed hierarchical AgNW nanostructures with controlled morphologies that significantly enhance sensing performance through increased surface area and improved electron transfer kinetics[3]. A notable advancement is their AgNW-graphene hybrid nanocomposites that combine the excellent conductivity of AgNWs with graphene's stability and biocompatibility, resulting in biosensors with detection limits in the picomolar range for various disease biomarkers[4]. Fudan's technology incorporates surface modification strategies using functional polymers and biomolecules to improve AgNW stability in biological fluids while maintaining high sensitivity. Their recent work demonstrates multiplexed detection capabilities through spatially arranged AgNW arrays functionalized with different recognition elements, enabling simultaneous detection of multiple analytes from a single sample with minimal cross-reactivity and interference effects[5].

Strengths: Exceptional sensitivity through hierarchical nanostructures; improved stability via hybrid composites with graphene; advanced multiplexing capabilities for complex sample analysis. Weaknesses: Complex fabrication processes potentially limiting mass production; relatively higher costs compared to conventional sensing materials; some remaining concerns about long-term biocompatibility in implantable applications.

Key Patents and Scientific Breakthroughs

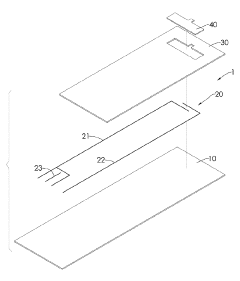

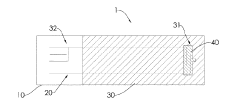

Silver nanowire-containing composition, biosensor strip including the same, and manufacturing method for the same

PatentInactiveJP2014153361A

Innovation

- A silver nanowire-containing composition is developed, comprising silver nanowires encapsulated in a coating agent made of hydroxyl or carbonyl compounds, which are dispersed in a polymer matrix with additives to enhance conductivity and stability, forming a conductive pattern layer on a biosensor strip.

Glycerin based synthesis of silver nanoparticles and nanowires

PatentInactiveUS20060115536A1

Innovation

- The development of silver nanoparticles and nanowires synthesized using glycerin as both the reducing agent and solvent, which can be used in compositions to inhibit viral infection by deactivating HIV and other viruses, and their potential integration into body care products and other applications.

Biocompatibility and Safety Considerations

The integration of silver nanowires (AgNWs) into biosensing platforms necessitates rigorous evaluation of their biocompatibility and safety profiles. Silver nanomaterials exhibit inherent antimicrobial properties that make them attractive for biosensing applications, yet these same properties raise concerns regarding cytotoxicity when interfacing with biological systems. Research indicates that AgNWs can induce dose-dependent cytotoxic effects through multiple mechanisms, including the release of silver ions, generation of reactive oxygen species (ROS), and direct physical interactions with cellular membranes.

Surface modification strategies have emerged as critical approaches to mitigate these cytotoxic effects while preserving the desirable electrical and optical properties of AgNWs. Functionalization with biocompatible polymers such as polyethylene glycol (PEG), chitosan, or specific proteins creates protective barriers that reduce silver ion leaching and minimize direct contact between nanowires and cellular components. These modifications have demonstrated significant improvements in cell viability and reduced inflammatory responses in both in vitro and in vivo studies.

Regulatory frameworks governing the use of nanomaterials in biomedical applications continue to evolve, with particular attention to silver-based nanomaterials. The FDA, EMA, and other international regulatory bodies have established guidelines for evaluating the safety profiles of nanomaterials intended for biological applications. Comprehensive toxicological assessments, including genotoxicity, immunogenicity, and long-term bioaccumulation studies, are increasingly required before AgNW-based biosensors can progress toward clinical implementation.

Environmental considerations also play a crucial role in the safety assessment of AgNW biosensors. The potential release of silver nanomaterials into ecosystems raises concerns about bioaccumulation in aquatic organisms and disruption of microbial communities. Sustainable design approaches incorporating biodegradable components or closed-loop systems for nanomaterial recovery are being explored to address these environmental challenges.

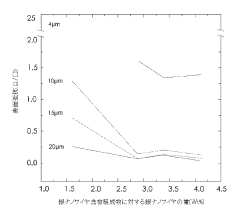

Recent advancements in AgNW synthesis have focused on developing "safer-by-design" approaches, where biocompatibility considerations are integrated from the earliest stages of material development. These include precise control over nanowire dimensions, as shorter AgNWs typically demonstrate reduced cytotoxicity compared to their longer counterparts, and the incorporation of biologically derived capping agents that enhance biocompatibility while maintaining sensing performance.

Standardized testing protocols specifically designed for evaluating nanomaterial-biological interactions are essential for meaningful safety assessments. The scientific community continues to work toward consensus on appropriate in vitro and in vivo models that accurately predict the biological responses to AgNW exposure in real-world applications, enabling more reliable risk assessment and facilitating regulatory approval processes for innovative AgNW-based biosensing technologies.

Surface modification strategies have emerged as critical approaches to mitigate these cytotoxic effects while preserving the desirable electrical and optical properties of AgNWs. Functionalization with biocompatible polymers such as polyethylene glycol (PEG), chitosan, or specific proteins creates protective barriers that reduce silver ion leaching and minimize direct contact between nanowires and cellular components. These modifications have demonstrated significant improvements in cell viability and reduced inflammatory responses in both in vitro and in vivo studies.

Regulatory frameworks governing the use of nanomaterials in biomedical applications continue to evolve, with particular attention to silver-based nanomaterials. The FDA, EMA, and other international regulatory bodies have established guidelines for evaluating the safety profiles of nanomaterials intended for biological applications. Comprehensive toxicological assessments, including genotoxicity, immunogenicity, and long-term bioaccumulation studies, are increasingly required before AgNW-based biosensors can progress toward clinical implementation.

Environmental considerations also play a crucial role in the safety assessment of AgNW biosensors. The potential release of silver nanomaterials into ecosystems raises concerns about bioaccumulation in aquatic organisms and disruption of microbial communities. Sustainable design approaches incorporating biodegradable components or closed-loop systems for nanomaterial recovery are being explored to address these environmental challenges.

Recent advancements in AgNW synthesis have focused on developing "safer-by-design" approaches, where biocompatibility considerations are integrated from the earliest stages of material development. These include precise control over nanowire dimensions, as shorter AgNWs typically demonstrate reduced cytotoxicity compared to their longer counterparts, and the incorporation of biologically derived capping agents that enhance biocompatibility while maintaining sensing performance.

Standardized testing protocols specifically designed for evaluating nanomaterial-biological interactions are essential for meaningful safety assessments. The scientific community continues to work toward consensus on appropriate in vitro and in vivo models that accurately predict the biological responses to AgNW exposure in real-world applications, enabling more reliable risk assessment and facilitating regulatory approval processes for innovative AgNW-based biosensing technologies.

Manufacturing Scalability and Cost Analysis

The scalability of silver nanowire (AgNW) manufacturing represents a critical factor in the widespread adoption of AgNW-based biosensing technologies. Current production methods include polyol synthesis, hydrothermal processes, and electrochemical deposition, each with varying degrees of scalability. The polyol process, while most commonly used in laboratory settings, faces challenges in maintaining uniform nanowire dimensions when scaled to industrial production volumes. This inconsistency can significantly impact biosensor performance metrics, particularly sensitivity and reproducibility.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs, with silver being the primary cost driver. The current market price of silver ($25-30 per troy ounce) creates a substantial baseline cost that cannot be easily reduced. Secondary expenses include specialized equipment, purification processes, and quality control measures, which collectively account for 25-35% of production costs. Labor and energy consumption represent the remaining cost factors.

Economies of scale offer potential for cost reduction, with estimates suggesting a 15-30% decrease in per-unit costs when production volumes increase from laboratory to industrial scale. However, this advantage is partially offset by the increased complexity of quality control systems required for larger batches. Current production costs for high-quality AgNWs range from $300-500 per gram for research-grade materials to $150-250 per gram for industrial quantities.

Several manufacturers have implemented continuous flow reactors to enhance production efficiency, achieving throughput increases of 200-300% compared to batch processing methods. These systems also demonstrate improved consistency in nanowire dimensions, addressing a key challenge in scaled production. Additionally, recent innovations in silver recovery and recycling processes have shown potential to reduce raw material costs by 15-20%.

Environmental considerations also impact manufacturing scalability, with increasing regulatory pressure regarding silver nanoparticle waste management. Compliant waste treatment systems add approximately 5-10% to overall production costs but are essential for sustainable large-scale manufacturing operations. Companies investing in closed-loop production systems report long-term cost benefits despite higher initial capital expenditure.

The integration of automated quality control systems represents another significant advancement in manufacturing scalability. Real-time monitoring using optical and electrical characterization techniques has reduced rejection rates by 30-40% in pilot-scale operations, substantially improving production economics. These systems, while requiring significant upfront investment, typically demonstrate return on investment within 18-24 months of implementation.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs, with silver being the primary cost driver. The current market price of silver ($25-30 per troy ounce) creates a substantial baseline cost that cannot be easily reduced. Secondary expenses include specialized equipment, purification processes, and quality control measures, which collectively account for 25-35% of production costs. Labor and energy consumption represent the remaining cost factors.

Economies of scale offer potential for cost reduction, with estimates suggesting a 15-30% decrease in per-unit costs when production volumes increase from laboratory to industrial scale. However, this advantage is partially offset by the increased complexity of quality control systems required for larger batches. Current production costs for high-quality AgNWs range from $300-500 per gram for research-grade materials to $150-250 per gram for industrial quantities.

Several manufacturers have implemented continuous flow reactors to enhance production efficiency, achieving throughput increases of 200-300% compared to batch processing methods. These systems also demonstrate improved consistency in nanowire dimensions, addressing a key challenge in scaled production. Additionally, recent innovations in silver recovery and recycling processes have shown potential to reduce raw material costs by 15-20%.

Environmental considerations also impact manufacturing scalability, with increasing regulatory pressure regarding silver nanoparticle waste management. Compliant waste treatment systems add approximately 5-10% to overall production costs but are essential for sustainable large-scale manufacturing operations. Companies investing in closed-loop production systems report long-term cost benefits despite higher initial capital expenditure.

The integration of automated quality control systems represents another significant advancement in manufacturing scalability. Real-time monitoring using optical and electrical characterization techniques has reduced rejection rates by 30-40% in pilot-scale operations, substantially improving production economics. These systems, while requiring significant upfront investment, typically demonstrate return on investment within 18-24 months of implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!