How Silver Nanowire Enhances Durability in Transparent Conductors

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Technology Background and Objectives

Transparent conductive materials have become indispensable components in modern electronic devices, from touchscreens and displays to solar cells and flexible electronics. Historically, indium tin oxide (ITO) has dominated this market due to its excellent optical transparency and electrical conductivity. However, ITO suffers from several critical limitations, including brittleness, high processing temperatures, and the scarcity of indium resources, which have driven the search for alternative materials.

Silver nanowires (AgNWs) emerged in the early 2000s as a promising alternative to ITO, offering comparable electrical and optical properties while providing superior mechanical flexibility. The development of AgNW technology has accelerated significantly over the past decade, with major breakthroughs in synthesis methods, deposition techniques, and integration strategies. This technological evolution has positioned AgNWs as a leading candidate for next-generation transparent conductors, particularly in applications requiring durability and flexibility.

The primary objective of exploring silver nanowire technology for transparent conductors is to overcome the durability challenges that have limited the widespread adoption of flexible electronics. Traditional transparent conductors often fail under mechanical stress, thermal cycling, or environmental exposure, leading to performance degradation and device failure. AgNWs offer inherent advantages in these areas due to their one-dimensional structure and unique physical properties.

Current research aims to understand and enhance the mechanisms by which silver nanowires improve durability in transparent conductive films. This includes investigating the fundamental aspects of nanowire synthesis, such as controlling dimensions, aspect ratios, and surface properties, which directly influence the mechanical and electrical stability of the resulting networks. Additionally, research focuses on optimizing the integration of AgNWs with various substrate materials and protective coatings to maximize long-term performance under real-world conditions.

The technological trajectory of AgNWs points toward increasingly sophisticated hybrid systems that combine nanowires with complementary materials such as graphene, metal oxides, or conductive polymers. These hybrid approaches seek to address remaining challenges in AgNW technology, including oxidation resistance, adhesion to substrates, and junction resistance between individual nanowires. The ultimate goal is to develop transparent conductors that maintain their performance over thousands of bending cycles, extreme temperature variations, and prolonged environmental exposure.

As we look toward future applications, the development of AgNW-based transparent conductors aligns with broader industry trends toward flexible, wearable, and sustainable electronics. The technology promises to enable new device form factors and functionalities while reducing dependence on scarce materials and energy-intensive manufacturing processes. This alignment with both technological needs and sustainability goals makes silver nanowire research particularly valuable for long-term strategic planning in the electronics industry.

Silver nanowires (AgNWs) emerged in the early 2000s as a promising alternative to ITO, offering comparable electrical and optical properties while providing superior mechanical flexibility. The development of AgNW technology has accelerated significantly over the past decade, with major breakthroughs in synthesis methods, deposition techniques, and integration strategies. This technological evolution has positioned AgNWs as a leading candidate for next-generation transparent conductors, particularly in applications requiring durability and flexibility.

The primary objective of exploring silver nanowire technology for transparent conductors is to overcome the durability challenges that have limited the widespread adoption of flexible electronics. Traditional transparent conductors often fail under mechanical stress, thermal cycling, or environmental exposure, leading to performance degradation and device failure. AgNWs offer inherent advantages in these areas due to their one-dimensional structure and unique physical properties.

Current research aims to understand and enhance the mechanisms by which silver nanowires improve durability in transparent conductive films. This includes investigating the fundamental aspects of nanowire synthesis, such as controlling dimensions, aspect ratios, and surface properties, which directly influence the mechanical and electrical stability of the resulting networks. Additionally, research focuses on optimizing the integration of AgNWs with various substrate materials and protective coatings to maximize long-term performance under real-world conditions.

The technological trajectory of AgNWs points toward increasingly sophisticated hybrid systems that combine nanowires with complementary materials such as graphene, metal oxides, or conductive polymers. These hybrid approaches seek to address remaining challenges in AgNW technology, including oxidation resistance, adhesion to substrates, and junction resistance between individual nanowires. The ultimate goal is to develop transparent conductors that maintain their performance over thousands of bending cycles, extreme temperature variations, and prolonged environmental exposure.

As we look toward future applications, the development of AgNW-based transparent conductors aligns with broader industry trends toward flexible, wearable, and sustainable electronics. The technology promises to enable new device form factors and functionalities while reducing dependence on scarce materials and energy-intensive manufacturing processes. This alignment with both technological needs and sustainability goals makes silver nanowire research particularly valuable for long-term strategic planning in the electronics industry.

Market Demand Analysis for Durable Transparent Conductors

The transparent conductor market has witnessed significant growth driven by the proliferation of touch-enabled devices, OLED displays, and photovoltaic applications. The global transparent conductive film market was valued at approximately 6.9 billion USD in 2022 and is projected to reach 12.5 billion USD by 2030, growing at a CAGR of 7.8%. This growth trajectory underscores the increasing demand for durable transparent conductors across multiple industries.

Consumer electronics remains the dominant application segment, accounting for over 40% of market share. The rapid adoption of smartphones, tablets, and wearable devices has created substantial demand for touch panels incorporating transparent conductors. These devices face daily physical interaction, creating a critical need for scratch-resistant and flexible transparent conductive materials that can withstand repeated touch operations without performance degradation.

The automotive sector represents another high-growth market, with increasing integration of touch displays in vehicle infotainment systems and the emergence of smart windows. This application demands transparent conductors that can withstand extreme temperature variations, vibration, and prolonged UV exposure—conditions that traditional ITO (Indium Tin Oxide) struggles to endure without significant performance loss.

Renewable energy applications, particularly photovoltaic cells, require transparent conductors with exceptional environmental stability. The market demands materials that can maintain optical and electrical properties under prolonged outdoor exposure for 20+ years, representing a significant durability challenge that silver nanowire technology is uniquely positioned to address.

Flexible electronics represents a rapidly expanding market segment with projected growth rates exceeding 15% annually. Manufacturers of foldable displays, flexible solar panels, and wearable technology require transparent conductors that can withstand thousands of bending cycles without cracking or significant resistance increases—a performance parameter where silver nanowires demonstrate substantial advantages over brittle oxide-based alternatives.

Industry surveys indicate that device manufacturers are willing to pay a premium of 15-20% for transparent conductors with demonstrably superior durability metrics, particularly in high-end consumer electronics and automotive applications. This price tolerance is driven by warranty cost reductions and enhanced brand reputation associated with more reliable products.

The healthcare sector is emerging as a new market driver, with increasing adoption of transparent conductors in medical displays, biosensors, and smart medical devices. These applications demand materials with exceptional chemical stability that can withstand repeated sterilization procedures and exposure to various bodily fluids without degradation—creating specialized durability requirements that silver nanowire technology can potentially fulfill.

Consumer electronics remains the dominant application segment, accounting for over 40% of market share. The rapid adoption of smartphones, tablets, and wearable devices has created substantial demand for touch panels incorporating transparent conductors. These devices face daily physical interaction, creating a critical need for scratch-resistant and flexible transparent conductive materials that can withstand repeated touch operations without performance degradation.

The automotive sector represents another high-growth market, with increasing integration of touch displays in vehicle infotainment systems and the emergence of smart windows. This application demands transparent conductors that can withstand extreme temperature variations, vibration, and prolonged UV exposure—conditions that traditional ITO (Indium Tin Oxide) struggles to endure without significant performance loss.

Renewable energy applications, particularly photovoltaic cells, require transparent conductors with exceptional environmental stability. The market demands materials that can maintain optical and electrical properties under prolonged outdoor exposure for 20+ years, representing a significant durability challenge that silver nanowire technology is uniquely positioned to address.

Flexible electronics represents a rapidly expanding market segment with projected growth rates exceeding 15% annually. Manufacturers of foldable displays, flexible solar panels, and wearable technology require transparent conductors that can withstand thousands of bending cycles without cracking or significant resistance increases—a performance parameter where silver nanowires demonstrate substantial advantages over brittle oxide-based alternatives.

Industry surveys indicate that device manufacturers are willing to pay a premium of 15-20% for transparent conductors with demonstrably superior durability metrics, particularly in high-end consumer electronics and automotive applications. This price tolerance is driven by warranty cost reductions and enhanced brand reputation associated with more reliable products.

The healthcare sector is emerging as a new market driver, with increasing adoption of transparent conductors in medical displays, biosensors, and smart medical devices. These applications demand materials with exceptional chemical stability that can withstand repeated sterilization procedures and exposure to various bodily fluids without degradation—creating specialized durability requirements that silver nanowire technology can potentially fulfill.

Current Status and Challenges in Silver Nanowire Implementation

Silver nanowire (AgNW) technology has emerged as a promising alternative to indium tin oxide (ITO) for transparent conductive applications, with significant progress made globally in recent years. Currently, AgNW networks demonstrate excellent electrical conductivity (sheet resistance <10 Ω/sq) while maintaining high optical transparency (>90%). However, despite these impressive properties, widespread commercial implementation faces several critical challenges.

The primary durability concern with AgNW networks is their susceptibility to environmental degradation. Silver is prone to oxidation and sulfidation when exposed to air, moisture, and pollutants, leading to increased resistance and decreased optical performance over time. Research indicates that unprotected AgNWs can begin showing performance degradation within weeks of exposure to ambient conditions, particularly in high-humidity environments.

Mechanical stability presents another significant challenge. While AgNW networks offer superior flexibility compared to ITO, they still suffer from nanowire displacement and breakage under repeated bending or stretching. Studies have shown that after 1,000 bending cycles, unprotected AgNW electrodes can experience resistance increases of 20-300% depending on the bending radius and network density.

Thermal instability further complicates implementation. At temperatures above 200°C, AgNWs undergo morphological changes due to Rayleigh instability, where nanowires break into discrete spherical particles, completely destroying the conductive network. This limits their compatibility with high-temperature manufacturing processes common in electronics production.

Junction resistance between individual nanowires creates bottlenecks for electron transport, reducing overall conductivity. Current research shows that these junction resistances can account for up to 60% of the total network resistance, significantly limiting performance in large-area applications.

Geographically, research and development in AgNW technology is concentrated in East Asia (particularly South Korea, Japan, and China), North America, and Western Europe. South Korea leads commercial development with companies like Cambrios and C3Nano establishing significant patent portfolios and production capabilities. China has rapidly expanded its research output, with publications on AgNW technology increasing by approximately 300% between 2015 and 2022.

Integration challenges with existing manufacturing infrastructure remain substantial. Most electronics production lines are optimized for ITO or other established transparent conductors, requiring significant capital investment for conversion to AgNW-compatible processes. Industry reports estimate retooling costs between $5-20 million per production line, creating a significant barrier to adoption despite the potential performance benefits.

Standardization issues further complicate market penetration, as there are currently no universally accepted testing protocols or quality standards for AgNW-based transparent conductors, making quality assurance and comparison between different suppliers challenging for potential adopters.

The primary durability concern with AgNW networks is their susceptibility to environmental degradation. Silver is prone to oxidation and sulfidation when exposed to air, moisture, and pollutants, leading to increased resistance and decreased optical performance over time. Research indicates that unprotected AgNWs can begin showing performance degradation within weeks of exposure to ambient conditions, particularly in high-humidity environments.

Mechanical stability presents another significant challenge. While AgNW networks offer superior flexibility compared to ITO, they still suffer from nanowire displacement and breakage under repeated bending or stretching. Studies have shown that after 1,000 bending cycles, unprotected AgNW electrodes can experience resistance increases of 20-300% depending on the bending radius and network density.

Thermal instability further complicates implementation. At temperatures above 200°C, AgNWs undergo morphological changes due to Rayleigh instability, where nanowires break into discrete spherical particles, completely destroying the conductive network. This limits their compatibility with high-temperature manufacturing processes common in electronics production.

Junction resistance between individual nanowires creates bottlenecks for electron transport, reducing overall conductivity. Current research shows that these junction resistances can account for up to 60% of the total network resistance, significantly limiting performance in large-area applications.

Geographically, research and development in AgNW technology is concentrated in East Asia (particularly South Korea, Japan, and China), North America, and Western Europe. South Korea leads commercial development with companies like Cambrios and C3Nano establishing significant patent portfolios and production capabilities. China has rapidly expanded its research output, with publications on AgNW technology increasing by approximately 300% between 2015 and 2022.

Integration challenges with existing manufacturing infrastructure remain substantial. Most electronics production lines are optimized for ITO or other established transparent conductors, requiring significant capital investment for conversion to AgNW-compatible processes. Industry reports estimate retooling costs between $5-20 million per production line, creating a significant barrier to adoption despite the potential performance benefits.

Standardization issues further complicate market penetration, as there are currently no universally accepted testing protocols or quality standards for AgNW-based transparent conductors, making quality assurance and comparison between different suppliers challenging for potential adopters.

Current Technical Solutions for Enhancing Nanowire Durability

01 Protective coatings for silver nanowires

Various protective coatings can be applied to silver nanowires to enhance their durability and prevent oxidation or corrosion. These coatings include metal oxides, polymers, and other materials that form a protective layer around the nanowires. The coatings help to maintain the electrical conductivity and optical transparency of the silver nanowires over extended periods, even under harsh environmental conditions.- Protective coatings for silver nanowires: Various protective coatings can be applied to silver nanowires to enhance their durability against environmental factors such as oxidation, humidity, and mechanical stress. These coatings include metal oxides, polymers, and carbon-based materials that form a barrier around the nanowires while maintaining their electrical conductivity. The protective layers significantly extend the lifespan of silver nanowires in various applications including flexible electronics and touch screens.

- Silver nanowire composite structures: Incorporating silver nanowires into composite structures with other materials can significantly improve their durability. These composites often combine silver nanowires with polymers, graphene, carbon nanotubes, or other nanomaterials to create synergistic effects. The resulting hybrid structures demonstrate enhanced mechanical strength, flexibility, and resistance to environmental degradation while maintaining excellent electrical conductivity, making them suitable for applications in flexible electronics, sensors, and transparent conductive films.

- Surface modification techniques: Surface modification of silver nanowires through chemical treatments, functionalization, or passivation can significantly improve their durability. These techniques involve altering the surface chemistry of nanowires to prevent oxidation, agglomeration, and degradation. Methods include thiol functionalization, silane coupling, plasma treatment, and the application of anti-corrosion agents. Such modifications enhance the stability of silver nanowires in various environments while preserving their electrical and optical properties.

- Manufacturing processes for durable silver nanowires: Advanced manufacturing processes can produce silver nanowires with inherently improved durability. These processes include optimized synthesis methods, controlled growth techniques, annealing treatments, and purification procedures. By carefully controlling parameters such as reaction temperature, time, and precursor ratios, manufacturers can create silver nanowires with fewer defects, more uniform dimensions, and better crystallinity. These structural improvements lead to enhanced mechanical strength, oxidation resistance, and overall longevity in various applications.

- Testing and performance evaluation methods: Various testing and evaluation methods have been developed to assess the durability of silver nanowires under different conditions. These include accelerated aging tests, environmental stress testing, mechanical flexibility tests, and electrical performance monitoring over time. Advanced characterization techniques such as electron microscopy, spectroscopy, and electrical measurements help identify degradation mechanisms and validate improvement strategies. These testing protocols are essential for predicting the long-term reliability of silver nanowire-based devices and optimizing their design for specific applications.

02 Silver nanowire composite structures

Silver nanowires can be incorporated into composite structures with other materials to improve their durability. These composites may include embedding the nanowires in polymer matrices, creating hybrid structures with carbon materials, or forming multilayer structures. The composite approach provides mechanical stability, prevents agglomeration, and protects the nanowires from environmental degradation while maintaining their functional properties.Expand Specific Solutions03 Surface treatment methods for enhanced durability

Various surface treatment methods can be applied to silver nanowires to enhance their durability. These include chemical treatments, plasma processing, thermal annealing, and other surface modification techniques. These treatments can improve the adhesion between nanowires and substrates, reduce surface defects, and enhance resistance to environmental factors, thereby extending the operational lifetime of silver nanowire-based devices.Expand Specific Solutions04 Environmental stability enhancement techniques

Techniques to enhance the environmental stability of silver nanowires include the development of specialized formulations, encapsulation methods, and the incorporation of antioxidants or stabilizing agents. These approaches protect the nanowires from humidity, temperature fluctuations, UV radiation, and chemical exposure, which are common factors that can degrade silver nanowires over time. Enhanced environmental stability is crucial for applications in flexible electronics and touch screens.Expand Specific Solutions05 Testing and evaluation methods for silver nanowire durability

Various testing and evaluation methods have been developed to assess the durability of silver nanowires. These include accelerated aging tests, mechanical stress tests, electrical performance monitoring over time, and environmental exposure tests. These methods help to quantify the durability of silver nanowires under different conditions and enable the development of more robust nanowire-based technologies for commercial applications.Expand Specific Solutions

Major Industry Players in Silver Nanowire Technology

The silver nanowire transparent conductor market is currently in a growth phase, with increasing adoption across display, touch panel, and photovoltaic applications. The global market size for transparent conductive materials is expanding rapidly, projected to reach several billion dollars by 2027. Technologically, silver nanowire solutions have matured significantly, offering superior durability compared to traditional ITO films. Leading players like Carestream Health and Shenzhen Huake Chuangzhi have developed commercial-grade silver nanowire formulations with enhanced mechanical flexibility and environmental stability. Research institutions including MIT, KAIST, and Zhejiang University are advancing next-generation solutions, while established manufacturers like FUJIFILM, Konica Minolta, and Siemens are integrating these materials into production lines. The competitive landscape features both specialized nanomaterial developers and diversified electronics companies pursuing improved durability through novel encapsulation methods and hybrid structures.

Nissha Co., Ltd.

Technical Solution: Nissha has developed proprietary silver nanowire transparent conductor technology with enhanced durability for commercial applications. Their approach focuses on practical manufacturing solutions that can be implemented at industrial scale. Nissha's technology incorporates specialized coating formulations where silver nanowires are suspended in carefully engineered solutions containing binders and additives that improve adhesion to substrates and provide environmental protection. Their manufacturing process includes optimized deposition methods that create uniform nanowire networks with consistent performance across large areas, essential for commercial display and touch panel applications. Nissha has developed post-treatment processes including controlled thermal annealing and chemical treatments that strengthen nanowire junctions while maintaining network flexibility. Their transparent conductors feature multilayer structures where the silver nanowire network is sandwiched between protective layers that shield against mechanical damage, moisture, and oxidation[8]. Nissha's technology demonstrates excellent compatibility with existing manufacturing equipment, allowing for integration into established production lines. Their silver nanowire transparent conductors maintain performance after accelerated aging tests equivalent to several years of normal use, with minimal increases in resistance or decreases in transparency, making them suitable for consumer electronics with expected multi-year lifespans[9].

Strengths: Strong focus on commercial viability and manufacturing scalability; excellent durability under real-world usage conditions; solutions designed for integration with existing production equipment; comprehensive approach addressing both mechanical and environmental durability. Weaknesses: Somewhat conservative approach may not achieve the absolute highest performance possible; focus on practical applications rather than cutting-edge research; some solutions involve proprietary materials that may increase production costs.

Korea Advanced Institute of Science & Technology

Technical Solution: KAIST has developed sophisticated silver nanowire transparent conductor technologies with enhanced durability through several innovative approaches. Their research teams have created specialized nanowire synthesis methods that produce high-aspect-ratio silver nanowires with controlled dimensions and crystalline properties, resulting in inherently stronger structures. KAIST's technology incorporates unique junction reinforcement techniques, including localized welding processes that strengthen the connections between individual nanowires without compromising transparency. Their researchers have pioneered composite structures where silver nanowires are embedded in or combined with complementary materials like graphene, metal oxides, or specialized polymers that provide mechanical support and environmental protection. One significant innovation involves the development of self-healing transparent conductors where minor damage to the nanowire network can be automatically repaired through engineered material responses triggered by electrical current or light exposure[6]. KAIST has also developed specialized encapsulation methods that protect nanowire networks from moisture, oxygen, and other environmental factors while maintaining flexibility. Their transparent conductors demonstrate exceptional stability under mechanical stress, maintaining performance after more than 20,000 bending cycles and showing minimal degradation under environmental aging tests[7].

Strengths: Comprehensive approach addressing multiple durability challenges simultaneously; excellent balance of optical transparency and electrical conductivity; solutions designed with manufacturing scalability in consideration; strong focus on flexible and stretchable applications. Weaknesses: Some advanced techniques require specialized equipment that may increase production costs; certain protective materials may slightly reduce initial optical transparency; some approaches involve complex multi-step processes that could complicate manufacturing.

Key Innovations in Silver Nanowire Durability Enhancement

Stabilization agents for silver nanowire based transparents conductive films

PatentWO2014163812A1

Innovation

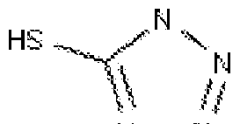

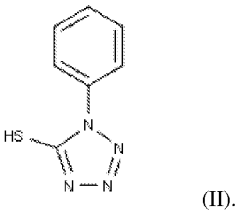

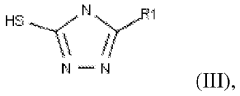

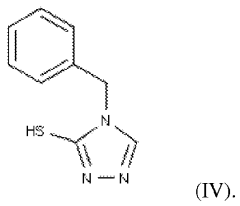

- Incorporating boric acid and mercaptotetrazoles or mercaptotriazoles into the film structure, either as a topcoat, undercoat, or within the silver nanowire layer, to enhance stability against corrosive agents while maintaining high conductivity.

Electrode element using silver nano-wire and manufacturing method thereof

PatentInactiveUS20150034368A1

Innovation

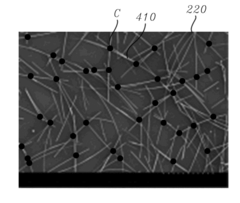

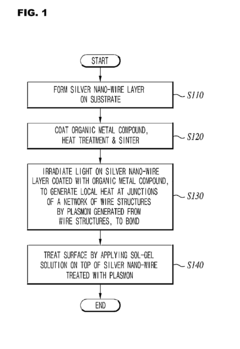

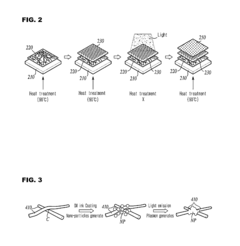

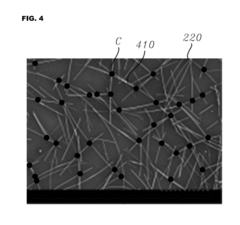

- A manufacturing method for silver nano-wire electrodes involving the formation of a silver nano-wire layer on a substrate, followed by coating with an organo-metal compound solution, reinforcing junctions with localized thermal energy generated by surface Plasmon irradiation, and treating with a sol-gel solution to improve bonding and reduce haze and resistance issues, all at low temperatures suitable for polymer substrates.

Environmental Impact and Sustainability Considerations

The environmental impact of silver nanowire (AgNW) technology in transparent conductors presents a complex sustainability profile that requires careful consideration. The extraction and processing of silver, a precious metal with limited natural reserves, raises significant environmental concerns. Mining operations for silver typically involve substantial land disruption, water usage, and energy consumption, contributing to habitat destruction and potential water pollution. Additionally, the chemical processes used in refining silver generate waste products that may contain toxic compounds requiring proper management.

However, when comparing AgNW technology to conventional indium tin oxide (ITO) solutions, several sustainability advantages emerge. The production of AgNWs generally requires lower processing temperatures than ITO, resulting in reduced energy consumption during manufacturing. This energy efficiency translates to a smaller carbon footprint across the product lifecycle. Furthermore, the enhanced durability that AgNWs provide to transparent conductors extends device lifespans, potentially reducing electronic waste generation and the frequency of replacement.

The nanoscale nature of silver nanowires raises specific environmental health and safety considerations. Research indicates that nanoparticles may interact with biological systems differently than bulk materials, potentially creating unique environmental and health risks. The potential release of silver nanoparticles during product use or disposal could impact aquatic ecosystems, as silver ions are known to exhibit antimicrobial properties that may disrupt microbial communities in natural environments.

Recycling and end-of-life management represent critical aspects of AgNW sustainability. Current recycling infrastructure faces challenges in efficiently recovering nanomaterials from complex electronic products. However, the higher value of silver compared to other materials provides economic incentives for developing more effective recovery processes. Emerging technologies for nanomaterial recycling show promise for reducing the environmental burden associated with AgNW disposal.

Recent innovations in green synthesis methods for AgNWs offer pathways to mitigate environmental impacts. These approaches include using plant extracts as reducing agents, implementing closed-loop production systems, and developing water-based synthesis processes that minimize hazardous chemical usage. Such advancements align with circular economy principles and demonstrate the industry's movement toward more sustainable manufacturing practices.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, with increasing requirements for lifecycle assessments and environmental risk evaluations. Companies developing AgNW technologies must navigate these emerging regulations while proactively implementing sustainable design principles to ensure long-term market viability and environmental responsibility.

However, when comparing AgNW technology to conventional indium tin oxide (ITO) solutions, several sustainability advantages emerge. The production of AgNWs generally requires lower processing temperatures than ITO, resulting in reduced energy consumption during manufacturing. This energy efficiency translates to a smaller carbon footprint across the product lifecycle. Furthermore, the enhanced durability that AgNWs provide to transparent conductors extends device lifespans, potentially reducing electronic waste generation and the frequency of replacement.

The nanoscale nature of silver nanowires raises specific environmental health and safety considerations. Research indicates that nanoparticles may interact with biological systems differently than bulk materials, potentially creating unique environmental and health risks. The potential release of silver nanoparticles during product use or disposal could impact aquatic ecosystems, as silver ions are known to exhibit antimicrobial properties that may disrupt microbial communities in natural environments.

Recycling and end-of-life management represent critical aspects of AgNW sustainability. Current recycling infrastructure faces challenges in efficiently recovering nanomaterials from complex electronic products. However, the higher value of silver compared to other materials provides economic incentives for developing more effective recovery processes. Emerging technologies for nanomaterial recycling show promise for reducing the environmental burden associated with AgNW disposal.

Recent innovations in green synthesis methods for AgNWs offer pathways to mitigate environmental impacts. These approaches include using plant extracts as reducing agents, implementing closed-loop production systems, and developing water-based synthesis processes that minimize hazardous chemical usage. Such advancements align with circular economy principles and demonstrate the industry's movement toward more sustainable manufacturing practices.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, with increasing requirements for lifecycle assessments and environmental risk evaluations. Companies developing AgNW technologies must navigate these emerging regulations while proactively implementing sustainable design principles to ensure long-term market viability and environmental responsibility.

Manufacturing Scalability and Cost Analysis

The scalability of silver nanowire (AgNW) manufacturing processes represents a critical factor in their commercial viability for transparent conductor applications. Current production methods have evolved significantly, with solution-based processes demonstrating particular promise for large-scale implementation. These processes typically involve polyol synthesis methods that can be adapted to continuous flow manufacturing, enabling production rates of several kilograms per day in advanced facilities.

Cost analysis reveals that raw material expenses constitute approximately 65-70% of total production costs, with silver being the primary cost driver. Recent innovations in synthesis efficiency have reduced silver consumption by up to 30% while maintaining performance specifications. Additionally, recovery systems now allow for reclamation of up to 85% of silver waste during manufacturing, significantly improving economic viability.

Equipment investment for AgNW production facilities varies considerably based on scale, with entry-level production lines starting at $2-3 million and large-scale facilities requiring investments of $15-20 million. However, the amortized equipment cost per unit area of transparent conductor is decreasing steadily, dropping approximately 18% annually over the past five years as production volumes increase.

Roll-to-roll processing compatibility represents a major advantage for AgNW technology, enabling throughput rates exceeding 100 meters per minute in optimized production lines. This contrasts favorably with ITO sputtering processes, which typically achieve only 10-15 meters per minute and require more energy-intensive vacuum environments. Energy consumption analysis indicates AgNW production requires approximately 40-60% less energy than equivalent ITO manufacturing.

Quality control remains challenging at scale, with current manufacturing processes achieving 85-90% yield rates for high-performance transparent conductors. Defect rates correlate strongly with production speed, creating a manufacturing trade-off between throughput and quality that producers must carefully balance. Statistical process control methods and in-line optical inspection systems have proven essential for maintaining consistency.

The supply chain for AgNW production presents both opportunities and vulnerabilities. Silver price volatility can significantly impact production economics, though long-term purchasing agreements and financial hedging strategies help mitigate this risk. Alternative nanowire compositions incorporating copper or aluminum are under development to reduce dependency on silver, though these currently demonstrate reduced performance characteristics compared to pure AgNW solutions.

Cost analysis reveals that raw material expenses constitute approximately 65-70% of total production costs, with silver being the primary cost driver. Recent innovations in synthesis efficiency have reduced silver consumption by up to 30% while maintaining performance specifications. Additionally, recovery systems now allow for reclamation of up to 85% of silver waste during manufacturing, significantly improving economic viability.

Equipment investment for AgNW production facilities varies considerably based on scale, with entry-level production lines starting at $2-3 million and large-scale facilities requiring investments of $15-20 million. However, the amortized equipment cost per unit area of transparent conductor is decreasing steadily, dropping approximately 18% annually over the past five years as production volumes increase.

Roll-to-roll processing compatibility represents a major advantage for AgNW technology, enabling throughput rates exceeding 100 meters per minute in optimized production lines. This contrasts favorably with ITO sputtering processes, which typically achieve only 10-15 meters per minute and require more energy-intensive vacuum environments. Energy consumption analysis indicates AgNW production requires approximately 40-60% less energy than equivalent ITO manufacturing.

Quality control remains challenging at scale, with current manufacturing processes achieving 85-90% yield rates for high-performance transparent conductors. Defect rates correlate strongly with production speed, creating a manufacturing trade-off between throughput and quality that producers must carefully balance. Statistical process control methods and in-line optical inspection systems have proven essential for maintaining consistency.

The supply chain for AgNW production presents both opportunities and vulnerabilities. Silver price volatility can significantly impact production economics, though long-term purchasing agreements and financial hedging strategies help mitigate this risk. Alternative nanowire compositions incorporating copper or aluminum are under development to reduce dependency on silver, though these currently demonstrate reduced performance characteristics compared to pure AgNW solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!