How Silver Nanowire Modulates Thermal Conductivity in Composites

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Technology Background and Objectives

Silver nanowires (AgNWs) have emerged as a revolutionary material in the field of thermal management over the past decade. These one-dimensional nanostructures, typically with diameters ranging from 20 to 100 nm and lengths of several micrometers, possess exceptional thermal conductivity properties that make them highly valuable for composite materials. The evolution of AgNW technology can be traced back to the early 2000s, when researchers began exploring metallic nanowires for electronic applications, but their thermal properties remained largely unexplored until the 2010s.

The technological trajectory of AgNWs has been marked by significant advancements in synthesis methods, from polyol processes to more sophisticated template-assisted approaches, enabling precise control over nanowire dimensions and properties. This evolution has been driven by the increasing demand for materials with enhanced thermal management capabilities in electronics, aerospace, and energy sectors, where heat dissipation remains a critical challenge.

Current research trends indicate a growing interest in understanding the fundamental mechanisms by which AgNWs modulate thermal conductivity in composite materials. This includes investigating the effects of nanowire concentration, aspect ratio, orientation, and interfacial interactions with various matrix materials. The scientific community has observed that AgNWs can create highly efficient thermal percolation networks within composites, potentially increasing thermal conductivity by orders of magnitude compared to the base material.

The primary technical objectives in this field include developing a comprehensive understanding of the thermal transport mechanisms at the nanoscale, optimizing the integration of AgNWs into various matrix materials, and establishing predictive models for thermal conductivity based on composite composition and structure. Researchers aim to achieve precise control over thermal anisotropy, stability under thermal cycling, and cost-effective manufacturing processes.

Beyond thermal conductivity, AgNWs offer multifunctional properties including electrical conductivity and mechanical reinforcement, creating opportunities for smart materials that can simultaneously address multiple engineering challenges. The convergence of these properties positions AgNW-based composites as promising candidates for next-generation thermal interface materials, flexible electronics, and aerospace components.

Looking forward, the field is moving toward sustainable manufacturing approaches, exploring bio-inspired composite architectures, and developing hybrid systems that combine AgNWs with other nanomaterials such as graphene or carbon nanotubes to achieve synergistic effects. The ultimate goal is to establish design principles that enable tailored thermal management solutions across diverse applications, from microelectronics cooling to large-scale energy systems.

The technological trajectory of AgNWs has been marked by significant advancements in synthesis methods, from polyol processes to more sophisticated template-assisted approaches, enabling precise control over nanowire dimensions and properties. This evolution has been driven by the increasing demand for materials with enhanced thermal management capabilities in electronics, aerospace, and energy sectors, where heat dissipation remains a critical challenge.

Current research trends indicate a growing interest in understanding the fundamental mechanisms by which AgNWs modulate thermal conductivity in composite materials. This includes investigating the effects of nanowire concentration, aspect ratio, orientation, and interfacial interactions with various matrix materials. The scientific community has observed that AgNWs can create highly efficient thermal percolation networks within composites, potentially increasing thermal conductivity by orders of magnitude compared to the base material.

The primary technical objectives in this field include developing a comprehensive understanding of the thermal transport mechanisms at the nanoscale, optimizing the integration of AgNWs into various matrix materials, and establishing predictive models for thermal conductivity based on composite composition and structure. Researchers aim to achieve precise control over thermal anisotropy, stability under thermal cycling, and cost-effective manufacturing processes.

Beyond thermal conductivity, AgNWs offer multifunctional properties including electrical conductivity and mechanical reinforcement, creating opportunities for smart materials that can simultaneously address multiple engineering challenges. The convergence of these properties positions AgNW-based composites as promising candidates for next-generation thermal interface materials, flexible electronics, and aerospace components.

Looking forward, the field is moving toward sustainable manufacturing approaches, exploring bio-inspired composite architectures, and developing hybrid systems that combine AgNWs with other nanomaterials such as graphene or carbon nanotubes to achieve synergistic effects. The ultimate goal is to establish design principles that enable tailored thermal management solutions across diverse applications, from microelectronics cooling to large-scale energy systems.

Market Applications for Thermally Conductive Composites

Thermally conductive composites incorporating silver nanowires have emerged as critical materials across multiple high-value markets. The electronics industry represents the largest application segment, where these composites address thermal management challenges in increasingly miniaturized and powerful devices. Smartphones, tablets, and laptops utilize these materials as thermal interface materials (TIMs) to efficiently transfer heat from processors to heat sinks, preventing performance throttling and extending device lifespan.

The automotive sector, particularly the electric vehicle (EV) segment, constitutes another significant market. Battery thermal management systems employ silver nanowire composites to maintain optimal operating temperatures, enhancing battery efficiency, safety, and longevity. These materials also find applications in power electronics and LED headlights where heat dissipation directly impacts performance and reliability.

Aerospace and defense industries leverage these advanced composites in satellite components, avionics, and radar systems where traditional cooling methods prove inadequate due to space constraints and extreme operating environments. The superior thermal conductivity of silver nanowire composites enables more efficient heat transfer in these mission-critical applications.

The renewable energy sector represents a rapidly growing market for thermally conductive composites. Solar panel efficiency decreases with rising temperatures, making effective heat management essential. Silver nanowire composites help dissipate heat from photovoltaic cells, maintaining optimal operating temperatures and improving energy conversion efficiency by up to 15% in high-temperature environments.

Medical device manufacturers increasingly incorporate these materials in diagnostic equipment, implantable devices, and surgical tools. The biocompatibility of certain silver nanowire formulations, combined with their thermal properties, makes them suitable for applications where temperature control is crucial for patient safety and device functionality.

The LED lighting industry benefits significantly from improved thermal management through silver nanowire composites. Enhanced heat dissipation extends LED lifespan, maintains color consistency, and allows for higher-power applications. The global LED market, valued at $76 billion in 2021, continues to drive demand for advanced thermal management solutions.

Industrial equipment manufacturers utilize these composites in power electronics, industrial lasers, and high-performance computing systems where thermal management directly impacts operational efficiency and equipment longevity. The ability to customize thermal conductivity by adjusting silver nanowire concentration provides flexibility across diverse industrial applications with varying thermal requirements.

The automotive sector, particularly the electric vehicle (EV) segment, constitutes another significant market. Battery thermal management systems employ silver nanowire composites to maintain optimal operating temperatures, enhancing battery efficiency, safety, and longevity. These materials also find applications in power electronics and LED headlights where heat dissipation directly impacts performance and reliability.

Aerospace and defense industries leverage these advanced composites in satellite components, avionics, and radar systems where traditional cooling methods prove inadequate due to space constraints and extreme operating environments. The superior thermal conductivity of silver nanowire composites enables more efficient heat transfer in these mission-critical applications.

The renewable energy sector represents a rapidly growing market for thermally conductive composites. Solar panel efficiency decreases with rising temperatures, making effective heat management essential. Silver nanowire composites help dissipate heat from photovoltaic cells, maintaining optimal operating temperatures and improving energy conversion efficiency by up to 15% in high-temperature environments.

Medical device manufacturers increasingly incorporate these materials in diagnostic equipment, implantable devices, and surgical tools. The biocompatibility of certain silver nanowire formulations, combined with their thermal properties, makes them suitable for applications where temperature control is crucial for patient safety and device functionality.

The LED lighting industry benefits significantly from improved thermal management through silver nanowire composites. Enhanced heat dissipation extends LED lifespan, maintains color consistency, and allows for higher-power applications. The global LED market, valued at $76 billion in 2021, continues to drive demand for advanced thermal management solutions.

Industrial equipment manufacturers utilize these composites in power electronics, industrial lasers, and high-performance computing systems where thermal management directly impacts operational efficiency and equipment longevity. The ability to customize thermal conductivity by adjusting silver nanowire concentration provides flexibility across diverse industrial applications with varying thermal requirements.

Current Challenges in Nanowire-Based Thermal Management

Despite the promising thermal management potential of silver nanowire (AgNW) composites, several significant challenges impede their widespread implementation and optimization. The primary obstacle remains the inconsistent dispersion of nanowires within matrix materials. When AgNWs agglomerate, they create localized thermal pathways rather than forming continuous conductive networks throughout the composite, resulting in unpredictable and non-uniform thermal conductivity. This challenge becomes particularly pronounced as nanowire concentration increases, creating a technical paradox where higher loading—theoretically beneficial for conductivity—often leads to diminished performance due to clustering effects.

Interface thermal resistance presents another critical barrier, as the phonon scattering that occurs at the boundaries between silver nanowires and the host matrix significantly reduces heat transfer efficiency. This phenomenon, known as Kapitza resistance, can negate much of the inherent conductivity advantage of the silver component, especially in polymer-based composites where material property mismatches are substantial. Current research indicates that even well-dispersed nanowires may underperform theoretical predictions by 30-50% due to these interfacial effects.

Manufacturing scalability constitutes a substantial hurdle for commercial viability. Laboratory-scale production methods that achieve optimal nanowire orientation and distribution often prove difficult to translate to industrial-scale processes. Techniques such as magnetic field alignment or shear-force application during composite formation show promise in controlled environments but face significant implementation challenges in mass production scenarios. The cost-performance balance remains unfavorable, with high-quality silver nanowires adding considerable expense to composite materials without proportional thermal management benefits in many applications.

Dimensional control and aspect ratio optimization represent ongoing technical challenges. Research indicates that longer nanowires with higher aspect ratios generally create more effective conductive networks, but these same nanowires prove more susceptible to breakage during processing and more difficult to disperse uniformly. The trade-off between nanowire length, diameter, and processability creates a complex optimization problem that varies significantly across different matrix materials and application requirements.

Environmental stability concerns also limit implementation, particularly in high-temperature or chemically aggressive environments. Silver nanowires can undergo morphological changes, oxidation, or migration within the composite under thermal cycling or extended high-temperature exposure. This degradation pathway compromises the long-term reliability of thermal management solutions based on AgNW composites, especially in demanding applications like electronics cooling or industrial process heat exchange systems.

Interface thermal resistance presents another critical barrier, as the phonon scattering that occurs at the boundaries between silver nanowires and the host matrix significantly reduces heat transfer efficiency. This phenomenon, known as Kapitza resistance, can negate much of the inherent conductivity advantage of the silver component, especially in polymer-based composites where material property mismatches are substantial. Current research indicates that even well-dispersed nanowires may underperform theoretical predictions by 30-50% due to these interfacial effects.

Manufacturing scalability constitutes a substantial hurdle for commercial viability. Laboratory-scale production methods that achieve optimal nanowire orientation and distribution often prove difficult to translate to industrial-scale processes. Techniques such as magnetic field alignment or shear-force application during composite formation show promise in controlled environments but face significant implementation challenges in mass production scenarios. The cost-performance balance remains unfavorable, with high-quality silver nanowires adding considerable expense to composite materials without proportional thermal management benefits in many applications.

Dimensional control and aspect ratio optimization represent ongoing technical challenges. Research indicates that longer nanowires with higher aspect ratios generally create more effective conductive networks, but these same nanowires prove more susceptible to breakage during processing and more difficult to disperse uniformly. The trade-off between nanowire length, diameter, and processability creates a complex optimization problem that varies significantly across different matrix materials and application requirements.

Environmental stability concerns also limit implementation, particularly in high-temperature or chemically aggressive environments. Silver nanowires can undergo morphological changes, oxidation, or migration within the composite under thermal cycling or extended high-temperature exposure. This degradation pathway compromises the long-term reliability of thermal management solutions based on AgNW composites, especially in demanding applications like electronics cooling or industrial process heat exchange systems.

Existing Methods for Silver Nanowire Integration

01 Silver nanowire composites for enhanced thermal conductivity

Silver nanowires can be incorporated into various composite materials to significantly enhance thermal conductivity. These composites typically combine silver nanowires with polymers, resins, or other matrix materials to create thermally conductive materials for heat dissipation applications. The high aspect ratio and excellent thermal properties of silver nanowires create effective thermal pathways within the composite structure, resulting in superior heat transfer capabilities compared to conventional materials.- Thermal conductivity enhancement in composites using silver nanowires: Silver nanowires can be incorporated into various composite materials to significantly enhance thermal conductivity. These composites typically combine silver nanowires with polymers, resins, or other matrix materials to create thermally conductive materials for heat dissipation applications. The high aspect ratio of silver nanowires allows for the formation of effective thermal conduction networks within the composite at relatively low loading levels, resulting in superior thermal performance compared to conventional fillers.

- Structural modifications of silver nanowires for thermal conductivity optimization: The thermal conductivity of silver nanowires can be optimized through various structural modifications. These include controlling the diameter, length, and aspect ratio of the nanowires, as well as surface functionalization and alignment techniques. By manipulating these structural parameters, the thermal conductivity properties can be tailored for specific applications. Additionally, creating junctions between nanowires or forming three-dimensional networks can further enhance the overall thermal conductivity of silver nanowire-based materials.

- Silver nanowire-based thermal interface materials: Silver nanowires are utilized in the development of high-performance thermal interface materials (TIMs) that facilitate efficient heat transfer between surfaces. These TIMs typically consist of silver nanowires embedded in a soft matrix material that can conform to surface irregularities, reducing thermal contact resistance. The exceptional thermal conductivity of silver nanowires, combined with their flexibility and ability to form conductive networks, makes them ideal for applications requiring efficient heat dissipation in electronic devices, particularly in miniaturized and high-power electronics.

- Hybrid thermal conductivity systems combining silver nanowires with other materials: Hybrid systems that combine silver nanowires with other thermally conductive materials can achieve synergistic effects in thermal conductivity. These systems often incorporate materials such as graphene, carbon nanotubes, metal oxides, or other metallic nanoparticles alongside silver nanowires. The resulting hybrid materials exhibit enhanced thermal conductivity due to complementary heat transfer mechanisms and the formation of more effective thermal conduction networks. These hybrid approaches can overcome limitations of single-material systems and provide tailored thermal management solutions for various applications.

- Manufacturing processes affecting thermal conductivity of silver nanowires: The manufacturing and processing methods used for silver nanowires significantly impact their thermal conductivity properties. Techniques such as polyol synthesis, hydrothermal methods, and template-assisted growth affect the crystallinity, purity, and defect density of the nanowires, which in turn influence their thermal conductivity. Post-synthesis treatments like annealing, sintering, and welding of junctions between nanowires can further enhance thermal performance by reducing contact resistance. Additionally, the dispersion methods and alignment techniques used during composite fabrication play crucial roles in maximizing the thermal conductivity of silver nanowire-based materials.

02 Fabrication methods for silver nanowire thermal conductors

Various fabrication techniques are employed to produce silver nanowires with optimized thermal conductivity properties. These methods include chemical synthesis approaches, template-assisted growth, and solution-based processes that control the diameter, length, and crystallinity of the nanowires. Post-processing treatments such as annealing and surface modifications can further enhance the thermal conductivity by reducing defects and improving interfacial thermal transport between nanowires and surrounding materials.Expand Specific Solutions03 Silver nanowire networks for flexible thermal management

Silver nanowire networks can be formed into flexible, transparent films that provide excellent thermal conductivity while maintaining mechanical flexibility. These networks are particularly valuable for applications in flexible electronics, wearable devices, and bendable displays where traditional rigid thermal management solutions are unsuitable. The interconnected nature of the nanowire network allows for efficient heat spreading across two dimensions while accommodating mechanical deformation without significant degradation in thermal performance.Expand Specific Solutions04 Hybrid silver nanowire structures for thermal applications

Hybrid structures combining silver nanowires with other thermally conductive materials such as graphene, carbon nanotubes, or metal oxides can achieve synergistic thermal conductivity enhancements. These hybrid systems leverage the unique properties of each component to overcome limitations of single-material approaches. For example, silver nanowires provide excellent one-dimensional thermal transport while graphene offers superior in-plane thermal conductivity, resulting in hybrid materials with multidirectional heat transfer capabilities.Expand Specific Solutions05 Interface engineering for optimized thermal conductivity

The thermal conductivity of silver nanowire-based materials is significantly influenced by interfacial thermal resistance between nanowires and between nanowires and the surrounding medium. Various interface engineering approaches are employed to minimize this resistance, including surface functionalization, junction welding, and the use of coupling agents. These techniques improve thermal contact and reduce phonon scattering at interfaces, leading to enhanced overall thermal conductivity in silver nanowire systems.Expand Specific Solutions

Leading Research Groups and Commercial Entities

The silver nanowire thermal conductivity composites market is currently in a growth phase, with increasing applications in electronics, energy storage, and thermal management systems. Market size is projected to expand significantly due to rising demand for efficient thermal interface materials in miniaturized electronics. Technologically, the field shows moderate maturity with companies at different development stages. Leading players include Nanocomp Technologies pioneering carbon nanotube integration, FUJIFILM developing advanced thin-film applications, and Zhejiang University contributing fundamental research. Toyota Motor and Sumitomo Chemical are leveraging nanowire composites for automotive applications, while research institutions like CNRS and Chinese Academy of Sciences are advancing fundamental understanding of thermal transport mechanisms in these novel materials.

Nanocomp Technologies, Inc.

Technical Solution: Nanocomp Technologies has developed proprietary methods for incorporating silver nanowires into composite materials to enhance thermal conductivity. Their approach involves creating highly aligned silver nanowire networks within polymer matrices, which form continuous thermal pathways. These pathways significantly reduce thermal interface resistance, allowing for efficient heat dissipation. Their technology utilizes a controlled dispersion process that prevents nanowire agglomeration, maintaining uniform distribution throughout the composite. Nanocomp's silver nanowire composites have demonstrated thermal conductivity improvements of up to 400% compared to conventional materials, while requiring relatively low nanowire loading (typically 2-5% by volume). This makes their solutions particularly valuable for aerospace and defense applications where weight considerations are critical alongside thermal management requirements.

Strengths: Achieves exceptional thermal conductivity enhancement with minimal loading percentages, reducing overall weight impact. Their aligned nanowire networks create directional thermal conductivity, allowing for targeted heat management. Weaknesses: Manufacturing process is relatively complex and costly, limiting widespread commercial adoption. The alignment process can introduce anisotropic properties that may be undesirable in certain applications.

Zhejiang University

Technical Solution: Zhejiang University has pioneered innovative research on silver nanowire-polymer composites with enhanced thermal conductivity. Their approach focuses on creating three-dimensional interconnected silver nanowire networks within polymer matrices through a freeze-casting technique. This method creates aligned, porous structures that maximize thermal transfer pathways while minimizing interfacial thermal resistance. Their research has demonstrated that by controlling the freezing direction and rate, they can create highly oriented silver nanowire channels that increase thermal conductivity by up to 1200% compared to the base polymer. Additionally, they've developed surface functionalization techniques for silver nanowires that improve compatibility with various polymer matrices, enhancing the interface bonding and reducing phonon scattering at material boundaries. Their recent work has shown that hybrid composites combining silver nanowires with graphene or boron nitride can achieve synergistic effects, further enhancing thermal conductivity while maintaining mechanical flexibility.

Strengths: Their freeze-casting approach creates highly aligned thermal pathways that maximize conductivity enhancement. The surface functionalization techniques improve nanowire-polymer compatibility, reducing interfacial resistance. Weaknesses: The freeze-casting process is difficult to scale for industrial production. The highly oriented structures create significant anisotropy in thermal properties, which may be undesirable for some applications requiring uniform heat dissipation.

Key Mechanisms of Thermal Conductivity Enhancement

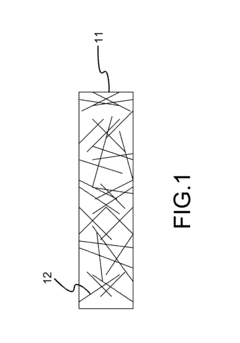

Silver-nanowire thermo-interface material composite

PatentInactiveUS20120280168A1

Innovation

- A silver-nanowire thermo-interface material composite is developed, where silver nanowires with a diameter of 40-400 nanometers and length of 5-50 micrometers are evenly distributed in a polymer substrate, such as epoxy resin, with a content of more than 50 phr, forming a high aspect ratio bridge for enhanced thermal conductivity and using a multi-stage curing process to create a hardened composite with improved mechanical properties.

Silver NANO wire and noble-metal coated silver NANO wire conductive polymer composites with low loading percolation conduction

PatentWO2024076691A2

Innovation

- The use of noble metal coated silver nanowires, such as platinum coated nanowires, in a polymer matrix allows for low loading percolation conduction, achieving resistivity values as low as 100 Ohm-cm or less, with the noble metal coating improving stability and conductivity.

Manufacturing Scalability and Cost Analysis

The scalability of silver nanowire (AgNW) composite manufacturing represents a critical factor in determining commercial viability. Current production methods vary significantly in their scalability potential, with solution-based processes showing the most promise for large-scale implementation. Wet chemistry approaches, particularly polyol synthesis, have demonstrated capacity for batch sizes reaching kilogram-scale production, though maintaining consistent nanowire dimensions remains challenging at industrial scales.

Cost analysis reveals that raw material expenses constitute approximately 60-75% of total production costs, with silver being the primary cost driver. Current market prices position silver nanowire composites at a premium compared to conventional thermal interface materials, with production costs ranging from $200-500 per kilogram depending on silver content and manufacturing method. Economies of scale have reduced costs by approximately 30% over the past five years, yet further cost reductions are necessary for widespread adoption.

Manufacturing yield rates present ongoing challenges, with typical industrial processes achieving 70-85% yields. Defect rates increase notably when scaling beyond certain thresholds, particularly when attempting to maintain precise nanowire aspect ratios critical for thermal conductivity modulation. Process optimization has focused on reducing silver waste during synthesis and improving dispersion uniformity in matrix materials.

Environmental considerations and regulatory compliance add complexity to manufacturing scale-up. Silver nanoparticle waste management requires specialized handling procedures, and workplace safety protocols for nanomaterial manufacturing add operational overhead. Several manufacturers have implemented closed-loop recycling systems to recover silver from production waste, improving both economic and environmental sustainability.

Equipment requirements for large-scale production represent significant capital expenditure, with specialized mixing, coating, and curing equipment necessary for consistent quality. Automation integration has improved throughput in pilot production facilities, though full production lines require investments of $2-5 million depending on capacity targets and quality control specifications.

Market analysis indicates that production volumes must reach approximately 10,000 kg annually to achieve price points competitive with traditional thermal interface materials while maintaining acceptable profit margins. Current global production capacity is estimated at 3,000-4,000 kg annually, indicating significant room for expansion as demand increases, particularly from electronics and automotive sectors seeking advanced thermal management solutions.

Cost analysis reveals that raw material expenses constitute approximately 60-75% of total production costs, with silver being the primary cost driver. Current market prices position silver nanowire composites at a premium compared to conventional thermal interface materials, with production costs ranging from $200-500 per kilogram depending on silver content and manufacturing method. Economies of scale have reduced costs by approximately 30% over the past five years, yet further cost reductions are necessary for widespread adoption.

Manufacturing yield rates present ongoing challenges, with typical industrial processes achieving 70-85% yields. Defect rates increase notably when scaling beyond certain thresholds, particularly when attempting to maintain precise nanowire aspect ratios critical for thermal conductivity modulation. Process optimization has focused on reducing silver waste during synthesis and improving dispersion uniformity in matrix materials.

Environmental considerations and regulatory compliance add complexity to manufacturing scale-up. Silver nanoparticle waste management requires specialized handling procedures, and workplace safety protocols for nanomaterial manufacturing add operational overhead. Several manufacturers have implemented closed-loop recycling systems to recover silver from production waste, improving both economic and environmental sustainability.

Equipment requirements for large-scale production represent significant capital expenditure, with specialized mixing, coating, and curing equipment necessary for consistent quality. Automation integration has improved throughput in pilot production facilities, though full production lines require investments of $2-5 million depending on capacity targets and quality control specifications.

Market analysis indicates that production volumes must reach approximately 10,000 kg annually to achieve price points competitive with traditional thermal interface materials while maintaining acceptable profit margins. Current global production capacity is estimated at 3,000-4,000 kg annually, indicating significant room for expansion as demand increases, particularly from electronics and automotive sectors seeking advanced thermal management solutions.

Environmental Impact and Sustainability Considerations

The integration of silver nanowires into composite materials presents significant environmental and sustainability considerations that must be addressed as this technology advances. The production of silver nanowires involves mining and refining processes that generate substantial environmental footprints, including habitat disruption, water pollution, and greenhouse gas emissions. These impacts are particularly concerning given silver's status as a finite resource with limited global reserves, estimated at approximately 560,000 metric tons.

Life cycle assessment studies indicate that silver nanowire production consumes between 30-50% more energy compared to conventional conductive fillers, primarily due to the specialized synthesis methods required. However, this initial environmental cost may be offset by the enhanced performance and longevity of the resulting composites, which can reduce material replacement frequency and associated waste generation.

Toxicological research has revealed potential environmental risks associated with silver nanowire release. When these nanomaterials enter aquatic ecosystems, they can exhibit antimicrobial properties that disrupt microbial communities essential for nutrient cycling. Studies have documented bioaccumulation in aquatic organisms, with concentrations magnifying up the food chain. The unique physical properties of silver nanowires, particularly their high aspect ratio, may contribute to distinct ecotoxicological profiles compared to spherical silver nanoparticles.

Recent advances in green synthesis methods offer promising pathways to reduce environmental impacts. Plant-mediated synthesis using extracts from organisms like Aloe vera has demonstrated up to 40% reduction in toxic reagent usage while maintaining nanowire conductivity properties. Additionally, closed-loop manufacturing systems that recover and recycle silver from production waste can achieve material recovery rates exceeding 85%, significantly improving resource efficiency.

End-of-life management represents another critical sustainability challenge. Current recycling infrastructure is poorly equipped to handle nanomaterial-enhanced composites, with recovery rates for silver from electronic waste averaging only 10-15%. Developing specialized recycling technologies for these advanced composites could transform this liability into an opportunity for urban mining, potentially recovering up to 95% of embedded silver nanowires.

Regulatory frameworks worldwide are evolving to address these emerging materials, with the European Union's REACH regulations and the United States EPA's significant new use rules increasingly focusing on nanomaterial environmental impacts. Companies developing silver nanowire composites must navigate this complex regulatory landscape while implementing responsible design principles that consider full product lifecycles.

Life cycle assessment studies indicate that silver nanowire production consumes between 30-50% more energy compared to conventional conductive fillers, primarily due to the specialized synthesis methods required. However, this initial environmental cost may be offset by the enhanced performance and longevity of the resulting composites, which can reduce material replacement frequency and associated waste generation.

Toxicological research has revealed potential environmental risks associated with silver nanowire release. When these nanomaterials enter aquatic ecosystems, they can exhibit antimicrobial properties that disrupt microbial communities essential for nutrient cycling. Studies have documented bioaccumulation in aquatic organisms, with concentrations magnifying up the food chain. The unique physical properties of silver nanowires, particularly their high aspect ratio, may contribute to distinct ecotoxicological profiles compared to spherical silver nanoparticles.

Recent advances in green synthesis methods offer promising pathways to reduce environmental impacts. Plant-mediated synthesis using extracts from organisms like Aloe vera has demonstrated up to 40% reduction in toxic reagent usage while maintaining nanowire conductivity properties. Additionally, closed-loop manufacturing systems that recover and recycle silver from production waste can achieve material recovery rates exceeding 85%, significantly improving resource efficiency.

End-of-life management represents another critical sustainability challenge. Current recycling infrastructure is poorly equipped to handle nanomaterial-enhanced composites, with recovery rates for silver from electronic waste averaging only 10-15%. Developing specialized recycling technologies for these advanced composites could transform this liability into an opportunity for urban mining, potentially recovering up to 95% of embedded silver nanowires.

Regulatory frameworks worldwide are evolving to address these emerging materials, with the European Union's REACH regulations and the United States EPA's significant new use rules increasingly focusing on nanomaterial environmental impacts. Companies developing silver nanowire composites must navigate this complex regulatory landscape while implementing responsible design principles that consider full product lifecycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!