Emerging Regulations and Standards for Silver Nanowire Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silver Nanowire Technology Background and Objectives

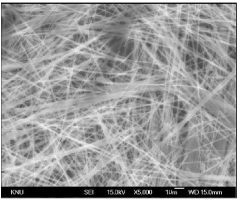

Silver nanowire (AgNW) technology has evolved significantly over the past two decades, emerging as a critical component in transparent conductive films and flexible electronics. Initially developed in the early 2000s as an alternative to indium tin oxide (ITO), silver nanowires have gained prominence due to their exceptional electrical conductivity, optical transparency, and mechanical flexibility. The historical trajectory shows a transition from laboratory curiosity to commercial viability, with major breakthroughs occurring around 2010-2012 when scalable synthesis methods were established.

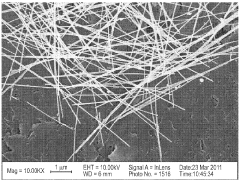

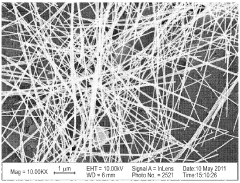

The technological evolution of silver nanowires has been characterized by continuous improvements in synthesis techniques, from polyol processes to more sophisticated methods that allow precise control over nanowire dimensions and properties. This evolution has enabled the production of nanowires with aspect ratios exceeding 1000, diameters below 30 nm, and lengths up to several hundred micrometers, significantly enhancing their performance in various applications.

Current technological trends indicate a growing focus on enhancing the stability of silver nanowires against environmental factors, improving their integration with various substrates, and developing hybrid materials that combine silver nanowires with other nanomaterials to achieve superior performance characteristics. Additionally, there is increasing attention to environmentally friendly synthesis methods and reducing the silver content while maintaining performance, driven by sustainability concerns and silver's relative scarcity.

The primary objective of silver nanowire technology development is to establish comprehensive regulatory frameworks and standards that ensure safe and sustainable implementation across industries. This includes developing standardized testing protocols for evaluating nanowire performance, safety assessments for human health and environmental impacts, and clear guidelines for manufacturing processes that minimize potential risks.

Another critical goal is to bridge the gap between laboratory research and industrial application by addressing scalability challenges, cost-effectiveness, and long-term reliability. This requires collaborative efforts between academic institutions, industry stakeholders, and regulatory bodies to establish consensus on best practices and standards.

Looking forward, the technology aims to enable next-generation flexible electronics, transparent heaters, touch panels, and photovoltaic devices with enhanced performance and reduced environmental footprint. The ultimate objective is to position silver nanowire technology as a sustainable, safe, and economically viable solution that can meet the growing demand for advanced electronic materials while adhering to increasingly stringent regulatory requirements worldwide.

The technological evolution of silver nanowires has been characterized by continuous improvements in synthesis techniques, from polyol processes to more sophisticated methods that allow precise control over nanowire dimensions and properties. This evolution has enabled the production of nanowires with aspect ratios exceeding 1000, diameters below 30 nm, and lengths up to several hundred micrometers, significantly enhancing their performance in various applications.

Current technological trends indicate a growing focus on enhancing the stability of silver nanowires against environmental factors, improving their integration with various substrates, and developing hybrid materials that combine silver nanowires with other nanomaterials to achieve superior performance characteristics. Additionally, there is increasing attention to environmentally friendly synthesis methods and reducing the silver content while maintaining performance, driven by sustainability concerns and silver's relative scarcity.

The primary objective of silver nanowire technology development is to establish comprehensive regulatory frameworks and standards that ensure safe and sustainable implementation across industries. This includes developing standardized testing protocols for evaluating nanowire performance, safety assessments for human health and environmental impacts, and clear guidelines for manufacturing processes that minimize potential risks.

Another critical goal is to bridge the gap between laboratory research and industrial application by addressing scalability challenges, cost-effectiveness, and long-term reliability. This requires collaborative efforts between academic institutions, industry stakeholders, and regulatory bodies to establish consensus on best practices and standards.

Looking forward, the technology aims to enable next-generation flexible electronics, transparent heaters, touch panels, and photovoltaic devices with enhanced performance and reduced environmental footprint. The ultimate objective is to position silver nanowire technology as a sustainable, safe, and economically viable solution that can meet the growing demand for advanced electronic materials while adhering to increasingly stringent regulatory requirements worldwide.

Market Demand Analysis for Silver Nanowire Applications

The silver nanowire (AgNW) market has experienced significant growth in recent years, driven primarily by the expanding touchscreen display industry. With the proliferation of smartphones, tablets, and other touch-enabled devices, the demand for transparent conductive materials has surged, positioning AgNWs as a compelling alternative to the traditional indium tin oxide (ITO). Market research indicates that the global silver nanowire market was valued at approximately $290 million in 2022 and is projected to grow at a compound annual growth rate of 16.8% through 2030.

The automotive sector represents another substantial market for AgNW applications, particularly in smart windows, heated windshields, and dashboard displays. As vehicle manufacturers increasingly incorporate advanced electronics and autonomous driving features, the demand for high-performance transparent conductors continues to rise. Industry analysts project that automotive applications could account for nearly 20% of the total AgNW market by 2025.

Flexible electronics constitute a rapidly expanding application area for silver nanowires. The unique combination of electrical conductivity and mechanical flexibility makes AgNWs ideal for wearable devices, flexible displays, and bendable sensors. Consumer electronics manufacturers are actively exploring AgNW integration to develop next-generation foldable smartphones and wearable health monitoring devices, creating a projected market segment worth over $150 million by 2027.

The photovoltaic industry has also demonstrated growing interest in silver nanowire technology. As solar energy adoption accelerates globally, manufacturers seek more efficient and cost-effective materials for solar cell production. AgNWs offer potential improvements in energy conversion efficiency while potentially reducing manufacturing costs compared to traditional silver paste electrodes. Market forecasts suggest the solar application segment could grow at 22% annually over the next five years.

Healthcare applications represent an emerging but promising market for AgNWs. Their antimicrobial properties make them suitable for medical devices, wound dressings, and hospital equipment. The COVID-19 pandemic has further accelerated interest in antimicrobial surfaces, creating additional market opportunities. The healthcare segment is expected to reach $85 million by 2026.

Regional analysis reveals that Asia-Pacific dominates the AgNW market, accounting for approximately 45% of global demand, followed by North America and Europe. This distribution aligns with the concentration of electronics manufacturing facilities in countries like China, South Korea, and Taiwan. However, as applications diversify beyond electronics, market distribution is expected to become more balanced across regions.

The automotive sector represents another substantial market for AgNW applications, particularly in smart windows, heated windshields, and dashboard displays. As vehicle manufacturers increasingly incorporate advanced electronics and autonomous driving features, the demand for high-performance transparent conductors continues to rise. Industry analysts project that automotive applications could account for nearly 20% of the total AgNW market by 2025.

Flexible electronics constitute a rapidly expanding application area for silver nanowires. The unique combination of electrical conductivity and mechanical flexibility makes AgNWs ideal for wearable devices, flexible displays, and bendable sensors. Consumer electronics manufacturers are actively exploring AgNW integration to develop next-generation foldable smartphones and wearable health monitoring devices, creating a projected market segment worth over $150 million by 2027.

The photovoltaic industry has also demonstrated growing interest in silver nanowire technology. As solar energy adoption accelerates globally, manufacturers seek more efficient and cost-effective materials for solar cell production. AgNWs offer potential improvements in energy conversion efficiency while potentially reducing manufacturing costs compared to traditional silver paste electrodes. Market forecasts suggest the solar application segment could grow at 22% annually over the next five years.

Healthcare applications represent an emerging but promising market for AgNWs. Their antimicrobial properties make them suitable for medical devices, wound dressings, and hospital equipment. The COVID-19 pandemic has further accelerated interest in antimicrobial surfaces, creating additional market opportunities. The healthcare segment is expected to reach $85 million by 2026.

Regional analysis reveals that Asia-Pacific dominates the AgNW market, accounting for approximately 45% of global demand, followed by North America and Europe. This distribution aligns with the concentration of electronics manufacturing facilities in countries like China, South Korea, and Taiwan. However, as applications diversify beyond electronics, market distribution is expected to become more balanced across regions.

Current Regulatory Landscape and Technical Challenges

The regulatory landscape for silver nanowire (AgNW) technology is currently fragmented across different regions, with no unified global framework specifically addressing nanomaterials. In the United States, the FDA regulates nanomaterials under existing frameworks, while the EPA has implemented specific reporting requirements under the Toxic Substances Control Act (TSCA) for nanoscale materials. The EU has adopted a more precautionary approach through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, requiring manufacturers to register nanomaterials and provide safety data.

Japan and South Korea have established voluntary reporting schemes, while China has recently begun developing nanomaterial-specific regulations under its chemical management framework. This regulatory divergence creates significant compliance challenges for companies operating globally in the AgNW market.

Technical challenges in meeting these emerging regulations are substantial. Firstly, there is a lack of standardized measurement and characterization methods for silver nanowires, making it difficult to consistently assess their properties across different laboratories and regulatory jurisdictions. The ISO Technical Committee 229 and ASTM International are working to develop these standards, but progress has been slow due to the complex nature of nanomaterials.

Secondly, toxicity assessment protocols for nanomaterials remain inadequate. Traditional toxicological testing methods may not accurately capture the unique properties and behaviors of silver nanowires, particularly their potential for bioaccumulation and long-term environmental impacts. This creates uncertainty in safety evaluations required by regulatory bodies.

Thirdly, lifecycle assessment challenges persist. Silver nanowires may undergo transformations during product use and disposal, potentially altering their toxicological profiles. Current regulations increasingly demand lifecycle considerations, but methodologies for tracking nanomaterials throughout their lifecycle remain underdeveloped.

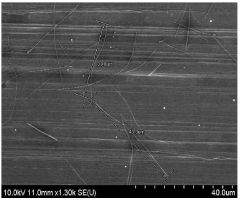

Manufacturing consistency presents another significant challenge. Producing silver nanowires with consistent dimensions, purity, and surface properties at industrial scale is technically demanding. Yet, emerging regulations increasingly require batch-to-batch consistency and detailed characterization data.

Lastly, the industry faces substantial data gaps regarding long-term environmental and health impacts of silver nanowires. Regulatory bodies are increasingly requesting comprehensive safety data, but generating this information requires significant investment in research and testing infrastructure.

These technical challenges are compounded by the rapid pace of innovation in silver nanowire applications, which often outpaces regulatory developments. Companies must navigate this complex landscape while maintaining competitiveness, creating a delicate balance between innovation and compliance.

Japan and South Korea have established voluntary reporting schemes, while China has recently begun developing nanomaterial-specific regulations under its chemical management framework. This regulatory divergence creates significant compliance challenges for companies operating globally in the AgNW market.

Technical challenges in meeting these emerging regulations are substantial. Firstly, there is a lack of standardized measurement and characterization methods for silver nanowires, making it difficult to consistently assess their properties across different laboratories and regulatory jurisdictions. The ISO Technical Committee 229 and ASTM International are working to develop these standards, but progress has been slow due to the complex nature of nanomaterials.

Secondly, toxicity assessment protocols for nanomaterials remain inadequate. Traditional toxicological testing methods may not accurately capture the unique properties and behaviors of silver nanowires, particularly their potential for bioaccumulation and long-term environmental impacts. This creates uncertainty in safety evaluations required by regulatory bodies.

Thirdly, lifecycle assessment challenges persist. Silver nanowires may undergo transformations during product use and disposal, potentially altering their toxicological profiles. Current regulations increasingly demand lifecycle considerations, but methodologies for tracking nanomaterials throughout their lifecycle remain underdeveloped.

Manufacturing consistency presents another significant challenge. Producing silver nanowires with consistent dimensions, purity, and surface properties at industrial scale is technically demanding. Yet, emerging regulations increasingly require batch-to-batch consistency and detailed characterization data.

Lastly, the industry faces substantial data gaps regarding long-term environmental and health impacts of silver nanowires. Regulatory bodies are increasingly requesting comprehensive safety data, but generating this information requires significant investment in research and testing infrastructure.

These technical challenges are compounded by the rapid pace of innovation in silver nanowire applications, which often outpaces regulatory developments. Companies must navigate this complex landscape while maintaining competitiveness, creating a delicate balance between innovation and compliance.

Current Compliance Solutions and Approaches

01 Synthesis methods for silver nanowires

Various methods can be employed to synthesize silver nanowires, including polyol processes, template-directed synthesis, and solution-based approaches. These methods control the growth direction and aspect ratio of the nanowires, resulting in different morphologies and properties. Parameters such as temperature, reaction time, and precursor concentration significantly influence the quality and dimensions of the produced silver nanowires.- Synthesis methods for silver nanowires: Various methods can be employed to synthesize silver nanowires, including polyol processes, template-directed synthesis, and electrochemical deposition. These methods control the growth direction and aspect ratio of the nanowires, resulting in different morphologies and properties. Parameters such as temperature, reaction time, and precursor concentration significantly influence the quality and dimensions of the produced silver nanowires.

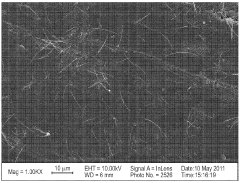

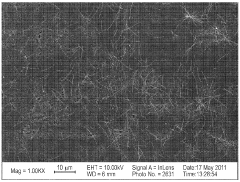

- Transparent conductive films using silver nanowires: Silver nanowires are widely used in the fabrication of transparent conductive films as alternatives to indium tin oxide (ITO). These films combine high electrical conductivity with optical transparency, making them suitable for touch screens, displays, and photovoltaic devices. The performance of these films can be enhanced through post-treatment processes such as annealing, pressing, or coating with other materials to improve junction resistance between nanowires.

- Surface modification and functionalization of silver nanowires: Surface modification techniques can enhance the properties and stability of silver nanowires. These include coating with protective layers such as metal oxides, polymers, or carbon materials to prevent oxidation and aggregation. Functionalization with specific chemical groups enables better dispersion in various matrices and improved compatibility with other materials, expanding their application range in composites and devices.

- Silver nanowire-based flexible and stretchable electronics: Silver nanowires are key components in flexible and stretchable electronic devices due to their ability to maintain conductivity under mechanical deformation. These nanowires can be embedded in elastomeric substrates or combined with other nanomaterials to create conductive networks that withstand bending, stretching, and folding. Applications include wearable sensors, flexible displays, and stretchable circuits for next-generation electronics.

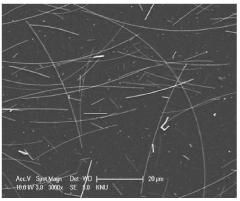

- Purification and processing techniques for silver nanowires: Various purification and processing techniques are employed to obtain high-quality silver nanowires suitable for industrial applications. These include filtration, centrifugation, and selective precipitation methods to remove byproducts and impurities. Advanced processing techniques such as spray coating, roll-to-roll processing, and inkjet printing enable the integration of silver nanowires into large-scale manufacturing processes for commercial devices.

02 Silver nanowire-based transparent conductive films

Silver nanowires can be used to create highly transparent and conductive films for applications in touch screens, displays, and photovoltaic devices. These films offer advantages over traditional indium tin oxide (ITO) including flexibility, lower cost, and comparable or superior conductivity. Various deposition techniques such as spray coating, roll-to-roll processing, and printing methods can be used to fabricate these transparent conductive films with controlled density and uniformity.Expand Specific Solutions03 Surface modification and functionalization of silver nanowires

Surface modification techniques can enhance the properties and stability of silver nanowires. These include coating with protective layers such as metal oxides, polymers, or carbon materials to prevent oxidation and aggregation. Functionalization with specific chemical groups can improve compatibility with various matrices and enable targeted applications. These modifications can significantly extend the lifetime of silver nanowire-based devices and improve their performance in harsh environments.Expand Specific Solutions04 Silver nanowire composites and hybrid materials

Silver nanowires can be incorporated into various matrices to form composite or hybrid materials with enhanced properties. These include polymer composites for flexible electronics, ceramic composites for thermal management, and hybrid structures with other nanomaterials like graphene or carbon nanotubes. The resulting materials often exhibit synergistic effects, combining the high conductivity of silver nanowires with the mechanical, thermal, or optical properties of the host material.Expand Specific Solutions05 Purification and quality control of silver nanowires

Various techniques are employed for the purification and quality control of silver nanowires, including centrifugation, filtration, and selective precipitation. These processes remove byproducts, unreacted precursors, and nanowires with undesired dimensions. Advanced characterization methods such as electron microscopy, spectroscopy, and electrical measurements are used to assess the quality, dimensions, and performance of the purified nanowires, ensuring consistency in large-scale production.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The silver nanowire market is currently in a growth phase, with emerging regulations and standards playing a crucial role in shaping its trajectory. The global market size is expanding rapidly, driven by applications in touchscreens, flexible electronics, and photovoltaics. Technical maturity varies across applications, with companies like C3 Nano and Carestream Health leading in transparent conductor films, while Shenzhen Huake Chuangzhi and Ningbo Xinzhida focus on touchscreen applications. Research institutions such as Cornell University and Fudan University are advancing fundamental science, while established corporations like BASF and Umicore are developing standardized manufacturing processes. The regulatory landscape is evolving to address nanomaterial safety, with environmental and health standards becoming increasingly stringent as commercial applications proliferate.

Zhejiang KECHUANG Advanced MATERIALS Technology Co., Ltd.

Technical Solution: Zhejiang KECHUANG has developed a comprehensive regulatory compliance framework for their silver nanowire products, focusing on environmental safety and workplace standards. Their approach includes implementing ISO 14001 environmental management systems specifically adapted for nanomaterial production. The company has pioneered a closed-loop manufacturing process that minimizes silver nanowire release into the environment, addressing concerns raised by the EU's REACH regulation and similar Asian regulatory frameworks. Their technical solution incorporates real-time monitoring systems for workplace exposure assessment, maintaining levels below 0.1 mg/m³ as recommended by emerging occupational safety guidelines. Additionally, they've developed standardized testing protocols for evaluating the environmental fate of their nanowires in accordance with OECD guidelines for nanomaterial testing, allowing for consistent regulatory reporting across different markets.

Strengths: Their closed-loop manufacturing system effectively addresses environmental release concerns while maintaining production efficiency. The integrated monitoring system provides real-time compliance data for multiple regulatory frameworks. Weaknesses: Their approach requires significant capital investment for smaller manufacturers to implement, and their testing protocols may need frequent updates as regulations continue to evolve rapidly across different regions.

C3 Nano, Inc.

Technical Solution: C3 Nano has developed a proprietary regulatory compliance platform specifically for their silver nanowire transparent conductive films. Their technical approach focuses on addressing the emerging regulations through material modification rather than process adaptation. They've engineered their silver nanowires with proprietary surface coatings that significantly reduce ion leaching, addressing concerns raised by the EU's biocidal products regulations and similar frameworks in North America. Their ActiveGrid™ technology incorporates these modified nanowires in a way that encapsulates them within the film matrix, reducing potential exposure during product lifecycle. C3 Nano has also established a comprehensive product stewardship program that includes detailed safety data sheets specifically designed to meet the varying disclosure requirements across different jurisdictions, including the more stringent European and Canadian nanomaterial registry requirements. Their technical documentation system automatically generates region-specific compliance documentation, addressing the fragmented regulatory landscape for nanomaterials.

Strengths: Their material modification approach provides inherent safety advantages without compromising electrical performance, and their automated compliance documentation system efficiently manages the complex global regulatory landscape. Weaknesses: The proprietary surface treatments may increase production costs compared to standard silver nanowires, and their approach is primarily focused on electronics applications rather than broader silver nanowire uses in other sectors.

Critical Patents and Technical Literature Review

Mass Production Method of Ag NanoWire

PatentActiveKR1020120010199A

Innovation

- A method involving a precursor solution with a specific metal catalyst having a standard reduction potential of -0.1 to -0.9 V, controlled stirring conditions, and use of a thickener to produce silver nanowires with a high aspect ratio and uniform diameter, preventing the formation of unwanted shapes like nanoparticles and nanorods.

Nanowire preparation methods, compositions, and articles

PatentWO2012177314A1

Innovation

- The method involves reducing a reducible metal ion, such as a silver ion, in the presence of bromide and chloride ions, along with different alkali metal ions like sodium or potassium, to produce silver nanowires with specific dimensions and aspect ratios suitable for various applications.

Environmental and Health Impact Assessment

Silver nanowires (AgNWs) present unique environmental and health considerations that necessitate comprehensive assessment frameworks. Current research indicates that AgNWs can be released into aquatic environments through manufacturing processes, product usage, and disposal, potentially affecting aquatic organisms through various toxicity mechanisms. Studies have documented bioaccumulation in fish and invertebrates, with size-dependent toxicity profiles showing smaller nanowires generally exhibiting higher toxicity due to increased cellular penetration capabilities.

In terrestrial ecosystems, AgNWs may alter soil microbial communities and enzyme activities, with evidence suggesting impacts on nitrogen cycling bacteria and potential biomagnification through food chains. The persistence of these nanomaterials varies significantly based on environmental conditions, with transformation processes including sulfidation, oxidation, and aggregation affecting their bioavailability and toxicity profiles over time.

Human health implications primarily center around respiratory, dermal, and ingestion exposure pathways. Inhalation studies have demonstrated that AgNWs can cause pulmonary inflammation, with length-dependent effects similar to those observed with asbestos fibers. Longer nanowires (>10 μm) show greater biopersistence in lung tissue, raising concerns about potential long-term effects. Dermal penetration appears limited in healthy skin but may increase with compromised skin barriers.

Emerging evidence suggests potential neurotoxicity and immunomodulatory effects following systemic exposure, though the clinical significance remains under investigation. Particularly concerning is the ability of certain AgNWs to cross biological barriers, including the blood-brain barrier and placental barrier, warranting careful consideration in risk assessments.

Current regulatory approaches vary globally, with the EU's REACH regulation and the US EPA's significant new use rules (SNURs) beginning to address nanomaterial-specific concerns. However, standardized testing protocols specifically designed for AgNWs remain underdeveloped, creating challenges for consistent risk assessment.

Life cycle assessment (LCA) studies indicate that environmental impacts vary significantly across different AgNW applications and manufacturing methods. The environmental footprint appears heavily influenced by synthesis methods, with green chemistry approaches showing promise for reducing overall impact. End-of-life management presents particular challenges, as conventional recycling systems are not optimized for nanomaterial recovery.

Knowledge gaps persist regarding long-term environmental fate, chronic exposure effects, and potential synergistic interactions with other environmental contaminants. These gaps highlight the need for standardized testing methodologies and more comprehensive monitoring programs to fully characterize the environmental and health implications of increasing AgNW deployment across multiple industries.

In terrestrial ecosystems, AgNWs may alter soil microbial communities and enzyme activities, with evidence suggesting impacts on nitrogen cycling bacteria and potential biomagnification through food chains. The persistence of these nanomaterials varies significantly based on environmental conditions, with transformation processes including sulfidation, oxidation, and aggregation affecting their bioavailability and toxicity profiles over time.

Human health implications primarily center around respiratory, dermal, and ingestion exposure pathways. Inhalation studies have demonstrated that AgNWs can cause pulmonary inflammation, with length-dependent effects similar to those observed with asbestos fibers. Longer nanowires (>10 μm) show greater biopersistence in lung tissue, raising concerns about potential long-term effects. Dermal penetration appears limited in healthy skin but may increase with compromised skin barriers.

Emerging evidence suggests potential neurotoxicity and immunomodulatory effects following systemic exposure, though the clinical significance remains under investigation. Particularly concerning is the ability of certain AgNWs to cross biological barriers, including the blood-brain barrier and placental barrier, warranting careful consideration in risk assessments.

Current regulatory approaches vary globally, with the EU's REACH regulation and the US EPA's significant new use rules (SNURs) beginning to address nanomaterial-specific concerns. However, standardized testing protocols specifically designed for AgNWs remain underdeveloped, creating challenges for consistent risk assessment.

Life cycle assessment (LCA) studies indicate that environmental impacts vary significantly across different AgNW applications and manufacturing methods. The environmental footprint appears heavily influenced by synthesis methods, with green chemistry approaches showing promise for reducing overall impact. End-of-life management presents particular challenges, as conventional recycling systems are not optimized for nanomaterial recovery.

Knowledge gaps persist regarding long-term environmental fate, chronic exposure effects, and potential synergistic interactions with other environmental contaminants. These gaps highlight the need for standardized testing methodologies and more comprehensive monitoring programs to fully characterize the environmental and health implications of increasing AgNW deployment across multiple industries.

International Standards Harmonization Strategies

The harmonization of international standards for silver nanowire applications represents a critical challenge in the global regulatory landscape. Currently, significant disparities exist between standards established by organizations such as ISO, IEC, ASTM International, and regional bodies like the European Committee for Standardization (CEN). These inconsistencies create substantial barriers for manufacturers and researchers working with silver nanowire technologies across multiple markets.

A comprehensive harmonization strategy requires multilateral engagement between standards development organizations (SDOs) through formal liaison relationships. The International Nanotechnology Standardization Roadmap provides a framework for coordinating these efforts, particularly focusing on measurement protocols, characterization methods, and safety assessment procedures specific to silver nanowires.

Technical committees from various jurisdictions have begun collaborative initiatives to develop unified testing methodologies. For example, the ISO/TC 229 (Nanotechnologies) and IEC/TC 113 (Nanotechnology for electrotechnical products) joint working groups are addressing the electrical, optical, and mechanical characterization of silver nanowires, with particular emphasis on transparency, conductivity, and flexibility parameters.

Mutual recognition agreements (MRAs) between regulatory bodies represent another crucial harmonization mechanism. These agreements enable test results and certifications from one jurisdiction to be accepted in another, significantly reducing redundant testing requirements and market entry barriers. The Asia-Pacific Economic Cooperation (APEC) has pioneered such arrangements for nanomaterials, which could serve as a model for silver nanowire applications.

Gap analysis studies conducted by international consortia have identified priority areas requiring immediate harmonization, including particle size distribution measurement, surface chemistry characterization, and environmental fate assessment methodologies. These technical aspects directly impact product performance claims and safety evaluations across different regulatory frameworks.

Industry participation in pre-standardization research is proving essential for developing scientifically sound and practically implementable harmonized standards. Public-private partnerships like the EU-US Nano Environmental and Health Safety Research Cooperation are generating reference materials and validated protocols that form the foundation for internationally accepted standards specific to silver nanowires.

Digital tools for standards interoperability are emerging as innovative solutions to harmonization challenges. Machine-readable standards formats and cross-referencing databases enable stakeholders to navigate complex regulatory landscapes more efficiently. The International Standards Information System (ISIS) initiative specifically targets nanomaterials regulations, including those applicable to silver nanowires, facilitating global compliance through improved information accessibility and interpretation.

A comprehensive harmonization strategy requires multilateral engagement between standards development organizations (SDOs) through formal liaison relationships. The International Nanotechnology Standardization Roadmap provides a framework for coordinating these efforts, particularly focusing on measurement protocols, characterization methods, and safety assessment procedures specific to silver nanowires.

Technical committees from various jurisdictions have begun collaborative initiatives to develop unified testing methodologies. For example, the ISO/TC 229 (Nanotechnologies) and IEC/TC 113 (Nanotechnology for electrotechnical products) joint working groups are addressing the electrical, optical, and mechanical characterization of silver nanowires, with particular emphasis on transparency, conductivity, and flexibility parameters.

Mutual recognition agreements (MRAs) between regulatory bodies represent another crucial harmonization mechanism. These agreements enable test results and certifications from one jurisdiction to be accepted in another, significantly reducing redundant testing requirements and market entry barriers. The Asia-Pacific Economic Cooperation (APEC) has pioneered such arrangements for nanomaterials, which could serve as a model for silver nanowire applications.

Gap analysis studies conducted by international consortia have identified priority areas requiring immediate harmonization, including particle size distribution measurement, surface chemistry characterization, and environmental fate assessment methodologies. These technical aspects directly impact product performance claims and safety evaluations across different regulatory frameworks.

Industry participation in pre-standardization research is proving essential for developing scientifically sound and practically implementable harmonized standards. Public-private partnerships like the EU-US Nano Environmental and Health Safety Research Cooperation are generating reference materials and validated protocols that form the foundation for internationally accepted standards specific to silver nanowires.

Digital tools for standards interoperability are emerging as innovative solutions to harmonization challenges. Machine-readable standards formats and cross-referencing databases enable stakeholders to navigate complex regulatory landscapes more efficiently. The International Standards Information System (ISIS) initiative specifically targets nanomaterials regulations, including those applicable to silver nanowires, facilitating global compliance through improved information accessibility and interpretation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!