Analysis of Micro Energy Harvester Integration in Minimalist Product Designs

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from laboratory curiosities to commercially viable solutions for powering small electronic devices. The field originated in the early 2000s with rudimentary piezoelectric and thermoelectric generators, but has since expanded to encompass a diverse array of energy harvesting mechanisms including photovoltaic, electromagnetic, triboelectric, and radio frequency harvesting technologies. This technological progression has been driven by the concurrent miniaturization of electronic components and the growing demand for autonomous, maintenance-free devices in various sectors.

The evolution of micro energy harvesting technology has been characterized by significant improvements in energy conversion efficiency, reduction in form factors, and enhanced durability. Early harvesters typically generated power in the microwatt range, whereas contemporary solutions can achieve milliwatt outputs while maintaining minimal dimensions. This progression has been facilitated by advancements in materials science, particularly the development of novel piezoelectric materials, flexible substrates, and high-efficiency photovoltaic cells specifically designed for indoor and low-light applications.

Market trends indicate a growing integration of these technologies in consumer electronics, healthcare devices, industrial sensors, and Internet of Things (IoT) applications. The proliferation of wireless sensor networks and the push toward edge computing have further accelerated interest in self-powered systems that can operate indefinitely without battery replacement. This trend aligns with broader sustainability initiatives and the need to reduce electronic waste associated with disposable batteries.

The primary objective of micro energy harvester integration in minimalist product designs is to achieve energy autonomy while maintaining aesthetic and functional integrity. This involves developing harvesting solutions that can be seamlessly incorporated into slim, elegant product architectures without compromising user experience or visual appeal. Secondary objectives include extending device operational lifetimes, reducing maintenance requirements, and decreasing the environmental footprint of electronic products.

Technical goals for this field include achieving energy density improvements of at least 30% over current commercial solutions, developing multi-modal harvesting systems that can simultaneously capture energy from different environmental sources, and creating adaptive harvesting circuits that can optimize energy capture under varying conditions. Additionally, there is a focus on developing manufacturing techniques that allow for cost-effective mass production of these technologies, potentially through roll-to-roll processing or advanced printing methods.

The convergence of micro energy harvesting with minimalist design principles represents a significant opportunity to redefine product development paradigms across multiple industries. By enabling self-powered operation in elegantly designed products, this technology has the potential to eliminate charging ports, reduce device thickness, and create truly maintenance-free user experiences that align with contemporary design sensibilities.

The evolution of micro energy harvesting technology has been characterized by significant improvements in energy conversion efficiency, reduction in form factors, and enhanced durability. Early harvesters typically generated power in the microwatt range, whereas contemporary solutions can achieve milliwatt outputs while maintaining minimal dimensions. This progression has been facilitated by advancements in materials science, particularly the development of novel piezoelectric materials, flexible substrates, and high-efficiency photovoltaic cells specifically designed for indoor and low-light applications.

Market trends indicate a growing integration of these technologies in consumer electronics, healthcare devices, industrial sensors, and Internet of Things (IoT) applications. The proliferation of wireless sensor networks and the push toward edge computing have further accelerated interest in self-powered systems that can operate indefinitely without battery replacement. This trend aligns with broader sustainability initiatives and the need to reduce electronic waste associated with disposable batteries.

The primary objective of micro energy harvester integration in minimalist product designs is to achieve energy autonomy while maintaining aesthetic and functional integrity. This involves developing harvesting solutions that can be seamlessly incorporated into slim, elegant product architectures without compromising user experience or visual appeal. Secondary objectives include extending device operational lifetimes, reducing maintenance requirements, and decreasing the environmental footprint of electronic products.

Technical goals for this field include achieving energy density improvements of at least 30% over current commercial solutions, developing multi-modal harvesting systems that can simultaneously capture energy from different environmental sources, and creating adaptive harvesting circuits that can optimize energy capture under varying conditions. Additionally, there is a focus on developing manufacturing techniques that allow for cost-effective mass production of these technologies, potentially through roll-to-roll processing or advanced printing methods.

The convergence of micro energy harvesting with minimalist design principles represents a significant opportunity to redefine product development paradigms across multiple industries. By enabling self-powered operation in elegantly designed products, this technology has the potential to eliminate charging ports, reduce device thickness, and create truly maintenance-free user experiences that align with contemporary design sensibilities.

Market Analysis for Energy Self-sufficient Products

The energy self-sufficient product market has experienced significant growth in recent years, driven by increasing consumer awareness of sustainability and the rapid advancement of micro energy harvesting technologies. The global market for energy harvesting systems was valued at approximately $440 million in 2021 and is projected to reach $1.3 billion by 2028, growing at a CAGR of 13.2% during the forecast period. This growth trajectory reflects the expanding applications of micro energy harvesters across various product categories.

Consumer electronics represents the largest market segment, with wearable devices leading the adoption of energy self-sufficient solutions. The smartwatch market alone grew by 24% in 2021, with energy-autonomous features becoming a key differentiator for premium products. Fitness trackers, hearables, and smart clothing are emerging as promising applications, with consumers showing willingness to pay a 15-20% premium for devices that require less frequent charging or no charging at all.

The Internet of Things (IoT) sector presents another substantial market opportunity. With an estimated 75 billion IoT devices expected to be deployed by 2025, the need for maintenance-free power solutions is critical. Energy self-sufficient sensors for smart homes, industrial monitoring, and agricultural applications are gaining traction, with market penetration increasing by 35% annually in these segments.

Geographic market distribution shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 16.8% annually, driven by rapid industrialization and smart city initiatives in China, South Korea, and Singapore.

Consumer behavior analysis indicates shifting preferences toward sustainable products, with 67% of global consumers considering environmental impact when making purchasing decisions. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate higher willingness to adopt energy self-sufficient products despite potential price premiums.

Market challenges include price sensitivity, with current cost structures limiting mass-market adoption. The average price premium for energy self-sufficient products remains at 25-30% compared to conventional alternatives, creating a significant barrier for mainstream market penetration. Additionally, consumer education remains a challenge, as 58% of potential users report limited understanding of energy harvesting technologies and their benefits.

Future market growth will likely be driven by technological advancements reducing production costs, increasing energy conversion efficiencies, and expanding application scenarios. Emerging markets for energy self-sufficient products include medical wearables, smart packaging, and autonomous environmental monitoring systems, each projected to grow at CAGRs exceeding 20% through 2028.

Consumer electronics represents the largest market segment, with wearable devices leading the adoption of energy self-sufficient solutions. The smartwatch market alone grew by 24% in 2021, with energy-autonomous features becoming a key differentiator for premium products. Fitness trackers, hearables, and smart clothing are emerging as promising applications, with consumers showing willingness to pay a 15-20% premium for devices that require less frequent charging or no charging at all.

The Internet of Things (IoT) sector presents another substantial market opportunity. With an estimated 75 billion IoT devices expected to be deployed by 2025, the need for maintenance-free power solutions is critical. Energy self-sufficient sensors for smart homes, industrial monitoring, and agricultural applications are gaining traction, with market penetration increasing by 35% annually in these segments.

Geographic market distribution shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 16.8% annually, driven by rapid industrialization and smart city initiatives in China, South Korea, and Singapore.

Consumer behavior analysis indicates shifting preferences toward sustainable products, with 67% of global consumers considering environmental impact when making purchasing decisions. This trend is particularly pronounced among millennials and Gen Z consumers, who demonstrate higher willingness to adopt energy self-sufficient products despite potential price premiums.

Market challenges include price sensitivity, with current cost structures limiting mass-market adoption. The average price premium for energy self-sufficient products remains at 25-30% compared to conventional alternatives, creating a significant barrier for mainstream market penetration. Additionally, consumer education remains a challenge, as 58% of potential users report limited understanding of energy harvesting technologies and their benefits.

Future market growth will likely be driven by technological advancements reducing production costs, increasing energy conversion efficiencies, and expanding application scenarios. Emerging markets for energy self-sufficient products include medical wearables, smart packaging, and autonomous environmental monitoring systems, each projected to grow at CAGRs exceeding 20% through 2028.

Technical Challenges in Miniaturized Energy Harvesting

The miniaturization of energy harvesting technologies presents significant technical challenges that must be overcome for successful integration into minimalist product designs. Current micro energy harvesters face fundamental physical limitations related to their size-to-power output ratio. As dimensions decrease, the available energy capture area or volume reduces proportionally, directly impacting harvesting efficiency. This creates a fundamental tension between the aesthetic and functional requirements of minimalist design and the physical space needed for effective energy generation.

Material constraints represent another major challenge. Advanced materials with superior energy conversion properties often come with higher costs, manufacturing complexities, or sustainability concerns. For instance, piezoelectric materials like lead zirconate titanate (PZT) offer excellent conversion efficiency but contain toxic lead, while alternatives such as aluminum nitride or zinc oxide provide lower efficiency but better environmental profiles. The trade-off between performance and material sustainability remains a significant hurdle.

Integration complexity increases exponentially as device size decreases. Micro energy harvesters require specialized manufacturing techniques such as MEMS (Micro-Electro-Mechanical Systems) fabrication, which involves complex lithography, etching, and deposition processes. These techniques demand high precision and controlled environments, significantly increasing production costs and limiting scalability for mass-market minimalist products.

Power management at the micro scale presents unique challenges. The intermittent and variable nature of harvested energy requires sophisticated power conditioning circuits to ensure stable power delivery. However, these circuits themselves consume energy and occupy valuable space, creating a parasitic loss that becomes proportionally more significant as device size decreases. Achieving high conversion efficiency while maintaining minimal footprint remains technically challenging.

Thermal management issues become more pronounced in compact designs. Energy conversion processes inevitably generate heat, which can be difficult to dissipate in tightly packed minimalist products. This can lead to reduced efficiency, shortened component lifespan, or even safety concerns in extreme cases. The limited surface area available for heat dissipation in minimalist designs exacerbates this challenge.

Reliability and durability concerns also increase with miniaturization. Micro energy harvesters are often subjected to mechanical stresses, temperature fluctuations, and environmental factors that can accelerate degradation. Ensuring long-term performance stability while maintaining minimal form factors requires advanced materials science and engineering solutions that are still evolving in the research community.

Material constraints represent another major challenge. Advanced materials with superior energy conversion properties often come with higher costs, manufacturing complexities, or sustainability concerns. For instance, piezoelectric materials like lead zirconate titanate (PZT) offer excellent conversion efficiency but contain toxic lead, while alternatives such as aluminum nitride or zinc oxide provide lower efficiency but better environmental profiles. The trade-off between performance and material sustainability remains a significant hurdle.

Integration complexity increases exponentially as device size decreases. Micro energy harvesters require specialized manufacturing techniques such as MEMS (Micro-Electro-Mechanical Systems) fabrication, which involves complex lithography, etching, and deposition processes. These techniques demand high precision and controlled environments, significantly increasing production costs and limiting scalability for mass-market minimalist products.

Power management at the micro scale presents unique challenges. The intermittent and variable nature of harvested energy requires sophisticated power conditioning circuits to ensure stable power delivery. However, these circuits themselves consume energy and occupy valuable space, creating a parasitic loss that becomes proportionally more significant as device size decreases. Achieving high conversion efficiency while maintaining minimal footprint remains technically challenging.

Thermal management issues become more pronounced in compact designs. Energy conversion processes inevitably generate heat, which can be difficult to dissipate in tightly packed minimalist products. This can lead to reduced efficiency, shortened component lifespan, or even safety concerns in extreme cases. The limited surface area available for heat dissipation in minimalist designs exacerbates this challenge.

Reliability and durability concerns also increase with miniaturization. Micro energy harvesters are often subjected to mechanical stresses, temperature fluctuations, and environmental factors that can accelerate degradation. Ensuring long-term performance stability while maintaining minimal form factors requires advanced materials science and engineering solutions that are still evolving in the research community.

Current Integration Solutions for Minimalist Product Designs

01 Piezoelectric energy harvesting systems

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesting applications. These systems can capture energy from vibrations, movements, and pressure changes in the environment. The harvested energy can be stored and used to power small electronic devices or sensors. Advanced designs incorporate flexible piezoelectric materials and optimized structural configurations to maximize energy conversion efficiency.- Piezoelectric energy harvesting systems: Piezoelectric materials are used to convert mechanical vibrations into electrical energy in micro energy harvesting systems. These systems can be integrated into various devices to capture ambient vibrations and generate power for low-energy electronics. The harvested energy can be stored in capacitors or batteries for later use. Advanced designs incorporate resonant frequency tuning mechanisms to optimize energy capture across different vibration conditions.

- Electromagnetic micro energy harvesters: Electromagnetic induction principles are applied in micro-scale to harvest energy from motion or vibration. These systems typically use small magnets moving relative to coils to generate electrical current. The compact design allows for integration into wearable devices, IoT sensors, and other small electronic systems. Advancements in materials and miniaturization techniques have improved the efficiency and power output of these electromagnetic micro harvesters.

- Thermal energy harvesting integration: Thermal energy harvesting technologies convert temperature differences into electrical energy using thermoelectric effects. These micro harvesters can be integrated into systems where temperature gradients exist, such as industrial equipment, body-heat powered wearables, or environmental monitoring devices. The integration often involves specialized thermal management to maximize the temperature differential and optimize power generation efficiency.

- Multi-source energy harvesting systems: Hybrid systems that integrate multiple energy harvesting technologies to improve reliability and power output. These systems combine different harvesting methods such as solar, vibration, thermal, and RF energy to ensure continuous power generation under varying environmental conditions. Advanced power management circuits are employed to efficiently combine and regulate the energy from different sources, providing more stable power for integrated electronics.

- Micro energy harvester integration for IoT and wearable applications: Specialized integration techniques for incorporating micro energy harvesters into Internet of Things (IoT) devices and wearable technology. These integration methods focus on miniaturization, flexibility, and seamless embedding of energy harvesting components into existing product designs. The approaches include flexible substrate technologies, 3D integration techniques, and co-design methodologies that consider both the energy harvesting and functional requirements of the target application.

02 Electromagnetic micro energy harvesters

Electromagnetic energy harvesting systems utilize the principle of electromagnetic induction to generate electrical energy from relative motion. These systems typically consist of magnets and coils arranged to produce electricity when there is movement between them. Innovations in this area include miniaturized designs, improved magnetic materials, and optimized coil configurations to enhance energy conversion efficiency in compact form factors suitable for integration into various applications.Expand Specific Solutions03 Thermal energy harvesting technologies

Thermal energy harvesting systems convert temperature differences into electrical energy using thermoelectric effects. These micro harvesters can capture waste heat from industrial processes, electronic devices, or human body heat. Recent advancements focus on improving thermoelectric materials, optimizing thermal interfaces, and developing flexible thermoelectric generators that can conform to curved surfaces for better thermal contact and energy harvesting efficiency.Expand Specific Solutions04 Integration of multiple energy harvesting mechanisms

Hybrid energy harvesting systems combine multiple energy harvesting technologies to maximize power generation from various ambient energy sources. These integrated systems may combine piezoelectric, electromagnetic, thermoelectric, or photovoltaic elements to harvest energy from different environmental sources simultaneously. This approach provides more consistent power output across varying environmental conditions and can significantly improve the overall energy harvesting efficiency and reliability.Expand Specific Solutions05 Energy management and storage solutions

Effective energy management systems are crucial for micro energy harvesters to function optimally. These systems include power conditioning circuits, energy storage elements like supercapacitors or thin-film batteries, and intelligent power management algorithms. Advanced designs incorporate ultra-low-power electronics that can operate with intermittent power sources, maximum power point tracking to optimize energy extraction, and efficient energy storage solutions tailored for the specific characteristics of micro energy harvesters.Expand Specific Solutions

Leading Companies in Micro Energy Harvesting Sector

The micro energy harvester integration market is currently in its growth phase, characterized by increasing adoption in minimalist product designs across IoT, wearables, and industrial applications. The global market size is expanding rapidly, projected to reach significant value as energy autonomy becomes critical in compact devices. From a technological maturity perspective, established players like Robert Bosch GmbH and Texas Instruments are leading commercial applications with advanced harvesting solutions, while Murata Manufacturing and Infineon Technologies offer specialized components for diverse integration scenarios. Research institutions including MIT, Georgia Tech, and Fraunhofer-Gesellschaft are driving fundamental innovations, while emerging companies like e-peas and Enervibe are developing niche solutions for specific applications. The competitive landscape shows a healthy balance between established manufacturers, specialized component providers, and innovative startups collaborating with research institutions.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric micro energy harvesters that convert mechanical vibration into electrical energy. Their MEMS-based energy harvesting solutions feature ultra-thin form factors (as thin as 0.4mm) and flexible designs that can be integrated into minimalist product designs with minimal visual impact. Murata's technology utilizes lead zirconate titanate (PZT) piezoelectric materials with optimized crystalline structures to maximize energy conversion efficiency, achieving up to 40% conversion rates in ideal conditions. Their latest harvesters can generate power from vibrations as low as 20Hz, making them suitable for wearable devices and IoT applications. Murata has also developed proprietary power management ICs that can efficiently store and regulate the harvested energy, addressing the intermittent nature of ambient energy sources. Their integrated solutions combine the harvester, power conditioning circuits, and energy storage in compact packages that can be seamlessly embedded into slim product designs.

Strengths: Industry-leading miniaturization capabilities with high power density; extensive manufacturing expertise ensuring reliability and scalability; comprehensive solution including power management. Weaknesses: Higher cost compared to conventional power solutions; limited power output requiring careful application selection; performance dependent on consistent environmental vibrations.

Stichting IMEC Nederland

Technical Solution: IMEC has developed cutting-edge micro energy harvesting technologies focused on extreme miniaturization and integration capabilities. Their proprietary thin-film photovoltaic cells achieve conversion efficiencies exceeding 20% while maintaining thicknesses below 10 micrometers, enabling seamless integration into product surfaces without disrupting minimalist aesthetics. IMEC's nanogenerator technology utilizes piezoelectric aluminum nitride thin films deposited through an innovative low-temperature process, allowing direct integration onto flexible substrates and even directly onto silicon ICs. Their micro-thermoelectric generators (μTEGs) feature unique 3D architectures that maximize temperature gradient capture in minimal space, achieving power densities up to 30μW/cm² at temperature differentials as low as 5°C. IMEC has pioneered heterogeneous integration techniques that combine multiple harvesting technologies with ultra-low-power electronics in single packages less than 2mm thick. Their power management solutions incorporate sub-threshold circuit design techniques that operate efficiently at voltages below 0.5V, enabling energy capture from previously unusable ambient sources.

Strengths: World-class research capabilities and access to advanced fabrication facilities; expertise in heterogeneous integration enabling multi-source harvesting; strong partnerships with commercial manufacturers for technology transfer. Weaknesses: Research-oriented approach sometimes prioritizing innovation over immediate commercial viability; complex fabrication processes potentially increasing production costs; technologies often requiring further development for mass production.

Key Patents and Innovations in Micro Energy Harvesters

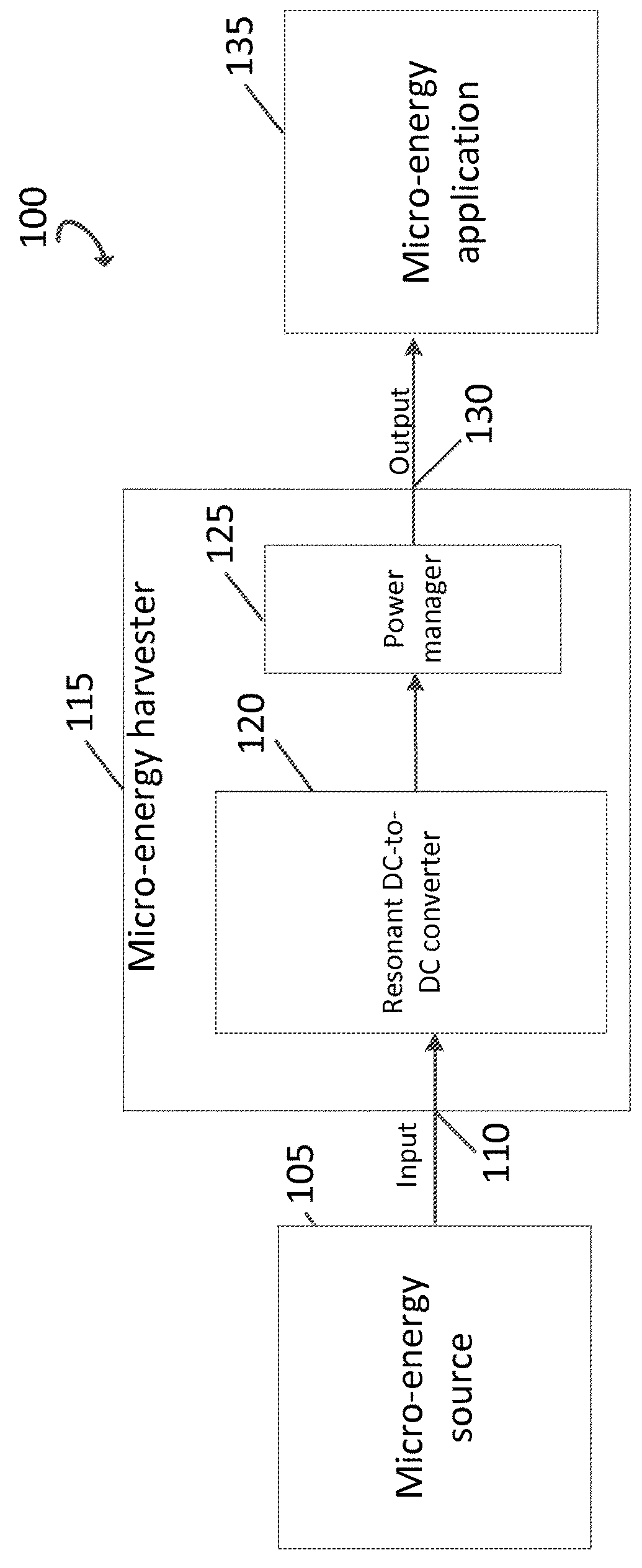

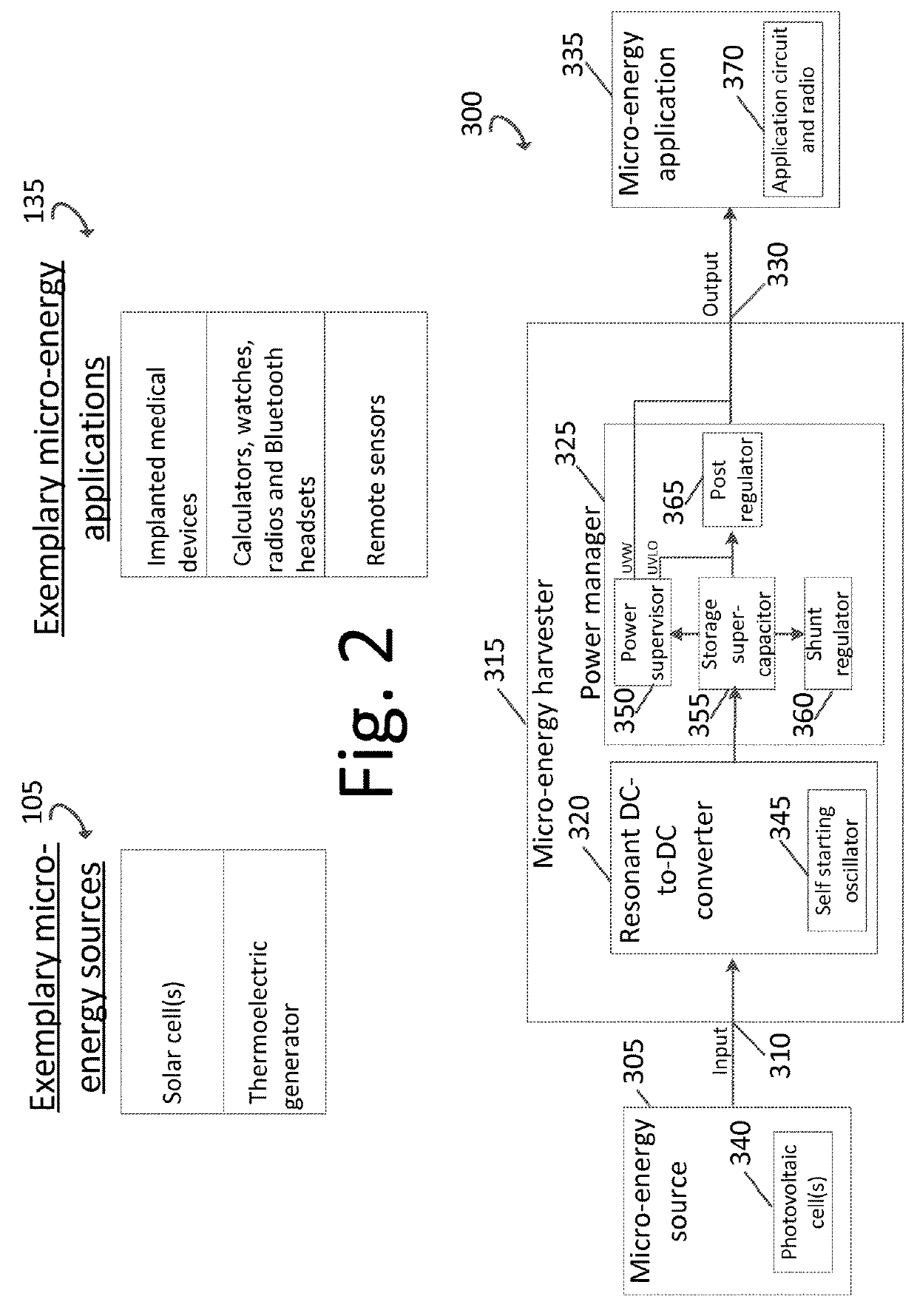

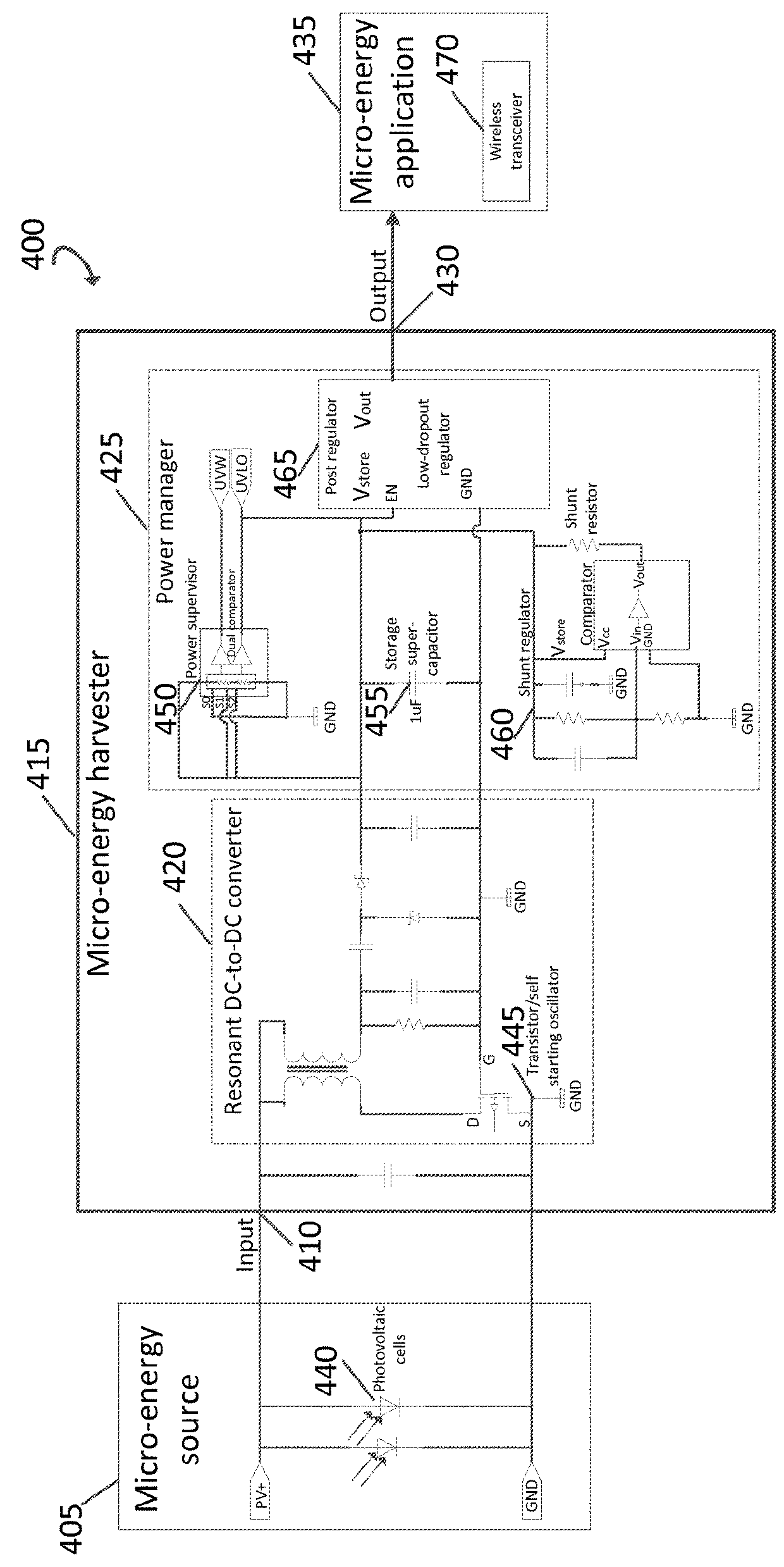

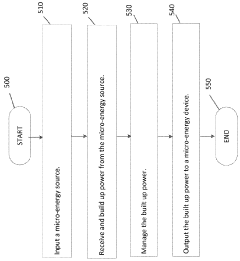

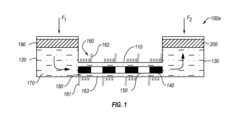

Micro-energy harvester for battery free applications

PatentInactiveUS10044218B2

Innovation

- A micro-energy harvester with an integrated power manager that uses a normally off transistor and MOSFET pass transistor to efficiently transform and store energy from low-power sources, including small solar cells, with a self-starting resonant DC-DC converter and power supervisor to manage energy storage and usage.

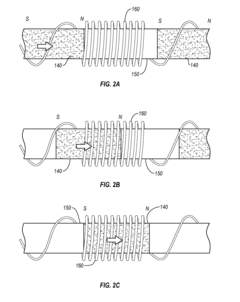

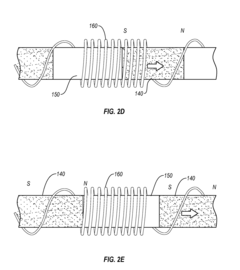

Micro-energy harvesting device for space-limited applications

PatentInactiveUS20150145470A1

Innovation

- A micro-energy harvesting device with a plurality of chambers and channels configured to circulate fluid, moving magnetic components past conductive coils to induce electrical energy, utilizing a circulation channel for extended motion and a self-recovering chamber to manage pressure and flow efficiently.

Materials Science Advancements for Energy Harvesting

Recent advancements in materials science have revolutionized the field of energy harvesting, particularly for micro-scale applications in minimalist product designs. The development of novel piezoelectric materials has significantly improved conversion efficiency, with lead-free alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) showing promising performance while addressing environmental concerns.

Flexible and stretchable materials represent another breakthrough area, with polyvinylidene fluoride (PVDF) and its copolymers emerging as leading candidates for wearable energy harvesters. These materials can generate electricity from subtle body movements while maintaining comfort and aesthetic appeal essential for minimalist design philosophies.

Nanomaterials and nanostructures have dramatically enhanced energy harvesting capabilities through increased surface area and quantum effects. Zinc oxide nanowires, carbon nanotubes, and graphene-based composites demonstrate exceptional mechanical-to-electrical energy conversion at the microscale. These materials enable energy harvesters to be integrated into products with minimal footprint while maximizing power output.

Hybrid material systems combining multiple harvesting mechanisms have shown particular promise for minimalist applications. Composites that simultaneously harvest energy from vibration, temperature gradients, and light can significantly increase overall energy yield without expanding physical dimensions. For instance, PVDF-ZnO nanocomposites can harvest both mechanical and solar energy within a single material layer.

Advances in thin-film deposition techniques have enabled the creation of ultra-thin energy harvesting layers that can be conformally applied to complex product geometries. Atomic layer deposition and solution processing methods allow for precise control of material composition and structure at the nanoscale, facilitating seamless integration with minimalist product aesthetics.

Self-healing materials represent an emerging frontier, with polymers containing microencapsulated healing agents showing potential for extending the operational lifetime of energy harvesters in consumer products. These materials can repair microcracks that develop during normal use, maintaining harvesting efficiency over extended periods without requiring replacement or maintenance.

Biodegradable and sustainable materials for energy harvesting are gaining traction, with cellulose-based piezoelectric materials and biopolymer composites offering environmentally responsible alternatives for temporary or disposable applications. These materials align with the growing emphasis on sustainability within minimalist design philosophies while providing adequate energy harvesting capabilities.

Flexible and stretchable materials represent another breakthrough area, with polyvinylidene fluoride (PVDF) and its copolymers emerging as leading candidates for wearable energy harvesters. These materials can generate electricity from subtle body movements while maintaining comfort and aesthetic appeal essential for minimalist design philosophies.

Nanomaterials and nanostructures have dramatically enhanced energy harvesting capabilities through increased surface area and quantum effects. Zinc oxide nanowires, carbon nanotubes, and graphene-based composites demonstrate exceptional mechanical-to-electrical energy conversion at the microscale. These materials enable energy harvesters to be integrated into products with minimal footprint while maximizing power output.

Hybrid material systems combining multiple harvesting mechanisms have shown particular promise for minimalist applications. Composites that simultaneously harvest energy from vibration, temperature gradients, and light can significantly increase overall energy yield without expanding physical dimensions. For instance, PVDF-ZnO nanocomposites can harvest both mechanical and solar energy within a single material layer.

Advances in thin-film deposition techniques have enabled the creation of ultra-thin energy harvesting layers that can be conformally applied to complex product geometries. Atomic layer deposition and solution processing methods allow for precise control of material composition and structure at the nanoscale, facilitating seamless integration with minimalist product aesthetics.

Self-healing materials represent an emerging frontier, with polymers containing microencapsulated healing agents showing potential for extending the operational lifetime of energy harvesters in consumer products. These materials can repair microcracks that develop during normal use, maintaining harvesting efficiency over extended periods without requiring replacement or maintenance.

Biodegradable and sustainable materials for energy harvesting are gaining traction, with cellulose-based piezoelectric materials and biopolymer composites offering environmentally responsible alternatives for temporary or disposable applications. These materials align with the growing emphasis on sustainability within minimalist design philosophies while providing adequate energy harvesting capabilities.

Design Principles for Aesthetics-Performance Balance

The integration of micro energy harvesters into minimalist product designs presents a unique challenge that requires balancing aesthetic considerations with functional performance. Successful integration demands adherence to specific design principles that maintain the clean, unobtrusive appearance characteristic of minimalist design while ensuring optimal energy harvesting capabilities.

Transparency in design represents a fundamental principle, where the energy harvesting components either become invisible within the product architecture or are transformed into aesthetic features. This approach requires careful material selection and innovative structural engineering to conceal technical elements without compromising their functionality. Companies like Apple and Muji have pioneered this approach, creating products where technology appears seamless within the overall design language.

Form-follows-function philosophy must be reimagined for energy harvesting integration. Rather than allowing harvesting components to dictate product form, designers must develop flexible harvesting technologies that can conform to predetermined minimalist shapes. This includes the development of malleable solar cells, piezoelectric materials that can be incorporated into structural elements, and thermoelectric generators designed as thin-film applications that follow product contours.

Material harmony represents another critical principle, where the materials used for energy harvesting components must visually and tactilely complement the primary materials of the product. This often requires custom development of harvesting technologies with specific surface treatments, colorations, and textures that align with minimalist aesthetic values while maintaining optimal energy conversion efficiency.

Proportional scaling ensures that energy harvesting elements maintain appropriate dimensional relationships with the overall product. This principle often necessitates miniaturization of harvesting technologies or their distribution across the product in patterns that maintain visual balance. Research indicates that consumers perceive products more favorably when technological elements observe the golden ratio or other classical proportional systems in relation to the overall product dimensions.

Interaction consistency demands that the presence of energy harvesting technology does not disrupt the user experience associated with minimalist products. This requires careful consideration of how harvesting components respond to user touch, movement, or environmental changes, ensuring these responses align with the product's overall interaction model and do not create unexpected feedback or behavior.

Multi-functional design elements represent perhaps the most sophisticated approach, where components serve both aesthetic and energy harvesting purposes simultaneously. Examples include textured surfaces that enhance grip while capturing kinetic energy, or translucent materials that filter light for visual effect while harvesting solar energy.

Transparency in design represents a fundamental principle, where the energy harvesting components either become invisible within the product architecture or are transformed into aesthetic features. This approach requires careful material selection and innovative structural engineering to conceal technical elements without compromising their functionality. Companies like Apple and Muji have pioneered this approach, creating products where technology appears seamless within the overall design language.

Form-follows-function philosophy must be reimagined for energy harvesting integration. Rather than allowing harvesting components to dictate product form, designers must develop flexible harvesting technologies that can conform to predetermined minimalist shapes. This includes the development of malleable solar cells, piezoelectric materials that can be incorporated into structural elements, and thermoelectric generators designed as thin-film applications that follow product contours.

Material harmony represents another critical principle, where the materials used for energy harvesting components must visually and tactilely complement the primary materials of the product. This often requires custom development of harvesting technologies with specific surface treatments, colorations, and textures that align with minimalist aesthetic values while maintaining optimal energy conversion efficiency.

Proportional scaling ensures that energy harvesting elements maintain appropriate dimensional relationships with the overall product. This principle often necessitates miniaturization of harvesting technologies or their distribution across the product in patterns that maintain visual balance. Research indicates that consumers perceive products more favorably when technological elements observe the golden ratio or other classical proportional systems in relation to the overall product dimensions.

Interaction consistency demands that the presence of energy harvesting technology does not disrupt the user experience associated with minimalist products. This requires careful consideration of how harvesting components respond to user touch, movement, or environmental changes, ensuring these responses align with the product's overall interaction model and do not create unexpected feedback or behavior.

Multi-functional design elements represent perhaps the most sophisticated approach, where components serve both aesthetic and energy harvesting purposes simultaneously. Examples include textured surfaces that enhance grip while capturing kinetic energy, or translucent materials that filter light for visual effect while harvesting solar energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!