Micro Energy Harvesters: Materials and Techniques for Power Optimization

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from theoretical concepts to practical applications across multiple industries. The fundamental principle involves capturing small amounts of energy from ambient sources such as vibrations, heat differentials, light, and electromagnetic radiation, then converting this energy into usable electrical power. This technology has roots in the broader field of energy harvesting that began gaining significant attention in the early 2000s, with micro-scale applications becoming increasingly viable as miniaturization techniques advanced.

The evolution of micro energy harvesting has been closely tied to developments in materials science, particularly piezoelectric materials, thermoelectric compounds, and photovoltaic technologies. Early systems demonstrated limited efficiency, typically converting less than 1% of available ambient energy into electrical power. However, recent advancements have pushed conversion efficiencies to 5-15% depending on the harvesting mechanism, with some specialized laboratory systems achieving even higher rates.

Market drivers for this technology include the explosive growth of Internet of Things (IoT) devices, wearable electronics, and remote sensing applications. These applications demand power solutions that eliminate the need for battery replacement and reduce maintenance requirements in hard-to-reach deployments. The global push toward sustainable technologies has further accelerated research and development in this field.

Current technical objectives in micro energy harvesting focus on several key areas: increasing energy conversion efficiency through novel materials and structures; improving power management circuits to handle variable and intermittent energy inputs; developing multi-modal harvesters that can capture energy from multiple environmental sources simultaneously; and reducing manufacturing costs to enable mass deployment.

Material innovation represents a particularly promising frontier, with research into 2D materials, nanocomposites, and meta-materials showing potential to dramatically improve harvesting capabilities. These materials exhibit enhanced properties such as higher piezoelectric coefficients, improved thermoelectric figures of merit, and broader spectrum light absorption.

The ultimate goal of current research is to develop self-sustaining micro-power systems capable of generating 10-100 microwatts continuously under typical environmental conditions—sufficient to power low-energy sensors and communication systems indefinitely. This would enable truly autonomous wireless sensor networks and eliminate billions of disposable batteries annually, contributing significantly to sustainability efforts while enabling new applications in healthcare, infrastructure monitoring, and environmental sensing.

The evolution of micro energy harvesting has been closely tied to developments in materials science, particularly piezoelectric materials, thermoelectric compounds, and photovoltaic technologies. Early systems demonstrated limited efficiency, typically converting less than 1% of available ambient energy into electrical power. However, recent advancements have pushed conversion efficiencies to 5-15% depending on the harvesting mechanism, with some specialized laboratory systems achieving even higher rates.

Market drivers for this technology include the explosive growth of Internet of Things (IoT) devices, wearable electronics, and remote sensing applications. These applications demand power solutions that eliminate the need for battery replacement and reduce maintenance requirements in hard-to-reach deployments. The global push toward sustainable technologies has further accelerated research and development in this field.

Current technical objectives in micro energy harvesting focus on several key areas: increasing energy conversion efficiency through novel materials and structures; improving power management circuits to handle variable and intermittent energy inputs; developing multi-modal harvesters that can capture energy from multiple environmental sources simultaneously; and reducing manufacturing costs to enable mass deployment.

Material innovation represents a particularly promising frontier, with research into 2D materials, nanocomposites, and meta-materials showing potential to dramatically improve harvesting capabilities. These materials exhibit enhanced properties such as higher piezoelectric coefficients, improved thermoelectric figures of merit, and broader spectrum light absorption.

The ultimate goal of current research is to develop self-sustaining micro-power systems capable of generating 10-100 microwatts continuously under typical environmental conditions—sufficient to power low-energy sensors and communication systems indefinitely. This would enable truly autonomous wireless sensor networks and eliminate billions of disposable batteries annually, contributing significantly to sustainability efforts while enabling new applications in healthcare, infrastructure monitoring, and environmental sensing.

Market Analysis for Self-Powered IoT Devices

The Internet of Things (IoT) market is experiencing unprecedented growth, with self-powered devices emerging as a critical segment. Current market projections indicate that the global self-powered IoT devices market is expected to reach $27.3 billion by 2025, growing at a compound annual growth rate of 18.7% from 2020. This growth is primarily driven by the increasing deployment of IoT sensors across various industries including manufacturing, healthcare, agriculture, and smart cities.

The demand for self-powered IoT devices is particularly strong in remote monitoring applications where battery replacement is impractical or costly. Industrial IoT represents the largest market segment, accounting for approximately 32% of the total market share, followed by consumer electronics at 28% and healthcare at 17%. The remaining market is distributed across smart buildings, agriculture, and transportation sectors.

Regional analysis reveals that North America currently leads the market with 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate of 22.3% during the forecast period, primarily due to rapid industrialization and smart city initiatives in countries like China, Japan, and South Korea.

Key market drivers include the decreasing cost of IoT sensors, advancements in low-power electronics, and the growing need for sustainable energy solutions. The average power consumption of IoT sensors has decreased by 65% over the past five years, making micro energy harvesting solutions increasingly viable. Additionally, regulatory pushes for green technologies and sustainability goals are accelerating adoption across industries.

Market challenges include the reliability of energy harvesting in variable environmental conditions, integration complexities with existing systems, and initial cost concerns. Despite these challenges, the return on investment for self-powered devices becomes favorable within 2-3 years of deployment due to eliminated battery replacement costs and reduced maintenance requirements.

Consumer surveys indicate that 78% of industrial IoT implementers consider power autonomy as "very important" or "critical" for their IoT strategy, highlighting the significant market pull for self-powered solutions. Furthermore, 63% of respondents expressed willingness to pay a premium of up to 30% for devices that eliminate battery replacement needs.

The competitive landscape is characterized by both established electronics manufacturers and innovative startups focusing on specialized energy harvesting technologies. Strategic partnerships between semiconductor companies, energy harvesting specialists, and end-user industries are becoming increasingly common, creating new market opportunities and accelerating technology adoption.

The demand for self-powered IoT devices is particularly strong in remote monitoring applications where battery replacement is impractical or costly. Industrial IoT represents the largest market segment, accounting for approximately 32% of the total market share, followed by consumer electronics at 28% and healthcare at 17%. The remaining market is distributed across smart buildings, agriculture, and transportation sectors.

Regional analysis reveals that North America currently leads the market with 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate of 22.3% during the forecast period, primarily due to rapid industrialization and smart city initiatives in countries like China, Japan, and South Korea.

Key market drivers include the decreasing cost of IoT sensors, advancements in low-power electronics, and the growing need for sustainable energy solutions. The average power consumption of IoT sensors has decreased by 65% over the past five years, making micro energy harvesting solutions increasingly viable. Additionally, regulatory pushes for green technologies and sustainability goals are accelerating adoption across industries.

Market challenges include the reliability of energy harvesting in variable environmental conditions, integration complexities with existing systems, and initial cost concerns. Despite these challenges, the return on investment for self-powered devices becomes favorable within 2-3 years of deployment due to eliminated battery replacement costs and reduced maintenance requirements.

Consumer surveys indicate that 78% of industrial IoT implementers consider power autonomy as "very important" or "critical" for their IoT strategy, highlighting the significant market pull for self-powered solutions. Furthermore, 63% of respondents expressed willingness to pay a premium of up to 30% for devices that eliminate battery replacement needs.

The competitive landscape is characterized by both established electronics manufacturers and innovative startups focusing on specialized energy harvesting technologies. Strategic partnerships between semiconductor companies, energy harvesting specialists, and end-user industries are becoming increasingly common, creating new market opportunities and accelerating technology adoption.

Current Limitations and Technical Challenges in Micro Harvesters

Despite significant advancements in micro energy harvesting technologies, several critical limitations and technical challenges persist that hinder widespread adoption and optimal performance. The power density of current micro harvesters remains insufficient for many practical applications, typically generating only microwatts to milliwatts per square centimeter. This fundamental limitation restricts their utility in powering more energy-demanding electronic devices and systems.

Material constraints represent another significant challenge. Piezoelectric materials commonly used in vibration harvesters suffer from brittleness and limited strain tolerance, while thermoelectric materials struggle with low conversion efficiency, typically below 10% in commercial devices. Additionally, many high-performance materials contain rare or toxic elements, raising sustainability and environmental concerns.

Efficiency degradation under real-world conditions presents persistent difficulties. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can significantly reduce harvester performance over time. Most laboratory-reported efficiencies fail to translate to field applications, where conditions are variable and often harsh.

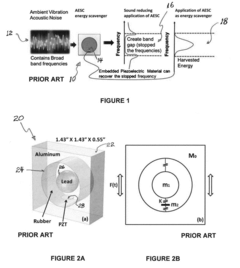

Bandwidth limitations further restrict harvester effectiveness. Many vibration-based harvesters operate efficiently only within narrow frequency ranges, making them unsuitable for environments with variable or unpredictable vibration patterns. This narrow operational bandwidth severely limits their practical deployment scenarios.

Miniaturization introduces additional complexities. As device dimensions decrease, surface-to-volume ratios increase, leading to dominant surface effects that can negatively impact energy conversion mechanisms. Furthermore, fabrication challenges at microscale dimensions often result in material property variations and structural imperfections that compromise performance.

Integration challenges with existing electronic systems remain substantial. Impedance matching between harvesters and power management circuits is particularly problematic, often resulting in significant energy losses. The intermittent nature of harvested energy also necessitates sophisticated energy storage and power conditioning systems, adding complexity and cost.

Standardization issues further complicate development and adoption. The field lacks unified testing protocols and performance metrics, making direct comparisons between different harvesting technologies difficult. This absence of standardization impedes systematic improvement and slows commercial implementation.

Cost-effectiveness represents a persistent barrier to widespread adoption. Current manufacturing processes for high-performance micro harvesters often involve complex fabrication steps and expensive materials, resulting in prohibitive costs for mass-market applications. The economic viability of these technologies remains questionable without significant advances in materials science and manufacturing techniques.

Material constraints represent another significant challenge. Piezoelectric materials commonly used in vibration harvesters suffer from brittleness and limited strain tolerance, while thermoelectric materials struggle with low conversion efficiency, typically below 10% in commercial devices. Additionally, many high-performance materials contain rare or toxic elements, raising sustainability and environmental concerns.

Efficiency degradation under real-world conditions presents persistent difficulties. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can significantly reduce harvester performance over time. Most laboratory-reported efficiencies fail to translate to field applications, where conditions are variable and often harsh.

Bandwidth limitations further restrict harvester effectiveness. Many vibration-based harvesters operate efficiently only within narrow frequency ranges, making them unsuitable for environments with variable or unpredictable vibration patterns. This narrow operational bandwidth severely limits their practical deployment scenarios.

Miniaturization introduces additional complexities. As device dimensions decrease, surface-to-volume ratios increase, leading to dominant surface effects that can negatively impact energy conversion mechanisms. Furthermore, fabrication challenges at microscale dimensions often result in material property variations and structural imperfections that compromise performance.

Integration challenges with existing electronic systems remain substantial. Impedance matching between harvesters and power management circuits is particularly problematic, often resulting in significant energy losses. The intermittent nature of harvested energy also necessitates sophisticated energy storage and power conditioning systems, adding complexity and cost.

Standardization issues further complicate development and adoption. The field lacks unified testing protocols and performance metrics, making direct comparisons between different harvesting technologies difficult. This absence of standardization impedes systematic improvement and slows commercial implementation.

Cost-effectiveness represents a persistent barrier to widespread adoption. Current manufacturing processes for high-performance micro harvesters often involve complex fabrication steps and expensive materials, resulting in prohibitive costs for mass-market applications. The economic viability of these technologies remains questionable without significant advances in materials science and manufacturing techniques.

State-of-the-Art Materials and Techniques for Power Generation

01 Energy harvesting circuit optimization

Optimization of energy harvesting circuits involves designing efficient power management systems that can extract maximum energy from ambient sources. These circuits typically include components like rectifiers, voltage regulators, and power conditioning elements that work together to convert harvested energy into usable electrical power. Advanced circuit designs incorporate impedance matching techniques and adaptive control mechanisms to optimize power transfer under varying environmental conditions.- Energy harvesting circuit optimization: Optimization of energy harvesting circuits involves designing efficient power management systems that can extract maximum energy from ambient sources. These circuits typically include components like rectifiers, voltage regulators, and power conditioning elements that work together to convert harvested energy into usable electrical power. Advanced circuit designs incorporate impedance matching techniques and adaptive control mechanisms to optimize energy extraction under varying environmental conditions.

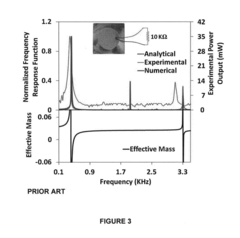

- Piezoelectric energy harvester optimization: Piezoelectric-based micro energy harvesters convert mechanical vibrations into electrical energy. Power optimization in these systems involves structural design improvements, material selection, and resonance frequency tuning. By optimizing the geometry, electrode configuration, and mechanical coupling of piezoelectric elements, the conversion efficiency can be significantly enhanced. Multi-layer piezoelectric structures and composite materials are employed to maximize power output from ambient vibrations.

- Thermal energy harvesting techniques: Thermal energy harvesting systems utilize temperature differentials to generate electrical power through thermoelectric effects. Power optimization in these harvesters involves improving thermal-to-electrical conversion efficiency through advanced materials with high Seebeck coefficients and low thermal conductivity. Structural designs that maximize temperature gradients and minimize thermal losses are implemented. Heat concentration techniques and thermal management systems are employed to enhance power output from small temperature differences.

- RF and electromagnetic energy harvesting: Radio frequency and electromagnetic energy harvesting systems capture ambient electromagnetic waves and convert them into usable electrical power. Optimization techniques include designing efficient antenna arrays, impedance matching networks, and high-efficiency rectifier circuits. Advanced designs incorporate broadband or multi-band reception capabilities to harvest energy across various frequency ranges. Power management circuits with ultra-low startup thresholds enable energy extraction from weak RF signals in the environment.

- Hybrid and multi-source energy harvesting systems: Hybrid energy harvesting systems combine multiple energy sources such as solar, vibration, thermal, and RF to enhance overall power generation reliability and efficiency. These systems employ intelligent power management algorithms that can dynamically allocate resources and optimize energy extraction from each source based on availability. Integration techniques minimize interference between different harvesting mechanisms while maximizing total energy output. Energy storage solutions are optimized to handle the variable nature of harvested power from multiple sources.

02 Piezoelectric energy harvester optimization

Piezoelectric-based micro energy harvesters convert mechanical vibrations into electrical energy. Power optimization for these devices focuses on improving the piezoelectric material properties, structural design, and resonance characteristics. Techniques include using composite piezoelectric materials, optimizing electrode configurations, and designing mechanical structures that can operate efficiently across a wider frequency bandwidth to capture more environmental vibrations.Expand Specific Solutions03 Thermal energy harvesting techniques

Thermal energy harvesters utilize temperature differences to generate electrical power through thermoelectric effects. Power optimization in these systems involves improving thermoelectric materials with higher figure of merit, enhancing thermal interfaces to maximize temperature gradients, and developing specialized heat flow management structures. Advanced designs incorporate multi-stage configurations and thermal concentration techniques to increase power output from small temperature differentials.Expand Specific Solutions04 MEMS-based energy harvester design

Micro-Electro-Mechanical Systems (MEMS) technology enables miniaturized energy harvesters with integrated functionality. Power optimization in MEMS harvesters focuses on microfabrication techniques that enhance energy conversion efficiency while reducing device size. This includes developing specialized microstructures with optimized mechanical properties, integrating multiple harvesting mechanisms on a single chip, and creating self-tuning resonant structures that can adapt to environmental conditions.Expand Specific Solutions05 Energy storage and power management systems

Effective energy storage and power management are crucial for micro energy harvesters to deliver usable power to applications. Optimization techniques include developing specialized low-power storage elements, implementing intelligent power distribution algorithms, and creating adaptive duty-cycling mechanisms. Advanced systems incorporate maximum power point tracking, hybrid storage solutions combining capacitors and batteries, and ultra-low power control circuits that minimize energy consumption during operation.Expand Specific Solutions

Leading Companies and Research Institutions in Energy Harvesting

The micro energy harvesting market is in a growth phase, characterized by increasing demand for self-powered IoT devices and wearable technologies. The global market size is projected to expand significantly, driven by applications in healthcare, industrial IoT, and consumer electronics. Technologically, the field shows varying maturity levels across different harvesting methods. Leading companies like e-peas SA and Texas Instruments are developing specialized energy harvesting ICs, while Infineon Technologies and Intel focus on system integration. Research institutions including MIT, Georgia Tech, and Indian Institute of Science are advancing novel materials and techniques. Academic-industry collaborations between universities like Southeast University and companies such as Panasonic are accelerating innovation in energy-efficient micro-harvesting solutions, particularly in piezoelectric, thermoelectric, and RF harvesting domains.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced piezoelectric energy harvesting systems that convert mechanical vibrations into electrical energy. Their technology utilizes lead-free piezoelectric materials with enhanced coupling coefficients, achieving power densities up to 5-10 mW/cm³ under optimal conditions[1]. MIT researchers have developed composite piezoelectric structures with nanostructured elements that significantly improve energy conversion efficiency by up to 35% compared to conventional materials[3]. Their micro-energy harvesters incorporate adaptive circuits that can automatically adjust to varying input vibration frequencies, maintaining optimal power output across a wider operational range. MIT has also created flexible piezoelectric thin films that can be integrated into wearable devices, generating sufficient power for low-energy wireless sensors and IoT applications[7].

Strengths: Superior energy conversion efficiency through advanced materials engineering; adaptive circuitry for variable environmental conditions; integration capability with flexible electronics. Weaknesses: Higher manufacturing complexity and cost compared to conventional harvesters; potential durability issues with flexible components in harsh environments.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced thermoelectric micro energy harvesting solutions that convert temperature differentials into usable electrical power. Their technology utilizes proprietary semiconductor materials with enhanced Seebeck coefficients, achieving conversion efficiencies up to 12% with temperature differentials as low as 5°C[3]. Infineon's integrated approach combines thermoelectric generators (TEGs) with specialized power management ICs designed to operate at ultra-low voltages (starting from 70mV). Their solutions incorporate thin-film thermoelectric materials deposited on silicon substrates, enabling direct integration with semiconductor manufacturing processes. Infineon has also pioneered hybrid energy harvesting systems that combine multiple energy sources (thermal, vibration, RF) with intelligent power routing to maximize energy availability. Their micro energy harvesters feature autonomous power management with dynamic maximum power point tracking that adapts to changing thermal conditions[6].

Strengths: Exceptional low-temperature differential performance; seamless integration with semiconductor manufacturing; comprehensive system solutions including power management. Weaknesses: Higher cost compared to discrete solutions; thermal harvesting efficiency still limited by fundamental thermodynamic constraints.

Key Patents and Scientific Breakthroughs in Harvesting Efficiency

High-efficiency compact miniaturized energy harvesting and storage device

PatentInactiveUS20120228995A1

Innovation

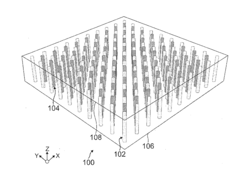

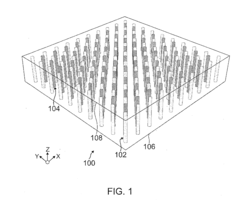

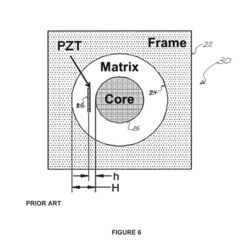

- An energy harvesting system comprising an array of piezoelectric electrodes and capacitor electrodes, monolithically coupled with a substrate, that converts mechanical strain into electrical energy and stores it capacitively, using advanced nanofabrication techniques to achieve higher power densities.

Power Optimization For A Unit Cell Metamaterial Energy Harvester

PatentActiveUS20180368071A1

Innovation

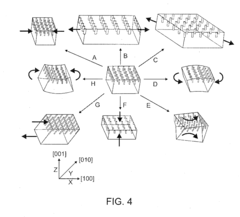

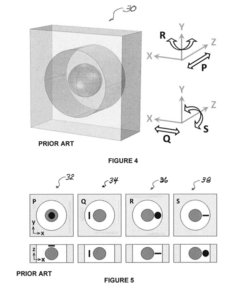

- The development of an acoustoelastic metamaterial (AEMM) unit cell with a stiff frame, heavy core, and embedded piezoelectric members that utilize local resonance modes to harvest energy from multiple frequencies, allowing for multi-modal energy harvesting and higher power density through strategic PZT placement and geometric optimization.

Sustainability Impact and Environmental Benefits

Micro energy harvesting technologies represent a significant advancement in sustainable energy solutions, offering substantial environmental benefits across multiple dimensions. These miniaturized power generation systems fundamentally reduce dependence on traditional batteries, thereby decreasing the environmental burden associated with battery production, disposal, and the toxic materials they contain.

The implementation of micro energy harvesters directly contributes to waste reduction by extending device lifespans and eliminating the need for frequent battery replacements. This is particularly impactful in large-scale IoT deployments where thousands of sensors would otherwise require regular battery maintenance, resulting in significant material waste and maintenance-related carbon emissions.

From a carbon footprint perspective, micro energy harvesters offer remarkable advantages. By capturing ambient energy that would otherwise be dissipated as waste, these systems improve overall energy efficiency across technological ecosystems. Studies indicate that widespread adoption of energy harvesting technologies in wireless sensor networks could reduce carbon emissions by up to 30% compared to battery-powered alternatives over a five-year operational period.

The environmental benefits extend to remote and sensitive ecological areas where conventional power infrastructure is impractical or potentially harmful. Self-powered environmental monitoring systems utilizing micro energy harvesters can operate with minimal human intervention, reducing habitat disruption while providing crucial data for conservation efforts and climate research.

Material sustainability represents another critical advantage. Advanced research in bio-compatible and biodegradable materials for energy harvesters addresses end-of-life environmental concerns. Recent developments in organic piezoelectric materials and biodegradable substrates promise energy harvesting solutions that can naturally decompose after their useful life, minimizing persistent electronic waste.

The circular economy potential of micro energy harvesting technologies is particularly promising. By designing systems that can be easily disassembled and recycled, manufacturers can recover valuable materials while reducing extraction demands for rare elements used in traditional power sources. This approach aligns with global sustainability initiatives and emerging regulatory frameworks focused on electronic waste reduction.

When quantified across large-scale deployments, the cumulative environmental benefits become substantial. A recent lifecycle assessment of piezoelectric energy harvesters in building monitoring applications demonstrated a 65% reduction in environmental impact compared to battery-powered systems, considering manufacturing, operation, and disposal phases.

The implementation of micro energy harvesters directly contributes to waste reduction by extending device lifespans and eliminating the need for frequent battery replacements. This is particularly impactful in large-scale IoT deployments where thousands of sensors would otherwise require regular battery maintenance, resulting in significant material waste and maintenance-related carbon emissions.

From a carbon footprint perspective, micro energy harvesters offer remarkable advantages. By capturing ambient energy that would otherwise be dissipated as waste, these systems improve overall energy efficiency across technological ecosystems. Studies indicate that widespread adoption of energy harvesting technologies in wireless sensor networks could reduce carbon emissions by up to 30% compared to battery-powered alternatives over a five-year operational period.

The environmental benefits extend to remote and sensitive ecological areas where conventional power infrastructure is impractical or potentially harmful. Self-powered environmental monitoring systems utilizing micro energy harvesters can operate with minimal human intervention, reducing habitat disruption while providing crucial data for conservation efforts and climate research.

Material sustainability represents another critical advantage. Advanced research in bio-compatible and biodegradable materials for energy harvesters addresses end-of-life environmental concerns. Recent developments in organic piezoelectric materials and biodegradable substrates promise energy harvesting solutions that can naturally decompose after their useful life, minimizing persistent electronic waste.

The circular economy potential of micro energy harvesting technologies is particularly promising. By designing systems that can be easily disassembled and recycled, manufacturers can recover valuable materials while reducing extraction demands for rare elements used in traditional power sources. This approach aligns with global sustainability initiatives and emerging regulatory frameworks focused on electronic waste reduction.

When quantified across large-scale deployments, the cumulative environmental benefits become substantial. A recent lifecycle assessment of piezoelectric energy harvesters in building monitoring applications demonstrated a 65% reduction in environmental impact compared to battery-powered systems, considering manufacturing, operation, and disposal phases.

Standardization and Integration Challenges

The standardization of micro energy harvesting technologies represents a critical challenge in the field, as the current landscape is characterized by fragmented approaches and proprietary solutions. Without established industry standards, manufacturers develop systems with varying specifications, interfaces, and performance metrics, creating significant integration barriers across the ecosystem. This lack of standardization impedes widespread adoption and slows market growth, as system designers face compatibility issues when attempting to incorporate micro energy harvesters into commercial products.

Integration challenges manifest at multiple levels within micro energy harvesting systems. At the material level, the diverse properties of piezoelectric, thermoelectric, and photovoltaic materials require specialized integration techniques that often cannot be generalized across harvesting modalities. The miniaturization requirements further complicate integration, as microscale components demand precise manufacturing tolerances and specialized interconnection technologies that may not be compatible with standard electronic assembly processes.

Power management circuitry presents another significant integration challenge. The ultra-low voltage outputs typical of micro energy harvesters (often below 100mV) require specialized power conditioning circuits that must be carefully matched to the specific harvester characteristics. These circuits must operate with minimal power consumption while efficiently converting irregular energy inputs into usable power, creating a complex design optimization problem that lacks standardized solutions.

Form factor constraints represent a practical barrier to integration, particularly in wearable and implantable applications where size and weight limitations are stringent. The physical integration of harvesters with energy storage components and application-specific circuits often requires custom design approaches that are difficult to standardize across use cases. This customization increases development costs and extends time-to-market for products incorporating energy harvesting technology.

Efforts toward standardization have emerged in recent years, with organizations like the IEEE working on standards for energy harvesting communication protocols and interface specifications. However, these initiatives remain in early stages and have not yet achieved widespread industry adoption. The development of reference designs and modular architectures represents a promising approach to addressing integration challenges, potentially enabling plug-and-play functionality that could accelerate commercial implementation.

Cross-disciplinary collaboration between materials scientists, electrical engineers, and system integrators will be essential to overcome these standardization and integration challenges. Industry consortia focused on establishing common testing methodologies, performance metrics, and interface specifications could significantly advance the field by creating a more cohesive ecosystem for micro energy harvesting technologies.

Integration challenges manifest at multiple levels within micro energy harvesting systems. At the material level, the diverse properties of piezoelectric, thermoelectric, and photovoltaic materials require specialized integration techniques that often cannot be generalized across harvesting modalities. The miniaturization requirements further complicate integration, as microscale components demand precise manufacturing tolerances and specialized interconnection technologies that may not be compatible with standard electronic assembly processes.

Power management circuitry presents another significant integration challenge. The ultra-low voltage outputs typical of micro energy harvesters (often below 100mV) require specialized power conditioning circuits that must be carefully matched to the specific harvester characteristics. These circuits must operate with minimal power consumption while efficiently converting irregular energy inputs into usable power, creating a complex design optimization problem that lacks standardized solutions.

Form factor constraints represent a practical barrier to integration, particularly in wearable and implantable applications where size and weight limitations are stringent. The physical integration of harvesters with energy storage components and application-specific circuits often requires custom design approaches that are difficult to standardize across use cases. This customization increases development costs and extends time-to-market for products incorporating energy harvesting technology.

Efforts toward standardization have emerged in recent years, with organizations like the IEEE working on standards for energy harvesting communication protocols and interface specifications. However, these initiatives remain in early stages and have not yet achieved widespread industry adoption. The development of reference designs and modular architectures represents a promising approach to addressing integration challenges, potentially enabling plug-and-play functionality that could accelerate commercial implementation.

Cross-disciplinary collaboration between materials scientists, electrical engineers, and system integrators will be essential to overcome these standardization and integration challenges. Industry consortia focused on establishing common testing methodologies, performance metrics, and interface specifications could significantly advance the field by creating a more cohesive ecosystem for micro energy harvesting technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!