Optimization of Micro Energy Harvesters for Low-Power Electronics

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology in the field of low-power electronics over the past two decades. The concept revolves around capturing minute amounts of ambient energy from the environment and converting it into usable electrical power. This technology has evolved from rudimentary mechanical harvesters in the early 2000s to sophisticated multi-source energy harvesting systems that we see today, capable of powering increasingly complex electronic devices.

The evolution trajectory shows a clear trend toward miniaturization, efficiency improvement, and integration of multiple harvesting mechanisms. Early systems primarily focused on single-source harvesting, predominantly from vibration or solar energy, with conversion efficiencies below 10%. Modern systems have achieved remarkable improvements, with some specialized harvesters reaching efficiency levels of 30-40% under optimal conditions.

The primary objective of micro energy harvesting technology is to create self-sustaining power sources for low-power electronic devices, eliminating the need for battery replacement or external charging. This is particularly crucial for applications where battery replacement is impractical, costly, or impossible, such as implantable medical devices, remote environmental sensors, and structural health monitoring systems.

Current technical objectives in the field include enhancing energy conversion efficiency across varying environmental conditions, reducing form factors to accommodate integration into increasingly miniaturized devices, and developing adaptive harvesting systems that can optimize energy capture based on available ambient sources. Additionally, there is a growing focus on improving power management circuits to maximize the utilization of harvested energy.

The field is witnessing a convergence with complementary technologies such as ultra-low-power electronics, advanced materials science, and Internet of Things (IoT) applications. This synergy is driving innovation toward systems that can operate effectively with power budgets in the microwatt to milliwatt range, opening new possibilities for autonomous sensing and computing devices.

Looking forward, the technology aims to achieve true energy autonomy for electronic systems, where devices can operate indefinitely without external power intervention. This vision encompasses not only improving harvesting mechanisms but also developing holistic energy-aware systems that intelligently balance power generation and consumption.

The ultimate goal is to enable a new generation of self-powered electronic devices that can form the backbone of sustainable smart environments, from connected cities to environmental monitoring networks, while minimizing maintenance requirements and environmental impact.

The evolution trajectory shows a clear trend toward miniaturization, efficiency improvement, and integration of multiple harvesting mechanisms. Early systems primarily focused on single-source harvesting, predominantly from vibration or solar energy, with conversion efficiencies below 10%. Modern systems have achieved remarkable improvements, with some specialized harvesters reaching efficiency levels of 30-40% under optimal conditions.

The primary objective of micro energy harvesting technology is to create self-sustaining power sources for low-power electronic devices, eliminating the need for battery replacement or external charging. This is particularly crucial for applications where battery replacement is impractical, costly, or impossible, such as implantable medical devices, remote environmental sensors, and structural health monitoring systems.

Current technical objectives in the field include enhancing energy conversion efficiency across varying environmental conditions, reducing form factors to accommodate integration into increasingly miniaturized devices, and developing adaptive harvesting systems that can optimize energy capture based on available ambient sources. Additionally, there is a growing focus on improving power management circuits to maximize the utilization of harvested energy.

The field is witnessing a convergence with complementary technologies such as ultra-low-power electronics, advanced materials science, and Internet of Things (IoT) applications. This synergy is driving innovation toward systems that can operate effectively with power budgets in the microwatt to milliwatt range, opening new possibilities for autonomous sensing and computing devices.

Looking forward, the technology aims to achieve true energy autonomy for electronic systems, where devices can operate indefinitely without external power intervention. This vision encompasses not only improving harvesting mechanisms but also developing holistic energy-aware systems that intelligently balance power generation and consumption.

The ultimate goal is to enable a new generation of self-powered electronic devices that can form the backbone of sustainable smart environments, from connected cities to environmental monitoring networks, while minimizing maintenance requirements and environmental impact.

Market Analysis for Low-Power Electronics Applications

The low-power electronics market has experienced substantial growth over the past decade, driven primarily by the proliferation of Internet of Things (IoT) devices, wearable technology, and autonomous sensor networks. The global market for low-power electronics reached approximately $65 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2028, potentially reaching $107 billion by that time.

Several key sectors are driving demand for micro energy harvesting technologies. The healthcare sector represents one of the most promising markets, with implantable medical devices and health monitoring systems requiring sustainable power sources that eliminate the need for battery replacement. This segment alone accounts for roughly 18% of the current low-power electronics market.

Consumer electronics constitutes another significant market segment, particularly with the expansion of wearable devices such as fitness trackers, smartwatches, and hearables. These devices typically operate in the 1-100 mW power range, making them ideal candidates for energy harvesting solutions. Industry analysts estimate that approximately 30% of wearable devices could incorporate some form of energy harvesting technology by 2027.

Industrial IoT applications present perhaps the largest potential market for micro energy harvesters. Wireless sensor networks deployed in manufacturing facilities, infrastructure monitoring, and agricultural settings often require deployment in remote or difficult-to-access locations where battery replacement is impractical. The industrial segment is expected to see the fastest growth, with a projected CAGR of 12.3% over the next five years.

Smart building technology represents another expanding application area, with energy harvesting sensors being integrated into HVAC systems, lighting controls, and security devices. This market segment is valued at approximately $7.2 billion currently and is expected to double within the next six years.

Regional analysis indicates that North America currently leads in adoption of micro energy harvesting technologies, followed closely by Europe and East Asia. However, the fastest growth is anticipated in emerging markets across Southeast Asia and Latin America, where the deployment of low-power electronics in agricultural and infrastructure applications is accelerating.

A critical market driver is the increasing focus on sustainability and environmental impact. As regulations around battery disposal become more stringent globally, manufacturers are seeking alternatives that reduce electronic waste. This regulatory pressure, combined with consumer demand for longer-lasting devices, creates a favorable market environment for energy harvesting solutions.

Several key sectors are driving demand for micro energy harvesting technologies. The healthcare sector represents one of the most promising markets, with implantable medical devices and health monitoring systems requiring sustainable power sources that eliminate the need for battery replacement. This segment alone accounts for roughly 18% of the current low-power electronics market.

Consumer electronics constitutes another significant market segment, particularly with the expansion of wearable devices such as fitness trackers, smartwatches, and hearables. These devices typically operate in the 1-100 mW power range, making them ideal candidates for energy harvesting solutions. Industry analysts estimate that approximately 30% of wearable devices could incorporate some form of energy harvesting technology by 2027.

Industrial IoT applications present perhaps the largest potential market for micro energy harvesters. Wireless sensor networks deployed in manufacturing facilities, infrastructure monitoring, and agricultural settings often require deployment in remote or difficult-to-access locations where battery replacement is impractical. The industrial segment is expected to see the fastest growth, with a projected CAGR of 12.3% over the next five years.

Smart building technology represents another expanding application area, with energy harvesting sensors being integrated into HVAC systems, lighting controls, and security devices. This market segment is valued at approximately $7.2 billion currently and is expected to double within the next six years.

Regional analysis indicates that North America currently leads in adoption of micro energy harvesting technologies, followed closely by Europe and East Asia. However, the fastest growth is anticipated in emerging markets across Southeast Asia and Latin America, where the deployment of low-power electronics in agricultural and infrastructure applications is accelerating.

A critical market driver is the increasing focus on sustainability and environmental impact. As regulations around battery disposal become more stringent globally, manufacturers are seeking alternatives that reduce electronic waste. This regulatory pressure, combined with consumer demand for longer-lasting devices, creates a favorable market environment for energy harvesting solutions.

Current Limitations and Technical Challenges in Micro Harvesters

Despite significant advancements in micro energy harvesting technologies, several critical limitations and technical challenges continue to impede their widespread adoption in low-power electronics applications. The fundamental challenge remains the inherently low power density of ambient energy sources, with most micro harvesters generating only microwatts to milliwatts of power, which severely constrains their application scope. This power limitation becomes particularly problematic when considering the intermittent nature of many ambient energy sources, such as solar, vibration, and thermal gradients, which fluctuate unpredictably based on environmental conditions.

Efficiency losses represent another major technical hurdle across all harvesting modalities. For piezoelectric harvesters, mechanical-to-electrical conversion efficiencies typically range from 20-30%, with significant energy dissipation occurring during the transduction process. Similarly, thermoelectric generators suffer from low Seebeck coefficients and thermal-to-electrical conversion efficiencies rarely exceeding 5-8% in practical applications, making them ineffective for harvesting small temperature differentials common in wearable or IoT devices.

Miniaturization presents complex engineering challenges that directly impact performance. As device dimensions decrease to the microscale, surface-to-volume ratios increase dramatically, leading to dominant parasitic effects and increased mechanical damping that weren't significant at larger scales. For electromagnetic harvesters, miniaturization results in reduced magnetic flux and consequently lower induced voltages, while electrostatic harvesters face challenges with decreased capacitance and charge storage capabilities at smaller dimensions.

Material limitations further constrain advancement, with current piezoelectric materials like PZT containing environmentally problematic lead, while lead-free alternatives typically demonstrate 30-50% lower piezoelectric coefficients. Similarly, thermoelectric materials with high figure-of-merit (ZT>2) remain expensive and difficult to integrate into flexible or conformable devices, limiting their practical application in wearable technologies.

Integration challenges persist at the system level, particularly regarding power management circuits that must operate efficiently at ultra-low voltage levels (often <0.5V). Conventional rectification and voltage regulation circuits introduce significant power losses that can consume a substantial portion of the harvested energy. Additionally, the lack of standardized testing protocols makes performance comparison between different harvesting technologies problematic, hampering informed design decisions.

Reliability and operational lifetime concerns also remain inadequately addressed, with many micro harvesters showing significant performance degradation after repeated mechanical cycling or exposure to environmental stressors. Piezoelectric materials experience fatigue and depolarization, while thermoelectric materials may develop microcracks or interface delamination over time, issues that become more pronounced at the microscale where structural integrity is more vulnerable.

Efficiency losses represent another major technical hurdle across all harvesting modalities. For piezoelectric harvesters, mechanical-to-electrical conversion efficiencies typically range from 20-30%, with significant energy dissipation occurring during the transduction process. Similarly, thermoelectric generators suffer from low Seebeck coefficients and thermal-to-electrical conversion efficiencies rarely exceeding 5-8% in practical applications, making them ineffective for harvesting small temperature differentials common in wearable or IoT devices.

Miniaturization presents complex engineering challenges that directly impact performance. As device dimensions decrease to the microscale, surface-to-volume ratios increase dramatically, leading to dominant parasitic effects and increased mechanical damping that weren't significant at larger scales. For electromagnetic harvesters, miniaturization results in reduced magnetic flux and consequently lower induced voltages, while electrostatic harvesters face challenges with decreased capacitance and charge storage capabilities at smaller dimensions.

Material limitations further constrain advancement, with current piezoelectric materials like PZT containing environmentally problematic lead, while lead-free alternatives typically demonstrate 30-50% lower piezoelectric coefficients. Similarly, thermoelectric materials with high figure-of-merit (ZT>2) remain expensive and difficult to integrate into flexible or conformable devices, limiting their practical application in wearable technologies.

Integration challenges persist at the system level, particularly regarding power management circuits that must operate efficiently at ultra-low voltage levels (often <0.5V). Conventional rectification and voltage regulation circuits introduce significant power losses that can consume a substantial portion of the harvested energy. Additionally, the lack of standardized testing protocols makes performance comparison between different harvesting technologies problematic, hampering informed design decisions.

Reliability and operational lifetime concerns also remain inadequately addressed, with many micro harvesters showing significant performance degradation after repeated mechanical cycling or exposure to environmental stressors. Piezoelectric materials experience fatigue and depolarization, while thermoelectric materials may develop microcracks or interface delamination over time, issues that become more pronounced at the microscale where structural integrity is more vulnerable.

Current Optimization Approaches for Micro Energy Harvesters

01 Piezoelectric energy harvesting optimization

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. Optimization techniques include improving material composition, structural design modifications, and resonance frequency tuning to maximize energy output from ambient vibrations. Advanced piezoelectric configurations such as cantilever beams with proof masses or arrays of piezoelectric elements can significantly enhance power generation efficiency in micro-scale applications.- Piezoelectric energy harvesting optimization: Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. Optimization techniques include improving material composition, structural design modifications, and resonance frequency tuning to maximize energy output from ambient vibrations. Advanced piezoelectric configurations such as cantilever beams, diaphragms, and multi-layer structures can significantly enhance energy conversion efficiency in micro-scale applications.

- Electromagnetic micro-generator enhancements: Electromagnetic micro-generators harvest energy through relative motion between magnets and coils. Optimization approaches include using high-performance magnetic materials, advanced coil winding techniques, and innovative mechanical coupling mechanisms. Miniaturization challenges are addressed through precision manufacturing and novel geometric configurations that maximize magnetic flux density while maintaining compact form factors for integration into micro-scale devices.

- Thermoelectric harvester efficiency improvements: Thermoelectric micro harvesters convert temperature differentials into electrical energy. Optimization focuses on enhancing the thermoelectric figure of merit through advanced semiconductor materials, nano-structuring techniques, and thermal management strategies. Improved thermal interfaces, heat concentration mechanisms, and multi-stage configurations help maximize energy generation from small temperature gradients in micro-scale applications.

- Hybrid and multi-source energy harvesting systems: Hybrid micro energy harvesters combine multiple energy conversion mechanisms (piezoelectric, electromagnetic, thermoelectric, etc.) to increase overall energy output and reliability. These systems incorporate intelligent power management circuits, energy storage solutions, and adaptive harvesting strategies to optimize energy capture from various environmental sources simultaneously. Integration challenges are addressed through modular designs and compatible interface technologies.

- MEMS-based energy harvester design optimization: Micro-Electro-Mechanical Systems (MEMS) technology enables highly miniaturized energy harvesters with optimized mechanical and electrical properties. Design optimization includes resonance frequency tuning, damping control, and structural modifications to enhance energy capture from low-amplitude environmental sources. Advanced MEMS fabrication techniques allow for precise control of device parameters, while novel materials and geometries improve durability and performance in micro-scale energy harvesting applications.

02 Electromagnetic micro-generator enhancements

Electromagnetic micro-generators harvest energy through relative motion between magnets and coils. Optimization approaches focus on magnetic circuit design, coil configuration, and miniaturization techniques to improve power density. Advanced designs incorporate multi-axis harvesting capabilities, magnetic flux concentration methods, and specialized geometries to capture energy from irregular or low-frequency movements, enhancing overall conversion efficiency in compact form factors.Expand Specific Solutions03 Thermal energy harvesting techniques

Thermal energy harvesters utilize temperature differentials to generate electricity through thermoelectric effects. Optimization strategies include developing advanced thermoelectric materials with higher Seebeck coefficients, improving thermal interfaces, and creating specialized geometries to maximize temperature gradients. Micro-scale thermal harvesters can be optimized through thin-film technologies, nanostructured materials, and innovative heat flow management to capture waste heat from various sources efficiently.Expand Specific Solutions04 Hybrid and multi-modal energy harvesting systems

Hybrid energy harvesting systems combine multiple conversion mechanisms (piezoelectric, electromagnetic, thermoelectric, etc.) to maximize energy capture from diverse environmental sources. Optimization focuses on integrated circuit design for efficient power management, complementary harvesting mechanisms selection, and adaptive operation based on available energy sources. These systems can be optimized through machine learning algorithms that dynamically adjust harvesting parameters based on environmental conditions.Expand Specific Solutions05 MEMS-based energy harvester fabrication and scaling

Micro-Electro-Mechanical Systems (MEMS) technology enables highly miniaturized energy harvesters with optimized performance. Fabrication optimization includes advanced micromachining techniques, material selection for compatibility with MEMS processes, and structural designs that maximize energy conversion at micro scales. Scaling considerations address challenges in maintaining efficiency at reduced dimensions through innovative geometries, resonant frequency tuning, and specialized electrode configurations to enhance charge collection and power output.Expand Specific Solutions

Leading Companies and Research Institutions in Energy Harvesting

The micro energy harvesting market for low-power electronics is currently in its growth phase, characterized by increasing adoption across IoT applications. The market is projected to reach approximately $2.5 billion by 2028, with a CAGR of 10-12%. Technologically, the field shows varying maturity levels, with piezoelectric and thermoelectric solutions being more established while triboelectric and RF harvesting remain emerging. Academic institutions (MIT, Southeast University, University of Tokyo) lead fundamental research, while commercial players demonstrate different specialization levels. Texas Instruments and Intel focus on integration with semiconductor technologies, Samsung and Panasonic develop consumer applications, and specialized firms like Saginomiya Seisakusho concentrate on specific harvesting technologies. This competitive landscape reflects a dynamic ecosystem balancing academic innovation with commercial implementation across multiple energy harvesting approaches.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed an extensive portfolio of micro energy harvesting solutions centered around their ultra-low-power microcontrollers and specialized power management ICs. Their BQ25570 and BQ25504 energy harvesting chips feature industry-leading cold-start capability, able to begin operation with input voltages as low as 330mV, significantly lower than competing solutions. TI's approach incorporates highly efficient DC-DC boost converters with up to 90% efficiency even at micro-watt power levels, maximizing the usable energy from small harvesters. Their technology includes advanced maximum power point tracking that automatically adjusts to the optimal operating point for various energy sources, whether solar, thermal, or vibration-based. TI has also pioneered programmable power management systems that can intelligently allocate harvested energy between immediate use and storage based on application priorities and environmental conditions, enabling more reliable operation in variable energy environments.

Strengths: Exceptional low-voltage operation capabilities allowing energy capture from minimal environmental sources. Comprehensive ecosystem of compatible components enabling complete system solutions. Weaknesses: Individual harvesting components sometimes require significant external circuitry for optimal performance, increasing system complexity for some applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered significant advancements in micro energy harvesting through their development of ultra-low-power MEMS (Micro-Electro-Mechanical Systems) vibration energy harvesters. Their technology utilizes piezoelectric materials with optimized geometries to capture ambient mechanical energy from various environmental sources. MIT researchers have created specialized frequency up-conversion techniques that allow harvesters to operate efficiently at the low frequencies typically found in real-world environments while generating power at higher, more efficient frequencies. Their recent breakthroughs include the development of broadband energy harvesters capable of capturing energy across a wide spectrum of vibration frequencies, significantly improving energy capture in variable environments. MIT has also integrated advanced power management circuits that can operate with input voltages as low as 20mV, enabling effective energy harvesting from extremely low-amplitude vibrations common in many IoT applications.

Strengths: Superior integration of advanced materials science with innovative mechanical designs, allowing for higher energy conversion efficiency. Their solutions demonstrate excellent performance in variable environmental conditions. Weaknesses: Higher manufacturing complexity and cost compared to simpler harvesting technologies, potentially limiting mass-market adoption in cost-sensitive applications.

Key Patents and Technical Breakthroughs in Harvester Efficiency

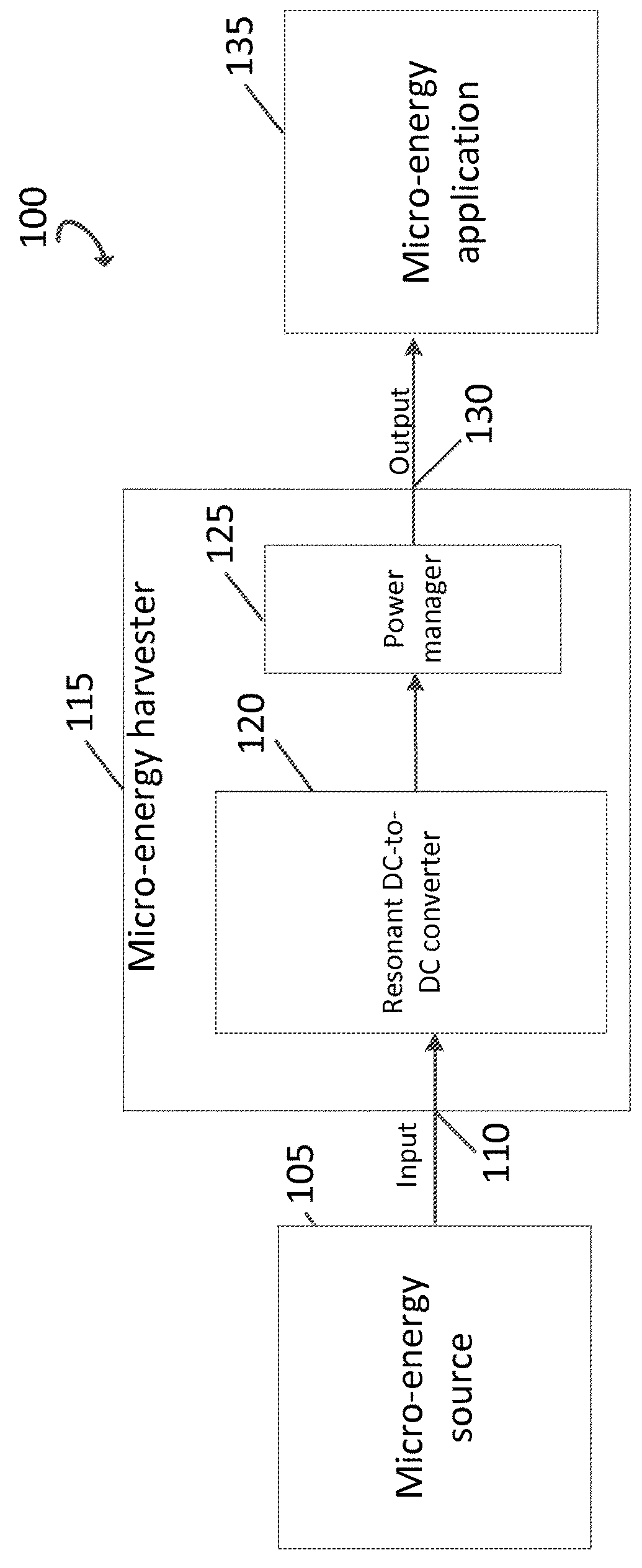

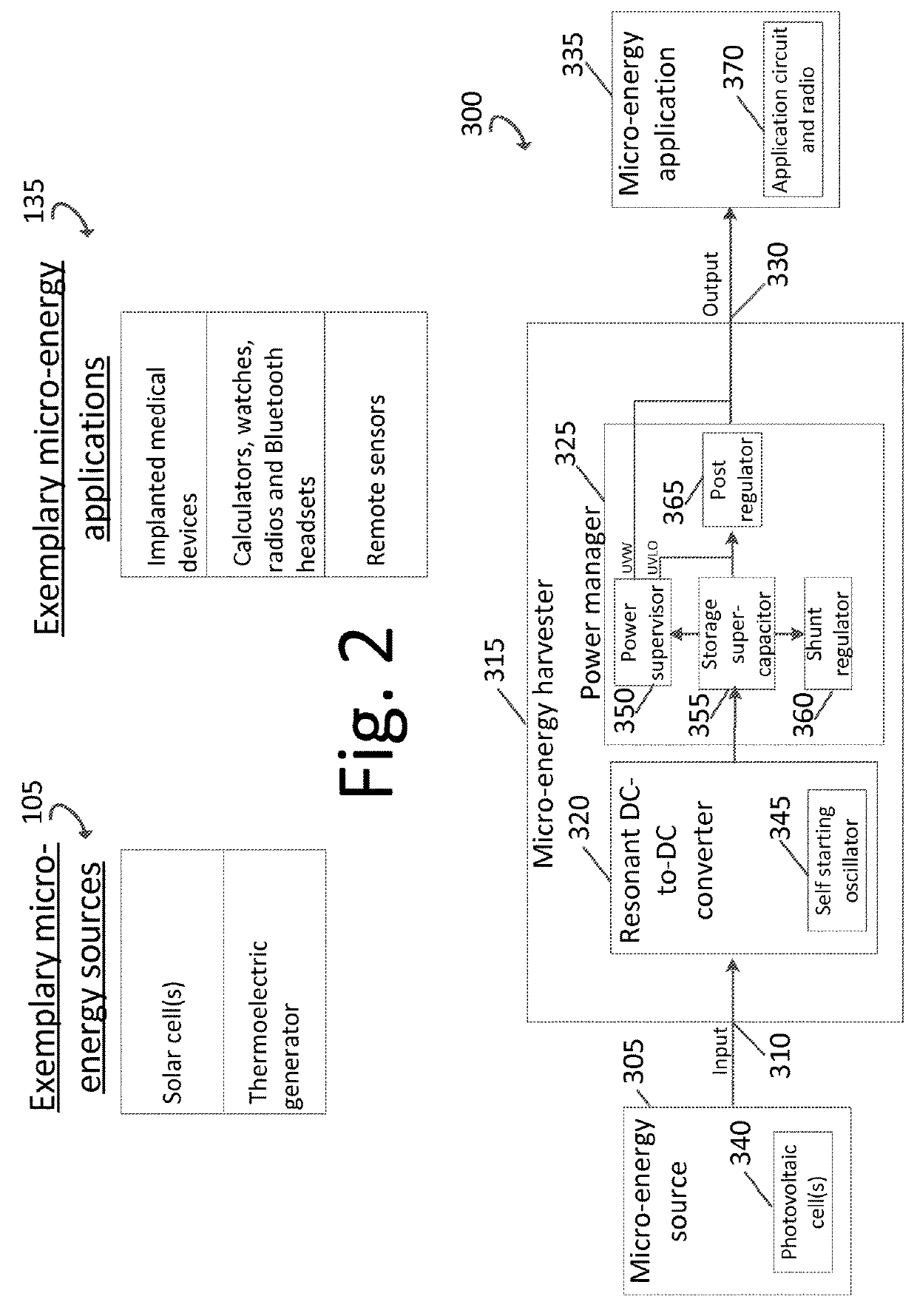

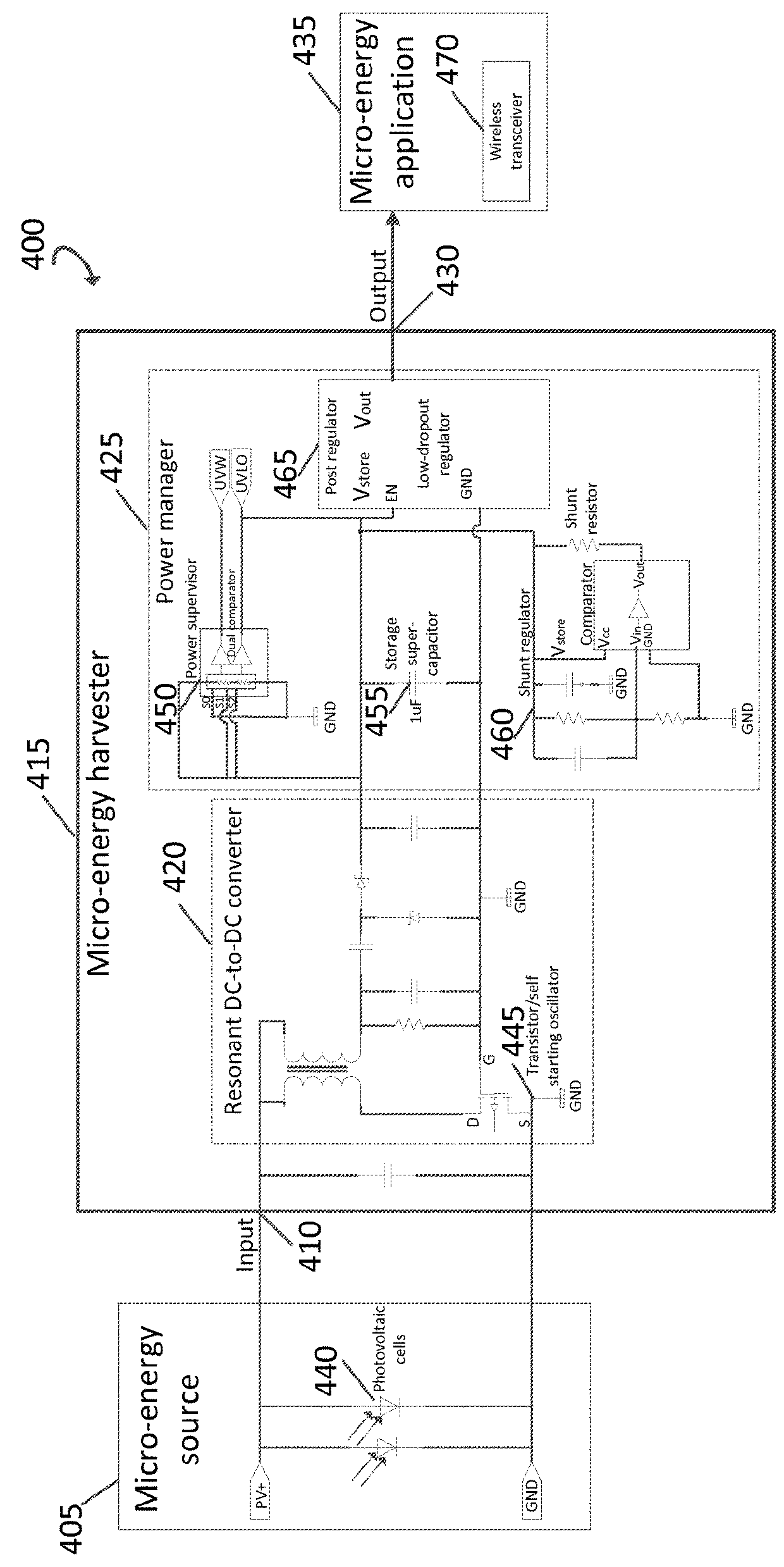

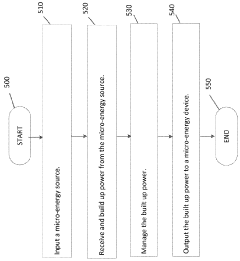

Micro-energy harvester for battery free applications

PatentInactiveUS10044218B2

Innovation

- A micro-energy harvester with an integrated power manager that uses a normally off transistor and MOSFET pass transistor to efficiently transform and store energy from low-power sources, including small solar cells, with a self-starting resonant DC-DC converter and power supervisor to manage energy storage and usage.

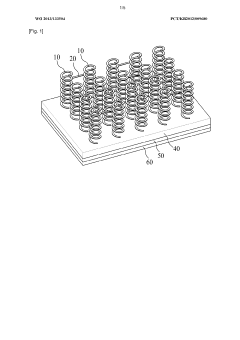

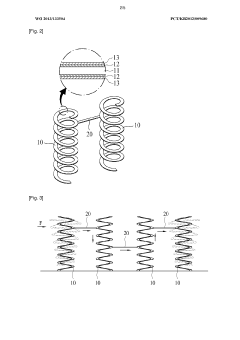

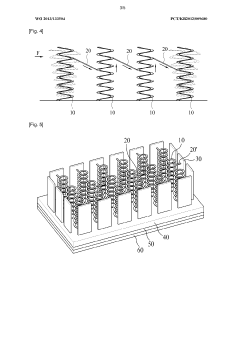

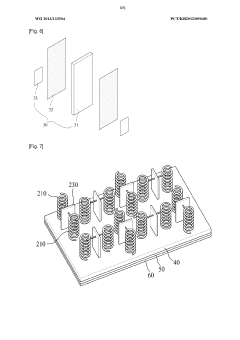

Energy-harvesting apparatus comprising coil spring-type microscale piezoelectric resonator

PatentWO2013133504A1

Innovation

- The energy harvesting device employs a plurality of micro-piezoelectric vibrators in the form of coil springs and plate-type piezoelectric vibrators connected through various connection units on a printed circuit board, allowing for efficient power generation from external forces and heat, with the ability to transmit and collect energy through diverse paths.

Materials Science Advancements for Harvester Performance

Recent advancements in materials science have significantly enhanced the performance of micro energy harvesters, addressing key limitations in energy density, conversion efficiency, and operational longevity. Novel piezoelectric materials, particularly lead-free compositions based on potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), have demonstrated superior piezoelectric coefficients while meeting environmental regulations. These materials show up to 30% improvement in energy conversion efficiency compared to traditional lead zirconate titanate (PZT) compositions.

Nanostructured materials represent another breakthrough area, with carbon-based nanomaterials like graphene and carbon nanotubes exhibiting exceptional mechanical flexibility and electrical conductivity. When incorporated into energy harvesting devices, these materials have demonstrated a power density increase of 45-60% compared to conventional structures, particularly in vibration-based harvesters operating at low frequencies (1-100 Hz).

Metamaterials engineered with precise periodic structures have enabled frequency bandwidth expansion in vibration harvesters, allowing effective operation across a wider range of environmental conditions. Recent research shows that metamaterial-based harvesters can maintain optimal performance across frequency ranges three times wider than traditional designs, significantly enhancing real-world applicability.

Thermoelectric material innovations have focused on enhancing the figure of merit (ZT) through nano-engineering approaches. Skutterudite compounds and half-Heusler alloys with carefully controlled nanostructures have achieved ZT values exceeding 1.5 at room temperature, representing a substantial improvement over conventional bulk materials with typical ZT values below 1.0.

Flexible and stretchable materials have enabled conformable energy harvesters that can be integrated into wearable electronics and IoT devices. Polymer-based piezoelectric materials like PVDF (polyvinylidene fluoride) and its copolymers, when fabricated as nanofibers through electrospinning, have demonstrated energy harvesting capabilities while withstanding mechanical deformation exceeding 150% of their original dimensions.

Composite materials combining multiple harvesting mechanisms have emerged as particularly promising. Hybrid structures incorporating piezoelectric, triboelectric, and electromagnetic principles have demonstrated synergistic effects, with energy outputs 75-100% higher than single-mechanism harvesters of comparable size. These multi-modal harvesters more effectively capture ambient energy across diverse environmental conditions.

Surface engineering techniques, including atomic layer deposition and plasma treatment, have been employed to optimize interface properties in harvesting devices, reducing parasitic losses and enhancing charge collection efficiency by up to 25% in recent experimental prototypes.

Nanostructured materials represent another breakthrough area, with carbon-based nanomaterials like graphene and carbon nanotubes exhibiting exceptional mechanical flexibility and electrical conductivity. When incorporated into energy harvesting devices, these materials have demonstrated a power density increase of 45-60% compared to conventional structures, particularly in vibration-based harvesters operating at low frequencies (1-100 Hz).

Metamaterials engineered with precise periodic structures have enabled frequency bandwidth expansion in vibration harvesters, allowing effective operation across a wider range of environmental conditions. Recent research shows that metamaterial-based harvesters can maintain optimal performance across frequency ranges three times wider than traditional designs, significantly enhancing real-world applicability.

Thermoelectric material innovations have focused on enhancing the figure of merit (ZT) through nano-engineering approaches. Skutterudite compounds and half-Heusler alloys with carefully controlled nanostructures have achieved ZT values exceeding 1.5 at room temperature, representing a substantial improvement over conventional bulk materials with typical ZT values below 1.0.

Flexible and stretchable materials have enabled conformable energy harvesters that can be integrated into wearable electronics and IoT devices. Polymer-based piezoelectric materials like PVDF (polyvinylidene fluoride) and its copolymers, when fabricated as nanofibers through electrospinning, have demonstrated energy harvesting capabilities while withstanding mechanical deformation exceeding 150% of their original dimensions.

Composite materials combining multiple harvesting mechanisms have emerged as particularly promising. Hybrid structures incorporating piezoelectric, triboelectric, and electromagnetic principles have demonstrated synergistic effects, with energy outputs 75-100% higher than single-mechanism harvesters of comparable size. These multi-modal harvesters more effectively capture ambient energy across diverse environmental conditions.

Surface engineering techniques, including atomic layer deposition and plasma treatment, have been employed to optimize interface properties in harvesting devices, reducing parasitic losses and enhancing charge collection efficiency by up to 25% in recent experimental prototypes.

Integration Strategies with IoT and Wearable Devices

The integration of micro energy harvesters with IoT and wearable devices represents a critical frontier in advancing self-powered electronics ecosystems. These integration strategies must address the unique constraints of both the harvesting technologies and the application environments while maximizing energy efficiency across the entire system.

Current integration approaches focus on developing modular harvester designs that can be easily incorporated into existing IoT platforms and wearable form factors. Companies like Texas Instruments and STMicroelectronics have pioneered power management integrated circuits (PMICs) specifically designed to interface between micro harvesters and low-power electronics, enabling efficient energy transfer and storage even with intermittent energy sources.

Architectural considerations for integration include both hardware and software components. On the hardware side, flexible printed circuit boards (PCBs) and stretchable electronics have emerged as enabling technologies for seamlessly incorporating harvesters into wearable devices. These technologies allow harvesters to conform to body contours or environmental surfaces while maintaining electrical connectivity and mechanical durability.

Protocol-level integration presents another dimension of the challenge. Energy-aware communication protocols such as Bluetooth Low Energy (BLE) and Zigbee have been optimized to operate with harvested energy, implementing adaptive duty cycling based on available power. More advanced implementations incorporate machine learning algorithms that predict energy availability patterns and adjust device operation accordingly.

The miniaturization trend in both harvesters and IoT devices has facilitated more elegant integration solutions. Multi-functional components that serve both as structural elements and energy harvesters represent a promising direction, such as textile-based triboelectric generators that function as both clothing material and power sources for wearable health monitors.

System-level energy management remains crucial for successful integration. Hybrid approaches combining multiple harvesting modalities (e.g., solar with thermal or mechanical) with intelligent power routing have demonstrated superior reliability in real-world deployments. These systems typically incorporate ultra-low-power microcontrollers that orchestrate energy flow between harvesters, storage elements, and functional components.

Commercial implementations have begun to emerge across various sectors. Health monitoring wearables from companies like Fitbit and Garmin are exploring integration of thermal harvesters to extend battery life, while industrial IoT sensor networks from Honeywell and Siemens increasingly incorporate vibration harvesters to eliminate battery replacement in hard-to-reach locations.

Current integration approaches focus on developing modular harvester designs that can be easily incorporated into existing IoT platforms and wearable form factors. Companies like Texas Instruments and STMicroelectronics have pioneered power management integrated circuits (PMICs) specifically designed to interface between micro harvesters and low-power electronics, enabling efficient energy transfer and storage even with intermittent energy sources.

Architectural considerations for integration include both hardware and software components. On the hardware side, flexible printed circuit boards (PCBs) and stretchable electronics have emerged as enabling technologies for seamlessly incorporating harvesters into wearable devices. These technologies allow harvesters to conform to body contours or environmental surfaces while maintaining electrical connectivity and mechanical durability.

Protocol-level integration presents another dimension of the challenge. Energy-aware communication protocols such as Bluetooth Low Energy (BLE) and Zigbee have been optimized to operate with harvested energy, implementing adaptive duty cycling based on available power. More advanced implementations incorporate machine learning algorithms that predict energy availability patterns and adjust device operation accordingly.

The miniaturization trend in both harvesters and IoT devices has facilitated more elegant integration solutions. Multi-functional components that serve both as structural elements and energy harvesters represent a promising direction, such as textile-based triboelectric generators that function as both clothing material and power sources for wearable health monitors.

System-level energy management remains crucial for successful integration. Hybrid approaches combining multiple harvesting modalities (e.g., solar with thermal or mechanical) with intelligent power routing have demonstrated superior reliability in real-world deployments. These systems typically incorporate ultra-low-power microcontrollers that orchestrate energy flow between harvesters, storage elements, and functional components.

Commercial implementations have begun to emerge across various sectors. Health monitoring wearables from companies like Fitbit and Garmin are exploring integration of thermal harvesters to extend battery life, while industrial IoT sensor networks from Honeywell and Siemens increasingly incorporate vibration harvesters to eliminate battery replacement in hard-to-reach locations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!