Micro Energy Harvesters and Their Role in Wireless Charge Solutions

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Technology Background and Objectives

Micro energy harvesting technology has evolved significantly over the past two decades, transforming from theoretical concepts into practical applications across multiple industries. This evolution has been driven by the convergence of advances in materials science, miniaturization techniques, and increasing demand for autonomous power solutions in wireless devices. Initially focused on simple piezoelectric and thermoelectric principles, the field has expanded to encompass a diverse range of energy capture mechanisms including electromagnetic, triboelectric, and photovoltaic technologies at the micro and nano scales.

The trajectory of development shows a clear trend toward higher energy conversion efficiencies, with notable breakthroughs occurring around 2010 when commercial viability began to emerge for specific applications. Recent advancements in flexible and printable harvesters have further accelerated adoption across wearable technology and IoT sectors, with energy density improvements averaging 15-20% annually over the past five years.

Current micro energy harvesting technologies can be categorized into mechanical (vibration, pressure), thermal (temperature gradients), radiant (light, RF), and biochemical (glucose, enzymatic) sources. Each category has demonstrated unique advantages in specific deployment scenarios, with mechanical and radiant sources currently showing the highest technology readiness levels for wireless charging applications.

The primary technical objective in this domain is to develop micro energy harvesting solutions capable of generating sufficient power density (target: >500 μW/cm²) to support wireless charging for low-power electronic devices while maintaining form factors below 1 cm³. Secondary objectives include enhancing operational reliability across variable environmental conditions, extending functional lifespans beyond 10 years, and reducing manufacturing costs to enable mass-market adoption.

Looking forward, the technology roadmap aims to achieve seamless integration with existing wireless charging standards while addressing key challenges in energy storage, power management, and system miniaturization. The ultimate goal is to enable truly autonomous wireless devices that can operate indefinitely by harvesting ambient energy from their surroundings, eliminating the need for traditional battery replacement or manual charging processes.

Industry projections suggest that micro energy harvesting technologies will play an increasingly critical role in wireless charging solutions, particularly as IoT device deployments accelerate and demand grows for maintenance-free power solutions in hard-to-access locations. The convergence with emerging technologies such as 5G/6G networks and edge computing further amplifies the strategic importance of this technology domain.

The trajectory of development shows a clear trend toward higher energy conversion efficiencies, with notable breakthroughs occurring around 2010 when commercial viability began to emerge for specific applications. Recent advancements in flexible and printable harvesters have further accelerated adoption across wearable technology and IoT sectors, with energy density improvements averaging 15-20% annually over the past five years.

Current micro energy harvesting technologies can be categorized into mechanical (vibration, pressure), thermal (temperature gradients), radiant (light, RF), and biochemical (glucose, enzymatic) sources. Each category has demonstrated unique advantages in specific deployment scenarios, with mechanical and radiant sources currently showing the highest technology readiness levels for wireless charging applications.

The primary technical objective in this domain is to develop micro energy harvesting solutions capable of generating sufficient power density (target: >500 μW/cm²) to support wireless charging for low-power electronic devices while maintaining form factors below 1 cm³. Secondary objectives include enhancing operational reliability across variable environmental conditions, extending functional lifespans beyond 10 years, and reducing manufacturing costs to enable mass-market adoption.

Looking forward, the technology roadmap aims to achieve seamless integration with existing wireless charging standards while addressing key challenges in energy storage, power management, and system miniaturization. The ultimate goal is to enable truly autonomous wireless devices that can operate indefinitely by harvesting ambient energy from their surroundings, eliminating the need for traditional battery replacement or manual charging processes.

Industry projections suggest that micro energy harvesting technologies will play an increasingly critical role in wireless charging solutions, particularly as IoT device deployments accelerate and demand grows for maintenance-free power solutions in hard-to-access locations. The convergence with emerging technologies such as 5G/6G networks and edge computing further amplifies the strategic importance of this technology domain.

Market Demand Analysis for Wireless Charging Solutions

The wireless charging market has experienced remarkable growth in recent years, driven by increasing consumer demand for convenient charging solutions across multiple device categories. According to market research, the global wireless charging market was valued at approximately $15 billion in 2022 and is projected to reach $40 billion by 2027, representing a compound annual growth rate (CAGR) of 21.3%. This substantial growth reflects the expanding integration of wireless charging capabilities in smartphones, wearables, and other consumer electronics.

Consumer behavior studies indicate that convenience is the primary driver behind wireless charging adoption. A 2022 survey revealed that 78% of smartphone users consider wireless charging a desirable feature when purchasing new devices, with 65% willing to pay a premium for this functionality. The elimination of cable clutter and the standardization around technologies like Qi have significantly contributed to market acceptance.

The automotive sector represents one of the fastest-growing segments for wireless charging solutions. Electric vehicle manufacturers are increasingly incorporating wireless charging pads in vehicle designs, with projections suggesting that by 2025, approximately 30% of premium electric vehicles will offer built-in wireless charging capabilities. This trend is further supported by infrastructure developments, with wireless charging stations being deployed in public spaces, offices, and residential buildings.

Healthcare applications present another significant growth opportunity. Medical device manufacturers are exploring wireless charging for implantable devices, wearable health monitors, and portable medical equipment. The market for medical wireless charging solutions is expected to grow at a CAGR of 24% through 2026, driven by the need for sealed, sterilizable charging solutions that reduce infection risks and improve device reliability.

Industrial IoT applications are creating substantial demand for micro energy harvesting technologies integrated with wireless charging. The deployment of sensor networks in manufacturing, agriculture, and smart city applications requires power solutions that can operate without frequent battery replacements. Market analysis indicates that 40% of industrial IoT implementations cite power management as a critical challenge, creating opportunities for hybrid solutions combining energy harvesting with wireless power transfer.

Regional analysis shows Asia-Pacific leading the market with 42% share, followed by North America (28%) and Europe (22%). China and South Korea are particularly significant manufacturing hubs for wireless charging components, while North American markets show the highest consumer adoption rates for premium wireless charging solutions.

The market is also witnessing a shift toward higher-power wireless charging solutions, with demand increasing for 15W+ charging capabilities that can support larger devices and faster charging times. This trend is driving innovation in thermal management, efficiency improvements, and new coil designs to support these higher power requirements.

Consumer behavior studies indicate that convenience is the primary driver behind wireless charging adoption. A 2022 survey revealed that 78% of smartphone users consider wireless charging a desirable feature when purchasing new devices, with 65% willing to pay a premium for this functionality. The elimination of cable clutter and the standardization around technologies like Qi have significantly contributed to market acceptance.

The automotive sector represents one of the fastest-growing segments for wireless charging solutions. Electric vehicle manufacturers are increasingly incorporating wireless charging pads in vehicle designs, with projections suggesting that by 2025, approximately 30% of premium electric vehicles will offer built-in wireless charging capabilities. This trend is further supported by infrastructure developments, with wireless charging stations being deployed in public spaces, offices, and residential buildings.

Healthcare applications present another significant growth opportunity. Medical device manufacturers are exploring wireless charging for implantable devices, wearable health monitors, and portable medical equipment. The market for medical wireless charging solutions is expected to grow at a CAGR of 24% through 2026, driven by the need for sealed, sterilizable charging solutions that reduce infection risks and improve device reliability.

Industrial IoT applications are creating substantial demand for micro energy harvesting technologies integrated with wireless charging. The deployment of sensor networks in manufacturing, agriculture, and smart city applications requires power solutions that can operate without frequent battery replacements. Market analysis indicates that 40% of industrial IoT implementations cite power management as a critical challenge, creating opportunities for hybrid solutions combining energy harvesting with wireless power transfer.

Regional analysis shows Asia-Pacific leading the market with 42% share, followed by North America (28%) and Europe (22%). China and South Korea are particularly significant manufacturing hubs for wireless charging components, while North American markets show the highest consumer adoption rates for premium wireless charging solutions.

The market is also witnessing a shift toward higher-power wireless charging solutions, with demand increasing for 15W+ charging capabilities that can support larger devices and faster charging times. This trend is driving innovation in thermal management, efficiency improvements, and new coil designs to support these higher power requirements.

Current State and Challenges in Micro Energy Harvesting

Micro energy harvesting technology has evolved significantly over the past decade, with current implementations spanning various energy sources including solar, thermal, vibration, and RF energy. The global market for these technologies reached approximately $460 million in 2022 and is projected to grow at a CAGR of 10.5% through 2028. Despite this growth trajectory, the field faces substantial technical limitations that hinder widespread commercial adoption, particularly in wireless charging applications.

The efficiency of current micro energy harvesters remains a primary challenge, with most commercial solutions achieving only 15-30% energy conversion rates. This limitation is particularly pronounced in indoor environments where ambient energy sources are typically sparse. For instance, indoor photovoltaic harvesters operate at significantly reduced efficiency compared to their outdoor counterparts, often generating only microwatts of power under standard office lighting conditions.

Power density constraints represent another significant barrier, with current technologies struggling to deliver sufficient energy for many practical applications. Most vibration-based harvesters, for example, generate only 10-100 μW/cm³, which falls short of the requirements for many IoT devices that need periodic bursts of higher power. This power gap necessitates complex energy storage and management systems, adding to overall system complexity and cost.

Material limitations further complicate advancement in this field. Piezoelectric materials used in vibration harvesters suffer from brittleness and limited operational temperature ranges, while thermoelectric generators require rare earth elements that pose sustainability and supply chain concerns. Additionally, the performance degradation of these materials over time impacts the long-term reliability of harvesting systems.

Miniaturization presents another formidable challenge. As devices shrink, the available surface area for energy capture decreases proportionally, creating fundamental physical constraints on energy generation capacity. This scaling issue is particularly problematic for applications in wearable technology and implantable medical devices where size constraints are stringent.

Integration complexity with existing electronic systems remains problematic. Current harvesters often require specialized interface circuits and energy management systems that add cost and complexity. The lack of standardization across harvesting technologies further complicates system design and implementation, creating barriers to widespread adoption.

Geographically, research and development in micro energy harvesting shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while East Asian countries, particularly Japan and South Korea, dominate in commercial applications and manufacturing scale. Emerging economies like China and India are rapidly increasing their research output in this field, focusing particularly on low-cost implementation strategies for developing markets.

The efficiency of current micro energy harvesters remains a primary challenge, with most commercial solutions achieving only 15-30% energy conversion rates. This limitation is particularly pronounced in indoor environments where ambient energy sources are typically sparse. For instance, indoor photovoltaic harvesters operate at significantly reduced efficiency compared to their outdoor counterparts, often generating only microwatts of power under standard office lighting conditions.

Power density constraints represent another significant barrier, with current technologies struggling to deliver sufficient energy for many practical applications. Most vibration-based harvesters, for example, generate only 10-100 μW/cm³, which falls short of the requirements for many IoT devices that need periodic bursts of higher power. This power gap necessitates complex energy storage and management systems, adding to overall system complexity and cost.

Material limitations further complicate advancement in this field. Piezoelectric materials used in vibration harvesters suffer from brittleness and limited operational temperature ranges, while thermoelectric generators require rare earth elements that pose sustainability and supply chain concerns. Additionally, the performance degradation of these materials over time impacts the long-term reliability of harvesting systems.

Miniaturization presents another formidable challenge. As devices shrink, the available surface area for energy capture decreases proportionally, creating fundamental physical constraints on energy generation capacity. This scaling issue is particularly problematic for applications in wearable technology and implantable medical devices where size constraints are stringent.

Integration complexity with existing electronic systems remains problematic. Current harvesters often require specialized interface circuits and energy management systems that add cost and complexity. The lack of standardization across harvesting technologies further complicates system design and implementation, creating barriers to widespread adoption.

Geographically, research and development in micro energy harvesting shows distinct patterns. North America and Europe lead in fundamental research and patent filings, while East Asian countries, particularly Japan and South Korea, dominate in commercial applications and manufacturing scale. Emerging economies like China and India are rapidly increasing their research output in this field, focusing particularly on low-cost implementation strategies for developing markets.

Current Technical Solutions for Wireless Energy Transfer

01 Piezoelectric micro energy harvesters

Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stress in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. Piezoelectric harvesters typically consist of a piezoelectric material layer mounted on a substrate that deforms under mechanical stress, generating electrical charge.- Piezoelectric micro energy harvesters: Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stress in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. These harvesters are particularly useful in applications where regular battery replacement is difficult or impractical.

- Electromagnetic micro energy harvesting systems: Electromagnetic energy harvesters generate electricity through electromagnetic induction when a conductor moves relative to a magnetic field. These systems typically consist of a magnet, coil, and mechanical component that enables relative motion. They can harvest energy from various sources including vibrations, fluid flow, and human movement. The design focuses on optimizing the conversion efficiency while maintaining a compact form factor suitable for micro-scale applications.

- Thermal energy harvesting technologies: Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These micro-scale devices can capture waste heat from industrial processes, electronic components, or ambient temperature gradients. The technology typically employs thermoelectric materials arranged in arrays to maximize power output. Applications include self-powered sensors, wearable electronics, and IoT devices operating in environments with thermal gradients.

- RF and ambient energy harvesting solutions: Radio frequency (RF) and ambient energy harvesters capture electromagnetic waves from the environment, including Wi-Fi signals, cellular networks, and broadcast transmissions. These systems use specialized antennas and rectifier circuits to convert RF energy into usable DC power. The technology enables battery-free operation of low-power electronic devices in environments with sufficient RF energy density, making them ideal for wireless sensor networks and IoT applications.

- Hybrid and multi-source micro energy harvesting: Hybrid energy harvesting systems combine multiple energy conversion mechanisms to improve reliability and power output. These integrated solutions can simultaneously harvest energy from various sources such as vibration, thermal gradients, light, and RF signals. By combining different harvesting technologies, these systems can operate effectively across diverse environmental conditions. Advanced power management circuits optimize energy collection and storage from multiple sources to provide consistent power to microelectronic devices.

02 Triboelectric micro energy harvesters

Triboelectric energy harvesters generate electricity through contact electrification and electrostatic induction when two different materials come into contact and separate. These harvesters can convert various mechanical energies such as vibration, sliding, and rotation into electrical energy. They typically consist of two materials with different electron affinities that generate electrical charges when they contact and separate, making them suitable for self-powered sensors and IoT devices.Expand Specific Solutions03 Electromagnetic micro energy harvesters

Electromagnetic micro energy harvesters utilize Faraday's law of electromagnetic induction to convert mechanical motion into electrical energy. These systems typically consist of a magnet and a coil arrangement where relative movement between them induces current in the coil. The harvested energy can be used for powering wireless sensor networks, wearable devices, and other low-power electronics. These harvesters are particularly effective for applications with continuous vibration or motion.Expand Specific Solutions04 Thermal micro energy harvesters

Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These micro-scale devices can harvest energy from ambient temperature gradients or waste heat sources. They typically employ thermoelectric materials that generate voltage when subjected to a temperature difference across their surfaces. Applications include powering wearable electronics, remote sensors, and IoT devices in environments where temperature differences naturally occur.Expand Specific Solutions05 Hybrid and multi-source micro energy harvesters

Hybrid micro energy harvesters combine multiple energy harvesting mechanisms in a single device to improve efficiency and reliability. These systems can simultaneously or selectively harvest energy from different sources such as vibration, thermal gradients, solar, and RF signals. By integrating multiple harvesting technologies, these systems can provide more consistent power output under varying environmental conditions, making them suitable for autonomous sensors and IoT applications in dynamic environments.Expand Specific Solutions

Key Industry Players in Micro Energy Harvesting

The micro energy harvesting market for wireless charging solutions is currently in a growth phase, with increasing adoption across IoT applications. The market is projected to expand significantly as energy-efficient devices proliferate, though still represents a niche segment within the broader wireless power industry. Technologically, the field shows varying maturity levels, with companies like Energous, Atmosic Technologies, and Qualcomm leading commercial development of over-the-air wireless power solutions. Research institutions including Georgia Tech, KAIST, and IMEC Nederland are advancing fundamental technologies, while established electronics giants Samsung, Intel, and Sony are strategically positioning through patent development. The ecosystem demonstrates a healthy balance between academic innovation and commercial implementation, with semiconductor specialists like Nordic Semiconductor and STMicroelectronics providing enabling components for energy harvesting systems.

Stichting IMEC Nederland

Technical Solution: IMEC has developed cutting-edge micro energy harvesting technologies that push the boundaries of power efficiency and miniaturization. Their approach focuses on ultra-low-power integrated solutions that combine multiple harvesting modalities with advanced power management. IMEC's photovoltaic harvesters achieve record-breaking efficiency levels for indoor light conditions, converting artificial light to usable power at efficiency rates exceeding 30% in typical indoor environments[7]. Their vibration energy harvesters utilize piezoelectric MEMS technology with novel mechanical designs that can generate usable power from extremely low-frequency vibrations (below 100 Hz). IMEC has also pioneered thermoelectric generators with unique thin-film structures that can harvest energy from temperature differentials as low as 1°C. Their RF energy harvesting circuits can operate at ultra-low power levels (-30 dBm) and feature specialized rectifier designs with efficiency exceeding 70% for common RF bands. These technologies are integrated with IMEC's power management ICs that include maximum power point tracking, efficient DC-DC conversion with >90% efficiency even at micro-watt levels, and intelligent power routing algorithms[8].

Strengths: Industry-leading miniaturization and integration capabilities; extremely high efficiency across multiple harvesting modalities; advanced fabrication techniques enabling mass production of micro-scale harvesters. Weaknesses: Higher cost for cutting-edge solutions; some technologies still in research/prototype phase rather than full commercialization; complex integration requirements for system designers.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has developed a comprehensive portfolio of micro energy harvesting solutions targeting wireless charging applications across multiple markets. Their technology includes specialized power management ICs (PMICs) designed specifically for energy harvesting applications, capable of operating from input voltages as low as 100mV while providing regulated output for powering microcontrollers and wireless transceivers[9]. ST's SPV1050 energy harvesting IC integrates MPPT (Maximum Power Point Tracking) functionality with ultra-low power DC-DC conversion and battery management, enabling efficient harvesting from photovoltaic, thermoelectric, and piezoelectric sources. For wireless charging applications, ST has developed resonant inductive coupling solutions that operate at 6.78MHz (A4WP/Rezence standard) and 100-200kHz (Qi standard), providing flexibility across different wireless power standards. Their latest STWBC series wireless charging transmitters incorporate digital control algorithms that optimize power transfer efficiency while minimizing electromagnetic interference. ST has also pioneered specialized NFC-powered energy harvesting solutions that can extract power from NFC fields to enable battery-less operation of small sensors and electronic tags[10].

Strengths: Comprehensive ecosystem of components from energy harvesting to power management; production-ready solutions with established reliability and certification; strong integration with their microcontroller and sensor portfolios. Weaknesses: Individual components require significant system integration expertise; wireless charging solutions primarily focused on near-field rather than long-distance power transfer; performance highly dependent on proper system design and implementation.

Core Patents and Innovations in Micro Energy Harvesting

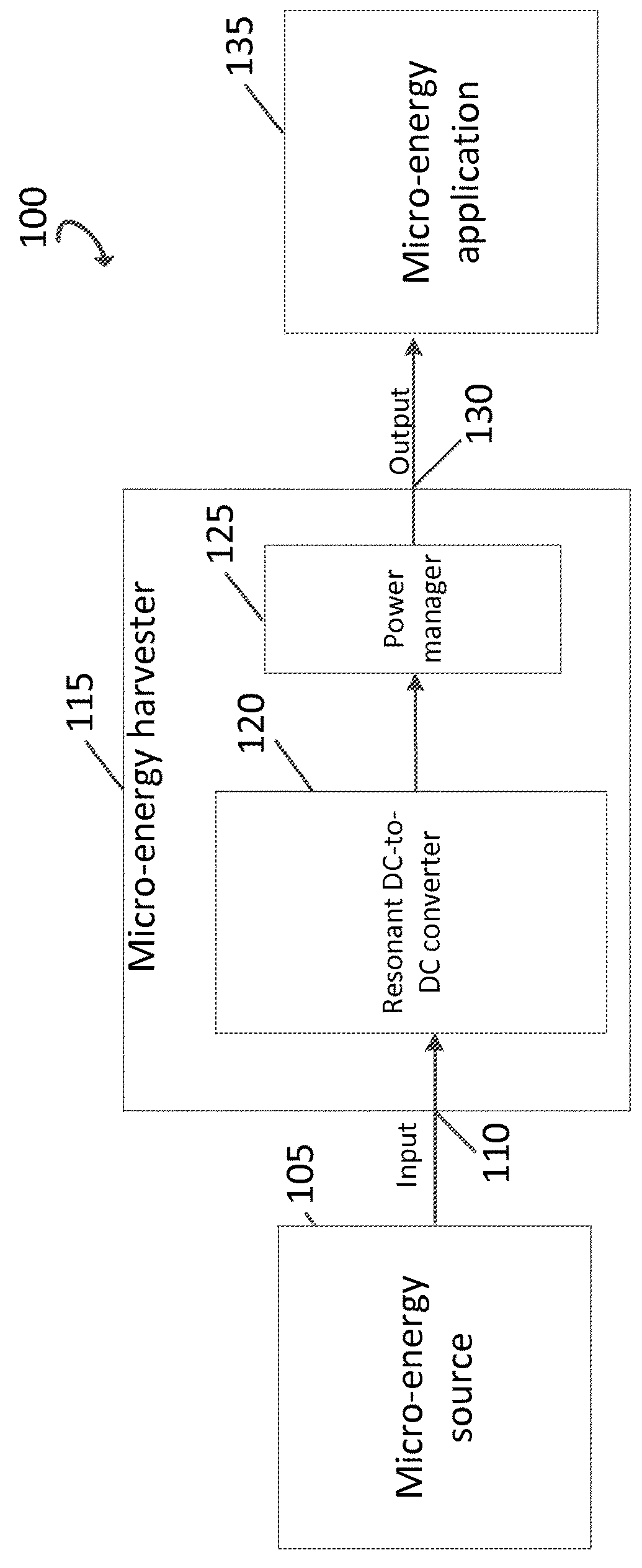

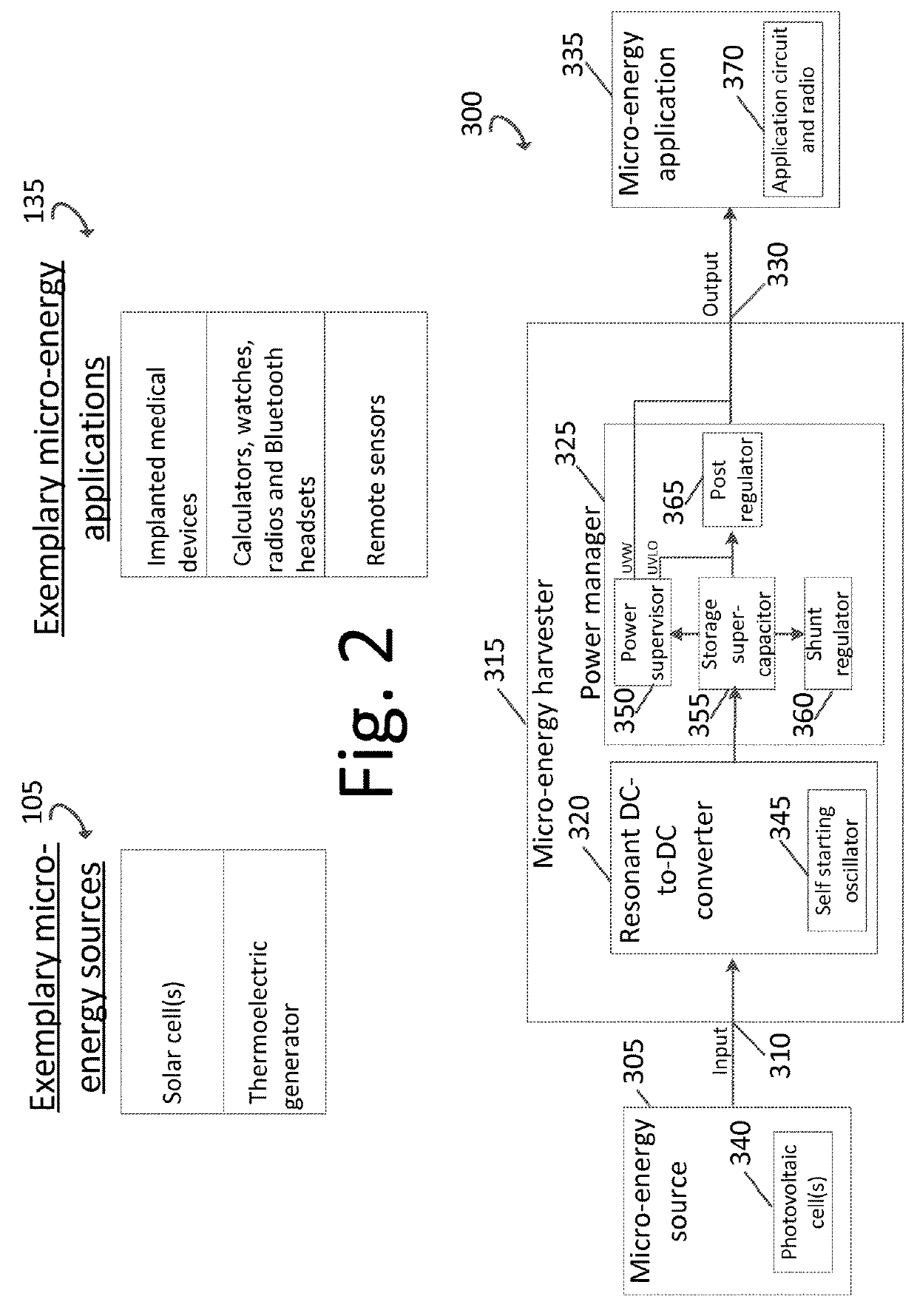

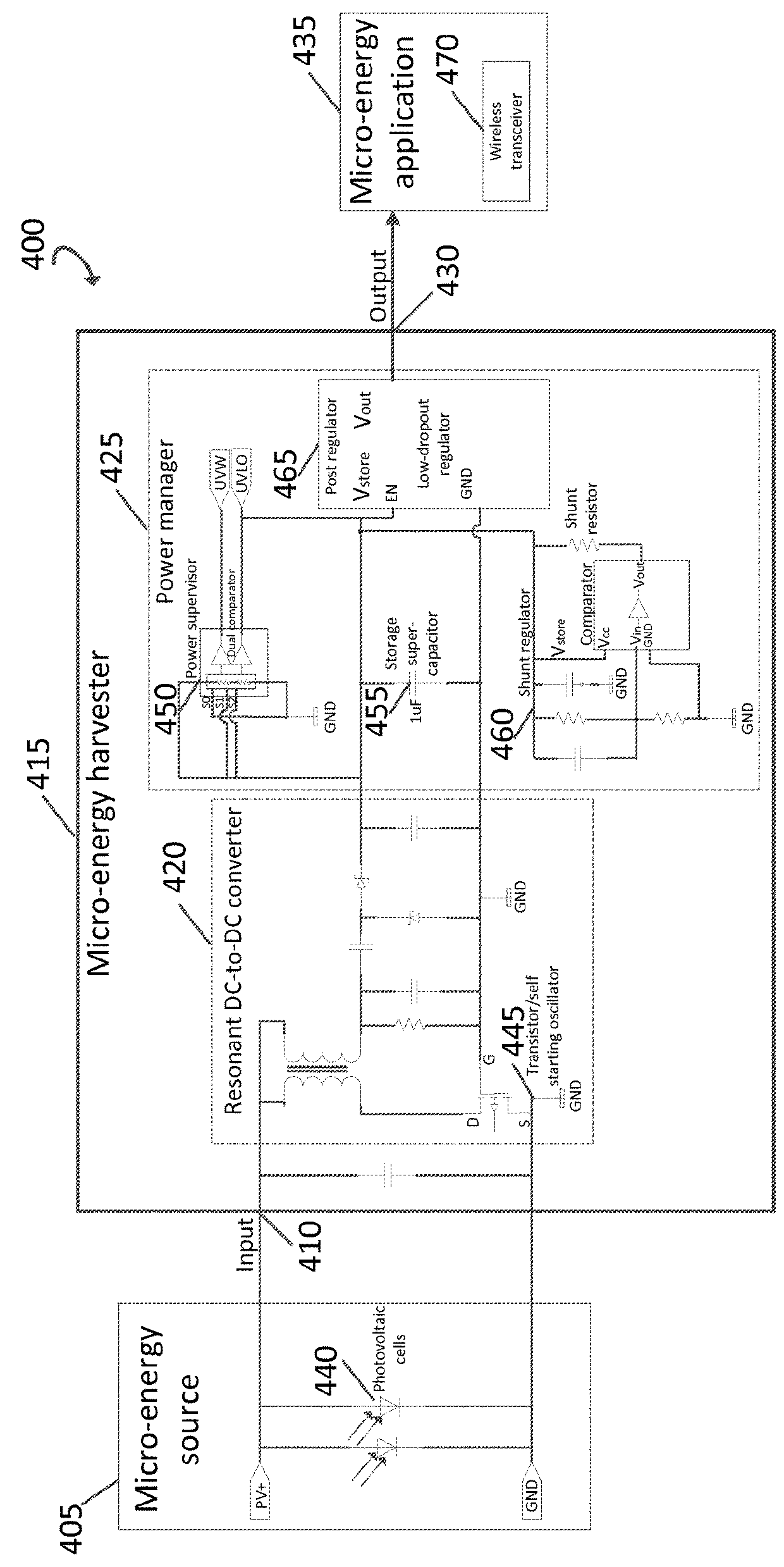

Micro-energy harvester for battery free applications

PatentInactiveUS10044218B2

Innovation

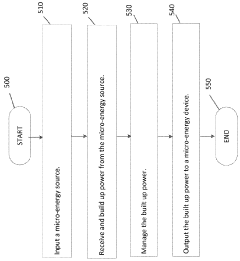

- A micro-energy harvester with an integrated power manager that uses a normally off transistor and MOSFET pass transistor to efficiently transform and store energy from low-power sources, including small solar cells, with a self-starting resonant DC-DC converter and power supervisor to manage energy storage and usage.

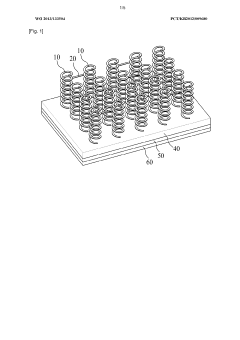

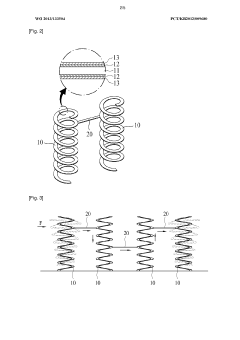

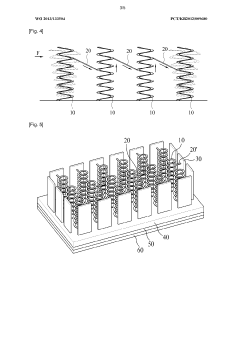

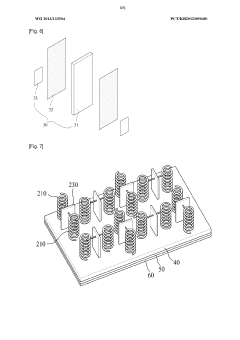

Energy-harvesting apparatus comprising coil spring-type microscale piezoelectric resonator

PatentWO2013133504A1

Innovation

- The energy harvesting device employs a plurality of micro-piezoelectric vibrators in the form of coil springs and plate-type piezoelectric vibrators connected through various connection units on a printed circuit board, allowing for efficient power generation from external forces and heat, with the ability to transmit and collect energy through diverse paths.

Energy Efficiency and Conversion Rate Optimization

Energy efficiency and conversion rate optimization are critical factors in the development and deployment of micro energy harvesters for wireless charging solutions. Current micro energy harvesting technologies demonstrate varying degrees of efficiency, with most commercial solutions operating at conversion rates between 15-40% depending on the energy source and harvesting mechanism employed.

Piezoelectric harvesters typically achieve efficiency rates of 20-30% when optimally configured, while electromagnetic systems can reach up to 35% in controlled environments. Thermoelectric generators remain somewhat limited at 5-15% efficiency, though recent advances in nanostructured materials have shown potential improvements approaching 20% in laboratory settings.

The efficiency challenge is particularly pronounced in ambient energy harvesting scenarios where energy sources are intermittent and variable in intensity. Optimization strategies have focused on adaptive circuitry that can dynamically adjust to changing input conditions, maximizing energy capture across diverse operational environments. Multi-physics modeling has emerged as a valuable tool for predicting system performance and identifying efficiency bottlenecks before physical prototyping.

Recent innovations in materials science have yielded significant improvements in conversion efficiency. Nanostructured piezoelectric materials with enhanced coupling coefficients have demonstrated up to 40% higher energy conversion compared to conventional materials. Similarly, advanced thermoelectric materials incorporating quantum well structures have shown promising results in laboratory testing, with theoretical efficiency limits approaching 30%.

Power management circuitry represents another critical area for optimization. Ultra-low-power maximum power point tracking (MPPT) algorithms have been developed specifically for micro-scale applications, ensuring optimal impedance matching between harvesters and storage elements. These systems typically add only 5-10% overhead while improving overall system efficiency by 25-40% under variable conditions.

For wireless charging applications, the end-to-end efficiency must consider not only the harvesting mechanism but also the power conditioning, storage, and transmission stages. Integrated approaches that optimize the entire energy chain have demonstrated overall system efficiencies of 10-25% in real-world applications, representing a significant improvement over earlier generations that struggled to exceed single-digit efficiency rates.

Future optimization pathways include hybrid harvesting systems that combine multiple energy capture mechanisms, self-tuning resonant structures for vibration-based harvesters, and machine learning algorithms that predict energy availability patterns to optimize harvesting strategies proactively rather than reactively.

Piezoelectric harvesters typically achieve efficiency rates of 20-30% when optimally configured, while electromagnetic systems can reach up to 35% in controlled environments. Thermoelectric generators remain somewhat limited at 5-15% efficiency, though recent advances in nanostructured materials have shown potential improvements approaching 20% in laboratory settings.

The efficiency challenge is particularly pronounced in ambient energy harvesting scenarios where energy sources are intermittent and variable in intensity. Optimization strategies have focused on adaptive circuitry that can dynamically adjust to changing input conditions, maximizing energy capture across diverse operational environments. Multi-physics modeling has emerged as a valuable tool for predicting system performance and identifying efficiency bottlenecks before physical prototyping.

Recent innovations in materials science have yielded significant improvements in conversion efficiency. Nanostructured piezoelectric materials with enhanced coupling coefficients have demonstrated up to 40% higher energy conversion compared to conventional materials. Similarly, advanced thermoelectric materials incorporating quantum well structures have shown promising results in laboratory testing, with theoretical efficiency limits approaching 30%.

Power management circuitry represents another critical area for optimization. Ultra-low-power maximum power point tracking (MPPT) algorithms have been developed specifically for micro-scale applications, ensuring optimal impedance matching between harvesters and storage elements. These systems typically add only 5-10% overhead while improving overall system efficiency by 25-40% under variable conditions.

For wireless charging applications, the end-to-end efficiency must consider not only the harvesting mechanism but also the power conditioning, storage, and transmission stages. Integrated approaches that optimize the entire energy chain have demonstrated overall system efficiencies of 10-25% in real-world applications, representing a significant improvement over earlier generations that struggled to exceed single-digit efficiency rates.

Future optimization pathways include hybrid harvesting systems that combine multiple energy capture mechanisms, self-tuning resonant structures for vibration-based harvesters, and machine learning algorithms that predict energy availability patterns to optimize harvesting strategies proactively rather than reactively.

Environmental Impact and Sustainability Considerations

Micro energy harvesting technologies represent a significant advancement in sustainable power generation for wireless charging solutions. These systems convert ambient energy from the environment into usable electrical power, offering a promising alternative to traditional battery-dependent devices. The environmental implications of this technology are substantial and multifaceted, warranting careful consideration as the field continues to evolve.

The primary environmental benefit of micro energy harvesters lies in their potential to reduce electronic waste. By extending device lifespans and eliminating or reducing the need for disposable batteries, these technologies directly address the growing global e-waste crisis. Current statistics indicate that only 20% of electronic waste is formally recycled, with the remainder contributing to landfill contamination and resource depletion. Micro energy harvesting solutions could significantly mitigate this impact by creating self-sustaining power systems.

Energy efficiency represents another critical environmental advantage. Traditional power generation and transmission systems experience substantial losses, whereas micro energy harvesters operate at the point of use, eliminating transmission losses. This localized generation model aligns with distributed energy principles, potentially reducing the carbon footprint associated with conventional power infrastructure.

Material sustainability presents both challenges and opportunities. Current micro energy harvesting technologies often utilize rare earth elements and specialized materials with complex supply chains and extraction impacts. Research into bio-compatible and biodegradable materials for harvesters shows promise for reducing these concerns. Recent innovations in organic piezoelectric materials and biopolymer-based triboelectric generators demonstrate progress toward more environmentally benign components.

Life cycle assessment (LCA) studies of micro energy harvesters reveal favorable environmental profiles compared to battery-powered alternatives. A comprehensive LCA comparing piezoelectric harvesters to lithium-ion batteries for wireless sensor applications demonstrated a 60% reduction in global warming potential over a five-year operational period. However, manufacturing processes for specialized harvester components remain energy-intensive, presenting opportunities for further optimization.

The circular economy potential of these technologies merits attention. Design approaches that facilitate end-of-life recovery and recycling of valuable materials from harvesters could establish closed-loop systems. Several manufacturers have begun implementing design-for-disassembly principles in their energy harvesting products, though industry-wide standards remain underdeveloped.

As wireless charging solutions incorporating micro energy harvesting become more prevalent, regulatory frameworks addressing their environmental impacts will need development. Current electronic product environmental regulations rarely account for the unique characteristics of energy harvesting technologies, creating potential regulatory gaps that could affect sustainable implementation.

The primary environmental benefit of micro energy harvesters lies in their potential to reduce electronic waste. By extending device lifespans and eliminating or reducing the need for disposable batteries, these technologies directly address the growing global e-waste crisis. Current statistics indicate that only 20% of electronic waste is formally recycled, with the remainder contributing to landfill contamination and resource depletion. Micro energy harvesting solutions could significantly mitigate this impact by creating self-sustaining power systems.

Energy efficiency represents another critical environmental advantage. Traditional power generation and transmission systems experience substantial losses, whereas micro energy harvesters operate at the point of use, eliminating transmission losses. This localized generation model aligns with distributed energy principles, potentially reducing the carbon footprint associated with conventional power infrastructure.

Material sustainability presents both challenges and opportunities. Current micro energy harvesting technologies often utilize rare earth elements and specialized materials with complex supply chains and extraction impacts. Research into bio-compatible and biodegradable materials for harvesters shows promise for reducing these concerns. Recent innovations in organic piezoelectric materials and biopolymer-based triboelectric generators demonstrate progress toward more environmentally benign components.

Life cycle assessment (LCA) studies of micro energy harvesters reveal favorable environmental profiles compared to battery-powered alternatives. A comprehensive LCA comparing piezoelectric harvesters to lithium-ion batteries for wireless sensor applications demonstrated a 60% reduction in global warming potential over a five-year operational period. However, manufacturing processes for specialized harvester components remain energy-intensive, presenting opportunities for further optimization.

The circular economy potential of these technologies merits attention. Design approaches that facilitate end-of-life recovery and recycling of valuable materials from harvesters could establish closed-loop systems. Several manufacturers have begun implementing design-for-disassembly principles in their energy harvesting products, though industry-wide standards remain underdeveloped.

As wireless charging solutions incorporating micro energy harvesting become more prevalent, regulatory frameworks addressing their environmental impacts will need development. Current electronic product environmental regulations rarely account for the unique characteristics of energy harvesting technologies, creating potential regulatory gaps that could affect sustainable implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!