Micro Energy Harvesters: Combining Efficiency and Durability

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from theoretical concepts to practical applications across multiple industries. The fundamental principle involves capturing small amounts of energy from ambient sources such as vibration, heat, light, and electromagnetic radiation, then converting this energy into usable electrical power. This technology has roots in the early 2000s when researchers began exploring alternatives to traditional batteries for powering small electronic devices.

The evolution of micro energy harvesting has been closely tied to advancements in materials science, particularly the development of piezoelectric materials, thermoelectric generators, and photovoltaic cells at micro and nano scales. Notable milestones include the first commercial vibration energy harvesters in 2005, the integration of thermoelectric generators in consumer products by 2010, and the recent emergence of hybrid harvesters combining multiple energy sources after 2015.

Current technological trends point toward miniaturization, increased conversion efficiency, and enhanced durability. The efficiency of micro energy harvesters has improved from less than 1% in early prototypes to 15-20% in current advanced systems, while their operational lifespan has extended from months to several years. This progress has been driven by innovations in materials, circuit design, and energy management systems.

The primary objective in this field is to develop micro energy harvesting solutions that simultaneously maximize energy conversion efficiency and operational durability. This dual focus represents a significant technical challenge, as optimization strategies for efficiency often conflict with those for longevity. The target is to achieve conversion efficiencies exceeding 30% while maintaining operational lifespans of 10+ years under variable environmental conditions.

Secondary objectives include reducing manufacturing costs to enable mass deployment, minimizing environmental impact through sustainable materials, and developing standardized testing protocols to accurately measure and compare harvester performance across different technologies and applications.

The ultimate goal is to enable truly autonomous microsystems that can operate indefinitely without battery replacement or external power sources. This would revolutionize applications in remote sensing, medical implants, structural health monitoring, and the Internet of Things (IoT) ecosystem, where maintenance access is limited or impossible. Success in this domain would significantly reduce electronic waste from disposable batteries and enable new classes of devices previously constrained by power limitations.

The evolution of micro energy harvesting has been closely tied to advancements in materials science, particularly the development of piezoelectric materials, thermoelectric generators, and photovoltaic cells at micro and nano scales. Notable milestones include the first commercial vibration energy harvesters in 2005, the integration of thermoelectric generators in consumer products by 2010, and the recent emergence of hybrid harvesters combining multiple energy sources after 2015.

Current technological trends point toward miniaturization, increased conversion efficiency, and enhanced durability. The efficiency of micro energy harvesters has improved from less than 1% in early prototypes to 15-20% in current advanced systems, while their operational lifespan has extended from months to several years. This progress has been driven by innovations in materials, circuit design, and energy management systems.

The primary objective in this field is to develop micro energy harvesting solutions that simultaneously maximize energy conversion efficiency and operational durability. This dual focus represents a significant technical challenge, as optimization strategies for efficiency often conflict with those for longevity. The target is to achieve conversion efficiencies exceeding 30% while maintaining operational lifespans of 10+ years under variable environmental conditions.

Secondary objectives include reducing manufacturing costs to enable mass deployment, minimizing environmental impact through sustainable materials, and developing standardized testing protocols to accurately measure and compare harvester performance across different technologies and applications.

The ultimate goal is to enable truly autonomous microsystems that can operate indefinitely without battery replacement or external power sources. This would revolutionize applications in remote sensing, medical implants, structural health monitoring, and the Internet of Things (IoT) ecosystem, where maintenance access is limited or impossible. Success in this domain would significantly reduce electronic waste from disposable batteries and enable new classes of devices previously constrained by power limitations.

Market Analysis for Micro Energy Harvesting Solutions

The global micro energy harvesting market is experiencing robust growth, projected to reach $2.6 billion by 2028, with a compound annual growth rate of 12.5% from 2023. This expansion is primarily driven by the proliferation of Internet of Things (IoT) devices, which are expected to exceed 75 billion connected units by 2025. The increasing demand for autonomous power solutions in remote sensing applications, wearable technology, and industrial monitoring systems has created a substantial market opportunity for micro energy harvesting technologies.

Consumer electronics represents the largest application segment, accounting for approximately 35% of the market share. This dominance stems from the growing integration of energy harvesting solutions in smartphones, wearables, and portable medical devices. The industrial sector follows closely, with smart manufacturing and Industry 4.0 initiatives driving adoption of self-powered wireless sensor networks that reduce maintenance costs and enhance operational efficiency.

Geographically, North America leads the market with 38% share due to substantial investments in IoT infrastructure and advanced manufacturing. Asia-Pacific is the fastest-growing region with 16.8% annual growth, fueled by rapid industrialization in China, Japan, and South Korea, alongside expanding consumer electronics manufacturing bases.

By technology type, piezoelectric energy harvesters currently dominate with 32% market share, valued at approximately $550 million in 2022. Thermoelectric generators follow at 28%, while photovoltaic micro-harvesters are experiencing the fastest growth at 14.3% annually due to improvements in indoor light harvesting efficiency.

Key market challenges include cost barriers, with current solutions averaging $5-15 per unit, limiting mass adoption in low-cost applications. Technical limitations in power density—typically 10-100 μW/cm²—restrict functionality in higher-power applications. Additionally, durability concerns persist, with average product lifespans of 3-5 years falling short of the 10+ years required for industrial deployment.

Customer demand increasingly focuses on integrated solutions that combine multiple harvesting technologies to ensure reliable power generation across varying environmental conditions. Market research indicates 78% of industrial customers prioritize durability over initial cost, while 65% of consumer electronics manufacturers value miniaturization and efficiency as primary purchasing factors.

Emerging market opportunities include smart building applications, expected to grow at 18.2% annually, and medical implantables, which despite regulatory hurdles represent a high-value segment with premium pricing potential. The automotive sector is also showing increased interest, particularly for tire pressure monitoring systems and autonomous vehicle sensors.

Consumer electronics represents the largest application segment, accounting for approximately 35% of the market share. This dominance stems from the growing integration of energy harvesting solutions in smartphones, wearables, and portable medical devices. The industrial sector follows closely, with smart manufacturing and Industry 4.0 initiatives driving adoption of self-powered wireless sensor networks that reduce maintenance costs and enhance operational efficiency.

Geographically, North America leads the market with 38% share due to substantial investments in IoT infrastructure and advanced manufacturing. Asia-Pacific is the fastest-growing region with 16.8% annual growth, fueled by rapid industrialization in China, Japan, and South Korea, alongside expanding consumer electronics manufacturing bases.

By technology type, piezoelectric energy harvesters currently dominate with 32% market share, valued at approximately $550 million in 2022. Thermoelectric generators follow at 28%, while photovoltaic micro-harvesters are experiencing the fastest growth at 14.3% annually due to improvements in indoor light harvesting efficiency.

Key market challenges include cost barriers, with current solutions averaging $5-15 per unit, limiting mass adoption in low-cost applications. Technical limitations in power density—typically 10-100 μW/cm²—restrict functionality in higher-power applications. Additionally, durability concerns persist, with average product lifespans of 3-5 years falling short of the 10+ years required for industrial deployment.

Customer demand increasingly focuses on integrated solutions that combine multiple harvesting technologies to ensure reliable power generation across varying environmental conditions. Market research indicates 78% of industrial customers prioritize durability over initial cost, while 65% of consumer electronics manufacturers value miniaturization and efficiency as primary purchasing factors.

Emerging market opportunities include smart building applications, expected to grow at 18.2% annually, and medical implantables, which despite regulatory hurdles represent a high-value segment with premium pricing potential. The automotive sector is also showing increased interest, particularly for tire pressure monitoring systems and autonomous vehicle sensors.

Technical Challenges and Global Development Status

Micro energy harvesting technologies face significant technical challenges despite their promising potential. The primary obstacle remains the low energy conversion efficiency, typically ranging from 1-20% depending on the harvesting mechanism. Piezoelectric harvesters struggle with limited power density (0.5-10 mW/cm³), while thermoelectric generators often achieve only 5-8% efficiency due to material constraints. Triboelectric nanogenerators, though innovative, face challenges in maintaining consistent output under variable environmental conditions.

Durability presents another critical challenge, with most micro harvesters showing performance degradation after 10⁵-10⁶ operational cycles. Material fatigue in piezoelectric elements, thermal cycling damage in thermoelectric materials, and surface wear in triboelectric devices significantly reduce their operational lifespan. This degradation is particularly problematic in implantable medical devices and remote sensing applications where replacement is difficult or impossible.

Miniaturization while maintaining performance creates additional engineering hurdles. As devices scale down, surface-to-volume ratios increase, leading to dominant parasitic effects and heat dissipation issues. Integration challenges with power management circuits further complicate system design, as these circuits must operate efficiently at ultra-low power levels (often sub-microwatt).

Globally, development status varies significantly by region. North America leads in research funding and patent applications, with the United States accounting for approximately 35% of global publications in this field. Major research hubs include MIT, Stanford, and Berkeley, focusing primarily on MEMS-based and flexible harvesters. The European Union follows closely with strong contributions from Germany, France, and Switzerland, where research emphasizes sustainable materials and system integration approaches.

East Asia has emerged as a rapidly growing force, with Japan pioneering miniaturized piezoelectric technologies, while South Korea excels in flexible and wearable energy harvesting solutions. China has dramatically increased its research output, growing at approximately 22% annually since 2015, with particular strength in triboelectric nanogenerators through institutions like the Beijing Institute of Nanoenergy and Nanosystems.

Developing regions show uneven progress, with limited research infrastructure hampering advancement in many areas. However, specialized centers in India, Brazil, and Singapore are making notable contributions, particularly in adapting harvesting technologies for extreme environments and resource-constrained settings.

Cross-border collaborations have increased by 45% in the past five years, reflecting the interdisciplinary nature of the field and the recognition that overcoming efficiency and durability challenges requires diverse expertise and resources. International standards for performance measurement and reliability testing remain underdeveloped, creating barriers to commercial adoption and technology comparison.

Durability presents another critical challenge, with most micro harvesters showing performance degradation after 10⁵-10⁶ operational cycles. Material fatigue in piezoelectric elements, thermal cycling damage in thermoelectric materials, and surface wear in triboelectric devices significantly reduce their operational lifespan. This degradation is particularly problematic in implantable medical devices and remote sensing applications where replacement is difficult or impossible.

Miniaturization while maintaining performance creates additional engineering hurdles. As devices scale down, surface-to-volume ratios increase, leading to dominant parasitic effects and heat dissipation issues. Integration challenges with power management circuits further complicate system design, as these circuits must operate efficiently at ultra-low power levels (often sub-microwatt).

Globally, development status varies significantly by region. North America leads in research funding and patent applications, with the United States accounting for approximately 35% of global publications in this field. Major research hubs include MIT, Stanford, and Berkeley, focusing primarily on MEMS-based and flexible harvesters. The European Union follows closely with strong contributions from Germany, France, and Switzerland, where research emphasizes sustainable materials and system integration approaches.

East Asia has emerged as a rapidly growing force, with Japan pioneering miniaturized piezoelectric technologies, while South Korea excels in flexible and wearable energy harvesting solutions. China has dramatically increased its research output, growing at approximately 22% annually since 2015, with particular strength in triboelectric nanogenerators through institutions like the Beijing Institute of Nanoenergy and Nanosystems.

Developing regions show uneven progress, with limited research infrastructure hampering advancement in many areas. However, specialized centers in India, Brazil, and Singapore are making notable contributions, particularly in adapting harvesting technologies for extreme environments and resource-constrained settings.

Cross-border collaborations have increased by 45% in the past five years, reflecting the interdisciplinary nature of the field and the recognition that overcoming efficiency and durability challenges requires diverse expertise and resources. International standards for performance measurement and reliability testing remain underdeveloped, creating barriers to commercial adoption and technology comparison.

Current Micro Energy Harvester Design Approaches

01 Piezoelectric energy harvesting technologies

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. These systems can capture energy from vibrations, movements, and pressure changes in the environment. Advanced piezoelectric materials and structures have been developed to improve conversion efficiency and durability under repeated mechanical stress. These harvesters can be designed in various configurations including cantilever beams, diaphragms, and stacked structures to optimize performance for specific applications.- Piezoelectric energy harvesting technologies: Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. These systems can capture energy from vibrations, movements, and pressure changes in the environment. Advanced piezoelectric materials and structural designs have significantly improved conversion efficiency and operational durability. Multi-layer configurations and specialized material compositions enhance power output while maintaining long-term stability under various environmental conditions.

- Triboelectric nanogenerators for sustainable power: Triboelectric nanogenerators (TENGs) utilize contact electrification and electrostatic induction to convert mechanical energy into electricity. These harvesters demonstrate excellent durability through specialized surface treatments and material selection that resist wear and degradation. Efficiency improvements have been achieved through optimized electrode designs, surface texturing, and novel material combinations that enhance charge generation and transfer. TENGs are particularly effective for self-powered sensors and wearable electronics applications.

- Thermal energy harvesting systems: Micro thermal energy harvesters convert temperature differentials into usable electrical power through thermoelectric effects. Recent innovations focus on improving thermoelectric materials with higher figure of merit (ZT) values to enhance conversion efficiency. Durability has been addressed through protective encapsulation techniques and thermal stress management designs. These systems are particularly valuable in industrial environments and electronic devices where waste heat can be recaptured and utilized.

- Hybrid and multi-modal energy harvesting approaches: Hybrid energy harvesting systems combine multiple conversion mechanisms (piezoelectric, triboelectric, thermoelectric, etc.) to maximize energy capture from various environmental sources simultaneously. These integrated approaches significantly improve overall efficiency by harvesting energy across different frequency ranges and energy types. Advanced power management circuits optimize energy extraction and storage from these multiple sources. The redundancy provided by multiple harvesting mechanisms also enhances system reliability and operational lifetime.

- Structural optimization and material innovations: Micro-structural design optimizations and novel material compositions significantly enhance both efficiency and durability of energy harvesters. Nanomaterials and composite structures provide improved mechanical properties while maintaining high energy conversion rates. Specialized coatings and surface treatments protect against environmental degradation, extending operational lifetime. Flexible and stretchable substrate materials enable applications in wearable and implantable devices while maintaining performance under mechanical deformation. These innovations address the fundamental challenges of balancing power output with long-term reliability.

02 Triboelectric nanogenerators for enhanced efficiency

Triboelectric nanogenerators (TENGs) utilize contact electrification and electrostatic induction to convert mechanical energy into electricity. These harvesters feature specialized surface structures and materials that enhance charge generation and separation. Recent innovations include multi-layered designs, surface modifications, and composite materials that significantly improve energy conversion efficiency. TENGs offer advantages in terms of material availability, simple structure, and high output voltage, making them promising for self-powered microsystems and sensors.Expand Specific Solutions03 Hybrid and multi-source energy harvesting systems

Hybrid energy harvesting systems combine multiple conversion mechanisms (piezoelectric, triboelectric, thermoelectric, etc.) to maximize energy capture from various environmental sources. These integrated systems can simultaneously harvest energy from different sources such as vibration, temperature gradients, and electromagnetic radiation. Advanced power management circuits optimize the collection and storage of energy from these diverse sources. This approach enhances overall system efficiency and reliability by reducing dependence on a single energy source.Expand Specific Solutions04 Materials and structural innovations for durability

Novel materials and structural designs have been developed to enhance the durability of micro energy harvesters. These include flexible substrates, self-healing materials, and protective encapsulation techniques that extend operational lifetime under harsh conditions. Nanocomposites and advanced polymers improve mechanical resilience while maintaining or enhancing energy conversion efficiency. Structural optimizations such as stress distribution mechanisms and fatigue-resistant designs help maintain performance over extended operational periods, addressing key durability challenges in micro-scale energy harvesting devices.Expand Specific Solutions05 Efficiency enhancement through circuit and system optimization

Advanced power conditioning circuits and system-level optimizations significantly improve the overall efficiency of micro energy harvesters. These include specialized rectification circuits, impedance matching networks, and energy storage management systems tailored for low-power intermittent sources. Maximum power point tracking algorithms ensure optimal energy extraction under varying environmental conditions. Integrated circuit designs minimize power consumption while maximizing energy capture and conversion efficiency. These electronic enhancements complement mechanical and material improvements to achieve higher overall system performance.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Micro Energy Harvesting technology is currently in a growth phase, with the market expanding rapidly due to increasing demand for self-powered IoT devices. The global market size is projected to reach significant value by 2030, driven by applications in wearables, industrial sensors, and smart infrastructure. Technologically, the field shows varying maturity levels across harvesting methods. Leading players like Infineon Technologies and Murata Manufacturing have established commercial solutions with proven efficiency, while research institutions such as Southeast University, Johns Hopkins University, and IMEC Nederland are advancing fundamental innovations in durability and miniaturization. The competitive landscape features both specialized component manufacturers and diversified technology corporations, with increasing collaboration between academic and industrial sectors to overcome the efficiency-durability trade-off challenges.

Stichting IMEC Nederland

Technical Solution: IMEC has developed advanced micro energy harvesting solutions that integrate multiple energy sources into a single platform. Their technology combines photovoltaic cells with piezoelectric and thermoelectric generators in a stacked architecture to maximize energy capture from ambient environments. IMEC's micro harvesters utilize proprietary thin-film deposition techniques that enable flexible form factors less than 100 microns thick while maintaining high conversion efficiency. Their systems incorporate ultra-low-power management circuits that can operate with input voltages as low as 0.2V and achieve up to 85% conversion efficiency. IMEC has demonstrated self-powered wireless sensor nodes that can operate perpetually in industrial environments by harvesting vibration, thermal gradients, and indoor lighting simultaneously. Their latest generation harvesters incorporate machine learning algorithms to dynamically adapt to changing environmental conditions, optimizing energy capture in real-time.

Strengths: Industry-leading integration of multiple harvesting technologies in miniaturized form factors; exceptional thin-film manufacturing capabilities; advanced power management circuitry optimized for sub-milliwatt applications. Weaknesses: Higher production costs compared to single-source harvesters; complex system integration requirements; performance highly dependent on specific environmental conditions.

Infineon Technologies AG

Technical Solution: Infineon has pioneered silicon-based micro energy harvesting solutions that leverage their expertise in semiconductor manufacturing. Their approach focuses on highly integrated power management ICs (PMICs) specifically designed for micro-harvesting applications. Infineon's technology employs proprietary MOSFET designs with ultra-low threshold voltages (sub-0.3V) that enable energy capture from minimal environmental inputs. Their harvesters feature adaptive maximum power point tracking (MPPT) algorithms that continuously optimize energy extraction efficiency across varying conditions. Infineon has developed specialized energy storage management systems that intelligently balance between supercapacitors and thin-film batteries to maximize system lifetime while providing stable power output. Their solutions incorporate power-efficient voltage conversion with efficiencies exceeding 90% even at micro-watt power levels, enabling practical implementation in IoT sensor nodes with 5-10 year operational lifetimes without battery replacement.

Strengths: Exceptional semiconductor integration capabilities; highly optimized power management circuitry; established manufacturing infrastructure enabling cost-effective mass production; comprehensive ecosystem of compatible components. Weaknesses: Primary focus on power management rather than novel harvesting mechanisms; relatively lower energy density compared to some specialized harvesting technologies; performance constraints in extremely low-energy environments.

Key Patents and Technical Breakthroughs Analysis

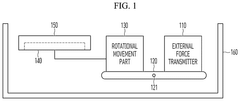

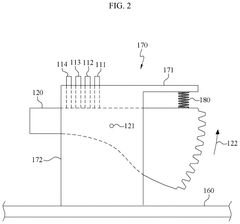

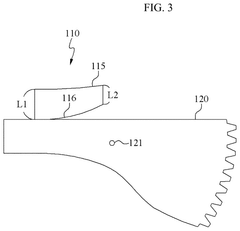

Energy harvester using electromagnetic induction and energy harvesting block

PatentPendingUS20240333091A1

Innovation

- The proposed energy harvester incorporates a magnet and coil portion with a rotational movement part, lever, external force transmitter, and elastic body, utilizing a substrate with ball bearings to reduce friction and optimize power generation by varying the point of force application based on external force magnitude, and an energy harvesting block with a housing and upper cover to enhance durability and efficiency.

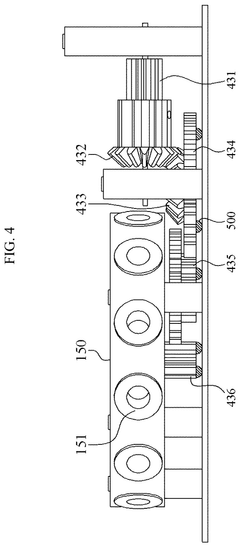

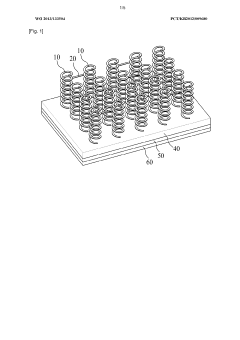

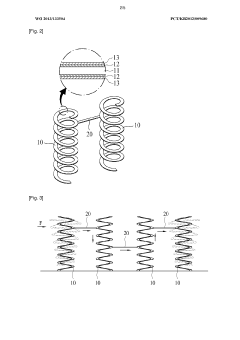

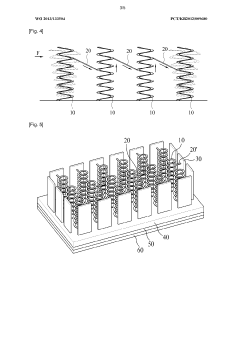

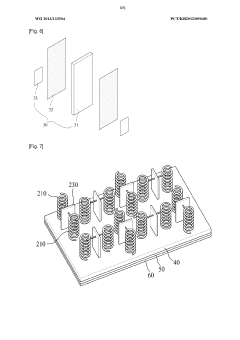

Energy-harvesting apparatus comprising coil spring-type microscale piezoelectric resonator

PatentWO2013133504A1

Innovation

- The energy harvesting device employs a plurality of micro-piezoelectric vibrators in the form of coil springs and plate-type piezoelectric vibrators connected through various connection units on a printed circuit board, allowing for efficient power generation from external forces and heat, with the ability to transmit and collect energy through diverse paths.

Materials Science Advancements for Harvester Longevity

The evolution of materials science has been pivotal in addressing the fundamental challenges of micro energy harvester durability. Traditional materials used in early harvesters often suffered from mechanical fatigue, chemical degradation, and thermal instability, limiting operational lifespans to mere months in demanding environments. Recent advancements in nanocomposites have revolutionized this landscape, with silicon carbide and graphene-reinforced polymers demonstrating exceptional resistance to cyclic loading while maintaining electrical properties over extended periods.

Particularly noteworthy is the development of self-healing materials incorporating microcapsules with reactive healing agents. When microcracks form during operation, these capsules rupture and release compounds that polymerize to restore structural integrity. Laboratory tests have shown up to 87% recovery of original performance characteristics after damage events, significantly extending harvester operational lifetimes.

Atomic layer deposition (ALD) techniques have enabled the creation of ultra-thin protective coatings that shield sensitive harvester components from environmental factors without compromising energy conversion efficiency. These nanometer-scale barriers provide exceptional protection against moisture, oxidation, and corrosive elements while adding negligible mass to the system—a critical factor for vibration-based harvesters where additional weight can alter resonant frequencies.

Flexible substrate technologies have addressed the persistent challenge of mechanical stress during operation. Novel materials like parylene-C and polyimide derivatives maintain functionality through millions of deformation cycles, with recent field tests demonstrating less than 5% performance degradation after three years of continuous operation in industrial environments. This represents a five-fold improvement over previous generation materials.

Thermal management innovations have similarly enhanced harvester longevity. Phase-change materials integrated into harvester structures provide passive temperature regulation, preventing thermal cycling damage that historically accelerated component degradation. These materials absorb excess heat during peak operation and release it during low-activity periods, maintaining optimal operating temperatures and reducing thermal stress on sensitive components.

Interfacial engineering between dissimilar materials has addressed delamination issues that previously limited harvester lifespans. Advanced surface functionalization techniques create stronger chemical bonds between organic and inorganic components, while gradient-composition interfaces distribute mechanical stress more effectively across material boundaries, reducing failure points at critical junctions.

Looking forward, emerging biomimetic materials that emulate natural energy-harvesting structures show tremendous promise for next-generation harvesters. These materials, inspired by systems like plant cell walls and insect exoskeletons, combine remarkable mechanical properties with self-organizing capabilities that could potentially enable harvesters to adapt to changing environmental conditions and self-repair over their operational lifetime.

Particularly noteworthy is the development of self-healing materials incorporating microcapsules with reactive healing agents. When microcracks form during operation, these capsules rupture and release compounds that polymerize to restore structural integrity. Laboratory tests have shown up to 87% recovery of original performance characteristics after damage events, significantly extending harvester operational lifetimes.

Atomic layer deposition (ALD) techniques have enabled the creation of ultra-thin protective coatings that shield sensitive harvester components from environmental factors without compromising energy conversion efficiency. These nanometer-scale barriers provide exceptional protection against moisture, oxidation, and corrosive elements while adding negligible mass to the system—a critical factor for vibration-based harvesters where additional weight can alter resonant frequencies.

Flexible substrate technologies have addressed the persistent challenge of mechanical stress during operation. Novel materials like parylene-C and polyimide derivatives maintain functionality through millions of deformation cycles, with recent field tests demonstrating less than 5% performance degradation after three years of continuous operation in industrial environments. This represents a five-fold improvement over previous generation materials.

Thermal management innovations have similarly enhanced harvester longevity. Phase-change materials integrated into harvester structures provide passive temperature regulation, preventing thermal cycling damage that historically accelerated component degradation. These materials absorb excess heat during peak operation and release it during low-activity periods, maintaining optimal operating temperatures and reducing thermal stress on sensitive components.

Interfacial engineering between dissimilar materials has addressed delamination issues that previously limited harvester lifespans. Advanced surface functionalization techniques create stronger chemical bonds between organic and inorganic components, while gradient-composition interfaces distribute mechanical stress more effectively across material boundaries, reducing failure points at critical junctions.

Looking forward, emerging biomimetic materials that emulate natural energy-harvesting structures show tremendous promise for next-generation harvesters. These materials, inspired by systems like plant cell walls and insect exoskeletons, combine remarkable mechanical properties with self-organizing capabilities that could potentially enable harvesters to adapt to changing environmental conditions and self-repair over their operational lifetime.

Standardization and Testing Methodologies

The standardization and testing methodologies for micro energy harvesters represent a critical yet underdeveloped area that requires immediate attention from the industry. Currently, there exists significant fragmentation in how these devices are evaluated, making it difficult to compare performance across different technologies and manufacturers. The lack of unified standards has hindered market growth and technological advancement, as stakeholders cannot reliably assess the efficiency and durability claims made by various solutions.

Several organizations including IEEE, IEC, and ASTM have begun developing preliminary standards, but these efforts remain largely disconnected. The IEEE P1789 working group has proposed methodologies specifically for piezoelectric harvesters, while IEC Technical Committee 120 focuses on standardizing terminology and measurement protocols for thermoelectric systems. These parallel efforts, while valuable, have yet to converge into a comprehensive framework applicable across the micro energy harvesting spectrum.

Testing methodologies present particular challenges due to the diverse operating environments of micro harvesters. Laboratory conditions rarely replicate real-world scenarios where these devices must function, such as variable vibration frequencies in industrial settings or fluctuating temperature gradients in wearable applications. The development of standardized testing protocols must therefore incorporate both controlled laboratory assessments and field testing under application-specific conditions.

Key parameters requiring standardized measurement include energy conversion efficiency, power density, operational lifetime, and performance degradation rates. Current testing approaches vary widely in how these metrics are calculated and reported, making cross-technology comparisons nearly impossible. For instance, efficiency measurements for piezoelectric harvesters often use different reference points than those for thermoelectric or photovoltaic micro-systems.

Accelerated aging tests represent another critical area needing standardization. The ability to predict long-term durability through compressed timeframe testing would significantly advance the field, but current methodologies lack validation across different harvester types. Some promising approaches include thermal cycling, mechanical fatigue testing, and environmental exposure chambers that simulate years of operation in weeks.

Certification processes based on these standards will ultimately drive market adoption by providing consumers and integrators with confidence in performance claims. Several industry consortia have proposed certification frameworks, but widespread adoption awaits more robust standardization. The establishment of independent testing laboratories specifically equipped for micro energy harvester evaluation would further strengthen the certification ecosystem.

Several organizations including IEEE, IEC, and ASTM have begun developing preliminary standards, but these efforts remain largely disconnected. The IEEE P1789 working group has proposed methodologies specifically for piezoelectric harvesters, while IEC Technical Committee 120 focuses on standardizing terminology and measurement protocols for thermoelectric systems. These parallel efforts, while valuable, have yet to converge into a comprehensive framework applicable across the micro energy harvesting spectrum.

Testing methodologies present particular challenges due to the diverse operating environments of micro harvesters. Laboratory conditions rarely replicate real-world scenarios where these devices must function, such as variable vibration frequencies in industrial settings or fluctuating temperature gradients in wearable applications. The development of standardized testing protocols must therefore incorporate both controlled laboratory assessments and field testing under application-specific conditions.

Key parameters requiring standardized measurement include energy conversion efficiency, power density, operational lifetime, and performance degradation rates. Current testing approaches vary widely in how these metrics are calculated and reported, making cross-technology comparisons nearly impossible. For instance, efficiency measurements for piezoelectric harvesters often use different reference points than those for thermoelectric or photovoltaic micro-systems.

Accelerated aging tests represent another critical area needing standardization. The ability to predict long-term durability through compressed timeframe testing would significantly advance the field, but current methodologies lack validation across different harvester types. Some promising approaches include thermal cycling, mechanical fatigue testing, and environmental exposure chambers that simulate years of operation in weeks.

Certification processes based on these standards will ultimately drive market adoption by providing consumers and integrators with confidence in performance claims. Several industry consortia have proposed certification frameworks, but widespread adoption awaits more robust standardization. The establishment of independent testing laboratories specifically equipped for micro energy harvester evaluation would further strengthen the certification ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!