Micro Energy Harvesters and the Future of Personal Electronics

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Technology Evolution and Objectives

Micro energy harvesting technology has evolved significantly over the past two decades, transforming from theoretical concepts to practical applications that power small electronic devices. The journey began in the early 2000s with rudimentary piezoelectric harvesters capable of generating only microwatts of power under specific conditions. By 2010, researchers had expanded the energy harvesting spectrum to include thermoelectric, photovoltaic, and electromagnetic mechanisms, marking a critical diversification in the field.

The evolution accelerated between 2010-2015 when efficiency breakthroughs allowed harvesters to generate power in the milliwatt range, enabling practical applications in low-power sensors and simple wearable devices. This period saw the first commercial implementations of energy harvesting technologies in consumer products, primarily in watches and simple health monitors.

From 2015-2020, integration capabilities improved dramatically, with multi-modal harvesters combining different energy sources to provide more consistent power output. Material science innovations, particularly in flexible and stretchable substrates, enabled better conformity to human body contours and everyday objects, significantly expanding application possibilities.

The current technological landscape (2020-present) features advanced nanoscale harvesters with dramatically improved power density, approaching 1-10 mW/cm³ for some technologies. Machine learning algorithms now optimize energy capture and storage in real-time, adapting to changing environmental conditions and user behaviors.

Looking forward, the primary objectives for micro energy harvesting technology development include achieving energy autonomy for personal electronic devices, eliminating the need for traditional battery charging. This requires improving conversion efficiency to exceed 30% across all harvesting modalities and developing ultra-low-power electronics that can operate reliably on harvested energy alone.

Another critical objective is miniaturization without performance compromise, targeting harvesters smaller than 1mm³ while maintaining current power outputs. Seamless integration with existing and emerging personal electronics platforms represents another key goal, requiring standardized interfaces and plug-and-play compatibility.

The field also aims to develop environmentally sustainable harvesting technologies using non-toxic, biodegradable materials to align with global sustainability initiatives. Finally, researchers are working toward creating adaptive harvesting systems that can intelligently switch between energy sources based on availability and demand, ensuring consistent power delivery regardless of environmental conditions.

The evolution accelerated between 2010-2015 when efficiency breakthroughs allowed harvesters to generate power in the milliwatt range, enabling practical applications in low-power sensors and simple wearable devices. This period saw the first commercial implementations of energy harvesting technologies in consumer products, primarily in watches and simple health monitors.

From 2015-2020, integration capabilities improved dramatically, with multi-modal harvesters combining different energy sources to provide more consistent power output. Material science innovations, particularly in flexible and stretchable substrates, enabled better conformity to human body contours and everyday objects, significantly expanding application possibilities.

The current technological landscape (2020-present) features advanced nanoscale harvesters with dramatically improved power density, approaching 1-10 mW/cm³ for some technologies. Machine learning algorithms now optimize energy capture and storage in real-time, adapting to changing environmental conditions and user behaviors.

Looking forward, the primary objectives for micro energy harvesting technology development include achieving energy autonomy for personal electronic devices, eliminating the need for traditional battery charging. This requires improving conversion efficiency to exceed 30% across all harvesting modalities and developing ultra-low-power electronics that can operate reliably on harvested energy alone.

Another critical objective is miniaturization without performance compromise, targeting harvesters smaller than 1mm³ while maintaining current power outputs. Seamless integration with existing and emerging personal electronics platforms represents another key goal, requiring standardized interfaces and plug-and-play compatibility.

The field also aims to develop environmentally sustainable harvesting technologies using non-toxic, biodegradable materials to align with global sustainability initiatives. Finally, researchers are working toward creating adaptive harvesting systems that can intelligently switch between energy sources based on availability and demand, ensuring consistent power delivery regardless of environmental conditions.

Market Demand Analysis for Self-Powered Personal Electronics

The global market for self-powered personal electronics is experiencing unprecedented growth, driven by increasing consumer demand for portable, sustainable, and maintenance-free devices. Current market research indicates that the wearable technology sector alone is projected to reach $265 billion by 2026, with energy-autonomous devices representing a rapidly expanding segment within this market. This growth trajectory is supported by the proliferation of Internet of Things (IoT) devices, which are expected to number over 75 billion connected devices worldwide by 2025.

Consumer preferences are shifting dramatically toward devices that eliminate the need for regular charging or battery replacement. A recent industry survey revealed that 78% of smartphone users cite battery life as their primary concern when purchasing new devices, while 64% express interest in self-charging capabilities. This represents a significant market opportunity for micro energy harvesting technologies that can extend or eliminate traditional charging requirements.

Healthcare applications represent a particularly promising market segment for self-powered electronics. The global medical wearables market is growing at a compound annual growth rate of 26.4%, with particular demand for continuous health monitoring devices that can operate without frequent battery changes. Implantable medical devices, which require long-term reliable power sources, constitute another high-value application area where micro energy harvesters could revolutionize patient care by eliminating risky battery replacement surgeries.

The consumer electronics industry is increasingly focused on sustainability, with major manufacturers committing to reducing electronic waste and carbon footprints. Self-powered devices align perfectly with these environmental initiatives by reducing battery waste and energy consumption. Market analysis shows that 72% of millennials and Gen Z consumers are willing to pay premium prices for sustainable technology products, creating a receptive market for energy harvesting innovations.

Regional market analysis reveals varying adoption patterns, with North America and Europe currently leading in terms of market value, while Asia-Pacific regions show the highest growth rates. China, in particular, is emerging as both a major consumer market and production hub for self-powered electronics, supported by substantial government investments in renewable energy technologies and advanced manufacturing capabilities.

Industry forecasts suggest that the initial market penetration will occur in high-value niches such as military applications, premium consumer wearables, and medical devices, before expanding to mass-market consumer electronics. The price sensitivity threshold appears to be decreasing as production scales up, with consumers increasingly willing to accept higher upfront costs for devices that offer long-term savings through eliminated charging needs and extended product lifespans.

Consumer preferences are shifting dramatically toward devices that eliminate the need for regular charging or battery replacement. A recent industry survey revealed that 78% of smartphone users cite battery life as their primary concern when purchasing new devices, while 64% express interest in self-charging capabilities. This represents a significant market opportunity for micro energy harvesting technologies that can extend or eliminate traditional charging requirements.

Healthcare applications represent a particularly promising market segment for self-powered electronics. The global medical wearables market is growing at a compound annual growth rate of 26.4%, with particular demand for continuous health monitoring devices that can operate without frequent battery changes. Implantable medical devices, which require long-term reliable power sources, constitute another high-value application area where micro energy harvesters could revolutionize patient care by eliminating risky battery replacement surgeries.

The consumer electronics industry is increasingly focused on sustainability, with major manufacturers committing to reducing electronic waste and carbon footprints. Self-powered devices align perfectly with these environmental initiatives by reducing battery waste and energy consumption. Market analysis shows that 72% of millennials and Gen Z consumers are willing to pay premium prices for sustainable technology products, creating a receptive market for energy harvesting innovations.

Regional market analysis reveals varying adoption patterns, with North America and Europe currently leading in terms of market value, while Asia-Pacific regions show the highest growth rates. China, in particular, is emerging as both a major consumer market and production hub for self-powered electronics, supported by substantial government investments in renewable energy technologies and advanced manufacturing capabilities.

Industry forecasts suggest that the initial market penetration will occur in high-value niches such as military applications, premium consumer wearables, and medical devices, before expanding to mass-market consumer electronics. The price sensitivity threshold appears to be decreasing as production scales up, with consumers increasingly willing to accept higher upfront costs for devices that offer long-term savings through eliminated charging needs and extended product lifespans.

Current State and Challenges in Micro Energy Harvesting

Micro energy harvesting technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia making substantial contributions. The current landscape reveals a diverse ecosystem of harvesting methods including piezoelectric, thermoelectric, photovoltaic, triboelectric, and RF energy harvesting technologies, each at varying levels of technological readiness.

Piezoelectric energy harvesters have demonstrated commercial viability in specific applications, achieving power densities of 10-100 μW/cm³ under optimal conditions. However, they face challenges in maintaining consistent output under variable mechanical stimuli and suffer from relatively low conversion efficiencies, typically below 20%.

Thermoelectric generators (TEGs) have reached maturity in specialized markets, with commercially available solutions providing 10-50 μW/cm² at temperature differentials of 5-10°C. The primary limitation remains their low conversion efficiency (typically 5-8%) and the requirement for consistent temperature gradients, which are often unpredictable in wearable applications.

Photovoltaic micro-harvesters represent the most mature technology, with indoor PV cells achieving efficiencies of 15-25% under artificial lighting conditions. Their primary challenge lies in the inconsistent availability of light sources, particularly for body-worn devices that may be frequently covered or in low-light environments.

Triboelectric nanogenerators (TENGs) have emerged as promising candidates for wearable applications, demonstrating power densities of 5-50 μW/cm² in laboratory settings. However, they face significant challenges in durability, with performance degradation occurring after repeated mechanical cycles, and output standardization remains problematic.

RF energy harvesting systems can extract power from ambient electromagnetic fields but typically deliver only 0.1-1 μW/cm² in urban environments, insufficient for many practical applications without significant advances in ultra-low-power electronics.

The integration of these technologies into practical personal electronic devices faces several critical challenges. Miniaturization remains a significant hurdle, as efficiency typically decreases with reduced harvester size. Current micro-harvesters struggle to maintain performance when scaled below 1 cm³, limiting their integration into increasingly compact wearable devices.

Energy storage integration presents another major challenge, as the intermittent nature of harvested energy requires efficient storage solutions. Current micro-batteries and supercapacitors often exceed the size of the harvesters themselves, creating a system-level size constraint.

Additionally, manufacturing scalability presents significant obstacles. Many promising micro-harvesting technologies demonstrate impressive results in laboratory settings but utilize fabrication processes incompatible with high-volume, low-cost production methods required for consumer electronics. This manufacturing gap has slowed commercial adoption despite promising research results.

Piezoelectric energy harvesters have demonstrated commercial viability in specific applications, achieving power densities of 10-100 μW/cm³ under optimal conditions. However, they face challenges in maintaining consistent output under variable mechanical stimuli and suffer from relatively low conversion efficiencies, typically below 20%.

Thermoelectric generators (TEGs) have reached maturity in specialized markets, with commercially available solutions providing 10-50 μW/cm² at temperature differentials of 5-10°C. The primary limitation remains their low conversion efficiency (typically 5-8%) and the requirement for consistent temperature gradients, which are often unpredictable in wearable applications.

Photovoltaic micro-harvesters represent the most mature technology, with indoor PV cells achieving efficiencies of 15-25% under artificial lighting conditions. Their primary challenge lies in the inconsistent availability of light sources, particularly for body-worn devices that may be frequently covered or in low-light environments.

Triboelectric nanogenerators (TENGs) have emerged as promising candidates for wearable applications, demonstrating power densities of 5-50 μW/cm² in laboratory settings. However, they face significant challenges in durability, with performance degradation occurring after repeated mechanical cycles, and output standardization remains problematic.

RF energy harvesting systems can extract power from ambient electromagnetic fields but typically deliver only 0.1-1 μW/cm² in urban environments, insufficient for many practical applications without significant advances in ultra-low-power electronics.

The integration of these technologies into practical personal electronic devices faces several critical challenges. Miniaturization remains a significant hurdle, as efficiency typically decreases with reduced harvester size. Current micro-harvesters struggle to maintain performance when scaled below 1 cm³, limiting their integration into increasingly compact wearable devices.

Energy storage integration presents another major challenge, as the intermittent nature of harvested energy requires efficient storage solutions. Current micro-batteries and supercapacitors often exceed the size of the harvesters themselves, creating a system-level size constraint.

Additionally, manufacturing scalability presents significant obstacles. Many promising micro-harvesting technologies demonstrate impressive results in laboratory settings but utilize fabrication processes incompatible with high-volume, low-cost production methods required for consumer electronics. This manufacturing gap has slowed commercial adoption despite promising research results.

Current Technical Solutions for Micro-Scale Energy Capture

01 Piezoelectric micro energy harvesters

Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stress in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. These harvesters are particularly useful in applications where regular battery replacement is difficult or impractical.- Piezoelectric micro energy harvesters: Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesting applications. These harvesters can capture energy from vibrations, movements, and pressure changes in the environment. The technology typically uses thin films or nanostructures of piezoelectric materials such as PZT, ZnO, or AlN that generate electrical charges when deformed. These systems can be optimized for specific frequency ranges and can be integrated into wearable devices, structural health monitoring systems, and IoT sensors.

- Triboelectric nanogenerators for energy harvesting: Triboelectric nanogenerators (TENGs) harvest energy through contact electrification and electrostatic induction when two materials with different electron affinities come into contact and separate. These devices can convert various mechanical energies like human motion, vibration, wind, and water flow into electricity. TENGs typically consist of two thin films with different triboelectric properties, electrodes, and an air gap or spacer. Their advantages include simple structure, low cost, high efficiency at low frequencies, and compatibility with flexible substrates, making them suitable for self-powered sensors and wearable electronics.

- Electromagnetic micro energy harvesting systems: Electromagnetic micro energy harvesters generate electricity based on Faraday's law of electromagnetic induction. These systems typically consist of magnets and coils arranged so that relative motion between them induces current in the coils. The designs can include suspended magnets with surrounding coils or moving coils with fixed magnets. These harvesters are particularly effective for converting low-frequency vibrations into usable electrical energy. Applications include self-powered wireless sensor networks, condition monitoring systems, and infrastructure health monitoring where ambient vibrations are present.

- Thermoelectric micro energy harvesters: Thermoelectric micro energy harvesters convert temperature differences into electrical energy using the Seebeck effect. These devices consist of arrays of thermoelectric materials connected electrically in series and thermally in parallel. When a temperature gradient exists across the device, charge carriers diffuse from the hot side to the cold side, generating a voltage. Miniaturized thermoelectric generators can harvest energy from body heat, industrial waste heat, or environmental temperature differences. Recent advances focus on improving efficiency through novel materials, nanostructuring, and optimized thermal management.

- Hybrid and multi-source micro energy harvesting technologies: Hybrid micro energy harvesters combine multiple energy harvesting mechanisms to improve efficiency and reliability. These systems can simultaneously or selectively harvest energy from different sources such as vibration, thermal gradients, solar radiation, and RF signals. By integrating complementary harvesting technologies, these systems can operate across diverse environmental conditions and provide more consistent power output. Advanced designs incorporate power management circuits that can efficiently extract energy from multiple sources with different characteristics and combine them to power microelectronic devices or charge energy storage components.

02 Electromagnetic micro energy harvesting systems

Electromagnetic micro energy harvesters generate electricity through electromagnetic induction when there is relative motion between a conductor and a magnetic field. These systems typically consist of a magnet and a coil arrangement that converts kinetic energy from vibrations or movements into electrical energy. They are effective for harvesting energy from low-frequency vibrations and can be designed in various configurations to optimize power output based on the specific application environment.Expand Specific Solutions03 Thermal energy harvesting technologies

Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These micro-scale devices can capture waste heat from industrial processes, body heat, or environmental temperature gradients to generate power. The technology typically employs thermoelectric materials that produce voltage when subjected to a temperature gradient. These harvesters are particularly valuable in environments with consistent temperature differences and can provide continuous power for low-energy electronic devices.Expand Specific Solutions04 RF and ambient energy harvesting solutions

Radio frequency (RF) and ambient energy harvesters capture electromagnetic waves from various sources such as Wi-Fi signals, cellular networks, and radio broadcasts to generate electrical power. These systems typically use specialized antennas and rectifier circuits to convert RF energy into DC power. This technology enables battery-free operation of low-power devices in environments with sufficient RF energy density, making it particularly suitable for IoT applications and wireless sensor networks in urban environments.Expand Specific Solutions05 Hybrid and integrated micro energy harvesting systems

Hybrid micro energy harvesters combine multiple harvesting technologies (such as piezoelectric, electromagnetic, and solar) into a single system to maximize energy capture from various environmental sources. These integrated systems can overcome the limitations of individual harvesting methods by adapting to changing environmental conditions and energy availability. Advanced power management circuits optimize the energy collection, storage, and distribution to connected devices, improving overall system efficiency and reliability in diverse operating environments.Expand Specific Solutions

Leading Companies and Research Institutions in Micro Energy Harvesting

The micro energy harvesting technology landscape is currently in a growth phase, with an estimated market size of $500-600 million and projected annual growth of 15-20%. The technology is advancing from early commercialization toward broader adoption, with varying maturity levels across harvesting methods. Leading academic institutions (MIT, Johns Hopkins, Georgia Tech) are driving fundamental research, while established corporations (Intel, Samsung, Analog Devices, Infineon) focus on commercial applications. Research organizations (ETRI, CSIRO) bridge the gap between theoretical and applied research. The competitive landscape shows a balanced ecosystem of academic innovation and industrial development, with increasing collaboration between sectors as the technology approaches mainstream adoption for personal electronics and IoT applications.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech has developed a comprehensive micro energy harvesting platform focused on triboelectric nanogenerators (TENGs) for personal electronics applications. Their proprietary technology converts mechanical energy from human motion, ambient vibrations, and fluid flows into electrical power through contact electrification and electrostatic induction. Georgia Tech's TENGs utilize specially engineered nanostructured surfaces that significantly enhance charge generation and transfer efficiency[2]. Their latest designs incorporate flexible, stretchable materials that can be seamlessly integrated into clothing and accessories, generating power from everyday movements. The research team has demonstrated practical applications including self-powered health monitoring systems that harvest energy from body movements to power sensors and wireless communication modules[4]. Georgia Tech has also pioneered hybrid energy harvesting systems that combine triboelectric, piezoelectric, and thermoelectric mechanisms to maximize power output across varying environmental conditions, achieving energy densities of up to 500 mW/m².

Strengths: Industry-leading expertise in triboelectric nanogenerators; highly flexible and wearable form factors suitable for personal electronics; effective hybridization of multiple harvesting mechanisms. Weaknesses: Output power can be inconsistent depending on user activity levels; some materials used have limited durability under repeated mechanical stress; optimization still needed for stable power management.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered significant advancements in micro energy harvesting technologies, particularly through their Microsystems Technology Laboratories. Their approach focuses on piezoelectric MEMS-based energy harvesters that convert ambient vibrations into usable electrical energy. MIT researchers have developed ultra-thin piezoelectric films capable of generating power from low-frequency vibrations commonly found in everyday environments. Their technology incorporates lead zirconate titanate (PZT) thin films with optimized crystalline structures that demonstrate conversion efficiencies up to 20% higher than conventional materials[1]. Additionally, MIT has created innovative multi-directional energy harvesters that can capture energy from random vibrations in multiple axes simultaneously, addressing one of the key limitations of traditional single-axis harvesters[3]. Their recent work includes self-powered wearable sensors that integrate energy harvesting with low-power electronics, enabling continuous operation without battery replacement.

Strengths: Superior material science expertise allowing for higher conversion efficiencies; multi-directional harvesting capabilities that maximize energy capture in real-world environments; strong integration with low-power electronics. Weaknesses: Higher manufacturing costs compared to conventional technologies; some solutions require specialized fabrication processes that limit mass production potential.

Key Patents and Innovations in Micro Energy Harvesting

Wide-bandwidth MEMS-scale piezoelectric energy harvesting device

PatentWO2011129855A2

Innovation

- The design incorporates a MEMS device with a piezoelectric beam anchored at both ends, subjected to external vibrations that induce stretching, coupled with an external proof mass to enhance power generation, utilizing nonlinear stiffness to achieve wider frequency bandwidth and higher power density, with electrodes configured to extract energy efficiently.

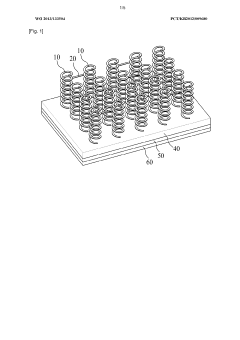

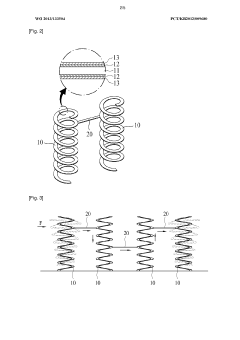

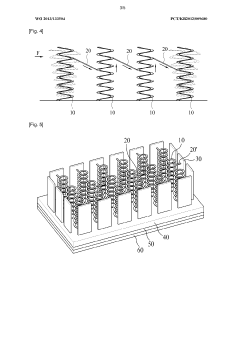

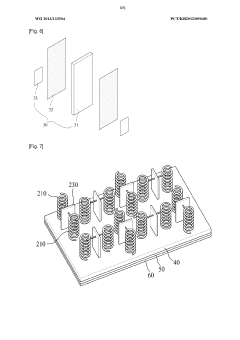

Energy-harvesting apparatus comprising coil spring-type microscale piezoelectric resonator

PatentWO2013133504A1

Innovation

- The energy harvesting device employs a plurality of micro-piezoelectric vibrators in the form of coil springs and plate-type piezoelectric vibrators connected through various connection units on a printed circuit board, allowing for efficient power generation from external forces and heat, with the ability to transmit and collect energy through diverse paths.

Integration Strategies with Personal Electronic Devices

The integration of micro energy harvesters with personal electronic devices represents a critical frontier in advancing sustainable consumer technology. Current integration approaches primarily focus on three methodologies: embedded integration, modular attachment, and wearable incorporation. Embedded integration involves designing energy harvesting components directly into device architecture during manufacturing, creating seamless power generation systems that complement traditional batteries without compromising device aesthetics or functionality.

Modular attachment strategies allow energy harvesters to be added as accessories to existing devices, offering flexibility and upgrade potential without requiring complete device redesign. This approach has gained traction in smartphone cases with integrated solar panels and kinetic energy capture mechanisms that extend battery life during active use.

Wearable incorporation merges energy harvesting with the growing wearable technology market, utilizing body heat, motion, and environmental energy sources to power fitness trackers, smartwatches, and health monitoring devices. This strategy capitalizes on the constant movement and thermal gradients naturally present during device usage.

Technical challenges in integration include miniaturization constraints, power management complexities, and material compatibility issues. The limited surface area of modern personal electronics restricts harvester size, while intermittent energy generation necessitates sophisticated power conditioning circuits to ensure stable device operation. Additionally, integrating harvesting components must not compromise device durability, weight distribution, or thermal management.

Several promising integration innovations have emerged recently, including flexible thin-film solar cells that conform to curved device surfaces, piezoelectric materials embedded in touchscreens that capture energy from user interactions, and thermoelectric generators integrated into device heat sinks that convert waste heat to usable power.

Industry standards development remains crucial for widespread adoption, with organizations like the Consumer Technology Association and IEEE working to establish protocols for harvester performance metrics, connection interfaces, and safety requirements. These standards will facilitate interoperability between harvesters and diverse electronic devices while ensuring consumer safety.

The integration roadmap for the next five years suggests progression from supplementary power sources to primary power solutions for low-energy devices, with eventual development of completely self-powered personal electronics for specific use cases. This evolution depends on continued advances in ultra-low-power electronics, energy storage technologies, and harvester efficiency improvements working in concert with thoughtful integration strategies.

Modular attachment strategies allow energy harvesters to be added as accessories to existing devices, offering flexibility and upgrade potential without requiring complete device redesign. This approach has gained traction in smartphone cases with integrated solar panels and kinetic energy capture mechanisms that extend battery life during active use.

Wearable incorporation merges energy harvesting with the growing wearable technology market, utilizing body heat, motion, and environmental energy sources to power fitness trackers, smartwatches, and health monitoring devices. This strategy capitalizes on the constant movement and thermal gradients naturally present during device usage.

Technical challenges in integration include miniaturization constraints, power management complexities, and material compatibility issues. The limited surface area of modern personal electronics restricts harvester size, while intermittent energy generation necessitates sophisticated power conditioning circuits to ensure stable device operation. Additionally, integrating harvesting components must not compromise device durability, weight distribution, or thermal management.

Several promising integration innovations have emerged recently, including flexible thin-film solar cells that conform to curved device surfaces, piezoelectric materials embedded in touchscreens that capture energy from user interactions, and thermoelectric generators integrated into device heat sinks that convert waste heat to usable power.

Industry standards development remains crucial for widespread adoption, with organizations like the Consumer Technology Association and IEEE working to establish protocols for harvester performance metrics, connection interfaces, and safety requirements. These standards will facilitate interoperability between harvesters and diverse electronic devices while ensuring consumer safety.

The integration roadmap for the next five years suggests progression from supplementary power sources to primary power solutions for low-energy devices, with eventual development of completely self-powered personal electronics for specific use cases. This evolution depends on continued advances in ultra-low-power electronics, energy storage technologies, and harvester efficiency improvements working in concert with thoughtful integration strategies.

Sustainability Impact and Environmental Benefits

Micro energy harvesting technologies represent a significant advancement in sustainable electronics development, offering profound environmental benefits that extend far beyond simple power generation. By capturing ambient energy that would otherwise be wasted, these systems fundamentally reduce dependence on traditional battery technologies, which contain toxic materials and present significant disposal challenges.

The environmental impact of micro energy harvesters manifests primarily through reduced electronic waste. Conventional batteries contribute approximately 180,000 tons of waste annually in the United States alone, with global figures reaching millions of tons. By extending device lifespans and eliminating or reducing battery replacement cycles, micro energy harvesting technologies directly address this growing environmental concern.

Carbon footprint reduction represents another critical sustainability benefit. The manufacturing, transportation, and disposal of conventional batteries generate substantial greenhouse gas emissions. Analysis indicates that widespread adoption of energy harvesting technologies in personal electronics could potentially reduce carbon emissions by 30-45% over device lifecycles when compared to traditional battery-powered alternatives.

Resource conservation emerges as a third significant environmental advantage. Battery production requires extensive mining operations for lithium, cobalt, and other rare earth elements, often resulting in habitat destruction, water pollution, and community displacement. Self-powered devices utilizing ambient energy significantly reduce these extractive pressures on fragile ecosystems and finite resources.

The circular economy potential of micro energy harvesters further enhances their sustainability profile. These technologies align perfectly with circular design principles by minimizing resource inputs and waste outputs. When integrated with biodegradable or recyclable materials, next-generation harvesters could approach true cradle-to-cradle sustainability in electronics design.

In urban environments, the collective impact of widespread micro energy harvester adoption could contribute to smart city sustainability goals. Networks of self-powered sensors and devices reduce infrastructure energy demands while enabling more efficient resource management across transportation, utilities, and public services.

Looking forward, the sustainability benefits of micro energy harvesting technologies will likely expand as materials science advances. Research into bioinspired materials, organic semiconductors, and zero-waste manufacturing processes promises to further reduce the environmental footprint of these technologies, potentially creating truly sustainable personal electronics ecosystems that operate in harmony with natural systems rather than at their expense.

The environmental impact of micro energy harvesters manifests primarily through reduced electronic waste. Conventional batteries contribute approximately 180,000 tons of waste annually in the United States alone, with global figures reaching millions of tons. By extending device lifespans and eliminating or reducing battery replacement cycles, micro energy harvesting technologies directly address this growing environmental concern.

Carbon footprint reduction represents another critical sustainability benefit. The manufacturing, transportation, and disposal of conventional batteries generate substantial greenhouse gas emissions. Analysis indicates that widespread adoption of energy harvesting technologies in personal electronics could potentially reduce carbon emissions by 30-45% over device lifecycles when compared to traditional battery-powered alternatives.

Resource conservation emerges as a third significant environmental advantage. Battery production requires extensive mining operations for lithium, cobalt, and other rare earth elements, often resulting in habitat destruction, water pollution, and community displacement. Self-powered devices utilizing ambient energy significantly reduce these extractive pressures on fragile ecosystems and finite resources.

The circular economy potential of micro energy harvesters further enhances their sustainability profile. These technologies align perfectly with circular design principles by minimizing resource inputs and waste outputs. When integrated with biodegradable or recyclable materials, next-generation harvesters could approach true cradle-to-cradle sustainability in electronics design.

In urban environments, the collective impact of widespread micro energy harvester adoption could contribute to smart city sustainability goals. Networks of self-powered sensors and devices reduce infrastructure energy demands while enabling more efficient resource management across transportation, utilities, and public services.

Looking forward, the sustainability benefits of micro energy harvesting technologies will likely expand as materials science advances. Research into bioinspired materials, organic semiconductors, and zero-waste manufacturing processes promises to further reduce the environmental footprint of these technologies, potentially creating truly sustainable personal electronics ecosystems that operate in harmony with natural systems rather than at their expense.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!