How Do Environmental Constraints Impact Micro Energy Harvester Design

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from theoretical concepts to practical applications across multiple industries. This technology focuses on capturing small amounts of energy from ambient environmental sources such as vibration, thermal gradients, light, and RF signals to power low-energy electronic devices. The evolution of this field has been driven by the increasing demand for autonomous, self-powered systems in applications where battery replacement is impractical or impossible.

The historical development of micro energy harvesting can be traced back to early piezoelectric and thermoelectric generators in the 1990s, followed by significant advancements in the 2000s with the introduction of MEMS-based harvesters. Recent years have witnessed remarkable progress in materials science, particularly in the development of high-efficiency piezoelectric materials, flexible substrates, and hybrid harvesting systems that can simultaneously capture energy from multiple sources.

Environmental constraints represent one of the most critical factors shaping the design and performance of micro energy harvesters. These constraints include available energy density, environmental variability, physical space limitations, and operational conditions such as temperature extremes, humidity, and mechanical stress. The fundamental challenge lies in optimizing harvester designs to function effectively within these constraints while delivering sufficient power for target applications.

Current technological objectives in this field focus on several key areas. First, increasing energy conversion efficiency to extract maximum power from limited environmental sources. Second, developing adaptive harvesting systems capable of functioning across varying environmental conditions. Third, miniaturization of harvesting components while maintaining or improving performance metrics. Fourth, creating multi-modal harvesting systems that can leverage multiple energy sources simultaneously to enhance reliability and output.

The market for micro energy harvesting is projected to grow significantly, driven by applications in wireless sensor networks, IoT devices, wearable technology, and remote monitoring systems. This growth is further supported by the increasing focus on sustainable energy solutions and the need for maintenance-free power sources in hard-to-reach locations.

Looking forward, the field aims to achieve greater integration with existing technologies, improved energy storage solutions, and enhanced power management systems. The ultimate goal is to develop completely autonomous micro-scale systems that can operate indefinitely in their target environments without external power intervention, effectively addressing the constraints imposed by diverse operational settings while meeting the energy demands of increasingly sophisticated electronic devices.

The historical development of micro energy harvesting can be traced back to early piezoelectric and thermoelectric generators in the 1990s, followed by significant advancements in the 2000s with the introduction of MEMS-based harvesters. Recent years have witnessed remarkable progress in materials science, particularly in the development of high-efficiency piezoelectric materials, flexible substrates, and hybrid harvesting systems that can simultaneously capture energy from multiple sources.

Environmental constraints represent one of the most critical factors shaping the design and performance of micro energy harvesters. These constraints include available energy density, environmental variability, physical space limitations, and operational conditions such as temperature extremes, humidity, and mechanical stress. The fundamental challenge lies in optimizing harvester designs to function effectively within these constraints while delivering sufficient power for target applications.

Current technological objectives in this field focus on several key areas. First, increasing energy conversion efficiency to extract maximum power from limited environmental sources. Second, developing adaptive harvesting systems capable of functioning across varying environmental conditions. Third, miniaturization of harvesting components while maintaining or improving performance metrics. Fourth, creating multi-modal harvesting systems that can leverage multiple energy sources simultaneously to enhance reliability and output.

The market for micro energy harvesting is projected to grow significantly, driven by applications in wireless sensor networks, IoT devices, wearable technology, and remote monitoring systems. This growth is further supported by the increasing focus on sustainable energy solutions and the need for maintenance-free power sources in hard-to-reach locations.

Looking forward, the field aims to achieve greater integration with existing technologies, improved energy storage solutions, and enhanced power management systems. The ultimate goal is to develop completely autonomous micro-scale systems that can operate indefinitely in their target environments without external power intervention, effectively addressing the constraints imposed by diverse operational settings while meeting the energy demands of increasingly sophisticated electronic devices.

Environmental Energy Source Demand Analysis

The global demand for micro energy harvesting technologies is experiencing significant growth, driven by the proliferation of Internet of Things (IoT) devices, wireless sensor networks, and wearable electronics. Market research indicates that the energy harvesting market is projected to reach $1.3 billion by 2027, with micro-scale harvesters representing a substantial segment of this expansion. This growth trajectory is particularly pronounced in sectors requiring autonomous power solutions for remote or inaccessible deployment scenarios.

Environmental energy sources present varying availability profiles that directly influence harvester design requirements. Solar energy offers the highest power density at approximately 100 mW/cm², but its intermittency necessitates supplementary storage solutions. Vibration-based sources typically provide 10-100 μW/cm³, while thermal gradients yield 10-50 μW/cm² depending on temperature differential magnitude. RF energy harvesting, though ubiquitous in urban environments, delivers the lowest power density at 0.1-1 μW/cm².

Industry analysis reveals distinct application-specific demands across sectors. Healthcare applications prioritize biocompatibility and miniaturization, with implantable devices requiring ultra-low power harvesting solutions that can operate within narrow thermal gradients of 1-2°C. Industrial monitoring systems emphasize robustness against harsh environmental conditions, including temperature extremes (-40°C to 85°C), chemical exposure, and mechanical shock resistance.

Consumer electronics demonstrate increasing demand for flexible, aesthetically integrated harvesting solutions, particularly for wearable technologies where form factor constraints are paramount. Military and aerospace applications require harvesters capable of functioning in extreme conditions, including temperature variations exceeding 100°C, high-G forces, and radiation exposure.

Geographic distribution of demand shows regional specialization patterns. North American markets focus predominantly on healthcare and military applications, European markets emphasize industrial and automotive implementations, while Asia-Pacific regions lead in consumer electronics integration. This regional variation necessitates customized design approaches to address specific environmental constraints prevalent in target deployment environments.

The demand analysis indicates a clear trend toward multi-source harvesting systems that can adapt to fluctuating environmental conditions. Market surveys show that 68% of end-users prefer hybrid solutions combining two or more harvesting modalities to ensure power reliability. This preference is driving research toward adaptive harvesting architectures capable of dynamically switching between energy sources based on environmental availability.

Environmental energy sources present varying availability profiles that directly influence harvester design requirements. Solar energy offers the highest power density at approximately 100 mW/cm², but its intermittency necessitates supplementary storage solutions. Vibration-based sources typically provide 10-100 μW/cm³, while thermal gradients yield 10-50 μW/cm² depending on temperature differential magnitude. RF energy harvesting, though ubiquitous in urban environments, delivers the lowest power density at 0.1-1 μW/cm².

Industry analysis reveals distinct application-specific demands across sectors. Healthcare applications prioritize biocompatibility and miniaturization, with implantable devices requiring ultra-low power harvesting solutions that can operate within narrow thermal gradients of 1-2°C. Industrial monitoring systems emphasize robustness against harsh environmental conditions, including temperature extremes (-40°C to 85°C), chemical exposure, and mechanical shock resistance.

Consumer electronics demonstrate increasing demand for flexible, aesthetically integrated harvesting solutions, particularly for wearable technologies where form factor constraints are paramount. Military and aerospace applications require harvesters capable of functioning in extreme conditions, including temperature variations exceeding 100°C, high-G forces, and radiation exposure.

Geographic distribution of demand shows regional specialization patterns. North American markets focus predominantly on healthcare and military applications, European markets emphasize industrial and automotive implementations, while Asia-Pacific regions lead in consumer electronics integration. This regional variation necessitates customized design approaches to address specific environmental constraints prevalent in target deployment environments.

The demand analysis indicates a clear trend toward multi-source harvesting systems that can adapt to fluctuating environmental conditions. Market surveys show that 68% of end-users prefer hybrid solutions combining two or more harvesting modalities to ensure power reliability. This preference is driving research toward adaptive harvesting architectures capable of dynamically switching between energy sources based on environmental availability.

Current Limitations and Environmental Challenges

Micro energy harvesters face significant environmental constraints that directly impact their design, efficiency, and overall performance. Temperature variations represent one of the most critical challenges, as extreme conditions can substantially alter material properties and conversion efficiencies. In cold environments, many piezoelectric materials experience reduced electromechanical coupling, while excessive heat can lead to depolarization and permanent damage to harvesting components. These temperature-related challenges necessitate specialized material selection and protective measures that often increase design complexity.

Humidity and moisture present another formidable obstacle, particularly for electromagnetic and electrostatic harvesters where water ingress can cause short circuits, corrosion, and accelerated degradation of sensitive components. Even sealed systems eventually face moisture-related challenges through permeation or seal degradation over time, requiring sophisticated encapsulation techniques that must balance protection with minimal impact on energy conversion efficiency.

Mechanical constraints such as vibration amplitude, frequency, and directionality significantly limit harvester effectiveness. Most vibration-based harvesters operate optimally within narrow frequency bands, yet real-world environments typically exhibit unpredictable, broadband vibration profiles. This frequency mismatch results in dramatically reduced power output when ambient vibrations fall outside the harvester's resonant frequency range, necessitating complex frequency tuning mechanisms or multi-modal designs.

Light-based energy harvesters contend with variable illumination conditions, including intensity fluctuations, spectral variations, and intermittency. Indoor photovoltaic harvesters must function efficiently under artificial lighting with spectral characteristics vastly different from natural sunlight, often at intensity levels 100-1000 times lower than outdoor conditions, severely limiting power generation capabilities.

Space constraints represent another critical limitation, as many application scenarios demand extremely compact solutions that must nevertheless generate sufficient power. This miniaturization challenge often forces compromises between power output and device size, particularly in wearable technologies and implantable medical devices where dimensional restrictions are severe.

Durability requirements further complicate harvester design, as many target applications involve harsh conditions including mechanical shock, chemical exposure, and radiation. These environmental stressors accelerate material degradation and component failure, necessitating robust designs that can withstand such conditions while maintaining performance over extended operational lifetimes of 5-10 years or more.

The combined effect of these environmental constraints creates a complex design space where engineers must make difficult tradeoffs between power output, reliability, size, and cost. Addressing these challenges requires interdisciplinary approaches spanning materials science, mechanical engineering, and electrical design to develop next-generation harvesters capable of reliable operation across diverse environmental conditions.

Humidity and moisture present another formidable obstacle, particularly for electromagnetic and electrostatic harvesters where water ingress can cause short circuits, corrosion, and accelerated degradation of sensitive components. Even sealed systems eventually face moisture-related challenges through permeation or seal degradation over time, requiring sophisticated encapsulation techniques that must balance protection with minimal impact on energy conversion efficiency.

Mechanical constraints such as vibration amplitude, frequency, and directionality significantly limit harvester effectiveness. Most vibration-based harvesters operate optimally within narrow frequency bands, yet real-world environments typically exhibit unpredictable, broadband vibration profiles. This frequency mismatch results in dramatically reduced power output when ambient vibrations fall outside the harvester's resonant frequency range, necessitating complex frequency tuning mechanisms or multi-modal designs.

Light-based energy harvesters contend with variable illumination conditions, including intensity fluctuations, spectral variations, and intermittency. Indoor photovoltaic harvesters must function efficiently under artificial lighting with spectral characteristics vastly different from natural sunlight, often at intensity levels 100-1000 times lower than outdoor conditions, severely limiting power generation capabilities.

Space constraints represent another critical limitation, as many application scenarios demand extremely compact solutions that must nevertheless generate sufficient power. This miniaturization challenge often forces compromises between power output and device size, particularly in wearable technologies and implantable medical devices where dimensional restrictions are severe.

Durability requirements further complicate harvester design, as many target applications involve harsh conditions including mechanical shock, chemical exposure, and radiation. These environmental stressors accelerate material degradation and component failure, necessitating robust designs that can withstand such conditions while maintaining performance over extended operational lifetimes of 5-10 years or more.

The combined effect of these environmental constraints creates a complex design space where engineers must make difficult tradeoffs between power output, reliability, size, and cost. Addressing these challenges requires interdisciplinary approaches spanning materials science, mechanical engineering, and electrical design to develop next-generation harvesters capable of reliable operation across diverse environmental conditions.

Current Environmental Adaptation Solutions

01 Piezoelectric energy harvesting systems

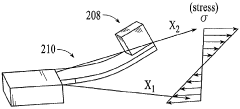

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. These systems can capture energy from vibrations, movements, or pressure in the environment. The designs often incorporate specialized structures to optimize energy conversion efficiency and may include cantilever beams, diaphragms, or arrays of piezoelectric elements to maximize power output from small mechanical inputs.- Piezoelectric energy harvesting systems: Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesters. These systems can capture energy from vibrations, movements, or pressure in the environment. Advanced designs incorporate optimized piezoelectric elements with specialized circuitry to maximize power output while maintaining small form factors. These harvesters are particularly useful in wearable devices, industrial sensors, and IoT applications where ambient vibrations are present.

- Electromagnetic micro generators: Electromagnetic micro energy harvesters utilize Faraday's law of induction to generate electricity from relative motion between magnets and coils. These systems are designed with miniaturized components including micro-magnets, precision coils, and optimized magnetic circuits to capture kinetic energy from the environment. The designs focus on maximizing magnetic flux density while minimizing the overall size, making them suitable for applications in self-powered sensors, wearable electronics, and small-scale renewable energy systems.

- Thermal energy harvesting devices: Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These micro-scale devices are designed with specialized materials that exhibit strong Seebeck effects, allowing them to generate voltage from temperature gradients. Advanced designs incorporate thermal management structures, optimized thermoelectric materials, and efficient heat transfer mechanisms to maximize power output from small temperature differences. These harvesters are particularly valuable in industrial environments, body-powered devices, and remote sensing applications.

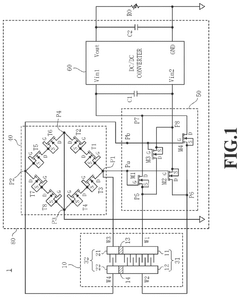

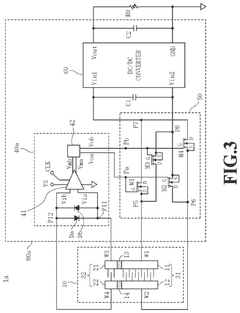

- Hybrid and multi-source energy harvesting: Hybrid micro energy harvesters combine multiple energy harvesting mechanisms in a single integrated system. These designs simultaneously capture energy from different sources such as vibration, thermal gradients, RF signals, or light to increase overall power output and reliability. The systems include specialized power management circuits that can efficiently combine and regulate energy from disparate sources with varying characteristics. This approach ensures continuous power availability even when individual energy sources fluctuate, making them ideal for autonomous sensors and IoT devices in variable environments.

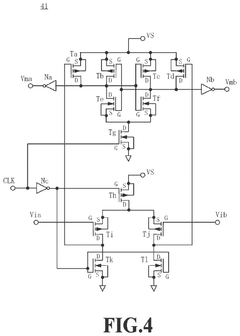

- MEMS-based energy harvesting solutions: Micro-Electro-Mechanical Systems (MEMS) technology enables the fabrication of extremely small energy harvesting devices with high precision. These harvesters utilize microfabrication techniques to create miniaturized mechanical structures that can capture ambient energy. The designs incorporate resonant structures, specialized materials, and integrated electronics optimized for specific frequency ranges and environmental conditions. MEMS-based harvesters offer advantages in terms of size, weight, and compatibility with semiconductor manufacturing processes, making them suitable for integration into microelectronic devices and systems.

02 Electromagnetic micro energy harvesters

Electromagnetic energy harvesting designs utilize Faraday's law of induction to generate electricity from relative motion between magnets and coils. These systems typically feature miniaturized magnet-coil arrangements optimized for capturing energy from low-frequency vibrations or movements. Advanced designs may incorporate resonant structures, magnetic flux guides, or specialized coil configurations to improve energy conversion efficiency at the micro scale.Expand Specific Solutions03 Thermal energy harvesting technologies

Micro energy harvesters based on thermal gradients utilize thermoelectric materials to convert temperature differences into electrical energy through the Seebeck effect. These designs typically feature arrays of thermocouples arranged to maximize energy capture from small temperature differentials. Advanced thermal harvesters may incorporate specialized heat concentrators, thermal isolation structures, or novel material combinations to improve conversion efficiency at micro scales.Expand Specific Solutions04 Hybrid and multi-source energy harvesting systems

Hybrid micro energy harvesters combine multiple energy conversion mechanisms in a single integrated device to capture energy from different environmental sources simultaneously. These designs may integrate piezoelectric, electromagnetic, thermoelectric, or photovoltaic elements to improve overall energy capture efficiency. The systems often include specialized power management circuits to handle the different electrical characteristics of each energy source and optimize the combined output.Expand Specific Solutions05 MEMS-based energy harvesting devices

Micro-Electro-Mechanical Systems (MEMS) technology enables the fabrication of extremely small energy harvesting devices with dimensions in the micrometer range. These harvesters typically utilize silicon microfabrication techniques to create precisely engineered mechanical structures that can capture energy from ambient vibrations, fluid flow, or pressure variations. MEMS harvesters often incorporate specialized resonant structures, electrostatic transducers, or piezoelectric thin films optimized for specific operating frequencies and environmental conditions.Expand Specific Solutions

Leading Companies and Research Institutions

Environmental constraints significantly impact micro energy harvester design across a rapidly evolving market currently valued at approximately $500 million, with projections to reach $2 billion by 2030. The industry is transitioning from early-stage development to commercial scaling, with varying levels of technological maturity among key players. Leading companies like Robert Bosch GmbH and Lockheed Martin have established robust harvesting technologies for industrial applications, while academic institutions including MIT, Caltech, and Nanyang Technological University drive fundamental innovations. Specialized firms such as Enervibe Ltd. focus on vibration energy harvesting solutions, while Taiwan Semiconductor Manufacturing Co. integrates harvesting capabilities into semiconductor technologies. Environmental factors including temperature fluctuations, spatial limitations, and ambient energy availability remain critical design constraints requiring application-specific optimization approaches.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive approach to micro energy harvester design that addresses environmental constraints through robust engineering and adaptive systems. Their MEMS-based energy harvesters are specifically designed to operate reliably in automotive environments with temperature ranges from -40°C to 125°C and withstand vibration profiles typical in vehicle applications. Bosch's micro harvesters incorporate protective packaging technologies that shield sensitive components from humidity, dust, and chemical contaminants while maintaining thermal management capabilities. Their systems feature adaptive power management circuits that can operate efficiently across varying input power levels (from microwatts to milliwatts), adjusting to fluctuating environmental energy availability. Bosch has implemented self-diagnostic capabilities in their energy harvesting systems that detect environmental stressors and modify operation parameters to prevent damage and extend operational lifetime. Their integrated approach combines multiple harvesting technologies (thermoelectric, piezoelectric, and electromagnetic) with intelligent power routing to maximize energy capture across diverse and changing environmental conditions.

Strengths: Exceptional durability in harsh automotive environments; proven manufacturing capabilities for high-volume, reliable production; comprehensive system integration expertise. Weaknesses: Solutions may be optimized primarily for automotive applications rather than broader use cases; relatively higher cost structure compared to academic solutions; proprietary technologies may limit wider ecosystem adoption.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced micro energy harvesting systems that adapt to environmental constraints through innovative materials and designs. Their research focuses on piezoelectric MEMS harvesters that can operate in variable temperature environments (-40°C to 85°C) while maintaining efficiency. MIT's approach incorporates adaptive circuit topologies that dynamically adjust to changing environmental conditions, maximizing power extraction across diverse scenarios. Their micro energy harvesters utilize multi-modal energy capture techniques, simultaneously harvesting from vibration, thermal gradients, and ambient RF, providing resilience against environmental variability. MIT researchers have pioneered ultra-low power management circuits specifically designed to function efficiently under extreme environmental constraints, with demonstrated operation at power levels below 10 nanowatts. Their systems incorporate self-optimization algorithms that continuously monitor environmental parameters and adjust harvester configuration to maintain optimal performance despite fluctuating external conditions.

Strengths: Superior adaptability to variable environmental conditions; cutting-edge materials research enabling broader operational ranges; comprehensive multi-modal approach. Weaknesses: Higher implementation complexity; potentially higher production costs; some solutions remain in research phase rather than commercial deployment.

Key Environmental Response Technologies

Environmental energy harvesting device

PatentActiveUS12107518B2

Innovation

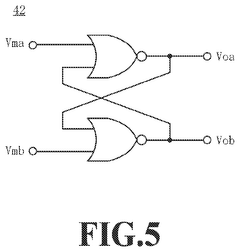

- An environmental energy harvesting device incorporating a vibration-driven energy converting element and an environmental sensor, with a power supply circuit that includes a rectifier circuit and a voltage limiting circuit using MOSFETs, where the rectifier circuit's operation is controlled by a signal from the environmental sensor to minimize energy loss, and a current-voltage conversion circuit that adjusts operation based on real-time outputs to optimize energy conversion.

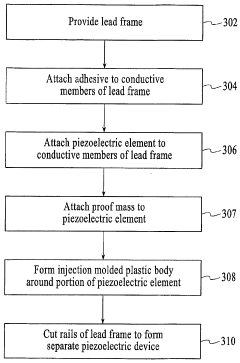

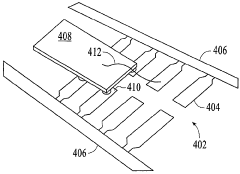

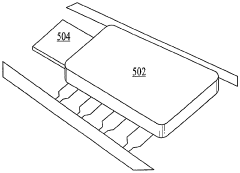

Injection molded energy harvesting device

PatentWO2007094948A1

Innovation

- An injection molded energy harvesting device utilizing a piezoelectric cantilever with a high-density proof mass and leadframe, encased in plastic, converts vibration energy into electrical power, suitable for environments like tire pressure monitoring systems, where traditional batteries are impractical.

Material Selection for Harsh Environments

Material selection represents a critical factor in the design and performance of micro energy harvesters operating in harsh environments. The environmental constraints directly influence the choice of materials, which must withstand specific conditions while maintaining optimal energy conversion efficiency. In extreme temperature scenarios, materials must exhibit thermal stability across wide operating ranges. For instance, piezoelectric materials like modified PZT ceramics maintain functionality between -40°C and 150°C, while specialized polymers like PVDF derivatives show resilience in cryogenic applications down to -196°C.

Chemical exposure presents another significant challenge, requiring materials with exceptional corrosion resistance. Noble metals such as platinum and gold offer superior protection in chemically aggressive environments but introduce cost constraints. Alternative solutions include specialized coatings like parylene conformal coatings, which provide chemical barrier properties while maintaining flexibility for vibration-based harvesters.

Mechanical stress resistance becomes paramount in high-vibration or shock-prone environments. Composite materials that combine ceramic elements with polymer matrices have demonstrated superior durability in aerospace applications, where mechanical loading can be unpredictable and severe. These composites offer an optimal balance between mechanical strength and the flexibility required for energy harvesting functionality.

Radiation exposure in nuclear or space applications demands radiation-hardened materials. Silicon carbide (SiC) and gallium nitride (GaN) semiconductors have shown remarkable radiation tolerance compared to conventional silicon, making them preferred choices for energy harvesting circuits in radiation-intensive environments. Additionally, specialized glass ceramics have demonstrated stability under gamma radiation exposure up to 10 MGy.

Humidity and moisture present challenges particularly for piezoelectric and triboelectric harvesters. Hydrophobic coatings based on fluoropolymers have emerged as effective solutions, maintaining surface properties even after prolonged exposure to humidity levels exceeding 95%. For underwater applications, hermetic packaging using ceramic-to-metal seals has proven effective in protecting sensitive harvesting components.

The selection process must balance environmental resilience with energy conversion efficiency. Recent advances in material science have yielded promising multi-functional materials that maintain harvesting capabilities while offering environmental protection. For instance, doped zinc oxide nanostructures demonstrate both piezoelectric properties and inherent UV resistance, making them suitable for outdoor solar-vibration hybrid harvesters without additional protective layers.

Chemical exposure presents another significant challenge, requiring materials with exceptional corrosion resistance. Noble metals such as platinum and gold offer superior protection in chemically aggressive environments but introduce cost constraints. Alternative solutions include specialized coatings like parylene conformal coatings, which provide chemical barrier properties while maintaining flexibility for vibration-based harvesters.

Mechanical stress resistance becomes paramount in high-vibration or shock-prone environments. Composite materials that combine ceramic elements with polymer matrices have demonstrated superior durability in aerospace applications, where mechanical loading can be unpredictable and severe. These composites offer an optimal balance between mechanical strength and the flexibility required for energy harvesting functionality.

Radiation exposure in nuclear or space applications demands radiation-hardened materials. Silicon carbide (SiC) and gallium nitride (GaN) semiconductors have shown remarkable radiation tolerance compared to conventional silicon, making them preferred choices for energy harvesting circuits in radiation-intensive environments. Additionally, specialized glass ceramics have demonstrated stability under gamma radiation exposure up to 10 MGy.

Humidity and moisture present challenges particularly for piezoelectric and triboelectric harvesters. Hydrophobic coatings based on fluoropolymers have emerged as effective solutions, maintaining surface properties even after prolonged exposure to humidity levels exceeding 95%. For underwater applications, hermetic packaging using ceramic-to-metal seals has proven effective in protecting sensitive harvesting components.

The selection process must balance environmental resilience with energy conversion efficiency. Recent advances in material science have yielded promising multi-functional materials that maintain harvesting capabilities while offering environmental protection. For instance, doped zinc oxide nanostructures demonstrate both piezoelectric properties and inherent UV resistance, making them suitable for outdoor solar-vibration hybrid harvesters without additional protective layers.

Sustainability and Lifecycle Considerations

Sustainability considerations are increasingly becoming central to micro energy harvester (MEH) design as environmental regulations tighten globally and consumer awareness grows. The lifecycle assessment of MEHs must account for raw material extraction, manufacturing processes, operational lifetime, and end-of-life disposal or recycling. Current research indicates that while MEHs offer sustainable energy alternatives, their production often involves rare earth elements and specialized manufacturing techniques with significant environmental footprints.

Material selection represents a critical sustainability factor in MEH design. Traditional piezoelectric materials like lead zirconate titanate (PZT) contain toxic elements, prompting research into lead-free alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). Similarly, thermoelectric harvesters often rely on tellurium and bismuth, which face supply constraints. Recent innovations focus on abundant, non-toxic alternatives including silicon-germanium composites and organic thermoelectric materials that demonstrate promising efficiency-to-environmental impact ratios.

Manufacturing processes for MEHs typically require clean room environments, specialized equipment, and energy-intensive procedures. Life cycle analyses reveal that the embodied energy in MEH fabrication can take months or years to recover through harvested energy, depending on deployment conditions. Advanced manufacturing techniques like roll-to-roll processing and additive manufacturing are emerging as more sustainable alternatives, reducing waste material by up to 40% compared to traditional subtractive methods.

The operational lifetime of MEHs directly impacts their sustainability profile. Environmental constraints such as temperature fluctuations, humidity, and mechanical stress can significantly reduce device longevity. Data from field deployments shows that MEHs designed for harsh environments often incorporate protective encapsulation that can increase device mass by 30-50%, affecting both performance and material usage. Designing for durability without excessive material use represents a key optimization challenge.

End-of-life considerations present particular challenges for MEH sustainability. The miniaturized, integrated nature of these devices often complicates component separation and material recovery. Innovative design approaches like modular construction and biodegradable substrates are gaining traction. Research from the University of Michigan demonstrates that biopolymer-based MEHs can achieve 85% biodegradability while maintaining 70% of the performance of conventional devices, offering promising pathways for environmentally responsible design.

The environmental constraints that impact MEH design thus extend beyond operational parameters to encompass the entire product lifecycle, requiring holistic approaches that balance performance requirements with sustainability imperatives. This perspective is increasingly essential as MEHs move from laboratory curiosities to widespread deployment in consumer electronics, medical devices, and IoT applications.

Material selection represents a critical sustainability factor in MEH design. Traditional piezoelectric materials like lead zirconate titanate (PZT) contain toxic elements, prompting research into lead-free alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). Similarly, thermoelectric harvesters often rely on tellurium and bismuth, which face supply constraints. Recent innovations focus on abundant, non-toxic alternatives including silicon-germanium composites and organic thermoelectric materials that demonstrate promising efficiency-to-environmental impact ratios.

Manufacturing processes for MEHs typically require clean room environments, specialized equipment, and energy-intensive procedures. Life cycle analyses reveal that the embodied energy in MEH fabrication can take months or years to recover through harvested energy, depending on deployment conditions. Advanced manufacturing techniques like roll-to-roll processing and additive manufacturing are emerging as more sustainable alternatives, reducing waste material by up to 40% compared to traditional subtractive methods.

The operational lifetime of MEHs directly impacts their sustainability profile. Environmental constraints such as temperature fluctuations, humidity, and mechanical stress can significantly reduce device longevity. Data from field deployments shows that MEHs designed for harsh environments often incorporate protective encapsulation that can increase device mass by 30-50%, affecting both performance and material usage. Designing for durability without excessive material use represents a key optimization challenge.

End-of-life considerations present particular challenges for MEH sustainability. The miniaturized, integrated nature of these devices often complicates component separation and material recovery. Innovative design approaches like modular construction and biodegradable substrates are gaining traction. Research from the University of Michigan demonstrates that biopolymer-based MEHs can achieve 85% biodegradability while maintaining 70% of the performance of conventional devices, offering promising pathways for environmentally responsible design.

The environmental constraints that impact MEH design thus extend beyond operational parameters to encompass the entire product lifecycle, requiring holistic approaches that balance performance requirements with sustainability imperatives. This perspective is increasingly essential as MEHs move from laboratory curiosities to widespread deployment in consumer electronics, medical devices, and IoT applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!