Analysis of Micro Energy Harvesters for Agricultural Technology

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from laboratory curiosities to practical power solutions for low-energy electronic devices. The fundamental concept involves capturing small amounts of energy from ambient environmental sources such as vibration, thermal gradients, solar radiation, and fluid flow, then converting this energy into usable electrical power. This technology has seen significant advancement since the early 2000s, with efficiency improvements of over 300% in piezoelectric harvesters and 250% in thermoelectric generators during this period.

In agricultural contexts, micro energy harvesting presents a particularly promising application domain. Modern precision agriculture increasingly relies on distributed sensor networks for monitoring soil conditions, crop health, weather parameters, and irrigation systems. These networks traditionally depend on batteries that require regular replacement or recharging, creating logistical challenges in expansive agricultural settings. The evolution of micro energy harvesting technology offers a potential solution to this limitation by enabling self-powered sensor nodes.

The technological trajectory indicates a clear trend toward miniaturization, increased conversion efficiency, and hybrid harvesting systems that can capture energy from multiple environmental sources simultaneously. Recent innovations have focused on flexible and biodegradable harvesters that align with sustainable agricultural practices, representing a significant departure from earlier rigid designs.

The primary objective of micro energy harvesting in agricultural technology is to develop autonomous, maintenance-free power solutions for remote sensing applications. Specific technical goals include achieving energy densities exceeding 100 μW/cm³ under typical agricultural conditions, developing harvesters that can withstand harsh environmental factors including temperature fluctuations, humidity, and exposure to agricultural chemicals, and creating systems with operational lifespans of at least five years without maintenance.

Secondary objectives include reducing the production costs to below $0.50 per harvester unit at scale, ensuring compatibility with existing agricultural sensor platforms, and developing energy management systems that can effectively handle the intermittent nature of harvested energy. These objectives align with the broader agricultural industry trend toward digitization and automation, where reliable power sources for distributed electronics represent a critical enabling technology.

The convergence of advances in materials science, particularly in piezoelectric polymers, flexible photovoltaics, and low-temperature thermoelectric materials, has accelerated development in this field. These technological improvements, coupled with the decreasing power requirements of modern sensor and communication technologies, have created a favorable environment for the practical implementation of micro energy harvesting solutions in agricultural settings.

In agricultural contexts, micro energy harvesting presents a particularly promising application domain. Modern precision agriculture increasingly relies on distributed sensor networks for monitoring soil conditions, crop health, weather parameters, and irrigation systems. These networks traditionally depend on batteries that require regular replacement or recharging, creating logistical challenges in expansive agricultural settings. The evolution of micro energy harvesting technology offers a potential solution to this limitation by enabling self-powered sensor nodes.

The technological trajectory indicates a clear trend toward miniaturization, increased conversion efficiency, and hybrid harvesting systems that can capture energy from multiple environmental sources simultaneously. Recent innovations have focused on flexible and biodegradable harvesters that align with sustainable agricultural practices, representing a significant departure from earlier rigid designs.

The primary objective of micro energy harvesting in agricultural technology is to develop autonomous, maintenance-free power solutions for remote sensing applications. Specific technical goals include achieving energy densities exceeding 100 μW/cm³ under typical agricultural conditions, developing harvesters that can withstand harsh environmental factors including temperature fluctuations, humidity, and exposure to agricultural chemicals, and creating systems with operational lifespans of at least five years without maintenance.

Secondary objectives include reducing the production costs to below $0.50 per harvester unit at scale, ensuring compatibility with existing agricultural sensor platforms, and developing energy management systems that can effectively handle the intermittent nature of harvested energy. These objectives align with the broader agricultural industry trend toward digitization and automation, where reliable power sources for distributed electronics represent a critical enabling technology.

The convergence of advances in materials science, particularly in piezoelectric polymers, flexible photovoltaics, and low-temperature thermoelectric materials, has accelerated development in this field. These technological improvements, coupled with the decreasing power requirements of modern sensor and communication technologies, have created a favorable environment for the practical implementation of micro energy harvesting solutions in agricultural settings.

Agricultural Market Demand for Energy Harvesting Solutions

The agricultural sector is experiencing a significant transformation driven by smart farming technologies, creating a substantial market demand for energy harvesting solutions. Current market research indicates that the global smart agriculture market is projected to reach $23.1 billion by 2026, growing at a CAGR of 9.8% from 2021. Within this expanding market, energy harvesting technologies are becoming increasingly vital as they address the fundamental challenge of powering distributed sensor networks and IoT devices across vast agricultural landscapes.

Primary market drivers for micro energy harvesting solutions in agriculture include the proliferation of wireless sensor networks for precision agriculture, which require sustainable power sources for continuous operation in remote locations. Farmers are increasingly adopting soil moisture sensors, weather stations, and crop monitoring systems that benefit from self-powered operation, reducing maintenance costs and extending deployment lifespans.

The demand is particularly strong in regions with limited grid infrastructure, where traditional power sources are impractical or cost-prohibitive. Developing countries with large agricultural sectors but underdeveloped power infrastructure represent a significant growth opportunity, with market penetration expected to increase by 15% annually over the next five years.

Market segmentation reveals varying needs across different agricultural applications. Livestock monitoring systems require reliable, continuous power for tracking animal health and location. Irrigation management systems benefit from solar and water flow energy harvesting to power automated valves and monitoring equipment. Greenhouse operations show strong demand for thermal energy harvesting solutions that can capitalize on temperature differentials.

Economic analysis demonstrates compelling return on investment for farmers adopting energy harvesting technologies. Case studies indicate that self-powered sensor networks can reduce water usage by up to 30% and fertilizer application by 20%, resulting in cost savings that typically offset the initial investment within two growing seasons.

Market surveys reveal that 78% of large-scale commercial farmers express interest in energy harvesting solutions, primarily motivated by operational cost reduction and environmental sustainability goals. However, adoption among small-scale farmers remains limited at 23%, primarily due to initial cost concerns and technical implementation barriers.

The regulatory landscape is increasingly favorable, with agricultural policies in major markets incentivizing sustainable farming practices and technology adoption. Government subsidies for green agricultural technologies in the EU, North America, and parts of Asia are accelerating market growth by offsetting initial implementation costs.

Primary market drivers for micro energy harvesting solutions in agriculture include the proliferation of wireless sensor networks for precision agriculture, which require sustainable power sources for continuous operation in remote locations. Farmers are increasingly adopting soil moisture sensors, weather stations, and crop monitoring systems that benefit from self-powered operation, reducing maintenance costs and extending deployment lifespans.

The demand is particularly strong in regions with limited grid infrastructure, where traditional power sources are impractical or cost-prohibitive. Developing countries with large agricultural sectors but underdeveloped power infrastructure represent a significant growth opportunity, with market penetration expected to increase by 15% annually over the next five years.

Market segmentation reveals varying needs across different agricultural applications. Livestock monitoring systems require reliable, continuous power for tracking animal health and location. Irrigation management systems benefit from solar and water flow energy harvesting to power automated valves and monitoring equipment. Greenhouse operations show strong demand for thermal energy harvesting solutions that can capitalize on temperature differentials.

Economic analysis demonstrates compelling return on investment for farmers adopting energy harvesting technologies. Case studies indicate that self-powered sensor networks can reduce water usage by up to 30% and fertilizer application by 20%, resulting in cost savings that typically offset the initial investment within two growing seasons.

Market surveys reveal that 78% of large-scale commercial farmers express interest in energy harvesting solutions, primarily motivated by operational cost reduction and environmental sustainability goals. However, adoption among small-scale farmers remains limited at 23%, primarily due to initial cost concerns and technical implementation barriers.

The regulatory landscape is increasingly favorable, with agricultural policies in major markets incentivizing sustainable farming practices and technology adoption. Government subsidies for green agricultural technologies in the EU, North America, and parts of Asia are accelerating market growth by offsetting initial implementation costs.

Current Micro Energy Harvesting Technologies and Challenges

Micro energy harvesting technologies have evolved significantly over the past decade, offering promising solutions for powering agricultural sensors and IoT devices in remote locations. Currently, several key technologies dominate the micro energy harvesting landscape in agricultural applications. Photovoltaic (PV) harvesters remain the most mature technology, with thin-film and organic PV cells providing flexibility and adaptability for various agricultural environments. These systems typically achieve 10-20% efficiency in ideal conditions but face significant challenges in dusty farm environments and during adverse weather conditions.

Piezoelectric energy harvesters convert mechanical vibrations from agricultural machinery, wind-induced plant movements, or raindrops into electrical energy. Recent advancements have improved their energy density to 10-100 μW/cm³, making them viable for low-power agricultural sensors. However, their output remains highly dependent on consistent mechanical stimulation, limiting reliability in static agricultural settings.

Thermoelectric generators (TEGs) leverage temperature differentials between soil layers or between plant surfaces and ambient air to generate electricity. While promising for continuous operation, current TEGs typically offer low conversion efficiencies of 2-5%, requiring substantial temperature gradients that are not always available in agricultural environments.

Triboelectric nanogenerators (TENGs) represent an emerging technology that harvests energy from friction, showing potential for applications in monitoring livestock movement or capturing energy from rainfall. Despite rapid development, TENGs still struggle with durability issues in harsh agricultural conditions.

RF energy harvesting systems capture ambient radio frequency signals from nearby communication infrastructure, but their effectiveness diminishes dramatically with distance from transmission sources, making them impractical for remote agricultural applications without dedicated transmitters.

The primary challenges facing micro energy harvesters in agricultural technology include durability in harsh environmental conditions (extreme temperatures, humidity, dust, and chemical exposure), inconsistent energy availability (seasonal variations in sunlight, wind, or temperature gradients), and low power density that limits application scope. Most current harvesters generate only 10-100 μW/cm², insufficient for power-hungry applications like real-time video monitoring or active intervention systems.

Integration challenges also persist, as many harvesting technologies require specialized interfaces and power management circuits that add complexity and cost to agricultural sensing systems. Additionally, the economic viability remains questionable, with current energy harvesting solutions often costing significantly more than conventional battery-powered systems when considering the total lifecycle cost.

Standardization issues further complicate adoption, as the lack of universal interfaces and protocols makes it difficult to create modular, interoperable agricultural monitoring systems that can leverage multiple energy harvesting technologies simultaneously.

Piezoelectric energy harvesters convert mechanical vibrations from agricultural machinery, wind-induced plant movements, or raindrops into electrical energy. Recent advancements have improved their energy density to 10-100 μW/cm³, making them viable for low-power agricultural sensors. However, their output remains highly dependent on consistent mechanical stimulation, limiting reliability in static agricultural settings.

Thermoelectric generators (TEGs) leverage temperature differentials between soil layers or between plant surfaces and ambient air to generate electricity. While promising for continuous operation, current TEGs typically offer low conversion efficiencies of 2-5%, requiring substantial temperature gradients that are not always available in agricultural environments.

Triboelectric nanogenerators (TENGs) represent an emerging technology that harvests energy from friction, showing potential for applications in monitoring livestock movement or capturing energy from rainfall. Despite rapid development, TENGs still struggle with durability issues in harsh agricultural conditions.

RF energy harvesting systems capture ambient radio frequency signals from nearby communication infrastructure, but their effectiveness diminishes dramatically with distance from transmission sources, making them impractical for remote agricultural applications without dedicated transmitters.

The primary challenges facing micro energy harvesters in agricultural technology include durability in harsh environmental conditions (extreme temperatures, humidity, dust, and chemical exposure), inconsistent energy availability (seasonal variations in sunlight, wind, or temperature gradients), and low power density that limits application scope. Most current harvesters generate only 10-100 μW/cm², insufficient for power-hungry applications like real-time video monitoring or active intervention systems.

Integration challenges also persist, as many harvesting technologies require specialized interfaces and power management circuits that add complexity and cost to agricultural sensing systems. Additionally, the economic viability remains questionable, with current energy harvesting solutions often costing significantly more than conventional battery-powered systems when considering the total lifecycle cost.

Standardization issues further complicate adoption, as the lack of universal interfaces and protocols makes it difficult to create modular, interoperable agricultural monitoring systems that can leverage multiple energy harvesting technologies simultaneously.

Existing Micro Energy Harvesting Implementation Methods

01 Piezoelectric micro energy harvesters

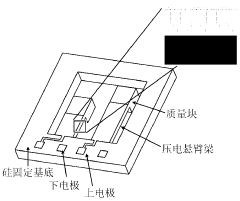

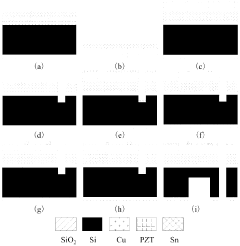

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesting applications. These harvesters can capture energy from vibrations, movements, and pressure variations in the environment. The technology typically uses thin-film piezoelectric materials like PZT, AlN, or ZnO deposited on flexible substrates to generate electricity when deformed. These systems are particularly useful in wearable devices, wireless sensor networks, and IoT applications where traditional power sources are impractical.- Piezoelectric micro energy harvesters: Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, or pressure in the environment. The harvested energy can be used to power small electronic devices or sensors. These systems typically consist of a piezoelectric material layer mounted on a substrate that deforms under mechanical stress, generating electrical charge that can be collected and stored.

- Triboelectric nanogenerators for energy harvesting: Triboelectric nanogenerators (TENGs) harvest energy from friction between different materials. When two dissimilar materials come into contact and then separate, they generate static electricity that can be captured and utilized. These devices can harvest energy from everyday movements, vibrations, or fluid flows. TENGs are characterized by their flexibility, high energy conversion efficiency, and ability to work with a wide range of materials, making them suitable for wearable electronics and self-powered sensors.

- Thermal energy harvesting microsystems: Thermal energy harvesters convert temperature differences into electrical energy using the thermoelectric effect. These micro-scale devices can capture waste heat from industrial processes, body heat, or environmental temperature gradients. They typically consist of arrays of thermoelectric materials that generate voltage when subjected to a temperature difference. These systems are particularly valuable in environments where temperature differentials naturally exist and can provide continuous power for low-energy electronics.

- RF and electromagnetic energy harvesting technologies: Radio frequency (RF) and electromagnetic energy harvesters capture ambient electromagnetic radiation from sources such as Wi-Fi signals, cellular networks, and radio broadcasts. These systems typically use specialized antennas and rectifier circuits to convert electromagnetic waves into usable DC power. The harvested energy can power wireless sensors, IoT devices, or be stored for later use. These technologies are particularly valuable in urban environments with high density of electromagnetic signals.

- Hybrid and multi-source micro energy harvesting systems: Hybrid energy harvesters combine multiple harvesting mechanisms in a single device to maximize energy capture from various environmental sources. These systems might integrate piezoelectric, triboelectric, thermoelectric, or photovoltaic elements to harvest energy from vibrations, friction, temperature differences, and light simultaneously. By combining different harvesting technologies, these systems can provide more consistent power output across varying environmental conditions, making them more reliable for powering autonomous sensors and IoT devices.

02 Triboelectric nanogenerators for energy harvesting

Triboelectric nanogenerators (TENGs) harvest energy through contact electrification and electrostatic induction. When two different materials come into contact and then separate, they generate electrical charges that can be collected. These devices can harvest energy from various mechanical sources including human motion, wind, and water waves. TENGs are characterized by their high energy conversion efficiency, flexibility, and ability to work with a wide range of materials, making them suitable for self-powered electronics and sensors.Expand Specific Solutions03 Electromagnetic micro energy harvesting systems

Electromagnetic micro energy harvesters generate electricity based on Faraday's law of electromagnetic induction. These systems typically consist of magnets and coils arranged so that relative motion between them induces electrical current. The technology can be miniaturized for micro-scale applications while maintaining efficiency. These harvesters are particularly effective for capturing energy from low-frequency vibrations and can be designed with resonant frequencies matching common environmental vibration sources, making them suitable for powering wireless sensor nodes and IoT devices.Expand Specific Solutions04 Thermal energy harvesting microdevices

Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These micro-scale devices utilize the Seebeck effect, where a temperature gradient across different materials generates voltage. Advanced thermoelectric materials and micro-fabrication techniques allow for efficient harvesting from small temperature differences. Applications include body heat harvesting for wearable electronics, industrial process monitoring, and remote sensing in environments with thermal gradients. These harvesters provide continuous power generation as long as temperature differences exist.Expand Specific Solutions05 Hybrid and multi-source micro energy harvesting

Hybrid micro energy harvesters combine multiple harvesting mechanisms to increase power output and reliability. These systems integrate two or more technologies such as piezoelectric, triboelectric, electromagnetic, or thermoelectric in a single device. This approach overcomes the limitations of individual harvesting methods and enables energy capture from multiple environmental sources simultaneously. Advanced power management circuits optimize energy collection from these diverse sources. These hybrid systems are particularly valuable in environments where energy availability varies or where higher power output is required for more demanding applications.Expand Specific Solutions

Leading Companies in Agricultural Micro Energy Harvesting

The micro energy harvesting market for agricultural technology is in its early growth phase, characterized by increasing adoption but still evolving technical standards. The market is projected to expand significantly as smart farming practices gain traction, with an estimated compound annual growth rate of 10-15% over the next five years. Regarding technical maturity, academic institutions like MIT, University of Florida, and Zhejiang University are leading fundamental research, while commercial players demonstrate varying levels of implementation readiness. Companies such as Bosch and Infineon are advancing in sensor-integrated harvesting solutions, while agricultural equipment manufacturers like Deere & Co. and CNH Industrial are incorporating these technologies into their smart farming platforms. TSMC and Intel are contributing semiconductor expertise essential for miniaturization and efficiency improvements in these systems.

Deere & Co.

Technical Solution: John Deere has developed a comprehensive micro energy harvesting ecosystem specifically designed for agricultural machinery and field operations. Their technology leverages vibration-based piezoelectric harvesters integrated directly into agricultural equipment, capable of generating 5-20mW during normal operation. These systems power a network of sensors that monitor equipment health, operational efficiency, and agronomic data. Deere's approach includes proprietary energy management systems that prioritize critical sensing and communication functions based on available power. Their harvesters incorporate ruggedized designs specifically engineered to withstand extreme agricultural conditions including dust, moisture, temperature variations, and mechanical stress. The company has implemented machine learning algorithms that optimize harvesting efficiency by predicting energy availability patterns based on equipment usage cycles. Deere's systems achieve approximately 60-70% energy conversion efficiency, significantly higher than industry averages of 30-40% for similar applications. The technology enables "install and forget" sensor deployments with operational lifespans exceeding 5 years without maintenance.

Strengths: Seamless integration with existing agricultural machinery; highly durable design specifically engineered for agricultural environments; comprehensive ecosystem approach including sensors, data management and analytics. Weaknesses: Solutions primarily optimized for Deere equipment; relatively high implementation cost; limited effectiveness in stationary agricultural applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced micro energy harvesting systems specifically for agricultural applications, focusing on self-powered wireless sensor networks (WSNs). Their technology combines multiple harvesting methods including piezoelectric, thermoelectric, and photovoltaic elements in a single integrated platform. The system captures energy from machinery vibrations, temperature differentials in agricultural equipment, and ambient light to power distributed sensor networks across farms. Bosch's micro harvesters typically generate 1-10mW of power, sufficient for low-power sensors that monitor soil conditions, equipment performance, and environmental parameters. Their proprietary power management integrated circuits (PMICs) optimize energy collection and storage, enabling sensor nodes to operate autonomously for years without battery replacement. The technology includes adaptive harvesting algorithms that adjust collection strategies based on available energy sources and consumption patterns.

Strengths: Superior integration of multiple harvesting technologies in a single platform; robust design suitable for harsh agricultural environments; advanced power management systems that maximize efficiency. Weaknesses: Higher initial cost compared to battery-powered alternatives; performance variability depending on environmental conditions; requires specialized installation expertise.

Key Patents and Innovations in Agricultural Energy Harvesting

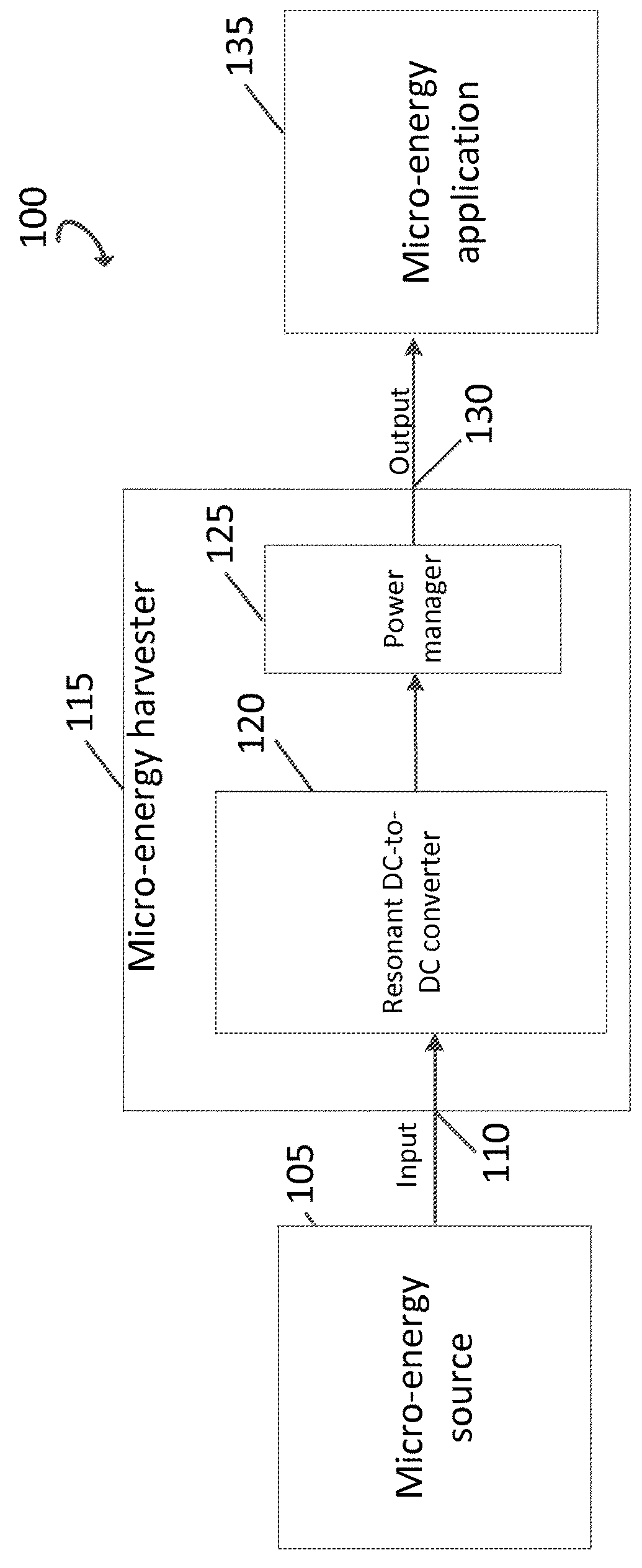

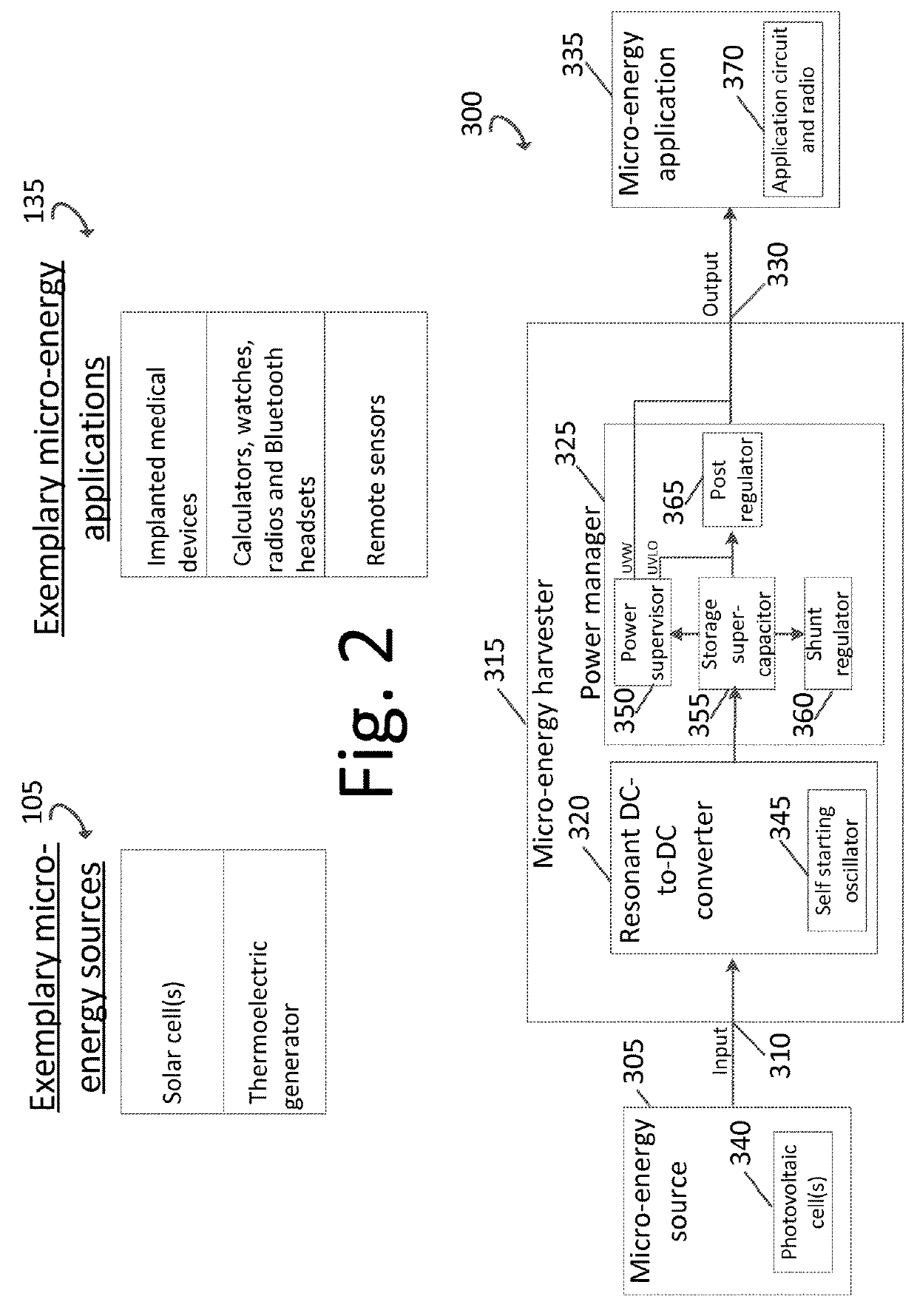

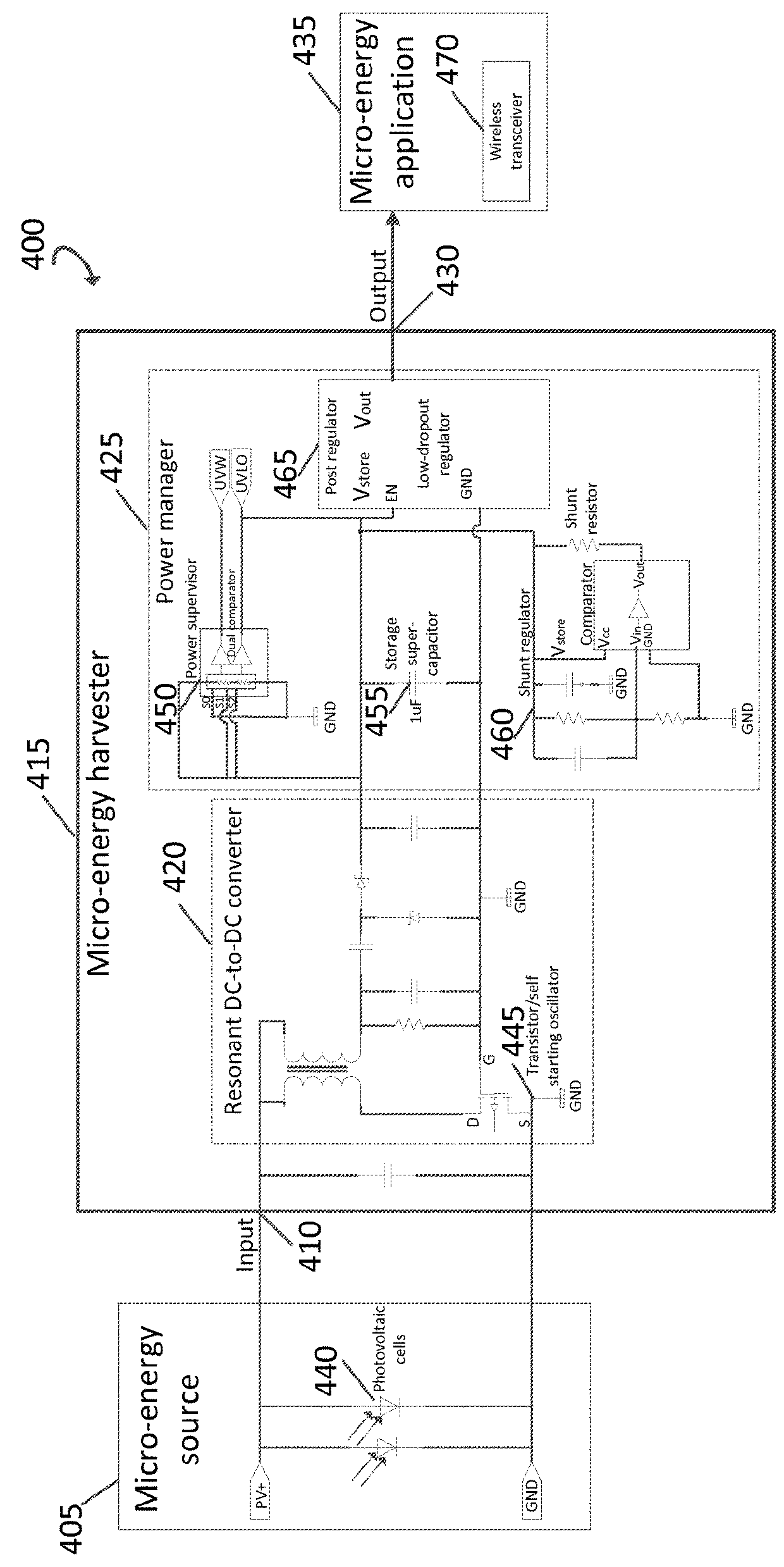

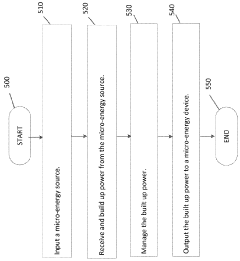

Micro-energy harvester for battery free applications

PatentInactiveUS10044218B2

Innovation

- A micro-energy harvester with an integrated power manager that uses a normally off transistor and MOSFET pass transistor to efficiently transform and store energy from low-power sources, including small solar cells, with a self-starting resonant DC-DC converter and power supervisor to manage energy storage and usage.

Micro energy collector based on piezoelectric thick film MEMS process and preparation method thereof

PatentWO2019090601A1

Innovation

- Using piezoelectric thick film MEMS technology, through eutectic bonding of piezoelectric ceramic wafers and silicon dioxide wafers, combined with electroplating and laser cutting processes, a multi-layered piezoelectric cantilever beam and fixed base are prepared to achieve piezoelectric thick film High performance and diverse structural design.

Environmental Impact and Sustainability Considerations

Micro energy harvesting technologies in agriculture represent a significant advancement toward sustainable farming practices. These systems convert ambient energy from the environment—such as solar radiation, thermal gradients, wind, and vibrations—into usable electrical power for agricultural sensors and monitoring equipment. The environmental benefits of implementing these technologies are substantial, particularly in reducing the carbon footprint associated with traditional power sources like disposable batteries.

The lifecycle assessment of micro energy harvesters reveals considerable environmental advantages. By eliminating the need for battery replacements, these systems significantly reduce electronic waste generation in agricultural settings. Research indicates that a single solar-powered micro harvester can prevent approximately 20-30 disposable batteries from entering landfills over its operational lifetime. Furthermore, the materials used in modern harvesters increasingly incorporate biodegradable components, minimizing environmental contamination when devices reach end-of-life.

Water conservation represents another critical environmental benefit of micro energy harvesting systems. When integrated with precision irrigation technologies, these self-powered sensors enable highly targeted water application based on real-time soil moisture data. Field studies demonstrate water savings of 30-50% compared to conventional irrigation methods, directly addressing agricultural water scarcity challenges while reducing energy consumption associated with pumping and distribution.

The sustainability implications extend to chemical input optimization as well. Self-powered soil nutrient sensors allow for precise fertilizer application, reducing both chemical runoff into waterways and the energy-intensive production of agricultural chemicals. This precision approach has demonstrated fertilizer use reductions of up to 40% in various crop systems while maintaining or improving yields.

From a circular economy perspective, micro energy harvesters contribute to closing resource loops in agricultural systems. Recent innovations include harvesters that simultaneously generate electricity and capture valuable byproducts. For instance, microbial fuel cells can generate power while processing agricultural waste, and certain piezoelectric systems can harvest energy while functioning as physical pest barriers.

Looking forward, the integration of biodegradable substrates and environmentally benign materials in harvester construction represents a promising frontier. Research teams have demonstrated functional prototypes using cellulose-based components and biodegradable polymers that maintain performance while decomposing harmlessly at end-of-life. These advancements align with broader sustainability goals by ensuring that the environmental benefits of energy harvesting aren't undermined by problematic material choices.

The lifecycle assessment of micro energy harvesters reveals considerable environmental advantages. By eliminating the need for battery replacements, these systems significantly reduce electronic waste generation in agricultural settings. Research indicates that a single solar-powered micro harvester can prevent approximately 20-30 disposable batteries from entering landfills over its operational lifetime. Furthermore, the materials used in modern harvesters increasingly incorporate biodegradable components, minimizing environmental contamination when devices reach end-of-life.

Water conservation represents another critical environmental benefit of micro energy harvesting systems. When integrated with precision irrigation technologies, these self-powered sensors enable highly targeted water application based on real-time soil moisture data. Field studies demonstrate water savings of 30-50% compared to conventional irrigation methods, directly addressing agricultural water scarcity challenges while reducing energy consumption associated with pumping and distribution.

The sustainability implications extend to chemical input optimization as well. Self-powered soil nutrient sensors allow for precise fertilizer application, reducing both chemical runoff into waterways and the energy-intensive production of agricultural chemicals. This precision approach has demonstrated fertilizer use reductions of up to 40% in various crop systems while maintaining or improving yields.

From a circular economy perspective, micro energy harvesters contribute to closing resource loops in agricultural systems. Recent innovations include harvesters that simultaneously generate electricity and capture valuable byproducts. For instance, microbial fuel cells can generate power while processing agricultural waste, and certain piezoelectric systems can harvest energy while functioning as physical pest barriers.

Looking forward, the integration of biodegradable substrates and environmentally benign materials in harvester construction represents a promising frontier. Research teams have demonstrated functional prototypes using cellulose-based components and biodegradable polymers that maintain performance while decomposing harmlessly at end-of-life. These advancements align with broader sustainability goals by ensuring that the environmental benefits of energy harvesting aren't undermined by problematic material choices.

Integration with IoT and Smart Farming Systems

The integration of micro energy harvesters with IoT and smart farming systems represents a transformative convergence that is reshaping modern agricultural practices. These energy harvesting technologies serve as sustainable power sources for the vast networks of sensors and communication devices that form the backbone of precision agriculture. By converting ambient energy from sources such as solar radiation, thermal gradients, wind, and vibrations into electrical power, these harvesters enable the deployment of autonomous sensing nodes throughout agricultural environments without the limitations of traditional power infrastructure.

The architecture of integrated systems typically consists of three primary components: the energy harvesting unit, power management circuitry, and the IoT device itself. This configuration allows for the creation of self-sustaining monitoring systems that can continuously collect and transmit critical agricultural data including soil moisture levels, nutrient content, temperature variations, and crop health indicators. The real-time nature of this data collection facilitates immediate response to changing field conditions, optimizing resource utilization and crop yields.

Current implementation models demonstrate varying levels of integration sophistication. Basic implementations feature simple sensor nodes powered by single-source harvesters, while advanced systems incorporate hybrid energy harvesting approaches with intelligent power management algorithms. These advanced systems can dynamically adjust their operation based on available energy and prioritize critical functions during periods of limited power availability, ensuring continuous operation of essential monitoring capabilities.

The scalability of these integrated systems presents both opportunities and challenges. While the distributed nature of agricultural IoT networks benefits from the decentralized power generation that micro harvesters provide, maintaining consistent performance across diverse environmental conditions remains technically challenging. Seasonal variations in available ambient energy sources necessitate adaptive harvesting strategies and robust energy storage solutions to maintain system reliability throughout the agricultural cycle.

Data management frameworks within these integrated systems have evolved to accommodate energy constraints. Edge computing architectures that process data locally before transmission significantly reduce power consumption compared to continuous raw data streaming. Additionally, machine learning algorithms deployed at the edge can identify anomalies or critical events that warrant immediate communication, further optimizing the energy utilization profile of the system.

Standardization efforts are gradually emerging to address interoperability challenges between diverse energy harvesting technologies and IoT platforms. Organizations such as the IEEE and various agricultural technology consortia are developing protocols that facilitate seamless integration of harvesting technologies with existing farm management systems. These standards are crucial for widespread adoption and will enable farmers to incrementally upgrade their operations without wholesale replacement of existing infrastructure.

The architecture of integrated systems typically consists of three primary components: the energy harvesting unit, power management circuitry, and the IoT device itself. This configuration allows for the creation of self-sustaining monitoring systems that can continuously collect and transmit critical agricultural data including soil moisture levels, nutrient content, temperature variations, and crop health indicators. The real-time nature of this data collection facilitates immediate response to changing field conditions, optimizing resource utilization and crop yields.

Current implementation models demonstrate varying levels of integration sophistication. Basic implementations feature simple sensor nodes powered by single-source harvesters, while advanced systems incorporate hybrid energy harvesting approaches with intelligent power management algorithms. These advanced systems can dynamically adjust their operation based on available energy and prioritize critical functions during periods of limited power availability, ensuring continuous operation of essential monitoring capabilities.

The scalability of these integrated systems presents both opportunities and challenges. While the distributed nature of agricultural IoT networks benefits from the decentralized power generation that micro harvesters provide, maintaining consistent performance across diverse environmental conditions remains technically challenging. Seasonal variations in available ambient energy sources necessitate adaptive harvesting strategies and robust energy storage solutions to maintain system reliability throughout the agricultural cycle.

Data management frameworks within these integrated systems have evolved to accommodate energy constraints. Edge computing architectures that process data locally before transmission significantly reduce power consumption compared to continuous raw data streaming. Additionally, machine learning algorithms deployed at the edge can identify anomalies or critical events that warrant immediate communication, further optimizing the energy utilization profile of the system.

Standardization efforts are gradually emerging to address interoperability challenges between diverse energy harvesting technologies and IoT platforms. Organizations such as the IEEE and various agricultural technology consortia are developing protocols that facilitate seamless integration of harvesting technologies with existing farm management systems. These standards are crucial for widespread adoption and will enable farmers to incrementally upgrade their operations without wholesale replacement of existing infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!