Integration of Micro Energy Harvesters with AI Systems: Challenges and Solutions

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Technology Evolution and Objectives

Micro energy harvesting technology has evolved significantly over the past two decades, transitioning from theoretical concepts to practical implementations. The journey began with rudimentary piezoelectric and thermoelectric generators in the early 2000s, capable of producing only microwatts of power under specific conditions. These early systems suffered from low efficiency, limited durability, and restricted application scenarios, primarily serving as proof-of-concept demonstrations rather than viable energy solutions.

By the mid-2010s, advancements in materials science and fabrication techniques enabled the development of more efficient and versatile micro energy harvesters. Multi-source energy harvesting systems emerged, capable of simultaneously capturing energy from various environmental sources such as vibration, temperature gradients, light, and RF signals. This period also witnessed significant improvements in power management circuits specifically designed for intermittent and low-power energy sources.

The current technological landscape features sophisticated micro energy harvesting solutions with conversion efficiencies approaching theoretical limits for certain modalities. Modern harvesters incorporate advanced materials like high-performance piezoelectric composites, flexible thermoelectric generators, and specialized photovoltaic cells optimized for indoor lighting conditions. These developments have expanded the application scope from simple sensing tasks to more complex operations requiring higher energy budgets.

The integration of micro energy harvesters with AI systems represents the next frontier in this technological evolution. This integration aims to create self-sustaining intelligent systems capable of operating indefinitely without battery replacement or external power sources. The primary objective is to develop energy-autonomous AI-enabled devices that can perform complex computational tasks while relying solely on ambient energy sources.

Specific technical objectives include developing ultra-low-power AI architectures compatible with the intermittent power supply characteristics of energy harvesters, creating adaptive power management systems that can optimize energy usage based on harvesting conditions and computational demands, and designing specialized hardware accelerators that can efficiently execute AI algorithms under severe energy constraints.

Another critical objective is to establish bidirectional optimization frameworks where AI algorithms can enhance energy harvesting efficiency while energy availability informs AI operation modes. This symbiotic relationship between energy harvesting and AI processing represents a paradigm shift from traditional power management approaches, potentially enabling new classes of perpetually operating intelligent systems for applications ranging from environmental monitoring to medical implants and infrastructure sensing.

By the mid-2010s, advancements in materials science and fabrication techniques enabled the development of more efficient and versatile micro energy harvesters. Multi-source energy harvesting systems emerged, capable of simultaneously capturing energy from various environmental sources such as vibration, temperature gradients, light, and RF signals. This period also witnessed significant improvements in power management circuits specifically designed for intermittent and low-power energy sources.

The current technological landscape features sophisticated micro energy harvesting solutions with conversion efficiencies approaching theoretical limits for certain modalities. Modern harvesters incorporate advanced materials like high-performance piezoelectric composites, flexible thermoelectric generators, and specialized photovoltaic cells optimized for indoor lighting conditions. These developments have expanded the application scope from simple sensing tasks to more complex operations requiring higher energy budgets.

The integration of micro energy harvesters with AI systems represents the next frontier in this technological evolution. This integration aims to create self-sustaining intelligent systems capable of operating indefinitely without battery replacement or external power sources. The primary objective is to develop energy-autonomous AI-enabled devices that can perform complex computational tasks while relying solely on ambient energy sources.

Specific technical objectives include developing ultra-low-power AI architectures compatible with the intermittent power supply characteristics of energy harvesters, creating adaptive power management systems that can optimize energy usage based on harvesting conditions and computational demands, and designing specialized hardware accelerators that can efficiently execute AI algorithms under severe energy constraints.

Another critical objective is to establish bidirectional optimization frameworks where AI algorithms can enhance energy harvesting efficiency while energy availability informs AI operation modes. This symbiotic relationship between energy harvesting and AI processing represents a paradigm shift from traditional power management approaches, potentially enabling new classes of perpetually operating intelligent systems for applications ranging from environmental monitoring to medical implants and infrastructure sensing.

Market Analysis for AI-Powered Self-Sustaining Systems

The market for AI-powered self-sustaining systems is experiencing unprecedented growth, driven by the convergence of energy harvesting technologies and artificial intelligence. Current market valuations indicate that this sector is expected to reach significant market size by 2030, with a compound annual growth rate substantially outpacing traditional IoT markets. This growth trajectory is supported by increasing demand across multiple industries seeking autonomous, maintenance-free smart systems.

Healthcare represents one of the most promising vertical markets, where self-powered wearable monitors and implantable devices are revolutionizing patient care through continuous health monitoring without battery replacement concerns. The industrial IoT sector similarly demonstrates robust demand, as manufacturers implement self-sustaining sensors throughout production facilities to optimize operations while minimizing maintenance requirements.

Smart infrastructure and urban environments constitute another major market segment, with self-powered environmental sensors, traffic monitors, and building management systems gaining significant traction. The agricultural sector is also rapidly adopting these technologies for autonomous field monitoring systems that can operate indefinitely in remote locations.

Consumer electronics manufacturers are increasingly incorporating energy harvesting capabilities into everyday devices, creating a substantial market for self-powered smart home products, wearables, and portable electronics. This trend is particularly evident in regions with established IoT ecosystems such as North America, Europe, and East Asia.

Market analysis reveals several key drivers accelerating adoption. The most significant is the dramatic reduction in operational costs achieved by eliminating battery replacement and associated maintenance. Environmental sustainability concerns are also propelling market growth as organizations seek to reduce electronic waste and carbon footprints associated with battery production and disposal.

Technological advancements in both energy harvesting efficiency and AI power optimization are continuously expanding the application scope, creating new market opportunities. Government initiatives promoting green technologies and sustainable development further support market expansion through favorable policies and funding programs.

Regional analysis shows Asia-Pacific leading in manufacturing capacity for these systems, while North America dominates in research innovation and premium market applications. Europe demonstrates strong growth driven by stringent environmental regulations and sustainability initiatives.

The competitive landscape features both established technology corporations expanding their portfolios and innovative startups developing specialized solutions. Strategic partnerships between energy harvesting specialists and AI companies are increasingly common, creating integrated solution providers capable of addressing complex market requirements.

Healthcare represents one of the most promising vertical markets, where self-powered wearable monitors and implantable devices are revolutionizing patient care through continuous health monitoring without battery replacement concerns. The industrial IoT sector similarly demonstrates robust demand, as manufacturers implement self-sustaining sensors throughout production facilities to optimize operations while minimizing maintenance requirements.

Smart infrastructure and urban environments constitute another major market segment, with self-powered environmental sensors, traffic monitors, and building management systems gaining significant traction. The agricultural sector is also rapidly adopting these technologies for autonomous field monitoring systems that can operate indefinitely in remote locations.

Consumer electronics manufacturers are increasingly incorporating energy harvesting capabilities into everyday devices, creating a substantial market for self-powered smart home products, wearables, and portable electronics. This trend is particularly evident in regions with established IoT ecosystems such as North America, Europe, and East Asia.

Market analysis reveals several key drivers accelerating adoption. The most significant is the dramatic reduction in operational costs achieved by eliminating battery replacement and associated maintenance. Environmental sustainability concerns are also propelling market growth as organizations seek to reduce electronic waste and carbon footprints associated with battery production and disposal.

Technological advancements in both energy harvesting efficiency and AI power optimization are continuously expanding the application scope, creating new market opportunities. Government initiatives promoting green technologies and sustainable development further support market expansion through favorable policies and funding programs.

Regional analysis shows Asia-Pacific leading in manufacturing capacity for these systems, while North America dominates in research innovation and premium market applications. Europe demonstrates strong growth driven by stringent environmental regulations and sustainability initiatives.

The competitive landscape features both established technology corporations expanding their portfolios and innovative startups developing specialized solutions. Strategic partnerships between energy harvesting specialists and AI companies are increasingly common, creating integrated solution providers capable of addressing complex market requirements.

Technical Barriers in Micro Energy Harvester-AI Integration

The integration of micro energy harvesters with AI systems faces significant technical barriers that currently limit widespread implementation. Power density constraints represent the most fundamental challenge, as micro energy harvesters typically generate power in the microwatt to milliwatt range, which is insufficient for conventional AI processing requirements. Even state-of-the-art harvesters struggle to deliver consistent power above 10mW/cm², creating a substantial energy gap for AI operations that often require orders of magnitude more power.

Energy intermittency presents another critical obstacle, as environmental energy sources (vibration, thermal gradients, ambient RF) fluctuate unpredictably. This variability creates misalignment with AI systems that require stable power for continuous operation, particularly for tasks involving real-time data processing and decision-making. Current energy storage solutions like thin-film batteries and supercapacitors offer inadequate energy density and suffer from limited charge-discharge cycles when miniaturized.

Dimensional incompatibility between harvesting components and AI hardware creates integration challenges at both physical and electrical levels. Micro energy harvesters require specialized interfaces and power conditioning circuits that add complexity, volume, and energy overhead to the system. The impedance matching between harvesters and AI processing units remains particularly problematic, often resulting in significant power transfer inefficiencies exceeding 40%.

Thermal management issues arise as AI processing generates heat that can interfere with certain harvesting mechanisms, particularly thermoelectric generators that rely on temperature differentials. This creates a counterproductive scenario where increased AI computational load generates heat that reduces harvesting efficiency, creating a negative feedback loop in integrated systems.

Efficiency degradation over time represents a long-term barrier, as micro energy harvesters typically experience performance deterioration due to mechanical fatigue, material degradation, and environmental exposure. This contrasts with AI systems that often require consistent or increasing computational capabilities over their operational lifetime, creating a widening performance gap as systems age.

Communication protocol incompatibilities between harvesting systems and AI processors create additional integration challenges. Most energy harvesters utilize simple analog interfaces while AI systems require digital communication protocols, necessitating additional conversion circuitry that consumes precious harvested energy and increases system complexity.

Energy intermittency presents another critical obstacle, as environmental energy sources (vibration, thermal gradients, ambient RF) fluctuate unpredictably. This variability creates misalignment with AI systems that require stable power for continuous operation, particularly for tasks involving real-time data processing and decision-making. Current energy storage solutions like thin-film batteries and supercapacitors offer inadequate energy density and suffer from limited charge-discharge cycles when miniaturized.

Dimensional incompatibility between harvesting components and AI hardware creates integration challenges at both physical and electrical levels. Micro energy harvesters require specialized interfaces and power conditioning circuits that add complexity, volume, and energy overhead to the system. The impedance matching between harvesters and AI processing units remains particularly problematic, often resulting in significant power transfer inefficiencies exceeding 40%.

Thermal management issues arise as AI processing generates heat that can interfere with certain harvesting mechanisms, particularly thermoelectric generators that rely on temperature differentials. This creates a counterproductive scenario where increased AI computational load generates heat that reduces harvesting efficiency, creating a negative feedback loop in integrated systems.

Efficiency degradation over time represents a long-term barrier, as micro energy harvesters typically experience performance deterioration due to mechanical fatigue, material degradation, and environmental exposure. This contrasts with AI systems that often require consistent or increasing computational capabilities over their operational lifetime, creating a widening performance gap as systems age.

Communication protocol incompatibilities between harvesting systems and AI processors create additional integration challenges. Most energy harvesters utilize simple analog interfaces while AI systems require digital communication protocols, necessitating additional conversion circuitry that consumes precious harvested energy and increases system complexity.

Current Integration Approaches and Architectures

01 Piezoelectric micro energy harvesters

Piezoelectric materials convert mechanical stress into electrical energy, making them ideal for micro energy harvesting applications. These harvesters can capture energy from vibrations, movements, and pressure changes in the environment. The technology typically uses thin-film piezoelectric materials like PZT, AlN, or ZnO deposited on flexible substrates to generate electricity when deformed. These devices are particularly useful in wearable electronics, wireless sensor networks, and IoT applications where traditional power sources are impractical.- Piezoelectric micro energy harvesters: Piezoelectric materials are used in micro energy harvesters to convert mechanical vibrations into electrical energy. These devices typically consist of a piezoelectric material layer mounted on a flexible substrate that deforms under mechanical stress, generating electrical charges. This technology is particularly useful for powering small electronic devices and sensors in environments where vibrations are present, such as industrial machinery, transportation systems, or wearable devices.

- Electromagnetic micro energy harvesting systems: Electromagnetic micro energy harvesters utilize the principle of electromagnetic induction to generate electrical energy from motion or vibration. These systems typically consist of a magnet moving relative to a coil, inducing current in the coil according to Faraday's law. The design can be optimized for specific frequency ranges and amplitudes of vibration, making them suitable for various applications including self-powered sensors, IoT devices, and portable electronics.

- Triboelectric nanogenerators for energy harvesting: Triboelectric nanogenerators (TENGs) harvest energy by converting mechanical energy into electricity through the triboelectric effect and electrostatic induction. These devices generate electrical charges when two different materials come into contact and separate. TENGs can be designed in various configurations to harvest energy from different types of mechanical motions such as sliding, contact-separation, or rotation, making them versatile for applications in self-powered sensors, wearable electronics, and IoT devices.

- Thermal micro energy harvesters: Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These devices typically consist of thermoelectric materials that generate voltage when subjected to a temperature gradient. Micro-scale thermal energy harvesters can be integrated into various systems to recover waste heat and power small electronic devices. Applications include body-heat powered wearables, industrial sensors in environments with temperature variations, and energy-autonomous IoT devices.

- Hybrid and multi-source micro energy harvesting systems: Hybrid micro energy harvesters combine multiple energy harvesting mechanisms to improve efficiency and reliability. These systems can simultaneously harvest energy from different sources such as vibration, thermal gradients, solar radiation, or RF signals. By integrating multiple harvesting technologies, these systems can provide more consistent power output under varying environmental conditions, making them suitable for applications requiring reliable energy supply in changing environments, such as environmental monitoring, structural health monitoring, and remote sensing.

02 Triboelectric nanogenerators for energy harvesting

Triboelectric nanogenerators (TENGs) harvest energy from friction between different materials. When two dissimilar materials come into contact and then separate, they generate static electricity that can be captured and utilized. These devices typically consist of two layers with different electron affinities that create electrical charges when rubbed together. TENGs can harvest energy from various mechanical sources including human motion, wind, and water waves, making them versatile for self-powered systems and sensors in smart devices.Expand Specific Solutions03 Electromagnetic micro energy harvesting systems

Electromagnetic energy harvesters utilize Faraday's law of induction to convert mechanical motion into electrical energy. These systems typically consist of magnets and coils arranged so that relative movement between them induces electrical current. The technology can be miniaturized for micro-scale applications while maintaining efficiency. These harvesters are particularly effective for capturing energy from vibrations and oscillatory movements in industrial environments, transportation systems, and infrastructure monitoring applications.Expand Specific Solutions04 Thermal energy harvesting for microdevices

Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These devices utilize the Seebeck effect, where a temperature gradient across certain materials generates voltage. Micro-scale thermal harvesters typically employ arrays of thermocouples made from semiconductor materials to maximize power output from small temperature differentials. Applications include powering wearable devices from body heat, industrial sensors from machinery heat, and environmental monitoring systems in locations with natural temperature variations.Expand Specific Solutions05 RF and ambient energy harvesting technologies

Radio frequency (RF) and ambient energy harvesting technologies capture electromagnetic energy from the environment, including radio waves, Wi-Fi signals, and cellular transmissions. These systems typically use specialized antennas and rectifier circuits to convert RF energy into DC power. The harvested energy can power low-energy devices in smart environments, eliminating the need for batteries in certain applications. This technology is particularly valuable for wireless sensor networks, IoT devices, and remote monitoring systems in urban environments with abundant RF signals.Expand Specific Solutions

Leading Companies in Micro Energy Harvesting and AI

The integration of micro energy harvesters with AI systems is currently in an early growth phase, with a market expected to reach significant expansion as IoT applications proliferate. Leading academic institutions (Southeast University, Beijing Institute of Technology) are collaborating with industrial players to advance fundamental research, while established tech corporations (Intel, Texas Instruments, STMicroelectronics) are developing commercial applications. Companies like Bosch and ABB are focusing on industrial implementations, while agricultural technology firms (Deere & Co., AGCO) are exploring specialized applications. The technology remains in early maturity stages, with challenges in energy density and AI optimization still being addressed through cross-sector partnerships between academia and industry to accelerate commercialization pathways.

Intel Corp.

Technical Solution: Intel has developed a comprehensive approach to integrating micro energy harvesters with AI systems through their Energy Harvesting Active Networked Tags (EHANT) platform. This solution combines ultra-low-power processors with specialized power management circuits that can efficiently capture, store, and utilize energy from multiple ambient sources including vibration, thermal gradients, RF, and light. Their technology employs adaptive duty cycling algorithms that dynamically adjust AI workloads based on available harvested energy. Intel's neuromorphic computing chips like Loihi are specifically designed to operate at extremely low power levels (under 1mW) while performing AI inference tasks, making them ideal for energy harvesting applications. The company has also pioneered specialized analog-to-digital converters that operate at sub-microwatt power levels to interface with various energy harvesting transducers. Their system architecture includes intelligent power budgeting that prioritizes critical AI functions when energy is scarce.

Strengths: Intel's solution benefits from vertical integration of hardware and software, allowing for optimized energy efficiency across the entire system stack. Their extensive experience in processor design enables AI computation at unprecedented low power levels. Weaknesses: The technology requires relatively complex power management circuitry that may increase system cost and size, potentially limiting applications in extremely space-constrained environments.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered an integrated approach to micro energy harvesting for AI systems through their MEMS-based energy harvesting technology. Their solution combines piezoelectric, thermoelectric, and photovoltaic harvesters in a single package, enabling multi-source energy capture to power AI edge devices. The company's proprietary power management integrated circuits (PMICs) can operate with input voltages as low as 0.2V, efficiently converting harvested energy to usable power for AI processing. Bosch's system employs a hierarchical computing architecture where ultra-low-power microcontrollers handle sensor data preprocessing before activating more power-intensive AI accelerators only when necessary. Their technology incorporates adaptive machine learning algorithms that can scale computational complexity based on available energy, ensuring continuous operation even under variable energy harvesting conditions. Bosch has demonstrated this technology in industrial IoT applications where their systems can operate perpetually by harvesting energy from machine vibrations, temperature differentials, and ambient light.

Strengths: Bosch's solution excels in industrial environments where multiple energy sources can be tapped simultaneously, providing more reliable power for AI systems. Their extensive experience in sensor technology enables highly efficient integration of sensing and energy harvesting functions. Weaknesses: The multi-source approach increases system complexity and may require more sophisticated installation to properly position different harvesting elements for optimal energy capture.

Key Patents and Research in Energy-Efficient AI Systems

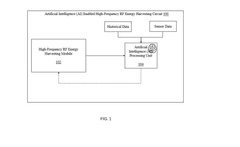

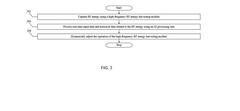

Artificial intelligence (AI) enabled high-frequency RF energy harvesting circuit with improved efficiency

PatentPendingIN202341066956A

Innovation

- An AI-enabled high-frequency RF energy harvesting circuit that integrates an AI processing unit to continuously analyze real-time data and environmental sensors, employing machine learning algorithms to optimize operational parameters such as impedance matching, duty cycles, and frequencies, and utilizing predictive modeling for proactive adjustments.

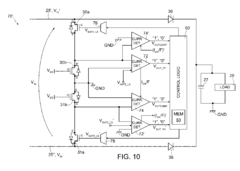

Energy harvesting interface with improved impedance matching, method for operating the energy harvesting interface, and energy harvesting system using the energy harvesting interface

PatentActiveEP2908421A3

Innovation

- An energy harvesting interface with a rectifier circuit that uses high-voltage and low-voltage switches, along with control logic to manage the switches and store energy efficiently, allowing for optimal impedance matching and energy transfer even at low signal amplitudes, using a buck or boost DC-DC converter to match impedance and regulate voltage.

Energy Management Strategies for Intermittent Computing

Intermittent computing presents unique challenges for AI systems integrated with micro energy harvesters. These systems operate in environments where power availability fluctuates unpredictably, necessitating sophisticated energy management strategies. Traditional computing paradigms assume continuous power supply, making them unsuitable for energy-harvesting scenarios where computation may be frequently interrupted.

Task-based scheduling has emerged as a fundamental approach for intermittent computing. This strategy divides computational workloads into atomic tasks that can be completed within a single power cycle. By implementing checkpointing mechanisms at task boundaries, systems can maintain progress despite power interruptions. Advanced implementations utilize static analysis to optimize task sizes based on expected energy availability patterns derived from harvester characteristics.

Dynamic voltage and frequency scaling (DVFS) techniques have been adapted specifically for energy harvesting contexts. Unlike traditional DVFS which primarily focuses on power reduction, harvester-aware DVFS algorithms dynamically adjust processing capabilities based on current energy levels and predicted future availability. This approach enables systems to maximize computational throughput while avoiding power failures during critical operations.

Energy-aware machine learning optimization represents a cutting-edge development in this field. Techniques such as approximate computing and precision scaling allow AI algorithms to adapt their computational intensity based on available energy. For instance, neural network inference can dynamically adjust precision levels, trading accuracy for energy efficiency when power is scarce. Some systems implement tiered execution models where simplified algorithms are used during energy constraints, with full-precision computation reserved for energy-abundant periods.

Predictive energy management leverages historical energy harvesting patterns to optimize system behavior. By analyzing temporal patterns in energy availability, these systems can schedule computation-intensive tasks during predicted high-energy periods. Machine learning models trained on harvesting data can forecast energy availability with increasing accuracy, enabling proactive rather than reactive energy management strategies.

Hardware-software co-design approaches have proven particularly effective, with non-volatile processors and specialized memory architectures designed specifically for intermittent operation. These architectures maintain system state during power failures without explicit checkpointing overhead. Complementary software frameworks provide programming abstractions that shield developers from the complexities of intermittent execution while maximizing energy efficiency.

Task-based scheduling has emerged as a fundamental approach for intermittent computing. This strategy divides computational workloads into atomic tasks that can be completed within a single power cycle. By implementing checkpointing mechanisms at task boundaries, systems can maintain progress despite power interruptions. Advanced implementations utilize static analysis to optimize task sizes based on expected energy availability patterns derived from harvester characteristics.

Dynamic voltage and frequency scaling (DVFS) techniques have been adapted specifically for energy harvesting contexts. Unlike traditional DVFS which primarily focuses on power reduction, harvester-aware DVFS algorithms dynamically adjust processing capabilities based on current energy levels and predicted future availability. This approach enables systems to maximize computational throughput while avoiding power failures during critical operations.

Energy-aware machine learning optimization represents a cutting-edge development in this field. Techniques such as approximate computing and precision scaling allow AI algorithms to adapt their computational intensity based on available energy. For instance, neural network inference can dynamically adjust precision levels, trading accuracy for energy efficiency when power is scarce. Some systems implement tiered execution models where simplified algorithms are used during energy constraints, with full-precision computation reserved for energy-abundant periods.

Predictive energy management leverages historical energy harvesting patterns to optimize system behavior. By analyzing temporal patterns in energy availability, these systems can schedule computation-intensive tasks during predicted high-energy periods. Machine learning models trained on harvesting data can forecast energy availability with increasing accuracy, enabling proactive rather than reactive energy management strategies.

Hardware-software co-design approaches have proven particularly effective, with non-volatile processors and specialized memory architectures designed specifically for intermittent operation. These architectures maintain system state during power failures without explicit checkpointing overhead. Complementary software frameworks provide programming abstractions that shield developers from the complexities of intermittent execution while maximizing energy efficiency.

Standardization Efforts for Energy Harvesting Interfaces

The standardization of energy harvesting interfaces represents a critical development in the integration of micro energy harvesters with AI systems. Currently, several international organizations are actively working to establish common standards that would facilitate seamless integration across different technologies and applications. The IEEE P1801 working group has been developing standards specifically for power modeling interfaces in energy harvesting systems, which aims to create a unified framework for power estimation and optimization in integrated circuits that incorporate energy harvesting capabilities.

In parallel, the International Electrotechnical Commission (IEC) has established the TC 120 committee focused on electrical energy storage systems, which includes standardization efforts for energy harvesting interfaces. Their work encompasses the development of technical specifications for the connection between energy harvesters and storage elements, as well as the interfaces with AI processing units.

The Wireless Power Consortium (WPC) has also expanded its scope beyond wireless charging to include standards for low-power energy harvesting interfaces, particularly relevant for IoT devices that integrate AI capabilities. Their Qi-EH specification addresses the unique requirements of micro-scale energy harvesting systems.

A significant challenge in standardization efforts is the diverse nature of energy harvesting technologies. Each harvesting method—whether piezoelectric, thermoelectric, photovoltaic, or RF—presents unique electrical characteristics that require specific interface considerations. The MIPI Alliance has recognized this challenge and is developing flexible interface standards that can accommodate various energy harvesting technologies while maintaining compatibility with AI processing requirements.

Industry consortiums like the EnOcean Alliance have focused on creating interoperability standards specifically for self-powered wireless devices, which often incorporate both energy harvesting and AI components. Their standardization work addresses not only the physical interfaces but also the communication protocols optimized for energy-constrained operations.

The emergence of edge AI applications has further complicated standardization efforts, as these systems require interfaces that can handle dynamic power management based on AI workload fluctuations. The Open Neural Network Exchange (ONNX) community has begun collaborating with energy harvesting standards bodies to ensure compatibility between AI model requirements and energy availability constraints.

Looking forward, the convergence of these standardization efforts will likely lead to a multi-tiered approach: physical interface standards for hardware connectivity, power management interface standards for efficient energy utilization, and application programming interfaces (APIs) that allow AI systems to adapt their operation based on available harvested energy.

In parallel, the International Electrotechnical Commission (IEC) has established the TC 120 committee focused on electrical energy storage systems, which includes standardization efforts for energy harvesting interfaces. Their work encompasses the development of technical specifications for the connection between energy harvesters and storage elements, as well as the interfaces with AI processing units.

The Wireless Power Consortium (WPC) has also expanded its scope beyond wireless charging to include standards for low-power energy harvesting interfaces, particularly relevant for IoT devices that integrate AI capabilities. Their Qi-EH specification addresses the unique requirements of micro-scale energy harvesting systems.

A significant challenge in standardization efforts is the diverse nature of energy harvesting technologies. Each harvesting method—whether piezoelectric, thermoelectric, photovoltaic, or RF—presents unique electrical characteristics that require specific interface considerations. The MIPI Alliance has recognized this challenge and is developing flexible interface standards that can accommodate various energy harvesting technologies while maintaining compatibility with AI processing requirements.

Industry consortiums like the EnOcean Alliance have focused on creating interoperability standards specifically for self-powered wireless devices, which often incorporate both energy harvesting and AI components. Their standardization work addresses not only the physical interfaces but also the communication protocols optimized for energy-constrained operations.

The emergence of edge AI applications has further complicated standardization efforts, as these systems require interfaces that can handle dynamic power management based on AI workload fluctuations. The Open Neural Network Exchange (ONNX) community has begun collaborating with energy harvesting standards bodies to ensure compatibility between AI model requirements and energy availability constraints.

Looking forward, the convergence of these standardization efforts will likely lead to a multi-tiered approach: physical interface standards for hardware connectivity, power management interface standards for efficient energy utilization, and application programming interfaces (APIs) that allow AI systems to adapt their operation based on available harvested energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!