Study of Hybrid Micro Energy Harvester Mechanisms and Applications

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Micro Energy Harvesting Background and Objectives

The field of micro energy harvesting has evolved significantly over the past two decades, driven by the increasing demand for sustainable power sources for small-scale electronic devices. Traditional energy harvesting methods have focused on single-source approaches, such as piezoelectric, thermoelectric, or photovoltaic technologies. However, these individual methods often suffer from limitations in power density, reliability, and adaptability to varying environmental conditions.

Hybrid micro energy harvesting represents a paradigm shift in this domain, combining multiple energy harvesting mechanisms into integrated systems capable of extracting energy from diverse ambient sources simultaneously. This approach emerged around 2010 when researchers began exploring the synergistic effects of combining different harvesting technologies to overcome the inherent limitations of single-source harvesters.

The evolution of hybrid micro energy harvesters has been accelerated by advancements in materials science, particularly the development of multifunctional materials that can respond to different energy stimuli. Nanomaterials and flexible substrates have enabled the creation of more efficient and compact hybrid systems, while improvements in power management circuits have enhanced the ability to effectively utilize harvested energy from multiple sources.

Current technological trends point toward increasingly sophisticated integration strategies, with a focus on maximizing power output while minimizing device footprint. The miniaturization of hybrid harvesters has opened new possibilities for applications in wearable technology, implantable medical devices, and distributed sensor networks for Internet of Things (IoT) implementations.

The primary objective of this technical research is to comprehensively analyze the mechanisms underlying hybrid micro energy harvesting systems and evaluate their practical applications across various industries. Specifically, we aim to identify the most promising combinations of harvesting technologies, assess their performance metrics under different operating conditions, and determine optimal integration strategies for specific use cases.

Additionally, this research seeks to map the technological roadmap for hybrid micro energy harvesters over the next five years, identifying potential breakthroughs in materials, designs, and fabrication techniques that could significantly enhance harvesting efficiency. We will examine how emerging technologies such as artificial intelligence and edge computing might interface with hybrid energy harvesting systems to create more adaptive and intelligent power solutions.

Finally, this study aims to provide strategic insights into market opportunities and challenges for commercializing hybrid micro energy harvesting technologies, considering factors such as manufacturing scalability, cost-effectiveness, and regulatory considerations across different application domains.

Hybrid micro energy harvesting represents a paradigm shift in this domain, combining multiple energy harvesting mechanisms into integrated systems capable of extracting energy from diverse ambient sources simultaneously. This approach emerged around 2010 when researchers began exploring the synergistic effects of combining different harvesting technologies to overcome the inherent limitations of single-source harvesters.

The evolution of hybrid micro energy harvesters has been accelerated by advancements in materials science, particularly the development of multifunctional materials that can respond to different energy stimuli. Nanomaterials and flexible substrates have enabled the creation of more efficient and compact hybrid systems, while improvements in power management circuits have enhanced the ability to effectively utilize harvested energy from multiple sources.

Current technological trends point toward increasingly sophisticated integration strategies, with a focus on maximizing power output while minimizing device footprint. The miniaturization of hybrid harvesters has opened new possibilities for applications in wearable technology, implantable medical devices, and distributed sensor networks for Internet of Things (IoT) implementations.

The primary objective of this technical research is to comprehensively analyze the mechanisms underlying hybrid micro energy harvesting systems and evaluate their practical applications across various industries. Specifically, we aim to identify the most promising combinations of harvesting technologies, assess their performance metrics under different operating conditions, and determine optimal integration strategies for specific use cases.

Additionally, this research seeks to map the technological roadmap for hybrid micro energy harvesters over the next five years, identifying potential breakthroughs in materials, designs, and fabrication techniques that could significantly enhance harvesting efficiency. We will examine how emerging technologies such as artificial intelligence and edge computing might interface with hybrid energy harvesting systems to create more adaptive and intelligent power solutions.

Finally, this study aims to provide strategic insights into market opportunities and challenges for commercializing hybrid micro energy harvesting technologies, considering factors such as manufacturing scalability, cost-effectiveness, and regulatory considerations across different application domains.

Market Demand Analysis for Micro Energy Harvesting Solutions

The global market for micro energy harvesting solutions is experiencing robust growth, driven by the increasing demand for autonomous and self-powered electronic devices across various industries. The market was valued at approximately $460 million in 2021 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 14.8% during the forecast period. This significant growth trajectory underscores the expanding commercial viability of micro energy harvesting technologies.

The Internet of Things (IoT) ecosystem serves as a primary driver for micro energy harvesting solutions. With an estimated 41.6 billion IoT devices expected to be in operation by 2025, the need for sustainable power sources that eliminate battery replacement and reduce maintenance costs is becoming increasingly critical. Industries such as manufacturing, healthcare, agriculture, and smart infrastructure are actively seeking energy harvesting solutions to power their growing networks of sensors and monitoring devices.

Consumer electronics represents another substantial market segment, with wearable technology and portable devices requiring innovative power solutions. The global wearable technology market is expected to grow at a CAGR of 15.9% from 2022 to 2030, creating significant opportunities for micro energy harvesters that can capture energy from human movement, body heat, or ambient light.

The automotive sector is emerging as a promising application area, particularly with the rise of electric and autonomous vehicles. These advanced transportation systems require numerous sensors and electronic components that could benefit from self-powered operation. The market for automotive energy harvesting systems is projected to grow at a CAGR of 19.3% through 2027.

Environmental monitoring applications are also driving demand for micro energy harvesting solutions. Remote sensing networks for climate research, wildlife tracking, and natural disaster prediction require long-lasting power sources that can operate in harsh environments without human intervention. This segment is expected to grow substantially as climate change concerns intensify global monitoring efforts.

Healthcare applications represent a high-value market segment, with implantable medical devices and remote patient monitoring systems increasingly adopting energy harvesting technologies. The medical device energy harvesting market is projected to grow at a CAGR of 18.7% through 2028, driven by the need for long-lasting power solutions that eliminate the risks associated with battery replacement surgeries.

Regional analysis indicates that North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing IoT adoption, and substantial investments in smart city infrastructure across countries like China, Japan, South Korea, and India.

The Internet of Things (IoT) ecosystem serves as a primary driver for micro energy harvesting solutions. With an estimated 41.6 billion IoT devices expected to be in operation by 2025, the need for sustainable power sources that eliminate battery replacement and reduce maintenance costs is becoming increasingly critical. Industries such as manufacturing, healthcare, agriculture, and smart infrastructure are actively seeking energy harvesting solutions to power their growing networks of sensors and monitoring devices.

Consumer electronics represents another substantial market segment, with wearable technology and portable devices requiring innovative power solutions. The global wearable technology market is expected to grow at a CAGR of 15.9% from 2022 to 2030, creating significant opportunities for micro energy harvesters that can capture energy from human movement, body heat, or ambient light.

The automotive sector is emerging as a promising application area, particularly with the rise of electric and autonomous vehicles. These advanced transportation systems require numerous sensors and electronic components that could benefit from self-powered operation. The market for automotive energy harvesting systems is projected to grow at a CAGR of 19.3% through 2027.

Environmental monitoring applications are also driving demand for micro energy harvesting solutions. Remote sensing networks for climate research, wildlife tracking, and natural disaster prediction require long-lasting power sources that can operate in harsh environments without human intervention. This segment is expected to grow substantially as climate change concerns intensify global monitoring efforts.

Healthcare applications represent a high-value market segment, with implantable medical devices and remote patient monitoring systems increasingly adopting energy harvesting technologies. The medical device energy harvesting market is projected to grow at a CAGR of 18.7% through 2028, driven by the need for long-lasting power solutions that eliminate the risks associated with battery replacement surgeries.

Regional analysis indicates that North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing IoT adoption, and substantial investments in smart city infrastructure across countries like China, Japan, South Korea, and India.

Current State and Challenges in Hybrid Energy Harvesting

Hybrid micro energy harvesting technology has evolved significantly over the past decade, with global research efforts intensifying to address the growing demand for sustainable power sources in IoT devices and wireless sensor networks. Currently, the field encompasses multiple energy conversion mechanisms including piezoelectric, electromagnetic, triboelectric, thermoelectric, and photovoltaic systems, with hybrid approaches combining two or more of these technologies to overcome individual limitations.

The state-of-the-art hybrid harvesters have demonstrated power densities ranging from microwatts to milliwatts per cubic centimeter, representing substantial improvement over single-mode harvesters. Notable achievements include piezoelectric-electromagnetic combinations achieving 30-40% higher output than individual systems, and triboelectric-photovoltaic hybrids demonstrating all-weather energy harvesting capabilities with conversion efficiencies exceeding 15% under optimal conditions.

Despite these advancements, significant technical challenges persist. Miniaturization remains problematic as the power output typically decreases with reduced device dimensions, creating a fundamental scaling limitation. Current hybrid systems often suffer from mechanical complexity and increased weight, compromising their integration into microelectronic applications. The impedance matching between different harvesting mechanisms presents another major hurdle, as optimal operating conditions for one mechanism may impede the performance of another.

Material compatibility issues frequently arise when integrating dissimilar harvesting technologies, leading to degraded performance and reduced operational lifespan. Most hybrid systems still demonstrate low energy conversion efficiencies, typically below 20% for combined mechanisms, which limits their practical application in energy-intensive scenarios. Additionally, the broadband response necessary for harvesting energy from variable environmental conditions remains difficult to achieve consistently.

From a geographical perspective, research leadership is distributed across several regions. North America and Europe lead in fundamental research and materials science, while East Asian countries, particularly Japan, South Korea, and China, dominate in miniaturization techniques and commercial applications. This distribution creates both collaborative opportunities and competitive challenges in the global technology landscape.

The economic viability of hybrid micro energy harvesters continues to be constrained by high manufacturing costs, with current production methods requiring specialized equipment and precise fabrication techniques. The resulting cost-per-watt metrics remain significantly higher than conventional power sources, limiting widespread adoption despite the clear technical advantages these systems offer for specific applications.

The state-of-the-art hybrid harvesters have demonstrated power densities ranging from microwatts to milliwatts per cubic centimeter, representing substantial improvement over single-mode harvesters. Notable achievements include piezoelectric-electromagnetic combinations achieving 30-40% higher output than individual systems, and triboelectric-photovoltaic hybrids demonstrating all-weather energy harvesting capabilities with conversion efficiencies exceeding 15% under optimal conditions.

Despite these advancements, significant technical challenges persist. Miniaturization remains problematic as the power output typically decreases with reduced device dimensions, creating a fundamental scaling limitation. Current hybrid systems often suffer from mechanical complexity and increased weight, compromising their integration into microelectronic applications. The impedance matching between different harvesting mechanisms presents another major hurdle, as optimal operating conditions for one mechanism may impede the performance of another.

Material compatibility issues frequently arise when integrating dissimilar harvesting technologies, leading to degraded performance and reduced operational lifespan. Most hybrid systems still demonstrate low energy conversion efficiencies, typically below 20% for combined mechanisms, which limits their practical application in energy-intensive scenarios. Additionally, the broadband response necessary for harvesting energy from variable environmental conditions remains difficult to achieve consistently.

From a geographical perspective, research leadership is distributed across several regions. North America and Europe lead in fundamental research and materials science, while East Asian countries, particularly Japan, South Korea, and China, dominate in miniaturization techniques and commercial applications. This distribution creates both collaborative opportunities and competitive challenges in the global technology landscape.

The economic viability of hybrid micro energy harvesters continues to be constrained by high manufacturing costs, with current production methods requiring specialized equipment and precise fabrication techniques. The resulting cost-per-watt metrics remain significantly higher than conventional power sources, limiting widespread adoption despite the clear technical advantages these systems offer for specific applications.

Current Hybrid Micro Energy Harvester Technical Solutions

01 Piezoelectric-based hybrid energy harvesters

These energy harvesters utilize piezoelectric materials that generate electrical energy when subjected to mechanical stress or vibration. The hybrid design often combines piezoelectric elements with other energy harvesting mechanisms to improve efficiency and power output. These systems can be integrated into various applications including wearable devices, structural health monitoring systems, and autonomous sensors, providing sustainable power generation from ambient mechanical energy sources.- Piezoelectric-based hybrid energy harvesters: These energy harvesters utilize piezoelectric materials that generate electrical energy when subjected to mechanical stress or vibration. The hybrid design often combines piezoelectric elements with other energy harvesting mechanisms to improve efficiency and power output. These systems can be miniaturized for micro-scale applications and are particularly useful in environments with abundant mechanical vibrations.

- Electromagnetic hybrid micro energy harvesters: These harvesters convert kinetic energy into electrical energy using electromagnetic induction principles. They typically consist of magnets and coils arranged to generate electricity when there is relative motion between them. The hybrid approach often combines electromagnetic generators with other harvesting technologies to capture energy from multiple sources simultaneously, enhancing overall power generation capability.

- Thermal-mechanical hybrid energy harvesting systems: These systems combine thermal energy harvesting (such as thermoelectric generators) with mechanical energy harvesting mechanisms. They can simultaneously capture energy from temperature differentials and mechanical movements, making them particularly effective in environments with both heat gradients and vibrations. This hybrid approach increases energy harvesting efficiency and provides more consistent power output across varying environmental conditions.

- Solar-kinetic hybrid micro energy harvesters: These harvesters integrate photovoltaic cells with kinetic energy harvesting technologies to capture energy from both sunlight and motion. The combination allows for continuous energy generation under various environmental conditions, whether in sunlight or shade, stationary or in motion. This approach is particularly valuable for powering small electronic devices in outdoor or mobile applications where energy sources vary throughout operation.

- Multi-source hybrid micro energy harvesting networks: These advanced systems integrate three or more energy harvesting technologies into a single network or platform. They may combine piezoelectric, electromagnetic, thermoelectric, triboelectric, and photovoltaic elements to maximize energy capture from the surrounding environment. These systems often include sophisticated power management circuits to optimize energy collection, storage, and distribution, making them suitable for autonomous sensor networks and IoT applications.

02 Electromagnetic hybrid micro energy harvesters

These harvesters convert kinetic energy into electrical energy through electromagnetic induction. The hybrid design typically incorporates permanent magnets and coils with other harvesting technologies to capture energy from multiple sources simultaneously. These systems are particularly effective for applications with varying environmental conditions, as they can generate power from low-frequency vibrations and movements, making them suitable for automotive, industrial, and consumer electronic applications.Expand Specific Solutions03 Thermal-mechanical hybrid energy harvesting systems

These systems combine thermal energy harvesting (such as thermoelectric generators) with mechanical energy harvesting technologies to capture energy from both temperature differentials and vibrations. By integrating multiple harvesting mechanisms, these hybrid systems can operate effectively in environments with fluctuating conditions, providing more consistent power output. Applications include industrial monitoring systems, remote sensors, and IoT devices deployed in environments with both thermal gradients and mechanical vibrations.Expand Specific Solutions04 Solar-vibration hybrid micro energy harvesters

These hybrid systems combine photovoltaic cells with vibration-based energy harvesting technologies to capture energy from both solar radiation and mechanical movement. This combination allows for continuous power generation under varying environmental conditions, such as day/night cycles or indoor/outdoor transitions. The integration of these complementary technologies enhances the reliability and efficiency of power generation for applications like wireless sensor networks, portable electronics, and environmental monitoring systems.Expand Specific Solutions05 Multi-source hybrid micro energy harvesters for transportation applications

These specialized hybrid energy harvesting systems are designed specifically for transportation applications, capturing energy from multiple sources present in vehicles, such as vibrations, thermal gradients, and motion. The harvested energy can power sensors, monitoring systems, and other low-power electronics without requiring battery replacement. These systems contribute to the development of more energy-efficient and autonomous vehicles by utilizing energy that would otherwise be wasted during normal vehicle operation.Expand Specific Solutions

Key Industry Players in Micro Energy Harvesting Field

The hybrid micro energy harvesting technology market is currently in a growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding, driven by the growing demand for self-powered IoT devices and wearable electronics, with projections suggesting significant growth over the next decade. Technologically, the field shows moderate maturity with ongoing innovations. Leading academic institutions like Xiamen University, Johns Hopkins University, and Southeast University are advancing fundamental research, while commercial players including Infineon Technologies, Hyundai Motor, and Honeywell are focusing on practical applications. Research institutes such as ETRI, KIST, and KERI are bridging the gap between academic research and industrial implementation, creating a competitive ecosystem that balances theoretical advancement with commercial viability.

Infineon Technologies AG

Technical Solution: Infineon Technologies AG has developed advanced hybrid micro energy harvesting solutions that integrate multiple energy sources including piezoelectric, thermoelectric, and photovoltaic technologies into a single system. Their approach focuses on maximizing energy capture efficiency through custom-designed power management integrated circuits (PMICs) that can simultaneously handle different types of harvested energy with varying characteristics. Infineon's technology employs ultra-low-power DC-DC converters with efficiency exceeding 90% even at micro-watt power levels, allowing effective energy extraction from ambient sources. Their solutions incorporate adaptive maximum power point tracking (MPPT) algorithms that continuously optimize energy extraction based on changing environmental conditions. Additionally, Infineon has pioneered miniaturized energy storage solutions using supercapacitors and thin-film batteries that complement their harvesting systems, creating complete power solutions for IoT and wearable applications.

Strengths: Industry-leading semiconductor expertise allows for highly integrated, efficient power management solutions. Their established manufacturing capabilities enable mass production with consistent quality. Weaknesses: Higher cost compared to single-source harvesters, and complexity in system integration requiring specialized design knowledge.

Korea Electrotechnology Research Institute

Technical Solution: Korea Electrotechnology Research Institute (KERI) has developed advanced hybrid micro energy harvesting systems that uniquely combine electromagnetic, piezoelectric, and triboelectric mechanisms in a single integrated device. Their multi-modal approach enables simultaneous energy capture from various ambient sources including vibration, motion, and mechanical pressure. KERI's technology features a layered architecture where complementary harvesting mechanisms are stacked vertically to maximize energy density per unit volume. Their systems incorporate specialized MEMS (Micro-Electro-Mechanical Systems) fabrication techniques to create microscale energy harvesters with precise resonant frequencies tuned to common environmental vibration sources. A significant innovation is their "frequency up-conversion" mechanism that can effectively harvest energy from low-frequency human movements and convert it to higher-frequency oscillations where piezoelectric generators operate more efficiently. KERI has also developed adaptive impedance matching circuits that dynamically optimize the electrical load seen by each harvesting element, maximizing power transfer efficiency across varying conditions. Their technology has been successfully demonstrated in self-powered wireless sensor networks for structural health monitoring and wearable health monitoring devices.

Strengths: Strong integration of multiple harvesting technologies in compact form factors, and excellent research capabilities in MEMS fabrication and materials science. Weaknesses: Some solutions require complex manufacturing processes that may challenge mass production, and optimization across multiple energy harvesting mechanisms increases system complexity.

Core Patents and Innovations in Hybrid Energy Harvesting

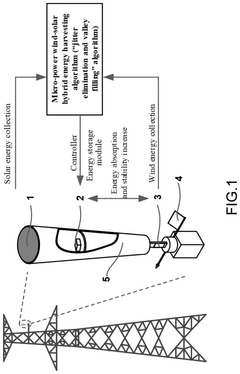

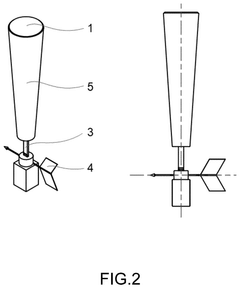

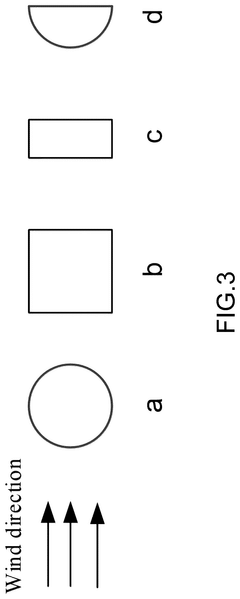

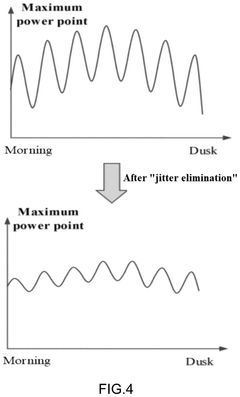

Micro-power wind-solar hybrid energy harvesting and power generating device, and energy harvesting method

PatentActiveUS12199436B2

Innovation

- A micro-power wind-solar hybrid energy harvesting and power generating device that employs a piezoelectric element to switch between energy collection and vibration suppression modes, using a wind-induced vibration structure and solar power generation module, with a control module to manage the piezoelectric element's role, ensuring continuous power output by leveraging both wind and solar energy sources.

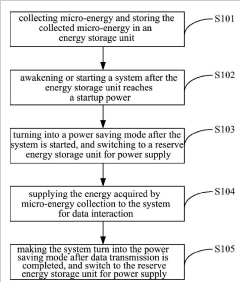

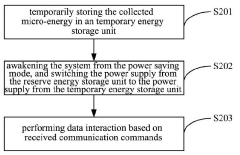

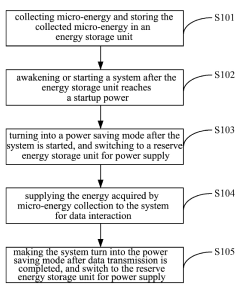

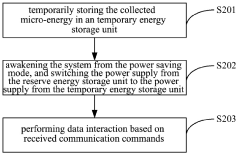

Hybrid power supply method, device, and micro-energy power supply based on micro-energy collection

PatentInactiveAU2019100309A4

Innovation

- A hybrid power supply method and device that combines environmental energy collection as the main power source with a chemical battery as an auxiliary source, using an ultra-low-power MCU and execution circuit to manage and switch between energy sources, ensuring continuous operation. The method involves collecting micro-energy, storing it, and switching to a reserve energy storage unit for power saving modes.

Energy Efficiency and Performance Metrics

The evaluation of energy efficiency and performance metrics is crucial for assessing the viability of hybrid micro energy harvester systems. These metrics provide quantitative measures to compare different harvesting technologies and guide optimization efforts. The most fundamental metric is power density, typically measured in μW/cm² or μW/cm³, which indicates how effectively a harvester converts ambient energy into electrical power within spatial constraints. For hybrid systems combining multiple harvesting mechanisms, this metric becomes particularly important as it reflects the synergistic benefits of integration.

Conversion efficiency represents another critical parameter, measuring the percentage of available ambient energy successfully converted to usable electrical energy. While conventional single-mode harvesters often achieve efficiencies between 5-30% depending on the energy source, hybrid systems can potentially exceed these ranges through complementary operation. Recent studies have demonstrated that piezoelectric-electromagnetic hybrid harvesters can achieve conversion efficiencies up to 45% under optimal conditions, significantly outperforming their individual components.

Bandwidth performance metrics are equally important for evaluating hybrid harvesters, particularly for vibration-based systems. The frequency range over which a harvester can effectively operate determines its adaptability to real-world environments where energy sources fluctuate. Hybrid designs typically exhibit broader operational bandwidths compared to single-mode harvesters, with recent piezoelectric-triboelectric combinations demonstrating effective energy capture across 15-200 Hz ranges.

Output stability metrics quantify the consistency of power generation under varying environmental conditions. This includes measurements of output voltage fluctuation, power intermittency, and energy storage requirements. Hybrid systems generally demonstrate superior stability by leveraging complementary harvesting mechanisms that operate under different optimal conditions, thereby maintaining power output across a wider range of environmental variations.

Longevity and reliability metrics assess the harvester's performance degradation over time. This includes cycle life testing, environmental resistance, and material degradation rates. These metrics are particularly relevant for hybrid systems where different components may age at varying rates. Current research indicates that properly designed hybrid systems can maintain at least 80% of initial performance after 10⁶ operational cycles, though long-term studies exceeding 5-10 years remain limited.

Cost-performance ratios provide crucial economic context, measuring power output against manufacturing costs, typically expressed as $/mW. While hybrid systems generally incur higher initial production costs due to increased complexity, their enhanced performance and versatility often result in more favorable lifetime cost-performance ratios, particularly in applications requiring sustained operation in variable environments.

Conversion efficiency represents another critical parameter, measuring the percentage of available ambient energy successfully converted to usable electrical energy. While conventional single-mode harvesters often achieve efficiencies between 5-30% depending on the energy source, hybrid systems can potentially exceed these ranges through complementary operation. Recent studies have demonstrated that piezoelectric-electromagnetic hybrid harvesters can achieve conversion efficiencies up to 45% under optimal conditions, significantly outperforming their individual components.

Bandwidth performance metrics are equally important for evaluating hybrid harvesters, particularly for vibration-based systems. The frequency range over which a harvester can effectively operate determines its adaptability to real-world environments where energy sources fluctuate. Hybrid designs typically exhibit broader operational bandwidths compared to single-mode harvesters, with recent piezoelectric-triboelectric combinations demonstrating effective energy capture across 15-200 Hz ranges.

Output stability metrics quantify the consistency of power generation under varying environmental conditions. This includes measurements of output voltage fluctuation, power intermittency, and energy storage requirements. Hybrid systems generally demonstrate superior stability by leveraging complementary harvesting mechanisms that operate under different optimal conditions, thereby maintaining power output across a wider range of environmental variations.

Longevity and reliability metrics assess the harvester's performance degradation over time. This includes cycle life testing, environmental resistance, and material degradation rates. These metrics are particularly relevant for hybrid systems where different components may age at varying rates. Current research indicates that properly designed hybrid systems can maintain at least 80% of initial performance after 10⁶ operational cycles, though long-term studies exceeding 5-10 years remain limited.

Cost-performance ratios provide crucial economic context, measuring power output against manufacturing costs, typically expressed as $/mW. While hybrid systems generally incur higher initial production costs due to increased complexity, their enhanced performance and versatility often result in more favorable lifetime cost-performance ratios, particularly in applications requiring sustained operation in variable environments.

Integration Challenges with IoT and Wearable Devices

The integration of hybrid micro energy harvesters with IoT and wearable devices presents significant technical challenges that must be addressed to achieve seamless functionality. One primary obstacle is the size constraint, as wearable devices demand extremely compact energy harvesting systems that do not compromise user comfort or device aesthetics. Current hybrid harvesters often require substantial volume to incorporate multiple energy conversion mechanisms, creating a fundamental design conflict.

Power management represents another critical challenge, as IoT and wearable applications typically exhibit intermittent operation patterns with varying power demands. Hybrid harvesters must incorporate sophisticated power conditioning circuits capable of handling multiple input sources with different electrical characteristics while maintaining high efficiency across diverse operating conditions. These circuits must be miniaturized without sacrificing performance, a task that pushes the boundaries of current electronic design capabilities.

Thermal management issues also emerge when integrating hybrid harvesters with wearable devices. The proximity to the human body creates unique thermal conditions that can affect harvester performance, particularly for thermoelectric components. Simultaneously, heat generated by the energy conversion process must be effectively dissipated to prevent user discomfort and potential safety concerns.

Material compatibility presents additional integration challenges. Materials used in hybrid harvesters must be biocompatible for wearable applications, resistant to sweat and environmental factors, while maintaining optimal energy conversion properties. The mechanical interface between rigid harvester components and flexible wearable substrates creates stress points that can lead to premature failure, necessitating innovative interface solutions.

Manufacturing scalability remains problematic as hybrid systems involve multiple fabrication processes that are difficult to standardize. The integration of disparate technologies such as piezoelectric materials, electromagnetic components, and thermoelectric elements requires specialized assembly techniques that are often incompatible with high-volume production methods used for consumer electronics.

Data synchronization between energy harvesting systems and the power management needs of IoT devices presents another layer of complexity. Real-time monitoring and adaptive control systems are needed to optimize energy capture based on available environmental sources while meeting the dynamic power requirements of connected devices. This necessitates sophisticated embedded software solutions that must operate with minimal computational overhead to preserve harvested energy.

Power management represents another critical challenge, as IoT and wearable applications typically exhibit intermittent operation patterns with varying power demands. Hybrid harvesters must incorporate sophisticated power conditioning circuits capable of handling multiple input sources with different electrical characteristics while maintaining high efficiency across diverse operating conditions. These circuits must be miniaturized without sacrificing performance, a task that pushes the boundaries of current electronic design capabilities.

Thermal management issues also emerge when integrating hybrid harvesters with wearable devices. The proximity to the human body creates unique thermal conditions that can affect harvester performance, particularly for thermoelectric components. Simultaneously, heat generated by the energy conversion process must be effectively dissipated to prevent user discomfort and potential safety concerns.

Material compatibility presents additional integration challenges. Materials used in hybrid harvesters must be biocompatible for wearable applications, resistant to sweat and environmental factors, while maintaining optimal energy conversion properties. The mechanical interface between rigid harvester components and flexible wearable substrates creates stress points that can lead to premature failure, necessitating innovative interface solutions.

Manufacturing scalability remains problematic as hybrid systems involve multiple fabrication processes that are difficult to standardize. The integration of disparate technologies such as piezoelectric materials, electromagnetic components, and thermoelectric elements requires specialized assembly techniques that are often incompatible with high-volume production methods used for consumer electronics.

Data synchronization between energy harvesting systems and the power management needs of IoT devices presents another layer of complexity. Real-time monitoring and adaptive control systems are needed to optimize energy capture based on available environmental sources while meeting the dynamic power requirements of connected devices. This necessitates sophisticated embedded software solutions that must operate with minimal computational overhead to preserve harvested energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!